For decades, timing belts have divided mechanics and drivers alike. On one hand, belts run quieter than chains, and replacing them can be straightforward on certain engines.

On the other, they can become an owner’s worst nightmare if they snap inside an interference design where valves and pistons share the same space at different times. A single break in that setup can turn a smooth commuter into an expensive paperweight.

The key difference lies in service costs and accessibility. Some engines were engineered with easy timing-belt access and affordable parts. Others are practically booby-trapped, requiring hours of labor and thousands in repairs when things go wrong.

Below are five timing-belt engines that are cheap to service and five interference nightmares you’ll want to think twice about before buying used.

Timing-Belt Engines That Are Cheap to Service

For many car owners, the mere mention of a “timing belt service” is enough to induce a wave of anxiety, often conjuring images of complex labor and daunting repair bills. While it’s true that neglecting this critical maintenance item can lead to catastrophic engine failure, not all timing-belt engines are budget-breaking propositions.

The reality is that a significant number of vehicles on the road are powered by engines designed with serviceability in mind, where this routine job remains surprisingly affordable.

This article will cut through the fear and highlight the timing-belt engines known for being genuinely cheap to service, empowering you to make informed decisions whether you’re shopping for a used car or simply planning your next maintenance visit.

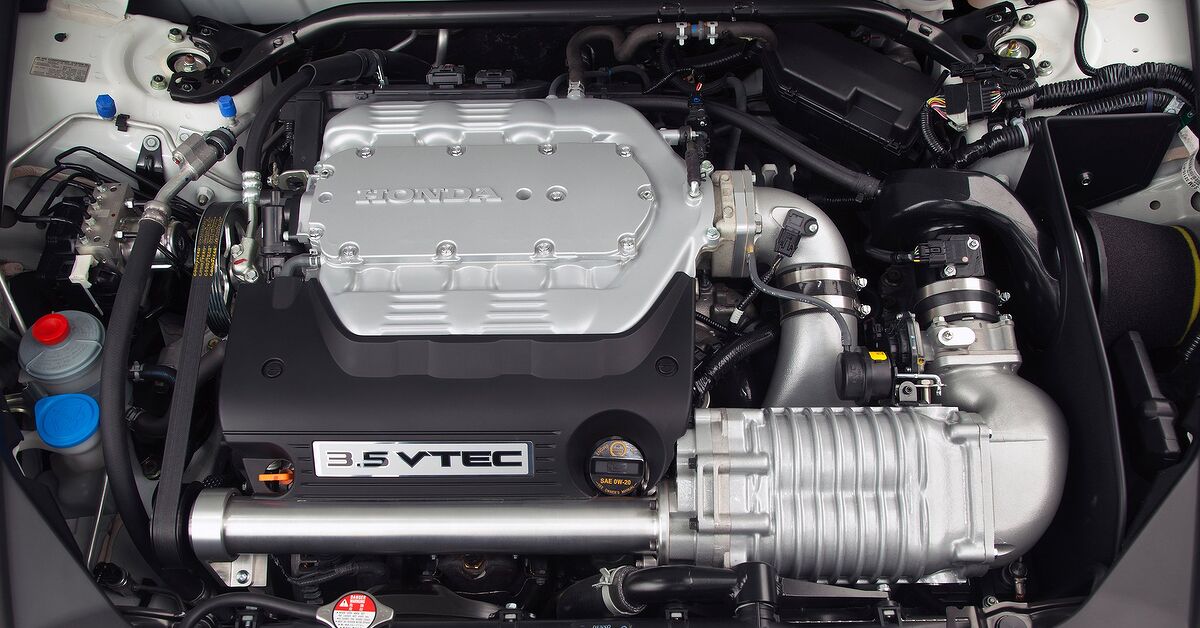

1. Honda 3.0L and 3.5L J-Series V6 (Accord, Odyssey, Pilot, Ridgeline)

Honda’s J-series V6 engines have earned their reputation for reliability, but they also happen to be among the least painful belt-driven engines to maintain.

Found in millions of Accords, Odysseys, and Pilots from the early 2000s through the 2010s, these engines use a straightforward front-end layout that gives mechanics easy access to the timing belt and water pump.

The full service belt, pump, tensioner, and seals can often be done for under $600 with OEM parts if you shop smartly or do it yourself.

Many shops charge about four labor hours, half what some interference engines demand.

Better yet, these V6s are non-catastrophic if the belt is replaced on time (typically every 100,000 miles). Properly maintained, these engines routinely cross 300,000 miles without internal damage.

The Honda 3.5 V6 engine, renowned for its durable performance and dependability, has been a fundamental component in a wide array of Honda and Acura models since its debut in the late 1990s.

Designated as the J-series, this power plant was engineered to strike a harmonious balance between strong output and fuel economy, cementing its status as a favored option for mid-size sedans, SUVs, and even certain performance-focused automobiles.

Across its production life, the J-series has seen numerous updates and refinements, each enhancing its technological features and performance capabilities while steadfastly upholding Honda’s legacy of superior engineering.

First introduced in the Honda Odyssey and Acura 3.5 RL, the J-series engine was subsequently adopted for use in a diverse lineup of other vehicles, such as the Honda Accord, Honda Pilot, and Acura MDX.

Boasting a displacement of 3.5 liters and a configuration that incorporates a 60-degree V-angle, this engine has consistently been commended for its refined operation and robust torque characteristics.

The evolution of the J-series has also included the integration of sophisticated technologies like VTEC (Variable Valve Timing and Lift Electronic Control) and later i-VTEC, which served to further improve power delivery and optimize fuel consumption.

However, for all its notable strengths, the Honda 3.5 V6 engine is not immune to shortcomings. Through years of service, owners have documented a variety of recurring concerns that can influence the engine’s operational efficiency and service life.

A clear comprehension of these potential problems is essential for both current owners and those considering a purchase, as they have the potential to result in expensive repairs and detract from the vehicle’s daily utility.

This article will explore the most frequently encountered issues linked to the Honda 3.5 V6 engine, offering detailed perspectives on their origins, the warning signs to watch for, and the possible remedies available.

Armed with this knowledge, owners can implement preventative strategies to reduce potential risks and ensure their vehicle is maintained in optimal condition.

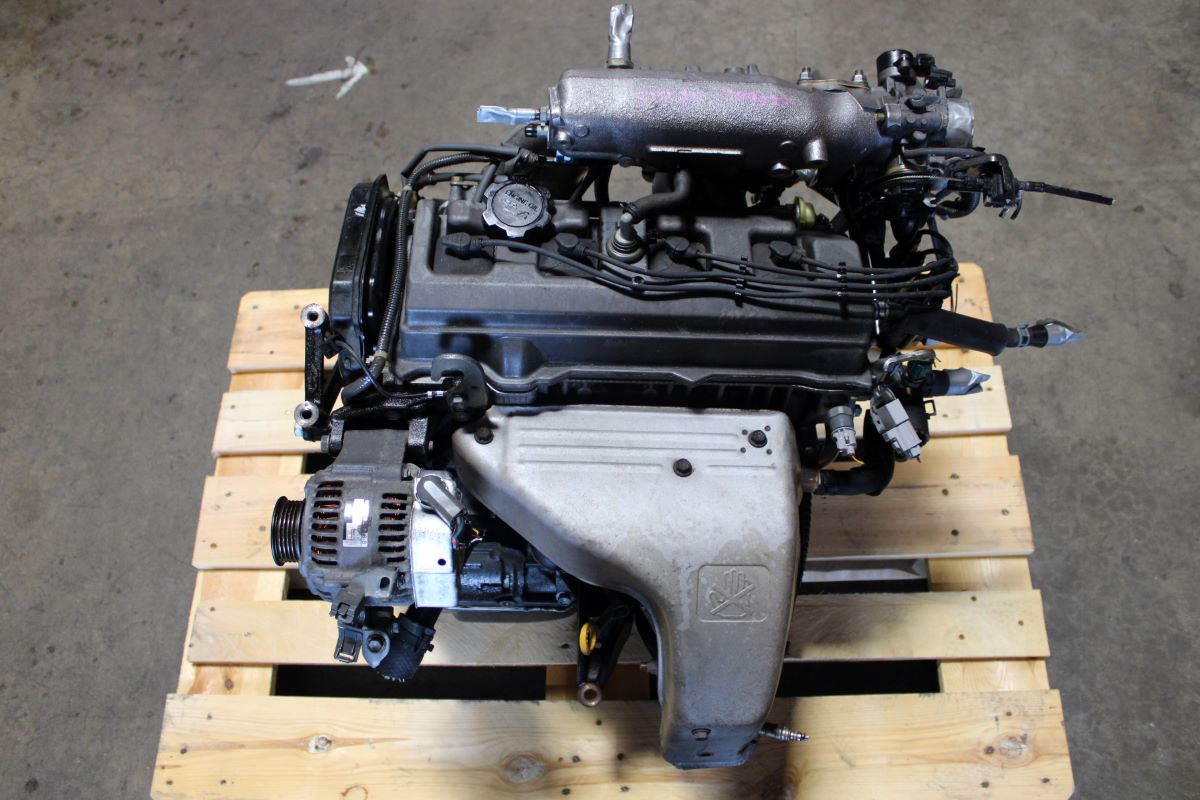

2. Toyota 5S-FE 2.2L Inline-4 (Camry, Celica, RAV4)

Before Toyota switched to timing chains in the 2000s, the 5S-FE engine powered millions of late-‘90s Camrys and Celicas.

It’s one of the simplest and cheapest belt engines to service so much so that many DIY owners handle the replacement in a single afternoon.

The 5S-FE is a non-interference engine, meaning even if the belt snaps, valves and pistons won’t collide. A full timing-belt kit costs under $200, and access is excellent thanks to its transverse layout and generous engine bay space.

For used car buyers, an old Camry with this engine is a safe bet, since a missed belt change won’t destroy it.

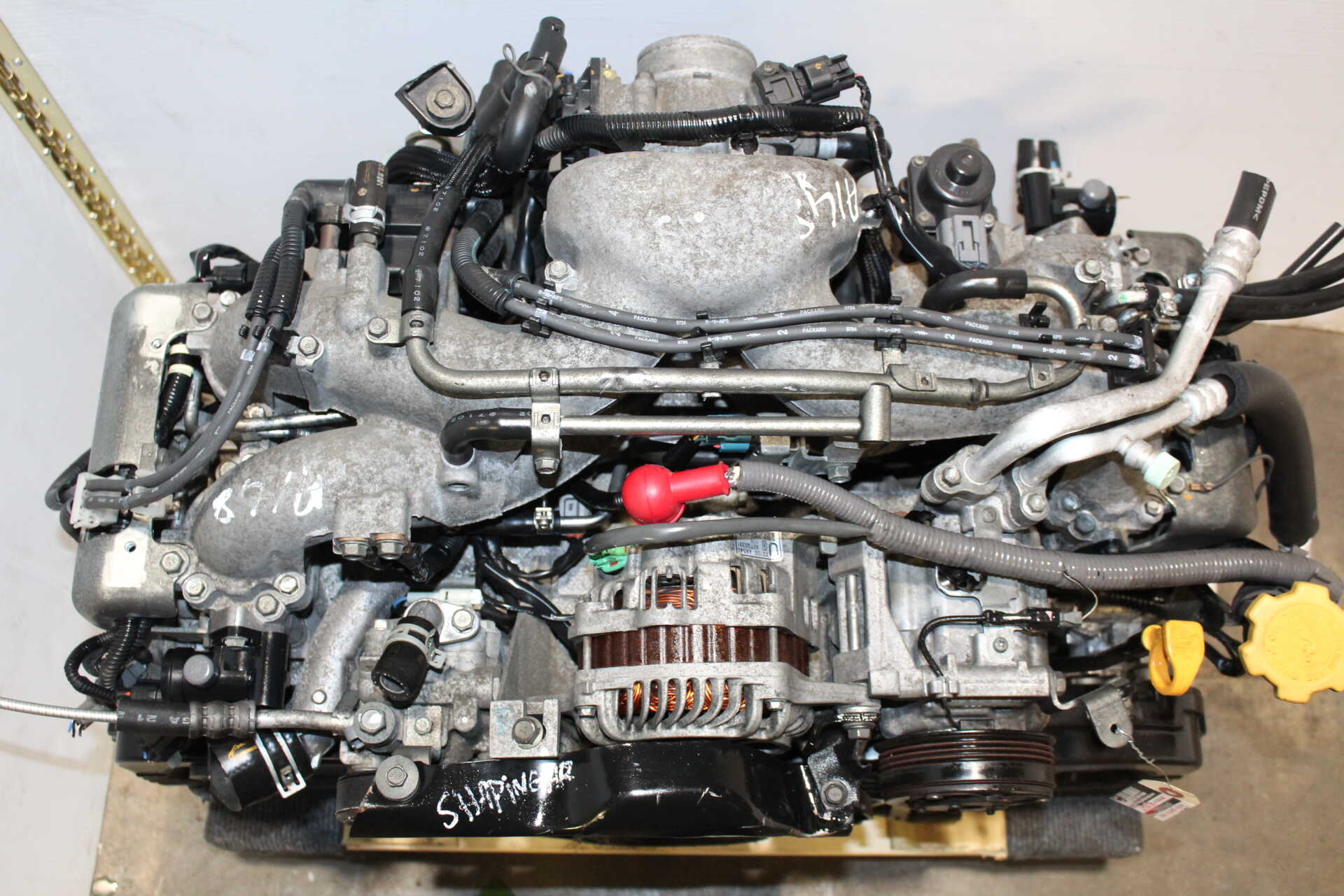

3. Subaru EJ22 (Legacy, Impreza, Outback)

Before Subaru’s later EJ25s gained a reputation for head gasket issues, the earlier EJ22 was a masterpiece of simplicity and durability.

Its timing belt setup is refreshingly serviceable especially for a boxer engine. Subaru even designed it as a non-interference engine, which is rare among flat-fours.

Changing the belt on an EJ22 is easier than it looks. There’s ample room at the front of the engine, and the job typically takes under three hours.

The parts themselves are inexpensive, and because there’s no catastrophic risk if the belt fails, the EJ22 remains one of the most forgiving timing-belt engines on the used market.

Introduced in 1990, the 2.2-liter engine was developed to power Subaru’s new model, the Legacy. This was followed by the 1.8-liter EJ18, which further expanded the burgeoning EJ engine family.

The inaugural version was the EJ22E engine. This designation encompasses all USDM naturally aspirated 2.2-liter engines manufactured from 1990 to 1996. This power plant is a four-cylinder boxer configuration, featuring an aluminum cylinder block with integrated cast iron sleeves.

It was equipped with SOHC aluminum cylinder heads and belt-driven camshafts. The compression ratio for the early EJ22 was set at 9.5:1. In 1997, the engine received a series of significant updates.

To achieve this, the engine incorporated pistons coated with molybdenum and redesigned for a weight reduction of approximately 100 grams. Furthermore, the intake manifold was reshaped to facilitate increased airflow mass and velocity.

The 1996 model year served as a transitional period, and it was common for the EJ22E to already be outfitted with new components that would define the later EJ22EZ, such as solid tappets or lifters. It is important to note that both the EJ22E and the EJ22EZ are classified as belonging to the Phase 1 engine design.

The EJ222 and EJ223 engines emerged for the model years 1999 to 2001. The most substantial alterations arrived in 1999. From this year forward, the 2.2-liter engine adopted the Phase 2 design and incorporated the EZ series features.

A principal characteristic of this update was the introduction of new SOHC cylinder heads where the valves were positioned at a wider angle; the intake valves were placed 23 degrees off-center, while the exhaust valves were set 20 degrees off-center. Additionally, the camshaft was now bolted directly to the cylinder head with a dedicated camshaft case.

It is also worthwhile to examine the turbocharged variants of the EJ22. The EJ22T is the engine found in the 1991-1994 USDM Legacy Turbo, where it produced 165 horsepower. This engine featured SOHC aluminum cylinder heads, oil sprayers inside the block for piston cooling, a fully closed-deck block design, and was not equipped with an intercooler.

The EJ22G, conversely, is a JDM engine based on the EJ20K STI power plant. It shares its DOHC cylinder heads and turbocharger assembly with the EJ20K but utilizes a 2.2-liter cylinder block that does not include oil sprayers for piston cooling.

This engine is built with forged pistons and stock connecting rods, and it operates with a compression ratio of 8.0:1. Its output is rated at 280 horsepower at 6,000 rpm and 268 lb-ft of torque at 3,200 rpm. This specific engine was purpose-built for the iconic Impreza STi 22B GC8 series.

4. Mitsubishi 4G63 (Eclipse, Galant, Lancer)

The 4G63 earned fame under the hood of performance icons like the Mitsubishi Eclipse GSX and Lancer Evolution, but even the base variants of this motor were relatively painless to maintain.

Timing-belt replacements on the 4G63 are well-documented, inexpensive, and surprisingly accessible for a compact engine bay.

Parts are dirt cheap, and enthusiasts have refined the belt service process over decades. Although the turbo variants are interference engines, the belt itself is straightforward and affordable to replace, often costing less than $400 for a full kit and labor.

The 4G63’s serviceability is one reason these cars remain tuner favorites decades later. The 4G63 engine is part of the Mitsubishi Sirius 4G6 engine family, which was first introduced in 1980. It is a four-cylinder, 2.0-liter gasoline engine that was naturally aspirated, with its turbocharged counterpart being designated the 4G63T.

The 4G63 is a significantly evolved version of the earlier G63B engine, which was a SOHC, carbureted eight-valve power plant used in various Mitsubishi models until approximately 1986-88.

This engine boasts a long and storied production history and has seen use in a broad spectrum of vehicles from manufacturers including Mitsubishi, Plymouth, Dodge, Eagle, and Hyundai. Throughout its production run, numerous versions were released, each incorporating new upgrades and different components.

A constant feature of the 4G63 engine is its cast iron cylinder block. This engine block is fitted with two balance shafts, often referred to as silent shafts.

It also originally featured a forged steel crankshaft and connecting rods, along with cast aluminum alloy pistons, though some engine variants utilized aluminum pistons that included steel inserts.

Depending on the specific modification, the engine was outfitted with several types of aluminum cylinder heads: an 8-valve SOHC head, a 16-valve SOHC head, and a 16-valve DOHC head. Every version employs a timing belt to drive either the intake and exhaust camshafts or a single camshaft.

In single camshaft configurations, the cam actuates the intake and exhaust valves via rocker arms, and this design requires periodic adjustment of the valve clearances. Cylinder heads with double overhead camshafts were introduced in 1987.

While these DOHC engines also use rocker arms, they feature an automatic hydraulic system for valve clearance compensation. The intake valve diameter measures 33 mm, and the exhaust valve diameter is 29 mm.

All 4G63 engines were equipped with Mitsubishi’s proprietary electronically controlled multi-point fuel injection system, known as ECI-MULTI. The DOHC versions of the engine also received an electronic ignition system.

5. Volkswagen 2.0L SOHC (Golf, Jetta, Beetle – 8-valve “AEG” engine)

Volkswagen’s 2.0L “AEG” single-cam engine, found in early 2000s Golfs and Jettas, is a surprisingly friendly timing-belt design.

Despite VW’s reputation for tricky service work, this engine is an exception. It’s simple, accessible, and non-interferencenso even if the belt snaps, internal damage is unlikely.

The timing-belt service interval runs about every 90,000 miles, and DIY kits can be found for $150 or less. The job itself is straightforward, with plenty of YouTube documentation from owners who’ve done it successfully in their driveways.

Among older Volkswagens, this is one of the cheapest and least stressful engines to keep running.

Interference Nightmares You Don’t Want to Face

While the term “interference engine” might sound like technical jargon, it describes a high-stakes reality for many car owners. In these engines, the clearance between the valves and pistons is so minimal that they occupy the same space at different times during the combustion cycle.

This precise engineering allows for greater efficiency and power. However, it comes with a critical vulnerability: if the timing belt snaps or jumps, the perfectly synchronized dance between the pistons and valves falls into chaos.

The result is often a catastrophic collision inside the engine, where bending valves, shattered pistons, and damaged cylinder heads lead to repair bills that can easily exceed the value of the car itself. These are the interference nightmares, sudden, severe, and incredibly expensive, that no driver ever wants to face.

1. Volkswagen/Audi 1.8T 20V Turbo (A4, Passat, Jetta, GTI)

The 1.8T engine may have powered a generation of sporty German sedans and hatches, but it’s a disaster if you miss a timing-belt interval.

This interference engine has tight tolerances and zero forgiveness. A single snapped belt or seized tensioner means bent valves, broken guides, and a $2,000+ repair bill.

Compounding the issue, the front of the engine must be removed (“service position”) just to access the belt.

That means what should be a basic maintenance item turns into a six-hour ordeal, even for professionals. Skip the service by even a few thousand miles, and you’ll regret it.

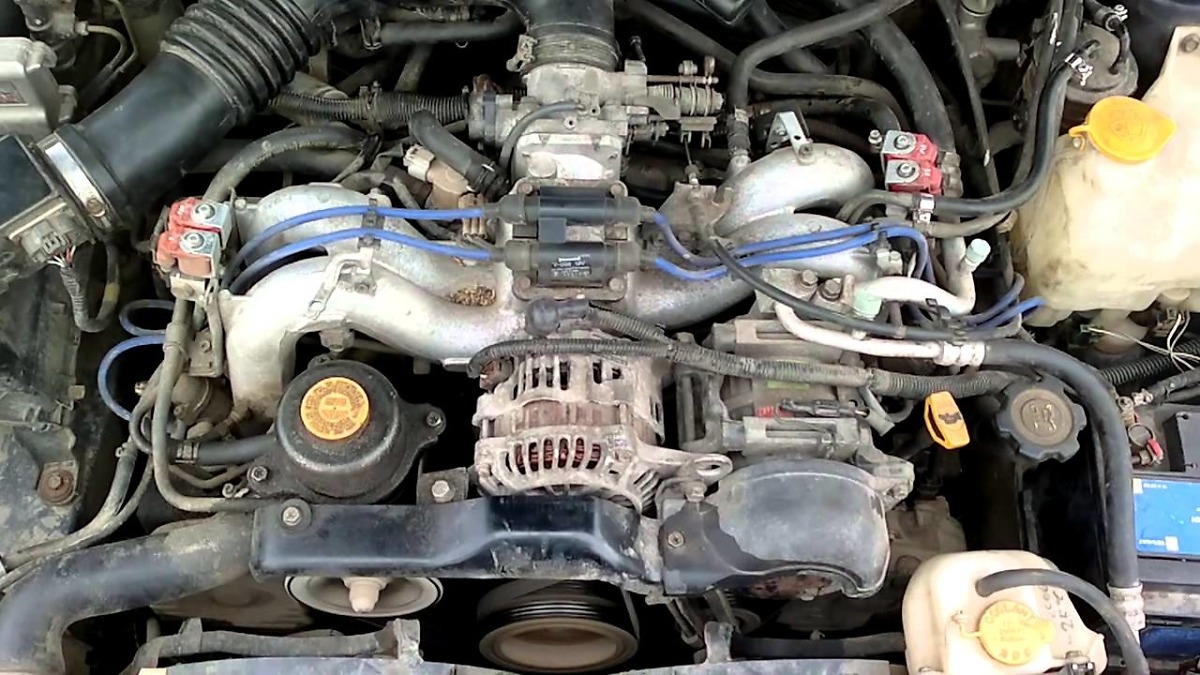

2. Subaru EJ25 (Outback, Forester, Legacy)

While the earlier EJ22 was safe and simple, its successor, the EJ25, introduced an interference design and head gasket headaches. The timing belt itself isn’t too expensive, but the consequences of skipping it are catastrophic.

If the belt snaps, valves collide with pistons instantly often ruining the cylinder heads. Replacing or repairing the engine can easily cost more than the car’s value.

Subaru owners who stay ahead of the maintenance are usually fine, but one missed interval (typically 105,000 miles) can spell disaster.

Of course. Here is the provided content rewritten in a continuous paragraph form, maintaining all the original information and detail.

The Subaru EJ25 engine, a 2.5-liter flat-four powerplant, has established a profoundly significant and enduring presence in the automotive landscape since its debut in the late 1990s.

Celebrated for its distinctive boxer engine layout, the EJ25 delivers a unique blend of performance, dependability, and adaptability, and is especially praised for its characteristically low center of gravity, which directly enhances vehicle stability and handling dynamics.

The horizontally opposed cylinder arrangement not only ensures remarkably smooth operation but also effectively reduces vibration, securing its status as a preferred choice among driving enthusiasts and daily commuters alike.

As a core member of Subaru’s extensive EJ engine family, the EJ25 has served as a foundational element of the brand’s identity for decades and has been subject to numerous updates and refinements throughout its production, each iteration aimed at boosting its output, responsiveness, and overall efficiency.

Originally conceived for naturally aspirated applications, its evolution later expanded to encompass turbocharged versions, thereby broadening its appeal to drivers seeking more potent performance.

Its remarkable versatility is demonstrated by its deployment across a wide spectrum of Subaru models, including the Legacy, where it made its inaugural appearance; the Outback, where it was a fundamental component; the Forester, which benefited from its trustworthy power; the Impreza, particularly in high-performance WRX and STI trims; and the distinctive Baja pickup truck.

Beyond these core models, the EJ25 engine has also been featured in various special editions and high-performance variants, further cementing its legendary reputation within the global Subaru community.

The EJ25 engine stands as a powerful testament to Subaru’s long-standing commitment to engineering excellence and innovation, representing a powertrain solution that successfully meets varied customer needs while steadfastly upholding the brand’s core principles of safety, durability, and engaging performance.

Its key specifications include a horizontally opposed 4-cylinder configuration, a displacement of 2.5 liters (2457 cc), a compression ratio of 10.5:1 for naturally aspirated and 8.0:1 for turbocharged variants, with maximum horsepower outputs around 165 hp for naturally aspirated and 250 hp for turbocharged versions, and maximum torque figures of approximately 166 lb-ft and 250 lb-ft, respectively.

3. Hyundai/Kia 2.7L Delta V6 (Sonata, Santa Fe, Optima)

Used across mid-2000s Hyundai and Kia models, the Delta 2.7-liter V6 is infamous among independent mechanics.

The design packs the timing belt deep behind accessories, and there’s little clearance to work. Labor costs can reach $900 or more for a belt and water pump change.

Worse, it’s an interference engine. A broken belt or tensioner failure results in severe internal damage, usually requiring a full rebuild or replacement.

The cost-to-value ratio of this job makes older Hyundai V6 models poor choices for anyone not committed to strict maintenance.

The 2.7L engine has established itself as a significant and versatile powerplant within the Hyundai and KIA vehicle lineup, recognized for its robust performance.

This V6 engine was engineered to achieve an effective equilibrium between power output and fuel efficiency, which contributed to its popularity across a spectrum of models.

Thanks to its smooth operational characteristics and respectable horsepower, the 2.7L engine successfully carved out a distinct niche in the automotive world, attracting the attention of daily commuters and driving enthusiasts alike.

The adaptability of the 2.7L engine is demonstrated by its deployment in numerous models under both the Hyundai and KIA brands, suited to a variety of vehicle types. The following list details notable automobiles that have been equipped with this engine:

The engineering behind the 2.7L engine was focused on delivering a respectable balance of power and fuel economy. It incorporates advanced technologies such as a DOHC (Dual Overhead Camshaft) architecture and VVT (Variable Valve Timing), features that actively contribute to the engine’s responsiveness and overall driving dynamics.

Although the engine has consistently been commended for its smooth operation and adequate torque delivery, it is important to note that it has since been discontinued and superseded by more modern, efficient powertrains.

Despite this progression, the 2.7L engine endures as a notable and impactful chapter in the engineering history of Hyundai and KIA, having left a definitive impression on the many vehicles it powered.

4. Acura/Honda 3.5L V6 with VTEC Variable Cylinder Management (VCM)

Not all Honda V6s are friendly. The later versions of the J35 with VCM used in certain Accords, Odysseys, and Pilots from 2008–2015 introduced complexity that makes the timing-belt job more tedious.

The system’s additional sensors, mounts, and coolant routing require extra teardown, which raises labor costs.

This engine is also interference, so a neglected belt can cause valve damage. While reliable when maintained, the cost of failure is steep.

It’s a rare misstep in Honda’s otherwise brilliant engine design history, but one that owners should respect by replacing belts religiously every 90,000 to 100,000 miles.

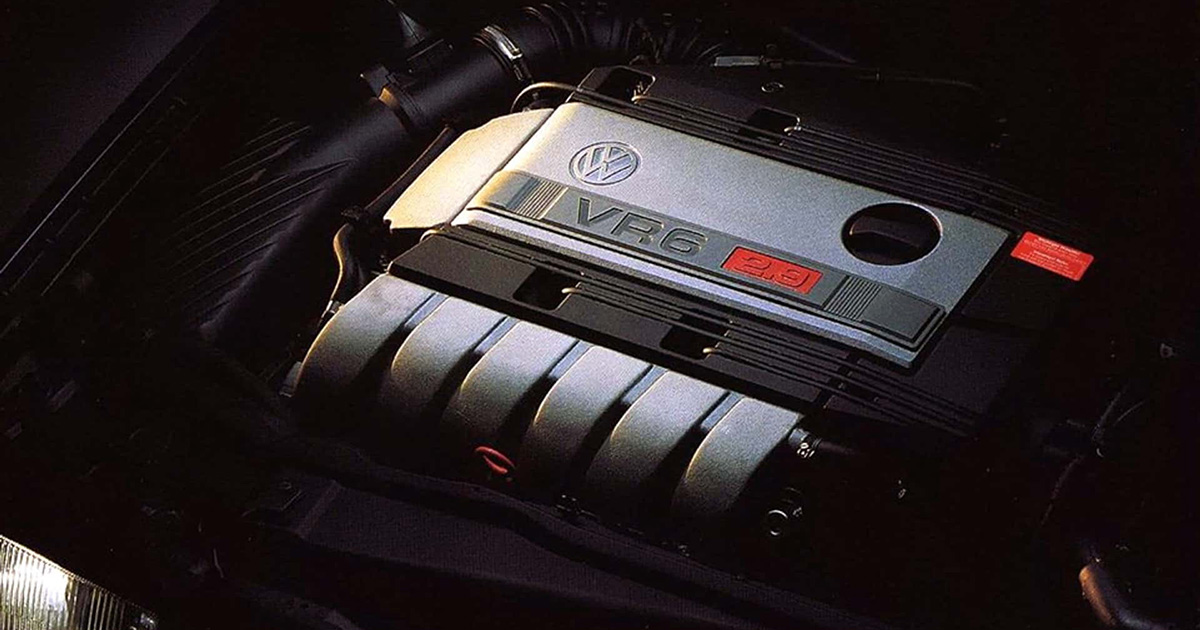

5. Volkswagen 2.8L VR6 (Passat, GTI, Jetta)

Volkswagen’s narrow-angle VR6 is an engineering marvel, but it’s a mechanic’s nightmare when it comes to the timing system.

The “belt” is actually a chain on later versions, but earlier models used a belt-like layout buried behind engine mounts and accessories.

Everything about servicing this engine is time-consuming and cramped. The design’s interference nature means any failure belt, chain, or tensioner leads to catastrophic internal damage.

Labor times can exceed eight hours, and total repair bills often exceed $2,500. Many owners sell their cars rather than face a VR6 timing service.

Timing belts aren’t inherently bad they’re just a tradeoff between quiet operation and maintenance discipline.

Some automakers, like Honda and Toyota, engineered their belt systems for simplicity and longevity. Others, like Volkswagen and Subaru, combined high performance with tight clearances that punish neglect.

If you’re shopping for a used vehicle in the U.S., knowing which engines fall on either side of that divide can save you thousands. Look for engines with easy access, affordable kits, and non-interference designs if you plan on doing your own work.

But if you’re buying something with a belt-driven interference setup, budget for the service upfront or risk turning your engine into a cautionary tale.