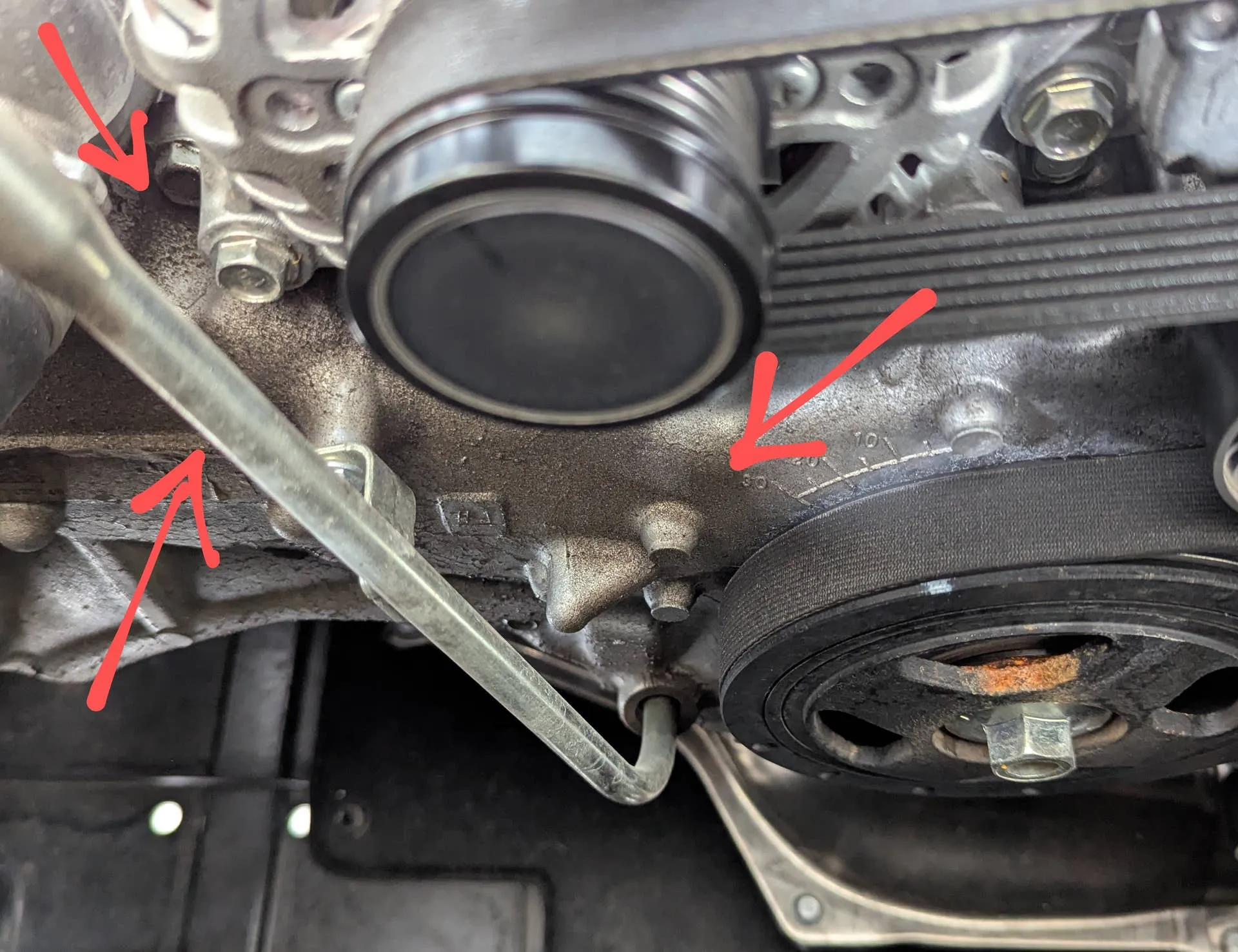

Oil dripping from your engine’s front end isn’t just messy; it’s a warning sign that could cost you thousands if ignored. Timing cover leaks start small, maybe just a few drops on your driveway that you wipe away and forget.

Then one day you notice your oil level dropping faster than it should, and suddenly you’re facing a repair bill that makes your stomach turn. We’re talking about $1,500 to $3,000 for timing cover reseal jobs that require removing half the engine just to access the problem.

Here’s what makes timing cover leaks so frustrating: they’re often preventable through better engineering. Some manufacturers use quality gaskets, proper sealing surfaces, and materials that withstand heat and pressure without failing.

Others cut corners with cheap gaskets and poor designs that guarantee leaks around 80,000 to 100,000 miles. This difference isn’t subtle either; we’re comparing engines that stay dry for 200,000+ miles versus those that start weeping oil before the warranty expires.

Why do timing covers leak? Sometimes it’s the gasket material that hardens and cracks with age. Other times, it’s RTV sealant that wasn’t applied correctly at the factory.

Oil pressure pulses, heat cycles, and vibration all stress these seals constantly. When manufacturers use inferior materials or flawed designs, failure becomes inevitable rather than just possible.

But some engines get it right, using robust sealing systems that last the vehicle’s entire life without needing attention.

Knowing which engines stay sealed and which ones are guaranteed to leak could save you thousands in repairs and help you avoid vehicles with expensive maintenance ahead.

8 Engines That Avoid Timing Cover Leaks

1. Toyota Camry 2.5L Dynamic Force (2021)

Japanese obsession with reliability extends to every seal and gasket. This 2.5-liter four-cylinder uses a timing cover design with generous sealing surfaces and high-quality gasket materials.

Toyota engineers understand that preventing leaks costs pennies during manufacturing but saves customers thousands later, so they invest in proper sealing systems from the start.

Gasket material is multi-layer steel with rubber coating that maintains flexibility through extreme temperature cycles. Cheap paper gaskets harden and crack, but Toyota’s MLS gaskets compress and recover repeatedly without losing sealing ability.

When gaskets stay flexible, they maintain seal integrity even as engines vibrate and thermal expansion causes components to move slightly.

Cover casting uses precision machining that creates flat sealing surfaces. When mating surfaces aren’t perfectly flat, gaskets can’t seal properly, regardless of material quality.

Toyota’s manufacturing processes ensure timing covers bolt to engine blocks with metal-to-metal contact across the entire sealing surface, allowing gaskets to do their job effectively.

Bolt torque specifications and tightening sequences are carefully engineered to distribute clamping force evenly.

Uneven bolt tension creates gaps where oil can escape, but Toyota’s procedures ensure consistent pressure across the entire gasket. When every bolt is tightened to exact specifications in the correct order, seals last indefinitely.

Real-world reliability proves the engineering works. Forums and mechanic experiences show these engines routinely reaching 200,000+ miles without timing cover leaks.

When engines consistently stay dry through high mileage, it validates the design choices manufacturers made during development.

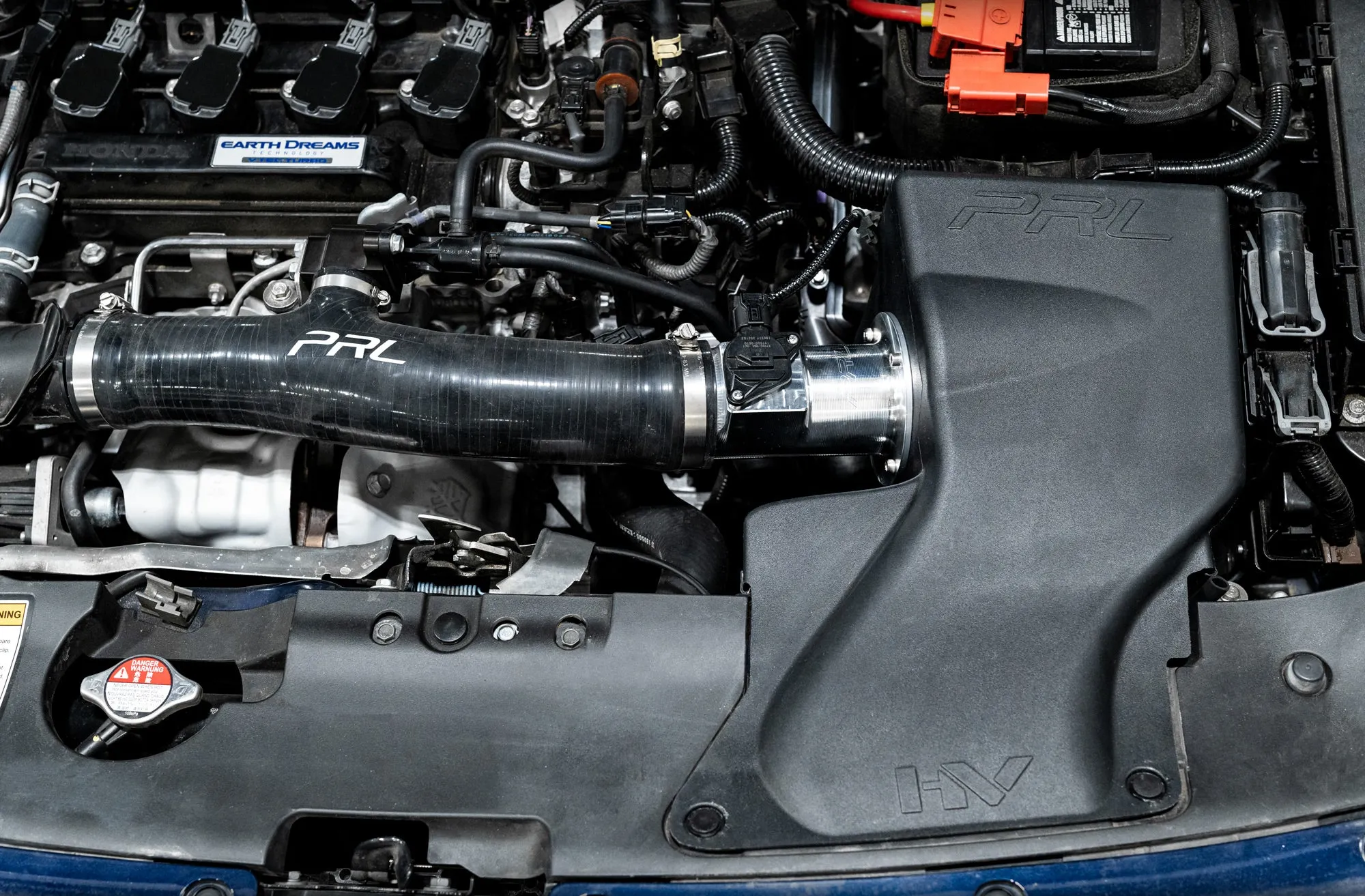

2. Honda Accord 1.5T Turbo (2022)

Turbocharged engines generate more heat and pressure, making sealing more challenging. Honda addressed this with upgraded gasket materials and improved cover design.

Rather than hoping standard sealing methods would suffice, engineers specified components specifically for turbo applications where conditions are more demanding.

Liquid gasket sealant applied by robots ensures consistent coverage and proper thickness. Human workers can make mistakes, but an automated application puts exactly the right amount of sealant in precisely the right locations.

This consistency eliminates the variability that causes some engines to leak while others from the same production line stay dry.

Cover design eliminates sharp corners where stress concentrations cause cracking. Honda uses generous radiuses and smooth transitions that prevent the fatigue cracks that develop in poorly designed covers.

When covers don’t crack, gaskets don’t fail, and engines stay leak-free throughout their service lives.

Oil passages through the timing cover use O-rings rather than relying solely on gasket material. This redundant sealing provides backup if the main gasket develops issues.

Layered protection prevents single-point failures that would otherwise cause leaks, showing thoughtful engineering that anticipates potential problems.

Warranty data supports these observations, with Honda reporting minimal timing cover leak claims on 1.5T engines. When manufacturers confidently warrant engines without expecting seal failures, it indicates genuine confidence in the engineering rather than just marketing promises.

Also Read: 10 Timing-Chain Engines That Actually Stay Quiet Past 200,000 Miles

3. Mazda CX-5 2.5L Skyactiv-G (2023)

Naturally aspirated engine design reduces sealing challenges compared to turbocharged alternatives.

Lower pressures and temperatures create easier operating conditions for gaskets and seals. Mazda took this inherent advantage and enhanced it through careful material selection and precise manufacturing.

Cork-rubber composite gasket provides excellent sealing while accommodating surface irregularities.

Pure rubber gaskets can extrude under pressure, while pure cork can dry out and crumble. Mazda’s composite combines benefits of both materials, creating seals that maintain integrity through years of service.

Cover attachment uses both bolts and studs in locations where loads are highest. Studs provide better clamping force and distribute stress more evenly than bolts alone.

This mixed fastener approach shows attention to detail that separates engines engineered for longevity from those designed to barely meet warranty requirements.

Surface preparation protocols ensure the covers bolt to blocks without trapped debris. Mazda’s assembly procedures require checking mating surfaces before gasket installation, preventing contamination that would compromise seals. When manufacturing processes include these quality checks, fewer defects reach customers.

Customer satisfaction data shows Mazda owners reporting minimal engine leak issues. Forums dedicated to CX-5 ownership rarely contain timing cover leak complaints, indicating the problem simply doesn’t occur frequently enough to generate discussion. This silence speaks louder than any marketing could.

4. Subaru Outback 2.4L Turbo (2020)

Boxer engine configuration places timing covers on the engine sides rather than the front, reducing exposure to road spray and debris.

This positioning provides natural protection that vertical engines lack. Combined with quality gasket materials, this design advantage helps these engines stay sealed longer than conventional layouts.

All-weather testing in harsh climates validated sealing systems before production. Subaru subjects engines to extreme cold and heat cycles that would expose sealing weaknesses.

When engines survive these tests without leaks, it proves that gaskets and covers can handle real-world conditions that customers will encounter.

Gasket material uses fluoroelastomer that resists oil degradation better than standard rubber. Modern synthetic oils contain additives that attack conventional gasket materials, but fluoroelastomer withstands these chemicals indefinitely. When gaskets don’t degrade chemically, they maintain sealing properties throughout engine life.

Assembly procedures require applying liquid sealant to gasket surfaces before installation. This additional sealing layer provides backup protection if the gasket material alone proves insufficient. Subaru’s belt-and-suspenders approach costs more during manufacturing but prevents customer problems later.

Long-term reliability tracking shows these engines maintaining dry timing covers through high mileage. Subaru owners in enthusiast communities report engines with 150,000+ miles showing no signs of timing cover leakage. This real-world durability proves the engineering decisions were correct.

5. Volkswagen Jetta GLI 2.0T (2021)

German precision manufacturing creates sealing surfaces flat enough to seal with minimal gasket compression. When surfaces are machined to tight tolerances, gaskets don’t need to fill large gaps.

This precision approach prevents gasket crushing that occurs when covers bolt to wavy surfaces requiring excessive compression.

Multi-lip seal design around crankshaft nose provides redundant protection. If the outer lip fails, the inner lips continue sealing until repair can be performed. This redundancy prevents catastrophic oil loss that would occur if single-lip seals failed.

Cover material uses a reinforced composite that resists warping from heat cycling. Metal covers can warp if castings have stress points, but engineered composites maintain dimensional stability. When covers don’t warp, gaskets maintain consistent compression and continue sealing effectively.

Installation procedures specify using thread sealant on bolt threads to prevent oil weeping past fasteners.

This detail often gets overlooked, but it prevents leaks that gaskets alone can’t stop. VW’s comprehensive approach addresses every potential leak path rather than just focusing on gasket surfaces.

Service records from VW dealerships show minimal timing cover leak repairs on these engines. When mechanics rarely see specific problems, it indicates manufacturers engineered them out rather than just hoping they wouldn’t occur frequently.

6. Lexus ES 350 3.5L V6 (2022)

Toyota’s luxury division uses premium materials throughout, including gasket and seal components.

That 3.5-liter V6 employs multi-layer steel timing cover gaskets with advanced sealing compounds. These aren’t budget components but carefully selected materials proven to last.

Manufacturing quality control includes leak testing every engine before installation. Lexus uses pressure testing to verify seals before engines leave the factory.

This catches defective gaskets or assembly errors before they become customer problems, ensuring only properly sealed engines reach buyers.

Cover design incorporates mounting bosses that prevent distortion when bolts are tightened. Simple flat covers can warp if bolt holes don’t provide adequate support.

Lexus engineers strategically placed reinforcement that keeps covers flat regardless of clamping forces, ensuring gaskets compress evenly.

Liquid sealant application uses precise amounts applied robotically in exact patterns. Too little sealant causes leaks while too much can squeeze into oil passages and cause problems.

Automated application eliminates human error, creating consistent sealing across every engine produced.

Customer satisfaction ratings place Lexus at the top, partly because reliability prevents repair costs. When engines don’t leak oil, owners don’t face expensive repairs that sour ownership experiences. This reliability builds brand loyalty that keeps customers returning.

7. Hyundai Sonata N Line 2.5T (2023)

Turbocharged performance engine uses upgraded sealing materials designed for higher pressures and temperatures.

Rather than adapting standard gaskets to turbo duty, Hyundai specified components specifically engineered for forced induction. This dedicated approach prevents the failures that occur when standard parts are used beyond their design limits.

Cover bolts use precise torque specifications with angle-tightening requirements. This “torque-to-yield” method ensures an optimal clamping force that maintains gasket compression throughout temperature cycles. When fasteners are tightened correctly, they maintain seal integrity indefinitely.

Gasket material resists hardening from the heat exposure that turbocharged engines generate. Standard rubber hardens and cracks, but Hyundai’s material maintains flexibility even after thousands of heat cycles. Flexible gaskets conform to surface irregularities and maintain sealing as engines vibrate during operation.

Ten-year warranty covering engine components demonstrates Hyundai’s confidence in sealing system durability.

Manufacturers offering extended warranties must engineer reliability into products since warranty repairs hurt profitability. This warranty backing suggests Hyundai expects these engines to stay sealed far beyond warranty periods.

Early ownership experiences show these engines maintain dry timing covers through initial years. While long-term data is accumulating, current results suggest proper engineering that should deliver leak-free operation throughout vehicle life.

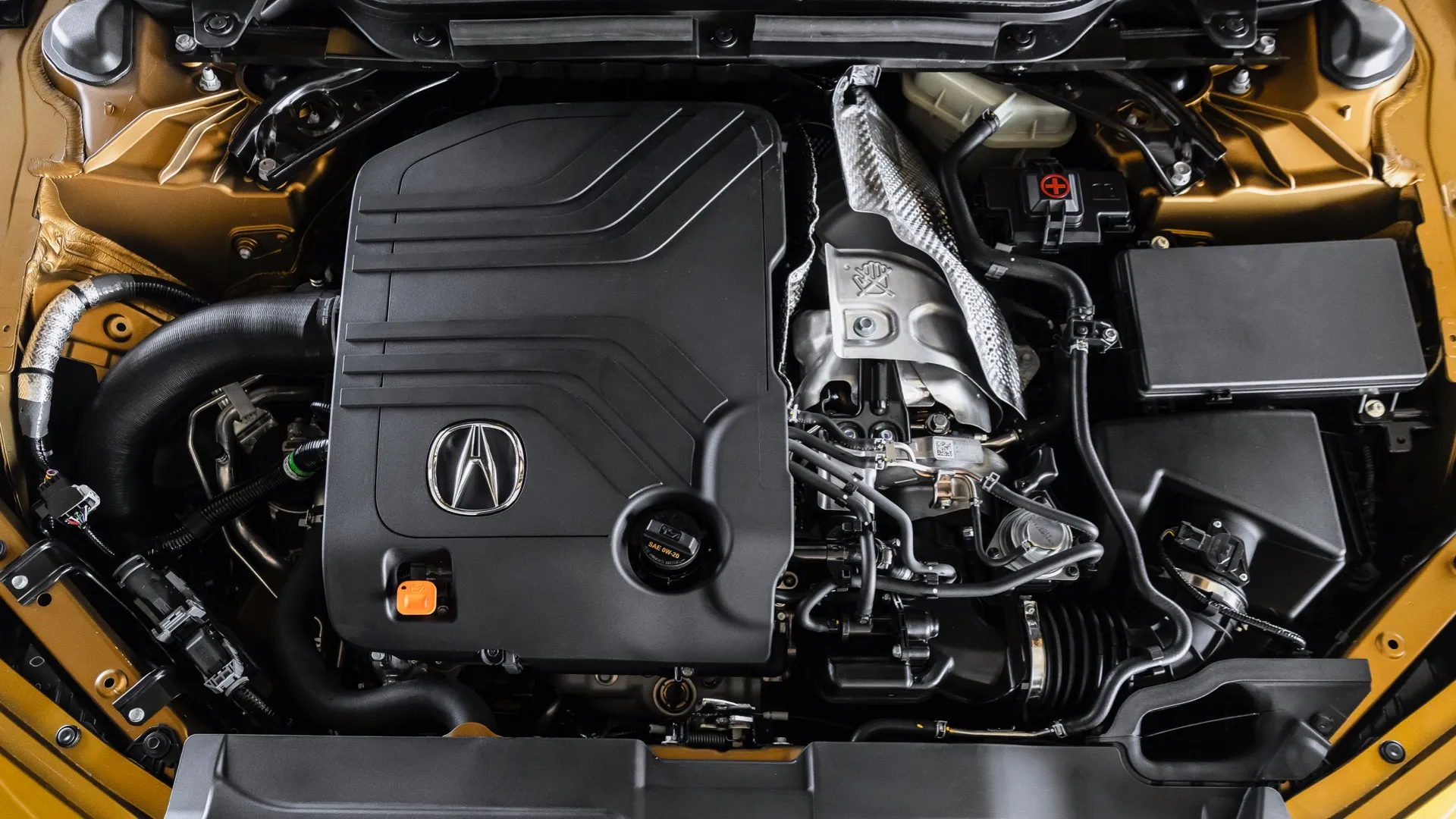

8. Acura TLX Type S 3.0T V6 (2022)

Performance V6 with twin turbochargers creates a challenging sealing environment. Honda engineering rose to this challenge with a sophisticated timing cover design and premium materials.

Engineers couldn’t accept leaks in a performance flagship, so they over-engineered sealing systems to ensure reliability.

Multi-piece timing cover design uses individual gaskets for each section, preventing single-point failures.

If one gasket develops issues, others continue sealing rather than allowing catastrophic leakage. This compartmentalized approach contains problems and prevents minor issues from becoming major failures.

Crankshaft seal uses an advanced lip design with garter spring maintaining constant tension. Simple seals lose tension as they age, but spring-loaded designs maintain sealing pressure throughout their service life. This technology costs more but delivers reliability that justifies premium pricing.

Assembly procedures require specific surface preparation, including cleaning solvents and inspection steps.

Honda doesn’t rush timing cover installation but follows a detailed procedure,s ensuring proper sealing. When assembly quality matches component quality, engines stay leak-free.

Warranty claims data show minimal timing cover issues on Type S models. Performance buyers are particularly sensitive to problems, so low complaint rates indicate genuine reliability rather than just tolerance of issues. When demanding customers are satisfied, it proves engineering excellence.

Leak-Prone Engines: Reseals Waiting to Happen

1. Ford EcoBoost 3.5L V6 (2013 F-150)

Twin-turbo V6 generates substantial heat and pressure that attack timing cover gaskets aggressively.

Many owners report leaks developing around 60,000 to 80,000 miles as gaskets harden and crack. Ford apparently underestimated sealing challenges when adapting this engine from car applications to truck duty.

Gasket material uses standard rubber that deteriorates under sustained high temperatures. Turbocharged engines run hotter than naturally aspirated alternatives, requiring upgraded gasket materials.

Ford’s use of conventional gaskets in demanding applications guaranteed premature failures that customers now pay to repair.

Cover design has an inadequate sealing surface area in critical locations. Engineers apparently prioritized packaging space over sealing reliability, creating covers with narrow gasket contact areas. When sealing surfaces are minimal, gaskets must compress more to seal, accelerating wear and hastening failure.

Oil pressure pulses from the variable cam timing system stress gaskets beyond what steady-state pressure would.

Constant pressure variations fatigue the gasket material, causing cracks that develop into leaks. Ford could have used stronger gaskets or a modified cover design to handle these pulses better.

Reseal costs are substantial because accessing the timing covers requires extensive disassembly. Labor alone exceeds $1,200, and parts add another $300-500.

When these repairs become expensive, commonly around 80,000 miles, it damages the brand’s reputation and drives customers toward competitors.

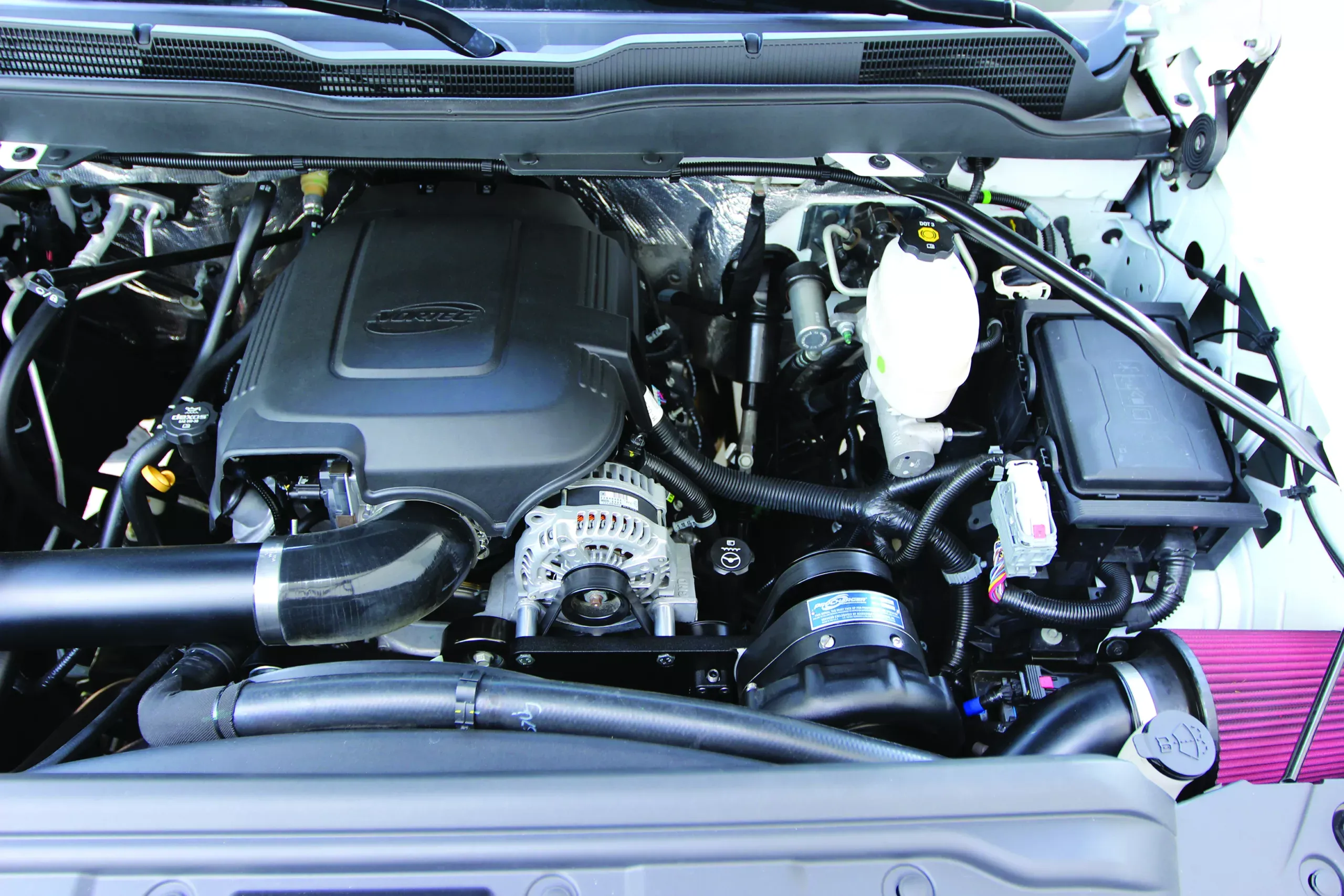

2. Chevrolet Silverado 1500 5.3L V8 (2016)

Active Fuel Management system creates unique sealing challenges. Cylinder deactivation changes oil pressure patterns that stress gaskets differently than conventional engines. GM apparently didn’t account for these different stress patterns when designing timing cover sealing systems.

RTV sealant applied at the factory often fails prematurely, allowing oil seepage. Many mechanics report finding inadequate or improperly applied sealant when performing reseals.

This suggests manufacturing quality control issues rather than fundamental design flaws, but customers pay either way.

Cover material uses a plastic composite that warps slightly from heat cycling. Even small warpage prevents gaskets from maintaining consistent compression across sealing surfaces. When covers don’t stay flat, no gasket material can seal effectively, regardless of quality.

Oil passages through the timing cover develop leaks at the press-fit plugs. These plugs should seal permanently but often work loose as engines age. Plug leaks are separate from gasket failures, creating multiple leak paths that make these engines notorious for oily front ends.

Dealer service departments see regular timing cover leak repairs on these engines. When mechanics recognize patterns and stock parts specifically for common repairs, it proves problems are systematic rather than isolated. GM never adequately addressed these issues through design changes.

3. Dodge Ram 1500 3.6L Pentastar V6 (2015)

V6 configuration requires a complicated timing cover shape with multiple sealing surfaces. Each surface represents a potential leak point, and this engine has too many.

Simple designs are often better, but Pentastar’s packaging requirements created complicated cover geometry prone to sealing problems.

Gasket material degrades rapidly in the presence of modern synthetic oils. Additives in low-viscosity oils attack rubber compounds, causing swelling and deterioration.

Chrysler apparently didn’t validate gasket compatibility with oils customers actually use, leading to premature failures.

Cover warpage from uneven bolt tightening during assembly occurs frequently. Factory assembly procedures apparently allow excessive variation in bolt torques, creating inconsistent gasket compression.

When gaskets compress unevenly, they fail prematurely at locations where compression is inadequate.

Multiple oil passages through the cover use O-rings that shrink and leak. These small O-rings are critical sealing points, but they harden and lose resilience after heat exposure. Replacing O-rings requires complete cover removal, making these minor seals expensive to address.

Owner forums overflow with Pentastar timing cover leak complaints. This consistent pattern across model years and applications proves fundamental problems rather than production anomalies. Chrysler never implemented effective fixes, leaving customers to absorb repair costs.

4. Nissan Frontier 4.0L V6 (2017)

Aging engine design uses timing cover sealing technology from previous decades. While adequate when new, gasket materials and designs haven’t kept pace with modern requirements.

Nissan’s conservative approach to updates left customers dealing with outdated sealing systems prone to failure.

Cover attachment uses too few bolts spaced too far apart. Inadequate fastener count allows cover flexing between bolt locations, preventing gaskets from maintaining consistent compression.

More bolts would solve this, but would require redesigning covers that Nissan didn’t want to invest in changing.

Gasket material hardens and becomes brittle after heat cycling. Once gaskets lose flexibility, they can’t accommodate thermal expansion, causing cracks that leak.

Nissan could have used better gasket materials, but apparently prioritized low component costs over long-term reliability.

The front crankshaft seal commonly leaks in addition to gasket failures. This seal uses a simple design without spring loading to maintain tension.

As seals wear, they lose sealing pressure and begin weeping oil. Combined with gasket leaks, these engines often have multiple leak sources simultaneously.

Resale values suffer as timing cover leaks become widely known. Buyers avoid Frontiers with 4.0L engines specifically because repair history shows inevitable sealing problems. When market prices reflect reliability concerns, it proves that problems are real and widespread.

5. Jeep Wrangler 3.6L Pentastar V6 (2018)

The same basic engine as the Dodge Ram experiences identical timing cover leak issues. Off-road use in Wranglers might accelerate problems through additional vibration and environmental exposure.

Dusty conditions can contaminate sealing surfaces during assembly, causing premature failures that wouldn’t occur in cleaner environments.

Harsh operating conditions in off-road applications stress gaskets beyond design limits. Water crossings create thermal shock, while mud and debris attack seals chemically and mechanically.

Jeep needed upgraded sealing systems for these demanding conditions, but used standard components that couldn’t handle the abuse.

Dealer service sees regular timing cover reseals on higher-mileage Wranglers. Mechanics stock gaskets and sealant because repairs are so common. When service departments keep specific parts on hand, it indicates frequent use rather than occasional repairs.

Repair costs are especially painful because Wrangler owners often already spend heavily on modifications.

When routine maintenance becomes expensive due to predictable failures, it adds financial stress to ownership. This creates dissatisfaction that damages Jeep’s relationship with its most loyal customers.

Online communities document countless leak complaints and reseal procedures. When enthusiast forums develop detailed DIY repair guides for specific problems, it proves issues affect enough owners to warrant collective knowledge sharing. This grassroots documentation indicts Chrysler’s engineering quality.

6. GMC Sierra 2500HD 6.0L V8 (2014)

Heavy-duty truck service accelerates timing cover gasket degradation. Sustained high loads and long-duration operation at elevated temperatures stress seals beyond what light-duty use creates. GM apparently didn’t specify gasket materials adequate for the demanding service these trucks see.

Cover design dates to the previous generation with minimal updates. While other engine components received improvements, the timing cover sealing system remained essentially unchanged. This neglect left customers dealing with outdated technology prone to leaks.

Factory sealant application shows wide variation in quality. Some engines stay dry while others leak early, suggesting inconsistent assembly procedures.

When identical engines from the same production line show different reliability patterns, manufacturing quality control rather than design appears to be the problem. Gasket replacement intervals become regular maintenance items rather than occasional repairs.

Owners accepting 100,000-mile reseal intervals budget accordingly, but this shouldn’t be necessary with proper engineering. When preventable maintenance becomes routine, it indicates manufacturer failures.

Commercial users are particularly affected because downtime costs money beyond just repair expenses. Contractors and fleet operators need reliable trucks, and timing cover leaks creates unscheduled downtime. This reliability failure pushes commercial buyers toward competitors offering better durability.

7. Infiniti Q50 Red Sport 3.0T V6 (2017)

Twin-turbo V6 generates heat loads that attack timing cover gaskets aggressively. Luxury car buyers expect reliability matching premium prices, but these engines develop leaks around 60,000 miles. Nissan’s luxury division apparently didn’t engineer sealing systems adequately for sustained high-performance use.

Gasket material doesn’t withstand synthetic oil chemistry long-term. Modern low-viscosity oils contain additives that swell and degrade standard rubber gaskets.

Infiniti needed specialized gasket compounds, but apparently used conventional materials that couldn’t handle the chemical environment.

Repair costs in luxury vehicles exceed mainstream cars substantially. Same basic work costs $2,500+ at Infiniti dealers versus $1,500 at independent shops. Premium pricing without premium reliability creates customer dissatisfaction that damages brand reputation.

Resale market reflects a leak reputation with Q50 Red Sport values dropping faster than competitors.

Smart buyers research reliability before purchasing luxury cars, and they’re avoiding models with documented problems. Depressed resale values hurt all owners regardless of whether specific vehicles have experienced leaks.

Also Read: 10 Hyundai/Kia Engines From The ‘Safe Years’ That Age Well

8. Cadillac XT5 3.6L V6 (2018)

GM’s V6 shares basic architecture with engines in cheaper brands, but uses supposedly upgraded components.

Despite premium positioning, timing, and cover leaks occur at similar rates as lower-priced siblings. This suggests upgraded components didn’t extend to sealing systems, leaving Cadillac owners paying luxury prices for mainstream reliability.

Cover warpage from casting stresses becomes apparent after heat cycling. Initial machining creates flat surfaces, but internal casting stresses cause warping as covers undergo temperature changes. Warped covers can’t maintain consistent gasket compression regardless of gasket quality.

Multiple oil passages through the cover use O-rings prone to shrinking. These small seals are critical but receive less attention than the main gasket. When O-rings fail, repairs require complete cover removal same as gasket failures, making these minor components expensive to address.

Luxury buyers are least tolerant of reliability issues, making leak problems particularly damaging. When customers pay premium prices, they expect premium reliability. Cadillac’s failure to deliver creates dissatisfaction that drives customers toward German and Japanese luxury brands.

Service bulletin addressing timing cover leaks acknowledges problems but doesn’t provide long-term solutions. GM recommends reseal procedures without addressing root causes, meaning problems recur after repairs. This inadequate response frustrates owners and mechanics alike.