The supercar world is filled with ambition, bold design, and engineering dreams that aim to push performance to new heights. For every success story that becomes an icon, there are other projects that struggle from the very beginning.

Some cars arrive with unrealistic expectations, others suffer from poor timing, limited funding, or technology that simply is not ready for real world use. In many cases, the warning signs are present long before the first customer ever turns a key.

Building a supercar is an incredibly complex challenge. It requires advanced engineering, reliable suppliers, precise manufacturing, and a strong dealer and service network.

When any of these elements fall short, even the most exciting design or powerful engine cannot save the project. Buyers in this segment expect not only speed and style, but also quality, reliability, and long term support.

Financial pressure is another major factor. Developing a low volume, high performance car is extremely expensive. Smaller manufacturers often underestimate costs or overestimate demand. When sales fail to meet expectations, the company can struggle to survive, leaving owners with uncertain parts availability and support.

Sometimes the problem is positioning. A car might be priced too high for its brand image, or too similar to better established rivals. Without a clear identity or competitive edge, even a technically interesting supercar can be overlooked by buyers.

The following eight supercars are remembered not just for their performance, but for the ways in which their projects were flawed from the start. Whether due to engineering challenges, financial trouble, or market misjudgment, these cars faced uphill battles that made success unlikely from day one.

Also Read: Top 10 SUVs That Successfully Balance Speed And Reliability

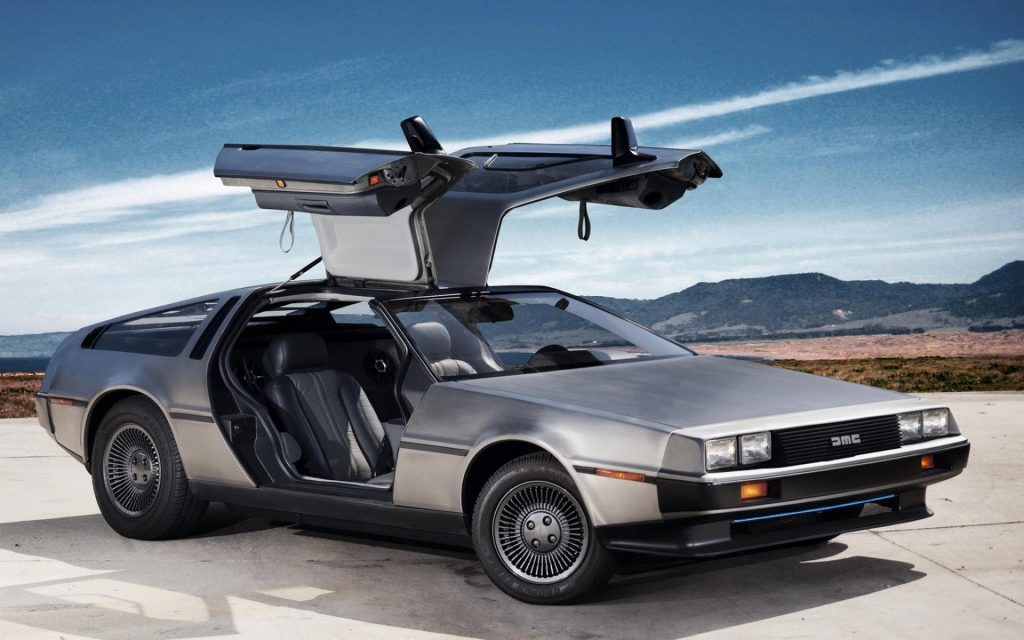

1. DeLorean DMC 12

The DeLorean DMC 12 is one of the most recognizable cars in the world today, largely thanks to its role in popular culture. However, as a supercar style project in its own time, it was troubled from the beginning. Ambitious goals, limited resources, and production challenges combined to create a car that struggled to live up to expectations.

From the start, the company aimed to build a futuristic sports car with stainless steel body panels and dramatic gullwing doors.

The design certainly stood out, and the car looked like something from the future. Unfortunately, the mechanical side did not match the visual promise. Performance fell short of what buyers expected from a car with such bold styling.

The engine choice became a major weakness. The V6 used in the car was not powerful enough to deliver the kind of acceleration that its appearance suggested. As a result, driving performance felt modest rather than exciting. For a car positioned as a premium performance machine, this mismatch hurt its credibility.

Build quality was another serious issue. Early production cars suffered from inconsistent assembly and reliability concerns. Electrical problems and fit and finish flaws were common, damaging the brand’s reputation quickly. Buyers who expected a cutting edge sports car often found themselves dealing with frustrating defects.

Financial instability also haunted the project. The company relied heavily on government support and struggled with cash flow from the start. Production delays and rising costs made it difficult to maintain momentum. As problems mounted, confidence among dealers and customers declined.

Marketing and pricing further complicated matters. The car was expensive relative to its performance, placing it in competition with more established sports car brands. Without a strong track record or proven engineering, the DeLorean found it difficult to justify its price tag.

Despite these issues, the DMC 12 achieved lasting fame through movies and pop culture. However, from a business and engineering perspective, the project was flawed early on. Weak performance, quality issues, and financial instability created obstacles that proved too great to overcome.

The DeLorean remains a fascinating chapter in automotive history, but it stands as a clear example of a supercar style project that faced serious challenges from the moment it was conceived.

2. Vector W8

The Vector W8 was conceived as an American answer to European supercars, promising extreme performance and advanced aerospace inspired design. On paper, it sounded like a revolutionary machine that would challenge the world’s best. In reality, the project was plagued by problems that made success unlikely from the outset.

The car’s design was radical, with sharp angles and a cockpit that looked more like a fighter jet than a road car.

While visually striking, this approach made the vehicle extremely complex and expensive to build. Low production volumes meant that development costs were spread over very few units, putting immense financial pressure on the company.

Engineering ambitions also outpaced practical reality. The W8 used a highly tuned twin turbocharged engine that delivered impressive power figures. However, integrating this performance into a reliable, road usable package proved difficult.

Early cars required frequent adjustments and specialized maintenance, which limited their appeal to buyers who wanted both speed and usability.

Production challenges added to the struggle. Each car required extensive hand assembly, leading to long build times and high costs. This limited output and made it hard to generate the revenue needed to sustain the company. Delays frustrated customers and strained relationships with investors.

Interior quality and ergonomics also fell short of expectations. The futuristic cabin design looked dramatic but was not always comfortable or intuitive. For a car with a high price tag, these shortcomings made it feel less polished than established rivals.

The company’s business structure was another weak point. Disputes between management and investors created instability that distracted from product development. Legal and financial issues overshadowed the car itself, making it difficult to build trust with potential buyers.

Market positioning was also problematic. The W8 was priced in direct competition with proven European exotics from brands with racing heritage and established dealer networks. Buyers willing to spend that much money often preferred the security of a well known manufacturer.

Although the Vector W8 achieved a certain cult status and remains a rare collector item, its project was burdened by unrealistic ambitions, financial strain, and engineering complexity from the beginning. These factors combined to make it a supercar that struggled to succeed from day one.

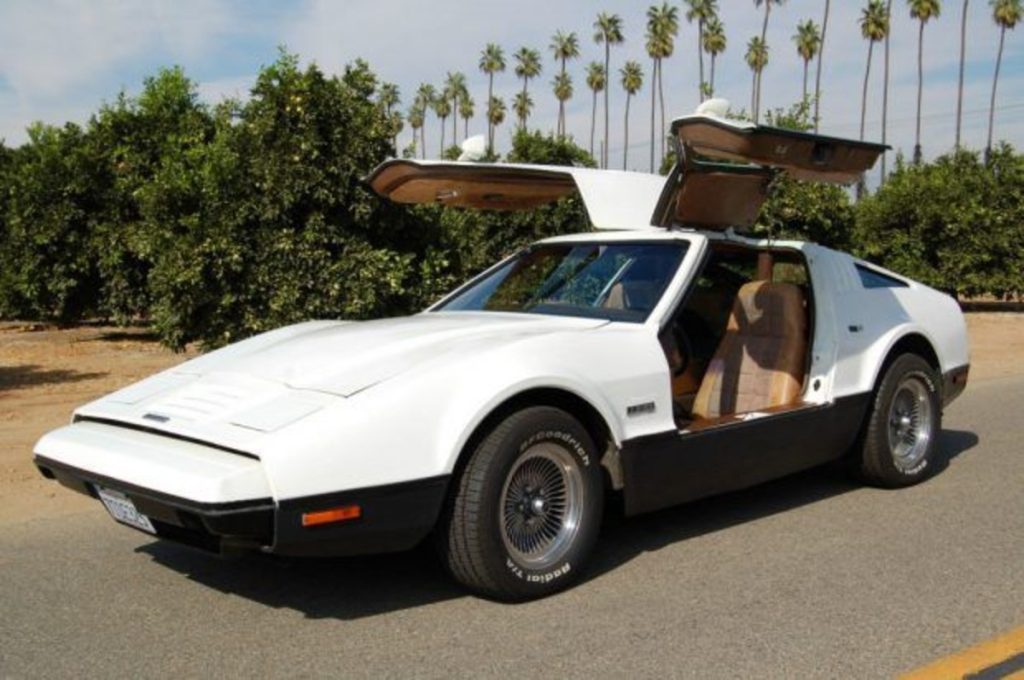

3. Bricklin SV 1

The Bricklin SV 1 was an ambitious attempt to create a safety focused sports car that could compete with established performance brands.

While the concept sounded promising, a series of practical and financial issues made the project vulnerable from the very beginning. Despite eye catching styling and bold marketing, the car struggled to find a stable footing in the demanding supercar segment.

One of the key selling points was safety innovation. The SV 1 featured integrated bumpers and a reinforced structure designed to improve crash protection. While this focus was admirable, it also added weight and complexity. The extra mass affected performance, making the car feel slower and less agile than many of its rivals.

The dramatic gullwing doors were another highlight, but they introduced engineering complications. The hydraulic systems that operated the doors were often unreliable, leading to frequent maintenance issues.

Owners sometimes found themselves dealing with doors that were slow to open or failed to function properly, which quickly became a source of frustration.

Powertrain choices did not help matters. The engines available were not powerful enough to match the car’s aggressive styling. Acceleration was modest, and the driving experience did not live up to the expectations created by its futuristic appearance. This gap between looks and performance hurt its appeal among enthusiasts.

Production quality also presented challenges. The car was built with limited resources and a complex supply chain, which led to inconsistent assembly standards. Early examples suffered from fit and finish problems that damaged the brand’s reputation. Buyers paying a premium price expected a higher level of refinement.

Financial difficulties plagued the company from the start. Development costs were high, and sales volumes were lower than anticipated. Without strong financial backing, it became difficult to maintain production and improve quality. Delays and uncertainty made dealers and customers cautious.

Market positioning was another problem. The SV 1 was priced in a range where buyers could choose established sports cars with proven reliability and performance. Without a strong brand history or competitive speed, the Bricklin struggled to justify its cost.

Although the SV 1 remains an interesting piece of automotive history, its combination of underwhelming performance, quality issues, and financial instability made long term success unlikely. From early engineering compromises to business challenges, the project faced obstacles that were difficult to overcome.

4. Cizeta Moroder V16T

The Cizeta Moroder V16T was an extraordinary concept that aimed to stand alongside the greatest supercars of its era. Featuring a massive sixteen cylinder engine and dramatic styling, it certainly captured attention. However, its development and business model were burdened with issues that made success extremely difficult from the outset.

The centerpiece of the car was its unique V16 engine, created by effectively combining two V8 units. While the idea was impressive on paper, the complexity of such a design made engineering and servicing extremely challenging.

Producing reliable performance from such an unusual layout required significant resources that the small company struggled to maintain.

Weight and packaging also became concerns. The large engine and supporting systems added considerable mass, which affected handling balance. Achieving the precise driving dynamics expected in a supercar proved difficult, especially without the extensive development budgets available to larger manufacturers.

Build quality varied because production was extremely limited and largely hand assembled. Each car required significant manual labor, increasing costs and slowing output. This approach made it hard to generate the volume needed to support ongoing development and customer service.

Financial backing was never truly secure. The company relied on a small group of investors and high end buyers, leaving it vulnerable to shifts in the market. Without a strong dealer network or global support structure, potential customers hesitated to commit to such an expensive and complex vehicle.

The car’s price placed it in direct competition with well known European exotics from brands with established reputations. Buyers spending that level of money often preferred manufacturers with proven reliability and long term parts support.

Marketing reach was also limited. Despite the involvement of a famous music producer in the project’s early promotion, awareness remained low compared to major supercar brands. Without strong global recognition, it was difficult to attract enough customers.

The Cizeta Moroder V16T remains a fascinating and rare machine, admired for its bold engineering and dramatic presence.

Yet the combination of extreme complexity, limited financial resources, and narrow market reach meant the project faced steep challenges from the very beginning. These factors made it a supercar that was always going to struggle to achieve lasting commercial success.

5. Jaguar XJ220

The Jaguar XJ220 is often remembered as one of the fastest cars of its era, yet it is also a prime example of a supercar whose project was troubled long before customers received their cars. Initial excitement gave way to disappointment due to changes in specifications, economic timing, and customer expectations that were not managed effectively.

When the XJ220 was first shown as a concept, it featured a V12 engine and all wheel drive. These elements created enormous enthusiasm, and many buyers placed deposits based on that vision.

However, when the production version arrived, it used a smaller twin turbo V6 engine and rear wheel drive instead. Although still extremely powerful, this change felt like a downgrade to many early supporters.

Performance remained impressive, but perception matters in the supercar market. Buyers who expected a twelve cylinder flagship felt misled. The difference between concept promises and final product damaged trust and led to order cancellations, which hurt sales momentum.

The timing of the car’s release also worked against it. The early 1990s saw an economic downturn that reduced demand for ultra expensive performance cars. Customers who might have followed through in better financial conditions became hesitant, leaving the company with fewer confirmed buyers than expected.

Practicality was another issue. The XJ220 was very low, wide, and difficult to use on everyday roads. Cabin comfort and visibility were limited, which reduced its appeal beyond a small group of enthusiasts. While supercars arerely on exclusivity, extreme compromises made ownership less attractive.

Servicing and support also created concern. Buyers worried about long term maintenance and parts availability for such a complex, low volume vehicle. Without a broad dealer network experienced in handling such cars, confidence was reduced.

Legal disputes over canceled orders added further negative publicity. Rather than focusing on the car’s impressive engineering, discussions often centered on contract disagreements. This overshadowed the vehicle’s technical achievements and hurt its reputation.

The XJ220 remains a remarkable performance machine and a significant piece of Jaguar history. However, mismatched expectations, economic conditions, and communication missteps made it difficult for the project to meet its original goals.

These challenges were present well before full production began, making success far more difficult than it appeared at first.

6. TVR Cerbera Speed 12

The TVR Cerbera Speed 12 was an extreme project that aimed to create one of the most powerful road legal cars ever built. While its ambition captured the imagination of enthusiasts, the very factors that made it exciting also made it nearly impossible to bring to market successfully.

The engine was at the heart of the challenge. Developed by combining two six cylinder units into a massive V12, the power output was enormous.

However, harnessing that level of performance in a controllable and reliable package proved extremely difficult. Even experienced drivers found the car intimidating, and the company itself questioned whether it was suitable for road use.

Engineering such a powerful machine required significant development resources. TVR, being a small manufacturer, did not have the same financial backing or technical infrastructure as larger brands. Ensuring durability, emissions compliance, and safety standards would have demanded investment that was hard to justify given the limited expected sales volume.

Driveability concerns also emerged. The car’s extreme power and lightweight construction made it challenging to handle, especially on public roads. Without advanced electronic stability systems, it relied heavily on driver skill. This limited its appeal to a very small group of buyers.

Production feasibility became another obstacle. Building a complex, low volume supercar with such a unique engine required specialized parts and expertise. Costs per unit would have been extremely high, making the final price difficult to position in the market.

Market demand was uncertain. While enthusiasts admired the concept, the number of customers willing to purchase and actually use such an extreme car was very small. This made the business case weak from the beginning.

In the end, even the company’s leadership reportedly decided the car was too extreme for road use. The project was effectively shelved before full production could begin. This decision reflected the gap between ambition and practical reality.

The Cerbera Speed 12 remains a legend among supercar fans, representing a bold vision of what was possible. Yet its combination of overwhelming power, limited development resources, and uncertain market demand meant that from an early stage, the project faced almost insurmountable challenges.

7. Gumpert Apollo

The Gumpert Apollo was created with a clear and ambitious goal. Build one of the fastest and most track focused road legal supercars in the world. From a performance standpoint, the car delivered astonishing speed and grip. However, several fundamental issues made long term success extremely difficult from the very beginning.

One of the Apollo’s biggest challenges was its extreme focus on track performance at the expense of everyday usability. The suspension was stiff, the ride harsh, and ground clearance minimal.

Driving on normal roads could be uncomfortable and impractical. While some supercar buyers accept compromises, the Apollo’s setup pushed those compromises to a level that limited its audience to a very small group of hardcore enthusiasts.

The interior also reflected this track first philosophy. The cabin was sparse, with limited sound insulation and minimal luxury features.

Materials and finish did not match the price point, especially when compared to established supercar brands that offered both performance and a sense of occasion. Buyers spending large sums of money often expect a balance between speed and comfort, which the Apollo did not fully provide.

Brand recognition was another hurdle. Gumpert was a new and relatively unknown manufacturer, without the history or prestige of brands like Ferrari or Porsche. Convincing customers to invest in such an expensive car from a small company required strong confidence in long term support and resale value. That confidence was difficult to establish.

Financial stability added to the uncertainty. Developing and producing a low volume supercar is extremely costly, and Gumpert operated with limited resources.

Economic downturns made it even harder to attract buyers in such a niche segment. When sales slowed, the company’s financial position weakened, creating concerns about future parts supply and servicing.

Design was also a divisive factor. The Apollo’s styling was driven primarily by aerodynamic efficiency rather than visual appeal. While this approach made sense for performance, the result was a car that many found awkward or unattractive. In a market where emotional appeal plays a huge role, this limited its broader desirability.

Dealer and service networks were limited as well. Owners of exotic cars often expect access to specialized technicians and convenient service locations. With a small global footprint, Gumpert struggled to provide the level of support buyers were used to from more established brands.

Despite its challenges, the Apollo earned respect for its engineering focus and extreme capabilities. On a track, it could compete with or outperform many better known supercars. However, its narrow focus, limited brand power, and financial vulnerability made commercial success very difficult.

From early on, the project faced structural challenges that went far beyond simple performance metrics, making it a supercar that was fighting an uphill battle from day one.

8. Fisker Automotive Karma

The Fisker Karma entered the automotive world with a bold vision. It aimed to combine luxury, striking design, and advanced hybrid technology in a way that would redefine what a high end performance car could be.

While the concept attracted enormous attention, the project was burdened by technical, financial, and market challenges that made long term success unlikely from the start.

One of the main issues was the complexity of the powertrain. The Karma used a plug in hybrid system that was innovative but difficult to perfect.

Integrating electric motors, batteries, and a gasoline engine into a seamless and reliable package proved far more challenging than expected. Early cars suffered from software glitches, battery related concerns, and drivability problems that required repeated updates and repairs.

Battery supply problems further complicated matters. The company relied heavily on a single supplier, and when that supplier encountered difficulties, production slowed dramatically. This disrupted delivery schedules and created uncertainty for customers who had already placed orders.

Build quality also became a concern. As a new manufacturer, Fisker did not have decades of production experience. Early vehicles showed inconsistencies in fit and finish, along with reliability issues that hurt the brand’s image. Buyers in the luxury segment expect a high level of refinement, and these problems made the car feel less polished than established competitors.

Financial stability was another major challenge. Developing advanced hybrid technology is extremely expensive, and Fisker operated with limited resources. Production delays and warranty costs strained the company’s finances. As funding became tighter, it became harder to maintain development and customer support.

Market positioning created additional pressure. The Karma was priced in a range where buyers could choose well known luxury and performance brands with proven track records. Convincing customers to take a chance on a new, unproven manufacturer was always going to be difficult, especially when early reliability concerns emerged.

Service and dealer networks were also limited. Owners faced challenges finding trained technicians and parts, which reduced confidence in long term ownership. Without a strong global support structure, even minor issues could become major inconveniences.

Despite these problems, the Karma’s design was widely admired, and its eco focused performance concept was ahead of its time. However, ambitious technology, supply chain weaknesses, and financial strain created a fragile foundation.

These issues were present from early development stages, meaning the project faced steep obstacles long before production reached full speed. The Karma remains a fascinating example of bold vision meeting harsh practical realities in the supercar and luxury performance world.

Some supercars capture headlines with bold promises, radical design, and extreme performance claims, yet struggle long before they ever reach lasting success.

In many cases, the problems begin at the concept stage, where ambition outpaces funding, engineering resources, or realistic market demand. These cars often look spectacular and generate excitement, but hidden weaknesses make survival in the real world very difficult.

Common issues include unreliable or overly complex technology, poor build quality, and limited testing before launch.

Small manufacturers frequently face financial pressure, leading to production delays and inconsistent support for customers. Without a strong dealer and service network, even minor issues can become major ownership headaches.

Market positioning is another challenge. When a new or unknown brand prices its car alongside established supercar names, buyers often hesitate. Trust, reputation, and long term support matter just as much as performance.

Together, these factors explain why some supercars, despite impressive ideas, were destined to struggle from day one.