Turbocharging has reshaped the modern automotive landscape. Once associated primarily with performance cars and motorsport applications, turbo engines are now found in family sedans, pickup trucks, compact crossovers, and even economy vehicles.

By compressing incoming air and forcing more oxygen into the combustion chamber, turbochargers allow smaller engines to produce more power while maintaining fuel efficiency. On paper, it is a perfect solution for balancing performance and emissions regulations. In practice, however, long term durability varies significantly.

A turbocharger introduces higher cylinder pressures, increased combustion temperatures, and additional mechanical stress. These forces place heavy demands on head gaskets, cylinder heads, cooling systems, pistons, and engine blocks.

When engineering margins are generous and thermal management is carefully designed, turbo engines can deliver impressive longevity.

When power outputs are pushed aggressively without adequate reinforcement, failures such as blown head gaskets, warped cylinder heads, and cracked components can emerge over time.

Durability often depends on design philosophy. Some manufacturers choose conservative boost levels, forged internal components, and oversized cooling systems to protect engine integrity. Others prioritize high output figures from small displacement engines, leaving limited tolerance for prolonged heat and pressure.

Oil circulation design, intercooler efficiency, and gasket material quality all play crucial roles in determining long term survival.

This article explores both sides of turbocharged engineering. First, we examine five turbo engines that have built strong reputations for reliability and endurance under boost. Then we shift focus to five engines that developed recurring gasket issues or pressure related failures.

Together, they highlight how thoughtful engineering decisions can determine whether a turbo engine becomes a long term workhorse or a costly liability.

Also Read: 10 Sports Cars With Fragile Dual-Clutch Gearboxes

5 Turbo Engines That Are Built for Longevity

Turbo engines are often unfairly labelled fragile, yet history shows that forced induction can coexist with durability when properly engineered. Longevity in a turbocharged engine depends primarily on heat control, internal strength, and sensible tuning.

Excess combustion pressure and sustained high temperatures are the leading causes of head gasket failure. Manufacturers that anticipate these stresses and overbuild key components frequently produce engines capable of high mileage reliability.

Effective cooling systems are essential. Larger radiators, efficient intercoolers, and well designed oil passages reduce thermal spikes that compromise gasket sealing surfaces.

Strong head bolt design and high quality gasket materials further protect against compression leaks. Conservative boost levels also play a role. Engines tuned with reasonable pressure targets often avoid the chronic over stressing that leads to premature failure.

Oil management is another critical factor. Turbochargers rely on consistent lubrication to prevent bearing wear and overheating.

Engines designed with stable oil circulation and minimal sludge buildup reduce long term risk. Proper crankcase ventilation also prevents pressure imbalances that can strain sealing surfaces.

In this section, we will examine five turbo engines that demonstrate how durability and boost can coexist. These engines have proven capable of high mileage performance without chronic gasket issues. Their engineering choices show that forced induction, when approached responsibly, does not have to compromise longevity.

1. Toyota 2JZ GTE

The Toyota 2JZ GTE is widely regarded as one of the most durable turbocharged engines ever produced. Developed in the 1990s, this 3.0 liter inline six became legendary not only for its performance potential but also for its structural strength.

What makes it particularly noteworthy in a discussion about longevity is how overbuilt it was from the factory. Toyota engineered the 2JZ GTE with a cast iron block, a forged steel crankshaft, and robust internals that could handle significant boost pressure without compromising reliability.

The head gasket design and head bolt clamping force were engineered to withstand elevated cylinder pressures. Even under stock boost levels, the engine operated well within its mechanical limits. This conservative tuning provided substantial safety margins, reducing the likelihood of head gasket failure in normal driving conditions.

Cooling efficiency also played a role. The engine featured a well designed coolant passage layout that helped manage thermal stress across the cylinder head and block.

Oil circulation in the 2JZ GTE was another strength. The lubrication system ensured consistent oil delivery to both the turbochargers and internal components, reducing heat related wear. When properly maintained with regular oil changes, these engines routinely surpass high mileage thresholds without internal sealing problems.

I am writing about the 2JZ GTE because it represents a benchmark in turbo durability. While many engines achieve reliability through modest performance, this one achieved both strength and tunability.

Its ability to tolerate increased boost levels without blowing head gaskets demonstrates how thoughtful engineering and generous safety margins can create a turbocharged engine built for the long haul.

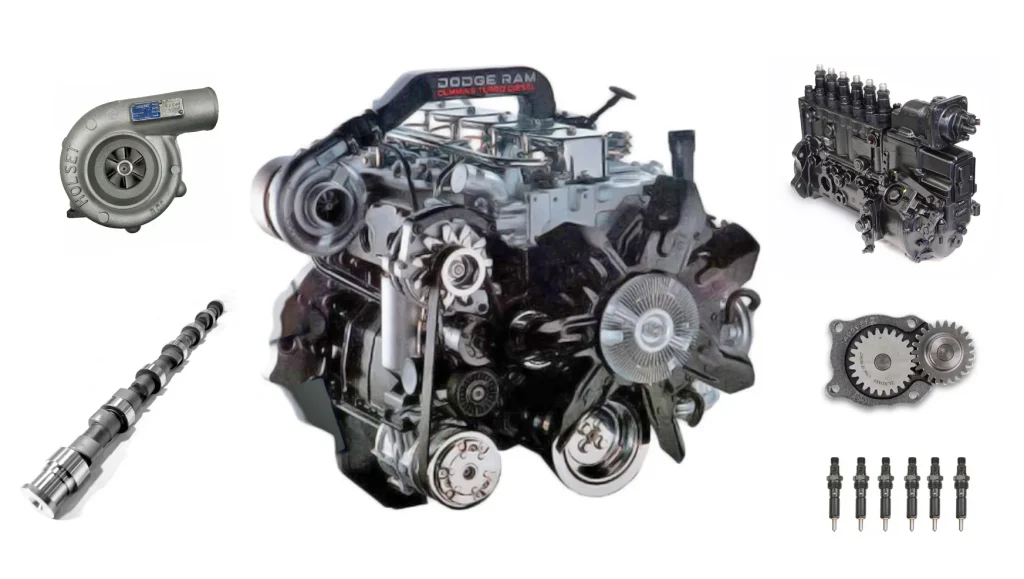

2. Cummins 6BT 5.9L Turbo Diesel

The Cummins 6BT 5.9 liter turbo diesel engine is a prime example of forced induction longevity in heavy duty applications. Originally designed for commercial use, this inline six diesel became popular in pickup trucks due to its exceptional durability and torque output.

Unlike high revving gasoline turbo engines, the 6BT operates at lower engine speeds and emphasizes strength over peak horsepower.

A major contributor to its longevity is the cast iron block and cylinder head construction. These components are engineered to withstand sustained high compression ratios typical of diesel engines.

The head gasket design is robust, supported by strong head bolts that maintain clamping force even under significant boost pressure.

Because diesel combustion relies on compression rather than spark ignition, cylinder pressures are high by nature. Cummins accounted for this by over engineering the block structure and sealing surfaces.

Cooling and lubrication systems are equally substantial. The 6BT features heavy duty cooling passages and a reliable oil system capable of handling extended operation under load.

Turbocharging in this engine enhances torque delivery without pushing components beyond their limits. The boost levels are matched carefully to the engine’s structural capacity, minimizing the risk of gasket failure.

I am including the Cummins 6BT because it demonstrates how turbocharging can coexist with extreme durability when engineering margins are generous. Many of these engines exceed hundreds of thousands of miles in commercial service without internal sealing failures.

Its reputation reinforces the idea that forced induction longevity depends less on the presence of a turbo and more on the quality of the foundation beneath it.

3. Volvo B230FT

The Volvo B230FT is another turbocharged engine that earned respect for long term reliability. Found in various Volvo models during the 1980s and 1990s, this 2.3 liter inline four combined turbo performance with traditional Scandinavian durability.

Built with a strong iron block and sturdy internal components, the B230FT was designed to handle boost without compromising structural integrity.

One of the key factors behind its longevity was moderate factory tuning. Rather than extracting maximum output from a small displacement engine, Volvo kept boost pressures conservative.

This decision reduced peak cylinder pressure and thermal stress on the head gasket. The engine’s thick cylinder walls and solid bottom end provided additional durability margins.

Cooling efficiency also contributed to its resilience. The B230FT featured a reliable cooling system that managed operating temperatures effectively, limiting heat induced gasket degradation. Proper maintenance further extended lifespan, and many examples have surpassed impressive mileage figures without internal engine failures.

Oil management was straightforward and dependable. The turbocharger received consistent lubrication, and the engine design minimized sludge formation when serviced regularly. Head gasket failures were relatively rare compared to many contemporary turbo engines, especially when cooling systems were kept in good condition.

I am writing about the Volvo B230FT because it illustrates how restraint in tuning can dramatically enhance turbo engine longevity. It was not the most powerful engine of its era, but it delivered a balance of boost and durability that earned lasting respect.

Its history proves that sustainable performance often comes from engineering discipline rather than chasing maximum output figures.

4. Saab B234R

The Saab B234R is one of the most respected turbocharged four cylinder engines from the 1990s, known for combining performance with impressive durability. Found in high output Saab models of its era, this 2.3 liter inline four was engineered with strength in mind.

Saab’s approach to turbocharging focused on balancing power gains with internal reinforcement, ensuring that the engine could withstand sustained boost without compromising longevity.

A defining characteristic of the B234R is its forged crankshaft and strong connecting rods. The block construction was robust, with thick cylinder walls that handled combustion pressure effectively.

The head gasket design was reliable when cooling systems were maintained properly. Saab engineers paid particular attention to managing cylinder pressure and knock control, which reduced excessive stress on sealing surfaces.

Thermal management played a significant role in the engine’s survival record. Efficient coolant routing helped distribute heat evenly across the cylinder head.

By preventing localized hot spots, the engine reduced the risk of warping or gasket failure under boost. Oil flow to the turbocharger was also carefully engineered, ensuring stable lubrication during extended spirited driving.

Factory boost levels were assertive but not reckless. While the engine delivered strong performance for its size, it was not pushed to the extreme edge of its mechanical capacity.

This balance gave owners room for reliable operation without constant fear of internal failure. Many examples have accumulated high mileage with original head gaskets intact.

I am including the Saab B234R because it demonstrates how a performance oriented turbo engine can still achieve durability through reinforced construction and intelligent calibration. It stands as proof that forced induction longevity depends on engineering depth rather than simply limiting power output.

5. Ford 2.3L EcoBoost

The Ford 2.3 liter EcoBoost engine represents a more modern example of turbocharged longevity when properly maintained. Used across a range of performance and utility vehicles, this direct injected inline four combines efficiency with respectable power output.

While some modern turbo engines face durability scrutiny, the 2.3 EcoBoost has generally proven resilient thanks to thoughtful design improvements over earlier forced induction attempts.

The engine features a strong aluminum block with reinforced internals designed to manage elevated combustion pressures. Cylinder head clamping force and gasket materials were engineered to tolerate sustained boost levels without chronic failure.

Ford incorporated advanced knock detection and fuel management systems that adjust timing dynamically to protect against detonation, which can compromise head gasket integrity.

Cooling system design was also prioritized. Integrated exhaust manifolds within the cylinder head help manage temperature and reduce turbo lag, while efficient coolant flow prevents overheating. Oil cooling systems ensure that the turbocharger receives stable lubrication even during extended high load operation.

Unlike older engines that relied solely on mechanical safeguards, the 2.3 EcoBoost benefits from electronic control precision. Boost pressure is carefully monitored and regulated to prevent excessive cylinder stress.

When maintained with high quality oil and proper service intervals, many of these engines have demonstrated strong long term reliability.

I am writing about the Ford 2.3 EcoBoost because it represents how modern turbocharging can be engineered responsibly. It shows that advanced technology and durability are not mutually exclusive.

By combining reinforced components, effective cooling, and intelligent electronic controls, this engine has established a reputation for dependable performance under boost.

5 That Blow Gaskets

Not all turbo engines achieve the same level of durability. When combustion pressures rise beyond what gasket materials or head bolt clamping force can reliably contain, failures occur.

Blown head gaskets often result from a combination of high boost levels, inadequate cooling, and marginal sealing design. Repeated overheating or detonation further weakens gasket integrity over time.

Some engines were engineered aggressively to deliver impressive power from small displacement platforms. While this approach may produce strong output figures, it leaves limited room for thermal margin.

Aluminum blocks paired with thin gasket materials can become vulnerable when subjected to sustained stress. In certain cases, insufficient cooling capacity leads to localized hot spots that compromise cylinder head flatness.

Maintenance also plays a role, but underlying engineering choices often determine whether gasket failures become common. Engines that lack sufficient clamping force or operate near their structural limits are more likely to experience sealing issues as mileage accumulates.

In the next section, we examine five turbocharged engines that developed reputations for head gasket problems or related sealing failures. Each illustrates how ambitious tuning or insufficient thermal management can undermine long term reliability.

1. Subaru EJ255

The Subaru EJ255 turbocharged engine developed a reputation for head gasket and sealing related issues that continue to be widely discussed among enthusiasts. Found in several performance oriented Subaru models, this 2.5 liter flat four delivered strong power and all wheel drive compatibility.

However, its boxer layout and elevated boost pressures created thermal and mechanical stresses that sometimes compromised long term durability.

One contributing factor was the open deck block design used in many versions of the EJ255. While this design helped with weight and cooling efficiency, it offered less structural reinforcement around the cylinder walls compared to closed deck alternatives.

Under sustained boost, cylinder pressure could introduce subtle movement that stressed head gasket sealing surfaces. Combined with high combustion temperatures, this sometimes resulted in gasket failure.

Cooling system sensitivity also played a role. Uneven heat distribution across the horizontally opposed cylinders occasionally led to localized hot spots. Over time, repeated heat cycling could weaken gasket material. When cooling maintenance was neglected, the likelihood of failure increased significantly.

Head bolt clamping force and gasket material choice were also scrutinized by owners. While many engines performed reliably with proper maintenance, others experienced premature sealing issues, especially when modified for higher boost levels. Aftermarket tuning amplified stress on components that were already operating near design limits.

I am writing about the Subaru EJ255 because it illustrates how layout and boost pressure interact with structural design.

While capable of impressive performance, its engineering margins were narrower than some rivals. As a result, head gasket problems became more common than in the turbo engines recognized earlier for longevity.

2. Mazda 2.3L DISI Turbo

The Mazda 2.3 liter DISI turbo engine delivered energetic performance in compact platforms, but it also developed a reputation for head gasket vulnerability under stress.

Designed to extract significant output from a relatively small displacement, this direct injected four cylinder operated at high cylinder pressures. While impressive in terms of acceleration, these elevated pressures increased strain on sealing surfaces.

The aluminum block construction prioritized weight savings and efficiency. However, aluminum’s sensitivity to overheating meant that consistent thermal management was essential.

When cooling systems were compromised or when engines were subjected to aggressive tuning, head gasket durability sometimes suffered. Detonation or pre ignition events could further accelerate wear on sealing components.

The engine’s factory tuning was assertive, leaving limited overhead for additional boost without internal reinforcement. Many owners pursued modifications that pushed cylinder pressures beyond safe margins, increasing the likelihood of gasket failure.

Even in stock form, some engines experienced issues related to uneven cooling or high combustion temperatures over extended mileage.

Oil consumption and carbon buildup were additional concerns that indirectly affected longevity. Direct injection engines can accumulate intake valve deposits, potentially influencing combustion stability. Irregular combustion events can increase localized pressure spikes, placing added stress on head gasket sealing.

I am including the Mazda 2.3 DISI turbo because it demonstrates how high specific output can narrow durability margins. While capable and engaging, its aggressive tuning and thermal sensitivity meant that gasket issues were not uncommon, particularly under demanding conditions.

3. Mini Cooper S N14 Turbo

The Mini Cooper S N14 turbocharged engine gained attention for its lively character but also for recurring mechanical concerns, including head gasket and related sealing problems.

Developed in collaboration with another manufacturer, this 1.6 liter turbo engine was engineered to deliver strong output from a compact package. However, high boost pressure combined with tight packaging created thermal challenges.

The engine bay layout left limited space for cooling airflow. Under sustained spirited driving, heat buildup could become significant. Elevated temperatures stress gasket materials and increase the likelihood of warping at the cylinder head interface. When overheating episodes occurred, sealing surfaces were especially vulnerable.

The N14 also faced issues related to carbon buildup and timing chain tensioner wear. While not directly gasket related, these problems contributed to engine stress and uneven combustion behavior. Irregular combustion can create pressure spikes that compromise gasket integrity over time.

Oil consumption concerns were also reported in some cases. Reduced lubrication quality affects thermal stability and may indirectly increase stress on sealing components. Combined with aggressive factory tuning for a small displacement engine, these factors contributed to durability concerns.

I am writing about the Mini Cooper S N14 because it highlights how compact performance engines often operate with minimal thermal margin. While delivering enjoyable power, its design left limited room for sustained high stress operation without increasing the risk of gasket or sealing failures.

4. BMW N54

The BMW N54 turbocharged inline six gained widespread acclaim for its smooth power delivery and strong tuning potential. Introduced as a 3.0 liter twin turbo engine, it marked a major shift toward modern forced induction in performance oriented applications.

While capable of impressive output and refinement, it also developed a reputation for head gasket related concerns, particularly as mileage increased or when modified beyond factory specifications.

One factor contributing to gasket vulnerability was the combination of high boost pressure and direct injection. The N54 operated at substantial cylinder pressures even in stock form.

When owners pursued aftermarket tuning, boost levels often rose significantly, pushing the engine closer to its structural limits. Elevated combustion pressure places intense stress on head gasket sealing surfaces and head bolt clamping force.

Cooling system reliability also played a role. The electric water pump, a critical component in maintaining stable engine temperatures, was known to fail prematurely in some cases.

Overheating episodes can warp aluminum cylinder heads or weaken gasket material, increasing the likelihood of sealing failure. Even brief temperature spikes may have long term consequences.

Carbon buildup on intake valves was another recurring issue due to the direct injection design. While not directly responsible for gasket failure, uneven combustion and detonation risks associated with carbon deposits can elevate localized pressure stress. Over time, these factors compound the strain placed on sealing surfaces.

I am including the BMW N54 because it illustrates how high performance potential can narrow reliability margins. While many engines perform well when maintained carefully, the combination of strong factory boost, frequent modifications, and cooling system sensitivity has led to documented gasket concerns.

It serves as a reminder that performance and durability must be carefully balanced in turbocharged designs.

5. Mitsubishi 4B11T

The Mitsubishi 4B11T turbocharged engine delivered strong performance in compact performance vehicles, but it has also been associated with head gasket and sealing issues under certain conditions.

This 2.0 liter turbo four was engineered to produce substantial power relative to its displacement, placing significant stress on internal components.

The aluminum block design featured an open deck configuration, which can allow minor cylinder movement under extreme pressure.

While adequate for factory boost levels, aggressive tuning or sustained high load operation increased stress on the head gasket interface. Elevated combustion temperatures and pressure spikes are primary contributors to sealing degradation.

Cooling system performance is critical in engines with high specific output. If coolant flow becomes restricted or if overheating occurs, aluminum cylinder heads can warp slightly.

Even minimal distortion may compromise gasket sealing integrity. Some reported failures followed overheating incidents or repeated hard driving without adequate cooling recovery.

Factory tuning aimed to balance performance and reliability, but many owners pursued aftermarket modifications that raised boost levels substantially. These modifications often exceeded the structural safety margin built into the engine. As cylinder pressure increases, gasket materials and head bolts experience greater clamping demands.

I am writing about the Mitsubishi 4B11T because it represents a common pattern among high output turbo engines. While capable and exciting, it operates close to its mechanical limits.

Without conservative tuning and diligent maintenance, the likelihood of head gasket failure increases. It reinforces the broader theme that turbo durability depends heavily on engineering margin and responsible operation.

Turbocharged engines can either become legends of durability or cautionary tales of mechanical stress, depending largely on engineering philosophy and thermal management. The engines recognized for longevity share common strengths.

The Toyota 2JZ GTE, Cummins 6BT 5.9L, Volvo B230FT, Saab B234R, and Ford 2.3L EcoBoost were built with reinforced internals, effective cooling systems, and reasonable boost levels.

Their manufacturers allowed generous safety margins, strong head bolt clamping force, and stable oil circulation. As a result, these engines have demonstrated that forced induction does not automatically shorten lifespan when heat and pressure are properly controlled.

In contrast, the Subaru EJ255, Mazda 2.3 DISI Turbo, Mini Cooper S N14, BMW N54, and Mitsubishi 4B11T illustrate how high output tuning and tight thermal margins can increase head gasket vulnerability.

Open deck block designs, aggressive boost levels, cooling system sensitivity, and frequent aftermarket modifications contributed to sealing issues in many cases. Overheating events and elevated cylinder pressures placed significant stress on gasket materials.

Ultimately, turbo longevity depends on engineering discipline. When manufacturers prioritize structural strength and temperature control, turbo engines can endure for hundreds of thousands of miles. When performance goals push components near their limits, gasket failures become far more likely over time.