The story of Japanese automakers transforming the global performance car world is one of engineering brilliance, innovative thinking, and an unwavering commitment to pushing boundaries.

From the ashes of post-World War II reconstruction, Japanese manufacturers emerged not just as competitors but as revolutionaries who fundamentally changed how the world viewed high-performance automobiles.

What began as an industry focused on economical transportation evolved into a powerhouse of automotive innovation that challenged and often surpassed European and American performance car dominance.

Japanese automakers brought a unique philosophy to performance engineering: the belief that exceptional speed, handling, and driving excitement didn’t require exotic price tags or temperamental maintenance schedules.

They democratized performance, making it accessible to enthusiasts who previously could only dream of owning truly fast cars. Through relentless refinement, cutting-edge technology, and a deep understanding of driver engagement, brands like Nissan, Toyota, Honda, Mazda, and Subaru created legendary machines that redefined entire segments.

From pioneering turbocharged engines and all-wheel-drive systems to perfecting the art of the lightweight sports car and introducing hybrid supercars, Japanese manufacturers consistently broke new ground.

Their influence extended beyond individual models to shape motorsport, tuning culture, and the very definition of what a performance car could be.

This revolution wasn’t just about raw numbers; it was about delivering soul-stirring driving experiences wrapped in reliable, well-engineered packages that owners could actually use every day. The impact of these innovations continues to resonate throughout the automotive world today.

1. Turbocharging Technology for the Masses

Japanese automakers fundamentally transformed the accessibility of turbocharged performance, taking what was once exotic racing technology and making it mainstream.

While European manufacturers had experimented with turbochargers, Japanese engineers refined and democratized the technology, making forced induction reliable, affordable, and devastatingly effective.

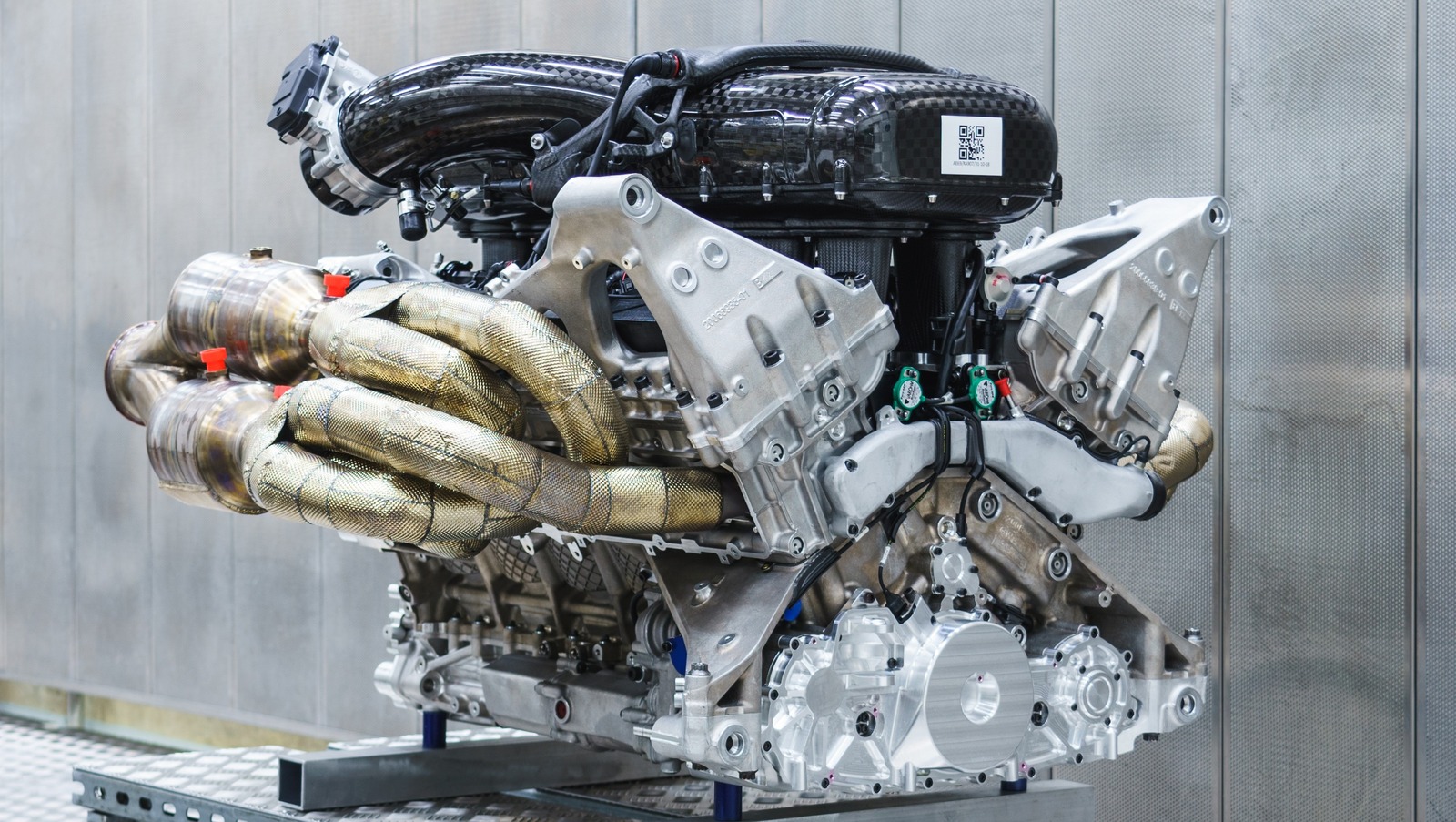

This revolution began in earnest during the 1980s when manufacturers like Nissan, Toyota, and Mitsubishi started equipping their performance models with sophisticated turbocharging systems that delivered incredible power from relatively small-displacement engines.

The brilliance of the Japanese approach lay in their methodical engineering philosophy. Rather than simply bolting on turbos for headline-grabbing horsepower figures, they developed complete systems that addressed heat management, durability, and drivability.

The iconic Nissan Skyline GT-R emerged as a poster child for this technology, with its RB26DETT engine featuring twin-turbo configuration that produced extraordinary power while maintaining remarkable reliability.

Similarly, Toyota’s 2JZ-GTE engine became legendary not just for its factory output but for its ability to handle substantially more power with minimal internal modifications.

Japanese manufacturers also pioneered technologies that made turbocharged engines more user-friendly. They developed advanced intercooling systems, sophisticated boost control mechanisms, and engine management systems that eliminated much of the turbo lag that had plagued earlier forced-induction engines.

The sequential twin-turbo systems found in cars like the Mazda RX-7 and Toyota Supra represented ingenious solutions to deliver both low-end responsiveness and high-rpm power.

The impact extended beyond pure performance applications. Japanese automakers demonstrated that turbocharging could enhance efficiency as well as power, presaging today’s widespread adoption of turbocharged engines across all vehicle segments.

Models like the Mitsubishi Lancer Evolution and Subaru WRX brought all-wheel-drive turbocharged performance to relatively affordable price points, creating entirely new market segments and inspiring countless enthusiasts.

The tuning community that emerged around these engines further demonstrated their robust engineering, with modified examples regularly producing two or three times their factory power output.

This turbocharging revolution made high performance attainable for average consumers, forever changing performance car ownership from an exclusive privilege to an accessible passion.

2. Perfecting All-Wheel Drive Performance Systems

The development of sophisticated all-wheel-drive systems specifically designed for performance applications stands as one of Japan’s most significant contributions to automotive engineering.

While AWD technology existed in utilitarian vehicles, Japanese manufacturers transformed it into a performance-enhancing tool that revolutionized handling dynamics and traction management.

This innovation created a new paradigm where power could be effectively deployed regardless of conditions, fundamentally changing what performance cars could achieve.

Subaru pioneered the performance AWD revolution with their symmetrical all-wheel-drive system, initially developed for rally competition before making its way into production vehicles.

The system’s longitudinally-mounted boxer engine and balanced drivetrain layout provided inherent advantages in weight distribution and handling characteristics.

When combined with turbocharged engines in models like the WRX and STI, this technology delivered point-and-shoot handling that allowed drivers to carry incredible speeds through corners while maintaining composure that rear-wheel-drive competitors simply couldn’t match.

Nissan’s approach with the Skyline GT-R took AWD performance to another level with the ATTESA E-TS system. This sophisticated electronic torque-split system could vary power distribution between front and rear axles in real-time, essentially creating a rear-biased sports car that could instantly summon front-axle traction when needed.

The system represented a quantum leap in intelligent power management, using sensors monitoring everything from wheel speed to lateral g-forces to optimize traction in milliseconds.

The technology proved so effective that it influenced supercar manufacturers, with modern exotics increasingly adopting AWD for both performance and usability. Today’s performance AWD world, from hot hatches to hypercars, owes its existence to these Japanese innovations.

3. The Lightweight Sports Car Philosophy

Japanese automakers rekindled and perfected the philosophy that driving excitement comes from minimizing weight rather than maximizing power, creating some of the most beloved sports cars in history.

This approach represented a counter-revolution against the trend toward heavier, more powerful vehicles, instead emphasizing the pure, visceral connection between driver and machine that comes from lightweight construction and balanced dynamics.

The resulting vehicles proved that affordable, lightweight sports cars could deliver more genuine driving pleasure than vehicles costing many times more.

Mazda’s MX-5 Miata stands as the definitive expression of this philosophy. Launched in 1989, the Miata channeled the spirit of classic British roadsters while eliminating their notorious unreliability.

Weighing barely over 2,100 pounds and powered by a modest four-cylinder engine, the Miata delivered extraordinary driving enjoyment through perfect 50/50 weight distribution, precise steering, and a chassis that communicated every nuance of the road surface.

The formula proved so successful that Mazda sold over a million examples, single-handedly reviving the affordable roadster segment and inspiring countless competitors.

Honda’s approach with the S2000 took lightweight sports car engineering to extremes. The car featured an aluminum hood and rear deck, magnesium hardtop components, and a race-derived high-revving engine that screamed to 9,000 rpm while producing an astonishing 120 horsepower per liter naturally aspirated.

The S2000’s near-perfect weight distribution and pin-sharp handling made it a favorite among driving purists, demonstrating that Honda’s VTEC technology could create intoxicating performance without forced induction.

Modern sports cars increasingly emphasize weight reduction alongside power increases, validating the Japanese philosophy that optimal performance comes from holistic engineering rather than simply adding horsepower.

4. High-Revving Naturally Aspirated Engines

Japanese engineers raised naturally aspirated engine technology to unprecedented heights, creating powerplants that delivered exhilarating performance through high-rpm capabilities and sophisticated valvetrain engineering rather than forced induction.

These engines became legendary for their screaming soundtracks, razor-sharp throttle response, and ability to produce extraordinary specific output while maintaining remarkable reliability.

The technology demonstrated that naturally aspirated engines could compete with turbocharged rivals while offering unique characteristics that many enthusiasts preferred.

Honda’s VTEC (Variable Valve Timing and Lift Electronic Control) system revolutionized four-cylinder performance by allowing engines to transform character at high rpm.

The Integra Type R’s B18C engine produced 195 horsepower from just 1.8 liters, delivering 108 horsepower per liter naturally aspirated figures that seemed impossible when the car launched in 1995.

More importantly, VTEC created two distinct personalities: tractable and efficient at low rpm, then aggressive and intoxicating past the switchover point. This technology made its way across Honda’s lineup, creating engines that rewarded drivers who explored their rev ranges.

Toyota took naturally aspirated performance even further with engines like the legendary 4A-GE, which featured innovative five-valve-per-cylinder technology in later iterations.

The engine powered iconic models like the AE86 Corolla and MR2, becoming beloved for its willingness to rev and robust construction.

Toyota’s collaboration with Yamaha on engines like the 2ZZ-GE further pushed boundaries, with that engine producing 190 horsepower from 1.8 liters while featuring both VVTL-i (Toyota’s variable valve timing system) and lift control.

The ultimate expression of Japanese naturally aspirated engineering came in exotic applications like the Honda NSX’s C30A/C32B V6, which featured titanium connecting rods and produced its power at screaming engine speeds while maintaining comfortable drivability.

Nissan’s VQ series V6 engines, particularly in applications like the 350Z and 370Z, delivered muscular naturally aspirated performance with distinctive exhaust notes that became immediately recognizable.

These high-revving naturally aspirated engines created a driving experience fundamentally different from turbocharged alternatives. The linear power delivery, instantaneous throttle response, and intoxicating soundtracks as they approached redline created emotional connections between drivers and their vehicles.

They rewarded skillful driving, encouraging drivers to use the full rev range and closely match revs during downshifts. Though turbocharging has become dominant for efficiency reasons, these naturally aspirated jewels remain highly sought after by enthusiasts who value their unique characteristics and the purity of their engineering approach.

Also Read: 9 Nearly-New Luxury Sports Cars That Cost Half as Much as a 911

5. Rotary Engine Innovation

Mazda’s commitment to developing and perfecting the Wankel rotary engine represents one of the most distinctive chapters in automotive history, showcasing Japanese perseverance in refining unconventional technology.

While other manufacturers abandoned rotary development due to challenges with emissions, fuel consumption, and reliability, Mazda persisted through decades of research and development to create some of the most charismatic and distinctive performance cars ever built.

This dedication to an alternative engine design demonstrated Japanese willingness to pursue innovation even when conventional wisdom suggested abandoning the effort.

The rotary engine offered compelling advantages for performance applications: exceptional power-to-weight ratio, compact dimensions, smooth operation free from reciprocating vibrations, and the ability to rev to stratospheric engine speeds.

Mazda’s RX-7 lineage showcased the technology’s evolution, with each generation delivering more power and refinement. The third-generation FD RX-7 particularly stands as a masterpiece of rotary engineering, with its twin-sequential-turbocharged 13B-REW engine producing 255 horsepower from just 1.3 liters of displacement while weighing remarkably little.

The engine’s compact size allowed designers to achieve near-perfect 50/50 weight distribution in a beautifully sculpted sports car body.

Mazda’s rotary development culminated in the RX-8, which featured the innovative Renesis engine with side exhaust ports that improved emissions and efficiency while producing 232 horsepower naturally aspirated.

The engine’s placement allowed for a unique four-door sports car configuration with rear-hinged suicide doors while maintaining sports car proportions and handling dynamics.

Though the RX-8 represented the swan song for production rotary vehicles, it demonstrated that Mazda had successfully addressed many historical rotary challenges.

The rotary engine’s impact extended beyond production vehicles to motorsport, where Mazda achieved the remarkable feat of winning the 24 Hours of Le Mans in 1991 with the four-rotor 787B the only Japanese manufacturer and only rotary-powered vehicle ever to claim victory at the prestigious endurance race.

his triumph vindicated Mazda’s decades of rotary development and demonstrated the engine’s potential when fully developed. The rotary created a passionate enthusiast community that celebrated the engine’s unique characteristics: the distinctive buzzing exhaust note, smooth power delivery, and compact packaging.

Tuners discovered enormous performance potential, with modified rotaries producing incredible power outputs. While challenges with fuel consumption and apex seal wear remained concerns, the rotary’s unique character created loyal devotees who appreciated its differences rather than demanding conventional piston engine characteristics.

Mazda continues researching rotary technology for range-extender applications in electric vehicles, suggesting this distinctive Japanese innovation may yet see new life in unexpected applications.

6. Affordable Supercar Performance

Japanese manufacturers shattered the notion that exotic supercar performance required exotic prices, creating vehicles that delivered legitimate supercar capabilities at fractions of traditional costs.

This democratization of extreme performance represented perhaps the most significant shift in automotive accessibility, allowing enthusiasts of modest means to experience acceleration, handling, and technology previously reserved for wealthy collectors.

The Japanese approach proved that careful engineering and efficient manufacturing could deliver performance rivaling dedicated exotics while maintaining everyday usability and reliability.

The Nissan GT-R (particularly the R35 generation launched in 2007) epitomized this revolution. With its twin-turbo V6 producing over 480 horsepower, sophisticated all-wheel-drive system, and advanced electronics, the GT-R could accelerate from zero to sixty in under three seconds and lap racetracks faster than supercars costing three or four times more.

The car’s party trick was making this performance accessible through intelligent technology that managed power delivery, optimized gear selection, and maximized traction with computerized precision. Professional drivers praised its capabilities while novices marveled at how the car’s systems made them appear heroic.

The Honda NSX (original generation) took a different approach to affordable supercar performance by emphasizing aluminum construction, balance, and usability.

Developed with input from Ayrton Senna, the NSX proved that mid-engine exotic performance didn’t require temperamental character or punishing maintenance costs.

Its naturally aspirated V6 VTEC engine delivered thrilling performance while the car remained comfortable enough for daily driving something Italian exotics of the era couldn’t claim. The NSX forced Ferrari to improve their products’ reliability and usability, fundamentally raising standards across the supercar segment.

Toyota’s Supra, particularly the fourth-generation model with its 2JZ-GTE engine, offered straight-line supercar performance at accessible prices.

The Supra’s robust twin-turbo inline-six became legendary in tuning circles for its ability to handle enormous power increases with minimal modifications.

Modified Supras regularly achieved 800-1,000 horsepower while remaining drivable on streets, creating a performance-per-dollar proposition that embarrassed exotic car manufacturers.

Even vehicles like the Mitsubishi 3000GT VR-4 brought supercar technology including all-wheel drive, all-wheel steering, active aerodynamics, and twin-turbo power to price points where upper-middle-class buyers could aspire to ownership.

These Japanese performance cars proved that exotic capabilities didn’t require exotic compromises, changing consumer expectations and forcing the entire performance car market to deliver greater value and reliability.

7. Motorsport Success Driving Innovation

Japanese manufacturers leveraged motorsport competition as both proving grounds for technology and marketing platforms that built legendary reputations for performance prowess.

Their successes across diverse racing disciplines from rally to endurance racing to touring cars not only demonstrated engineering excellence but directly influenced production vehicle development.

This race-to-road technology transfer created some of history’s most celebrated performance cars while establishing Japanese brands as legitimate performance authorities capable of defeating European competitors on their home turf.

Subaru’s World Rally Championship dominance through the 1990s and 2000s transformed the WRX and STI from Japanese-market sedans into global performance icons.

Drivers like Colin McRae and Petter Solberg piloted Imprezas to multiple manufacturers’ and drivers’ championships, with the distinctive blue-and-gold livery becoming instantly recognizable worldwide.

The rally program’s technology filtered directly into production vehicles: advanced all-wheel-drive systems, intercooler designs, suspension tuning, and aerodynamic developments all benefited from competition experience.

Each WRX STI generation incorporated lessons learned from grueling rally stages, creating road cars that genuinely reflected motorsport pedigree.

Mitsubishi’s parallel rally success with the Lancer Evolution created an intense rivalry that pushed both manufacturers to greater heights.

Tommi Mäkinen’s four consecutive WRC drivers’ championships in Evolutions demonstrated the car’s capabilities while establishing the Evo name among enthusiast communities worldwide.

The technology developed for competition including the sophisticated Super Active Yaw Control system made its way into production Evolutions, delivering unprecedented handling dynamics.

Nissan’s GT-R dominated touring car racing across multiple series, particularly the legendary Australian Touring Car Championship victories that earned the R32 GT-R its “Godzilla” nickname.

The car’s success became so overwhelming that regulations were eventually changed to limit its competitiveness. This racing pedigree transformed the GT-R from a Japanese domestic model into a global performance icon that commanded respect from enthusiasts worldwide.

Mazda’s 1991 Le Mans victory with the 787B rotary-powered prototype represented the pinnacle of Japanese endurance racing success, proving rotary technology’s viability at the sport’s highest level.

Honda’s Formula One engines powered championship-winning McLaren and Williams teams through the late 1980s and early 1990s, demonstrating Japanese engineering could compete in motorsport’s most technologically demanding category.

These motorsport successes weren’t mere marketing exercises they drove genuine technical innovation that made production performance cars faster, more capable, and more exciting while building brand equity that persists decades later.

8. Tuning Culture and Aftermarket Support

Japanese performance cars spawned an unprecedented global tuning culture, with manufacturers either intentionally or accidentally creating vehicles that possessed enormous modification potential.

This ecosystem of aftermarket support, tuning knowledge, and enthusiast community transformed how people engaged with performance cars, creating a participatory culture where owners could meaningfully enhance their vehicles.

The robust engineering underlying Japanese performance cars meant they could handle substantial power increases and modifications without catastrophic failures, encouraging experimentation and customization.

The Toyota Supra’s 2JZ-GTE engine became the poster child for tuning potential. Its iron block, strong internals, and sophisticated engine management system allowed tuners to reliably double or triple factory power output with turbo upgrades, fuel system enhancements, and tuning.

Supras achieving 800-1,000 horsepower while remaining street-drivable weren’t uncommon, and the platform’s legendary reliability even at extreme power levels created a devoted following. Tuning companies worldwide built businesses around Supra modifications, creating complete ecosystems of parts and knowledge.

Nissan’s SR20DET and RB26DETT engines similarly became tuning staples, with the latter powering GT-Rs to insane power levels. The RB26’s twin-turbo inline-six architecture responded incredibly well to modifications, and its presence in the legendary Skyline GT-R made it aspirational for tuners globally.

The SR20DET found in various Nissans including the 240SX/Silvia provided an affordable entry point for turbo tuning, becoming the engine of choice for drifting and time attack competition.

Honda’s B-series and K-series engines created a massive tuning culture around naturally aspirated performance. The engines’ high-revving nature and sophisticated VTEC valvetrains provided excellent baseline performance, while strong aftermarket support allowed tuners to extract even more through engine management, camshafts, forced induction, and complete engine builds.

The affordability of Honda platforms meant young enthusiasts could participate in modification culture, creating a grassroots community that remains vibrant today.

This tuning culture extended beyond engines to encompass suspension, brakes, aerodynamics, and interior modifications. Japanese manufacturers’ modular approaches and standardized components made modifications straightforward, while extensive parts compatibility between models reduced costs.

Online forums and communities shared knowledge, creating collective expertise that helped newcomers avoid expensive mistakes while pushing performance boundaries.

The culture influenced car design itself, with manufacturers increasingly recognizing enthusiast modification tendencies and engineering vehicles that accommodated them.

This symbiotic relationship between manufacturers and tuning culture created more engaging ownership experiences and helped Japanese performance cars maintain relevance and value long after production ended.

9. Hybrid and Electric Performance Innovation

Japanese manufacturers pioneered the integration of hybrid and electric technology into performance vehicles, demonstrating that electrification could enhance rather than compromise driving excitement.

While many enthusiasts initially viewed hybrid powertrains as antithetical to performance, Japanese engineering proved that electric motors’ instant torque and sophisticated energy management could create new performance paradigms.

This innovation established precedents that now guide the entire automotive industry’s transition toward electrified performance.

Honda’s second-generation NSX boldly reimagined supercar performance through its Sport Hybrid SH-AWD system, combining a twin-turbo V6 with three electric motors to deliver 573 horsepower and torque-vectoring capabilities impossible with conventional drivetrains.

The front axle’s independent electric motors could individually accelerate or decelerate each front wheel, creating unprecedented handling agility and corner exit traction.

This technology demonstrated that hybrid systems could enhance driver engagement rather than diminishing it, with the electric motors filling the traditional turbo lag void and providing instantaneous throttle response.

Lexus pursued electrified performance through models like the LC500h and various F Sport hybrids, proving that luxury performance vehicles could benefit from hybrid efficiency without sacrificing dynamic credentials.

The brand’s commitment to hybrid technology in performance applications helped normalize electrification among enthusiasts who might otherwise resist the transition.

Toyota’s Gazoo Racing division brought hybrid technology to endurance racing’s pinnacle with their TS050 Hybrid Le Mans prototype, which featured a powerful hybrid system recovering and deploying energy through corners and straightaways.

The car’s success at Le Mans demonstrated that hybrid technology could dominate motorsport’s most demanding competition, directly contradicting notions that electrification meant compromised performance.

Nissan’s experimental approaches like the ZEOD RC (Zero Emission On Demand Racing Car) that competed at Le Mans explored pure electric racing performance, completing laps entirely on battery power to showcase electric powertrains’ racing potential.

Though Nissan’s broader electrified performance efforts have been less focused than Honda’s, their willingness to experiment with technologies like the e-4ORCE all-wheel-drive system demonstrates ongoing commitment to electrified performance development.

The significance of Japanese hybrid performance innovation extends beyond individual models to philosophical validation that electrification can coexist with driving excitement.

By proving electric motors enhance performance through instant torque, precise power delivery, and enabling sophisticated torque-vectoring systems, Japanese manufacturers helped enthusiast communities accept and eventually embrace the inevitable transition toward electrified vehicles.

This groundwork makes today’s explosion of electric performance vehicles possible, from dedicated EVs to hybrid supercars that use electric motors to achieve performance impossible with combustion engines alone.

10. Reliability and Daily Usability

Perhaps the most revolutionary aspect of Japanese performance cars was their fundamental reliability and real-world usability, characteristics that European and American performance manufacturers often treated as secondary to raw performance.

Japanese engineering philosophy insisted that performance cars should start reliably every morning, require reasonable maintenance intervals, and tolerate daily driving without constant mechanical drama.

This approach democratized performance car ownership by eliminating the traditional penalty of frequent breakdowns and expensive repairs that historically accompanied high-performance vehicles.

The contrast with European exotics was stark and undeniable. While Italian supercars required regular major services costing thousands of dollars, Japanese performance cars followed conventional maintenance schedules with reasonable costs.

The Nissan GT-R, despite supercar-level performance, could be serviced at Nissan dealerships using parts sharing commonality with lesser models. The Honda NSX famously required only oil changes and basic maintenance despite mid-engine exotic performance.

This reliability made performance car ownership financially accessible beyond initial purchase prices by dramatically reducing long-term ownership costs.

Japanese manufacturers achieved this reliability through conservative engineering approaches, extensive testing, and quality manufacturing processes.

Engine internals typically featured substantial safety margins rather than being stressed to absolute limits. Cooling systems were overbuilt. Electrical systems used proven components.

While this sometimes meant Japanese performance cars initially produced less peak power than European competitors, their ability to repeatedly deliver advertised performance without failures proved more valuable to actual owners.

The daily usability extended beyond mechanical reliability to practical considerations. Japanese performance cars typically featured comfortable interiors, reasonable visibility, manageable clutch efforts, and livable ride quality. The Subaru WRX served equally well as a family sedan and weekend track car.

The Mazda MX-5 could handle daily commutes and grocery runs between weekend canyon drives. This versatility meant owners could justify single-car solutions rather than requiring dedicated performance vehicles plus separate daily transportation.

The long-term impact of Japanese reliability standards forced the entire performance car industry to improve. European manufacturers could no longer justify frequent breakdowns as character-building experiences when Japanese competitors proved reliability and performance weren’t mutually exclusive.

This philosophical approach that performance should be usable, reliable, and accessible remains perhaps the most enduring legacy of Japanese automotive engineering excellence.

Also Read: 6 Cars for Roseville Family Runs vs 6 That Hide Issues