Diesel engines are celebrated for their torque, efficiency, and durability, but not all designs perform equally over the long term. Some engines have earned a legendary reputation for longevity, operating reliably for hundreds of thousands of miles with minimal issues.

These engines, often mechanically simple and overbuilt, prioritize durability rather than advanced electronics or complex emissions systems. Examples like the Cummins 5.9L 12-Valve and Toyota 1HZ show that conservative engineering, strong materials, and straightforward fuel systems can create workhorses capable of lasting decades under heavy use.

Modern diesel engines, however, face increasing complexity due to strict emissions regulations. Features such as Diesel Particulate Filters (DPF), Selective Catalytic Reduction (SCR), and Exhaust Gas Recirculation (EGR) were designed to reduce pollutants, but they also create new failure points.

Engines like the Ford 6.4L and 6.0L Power Stroke or the GM 6.6L Duramax LML frequently experience soot buildup, sensor failures, and fluid system problems, leading to expensive repairs and reliability challenges. Comparing these two groups of diesel engines highlights the trade-offs between mechanical simplicity, longevity, emissions compliance, and the real-world cost of ownership.

5 Diesel Engines Known for Longevity

1. Cummins 5.9L 12-Valve: The Ultimate Diesel Workhorse

The Cummins 5.9L 12-Valve, installed in Dodge Ram 2500 and 3500 trucks from 1989 to 1998, is legendary for its longevity and reliability. Unlike modern diesels, it features a fully mechanical design with no Engine Control Module (ECM) or complex sensors, making it highly resistant to electrical failures.

The latter 1994–1998 models use the Bosch P7100 inline injection pump, which delivers high-pressure fuel with minimal failure points. Its gear-driven timing eliminates common belt or chain issues, while the absence of emissions systems like EGR, DPF, or SCR ensures fewer components can fail prematurely.

This simplicity has earned it a reputation as a “million-mile motor,” with many engines surpassing 500,000 miles on basic maintenance.

Durability is further reinforced by the engine’s overbuilt construction. Both the block and head are cast iron, providing exceptional strength against heat and stress, while forged-steel connecting rods and crankshaft handle extreme torque. The crankshaft rides on seven main bearings to minimize wear, and the six-bolt-per-cylinder head design reduces the likelihood of head gasket failures even under big boost.

Combined with effective cooling and a low-stress operating design producing massive torque at low RPMs, the engine endures heavy-duty use, towing, and hauling far better than many contemporaries. Factory power ratings were modest, between 160 and 215 hp, depending on the year, ensuring internal components were never pushed to their limits.

The engine evolved over its production years, with early 1989–1993 models using a rotary VE pump praised for fuel efficiency and reliable cold starts. The 1994–1998 “P-pump” era increased injection pressures and fueling potential, with manual transmission trucks reaching up to 215 hp and 440 lb-ft of torque.

While nearly indestructible, the 12-valve engine has a known weak point: the Killer Dowel Pin in the timing cover, which can loosen and cause internal damage. Other common issues include lift pump wear, exhaust manifold cracks, and minor oil leaks, all of which are easily manageable with routine maintenance and inexpensive preventive measures.

The 5.9L 12-valve Cummins also has significant performance potential, making it a favorite among diesel enthusiasts. Simple adjustments such as injector upgrades or fuel plate tuning can substantially increase horsepower, and well-built P-pump engines are capable of producing over 1,000 hp for competitive use.

Despite lacking modern electronics or cabin refinements, the engine’s combination of mechanical simplicity, overbuilt internals, and sheer torque ensures its place as one of the most durable and revered diesel engines in light-duty truck history.

2. Ford 7.3L Power Stroke: The Million-Mile Diesel

The Ford 7.3L Power Stroke is renowned for its durability and reliability. Produced between 1994 and 2003, it features a cast-iron block and cylinder heads, forged connecting rods in pre-2001 models, and six head bolts per cylinder.

The Hydraulic Electronic Unit Injection system provides precise fuel delivery using engine oil pressure and avoids the complexity of modern emissions equipment such as EGR coolers, diesel particulate filters, or diesel exhaust fluid systems.

This combination of mechanical strength and simplicity allows many engines to surpass 300,000 to 500,000 miles with proper maintenance, earning it a reputation as a million-mile motor among diesel enthusiasts.

The 7.3L Power Stroke is designed for long-term reliability with low-stress internal components. Early models feature forged steel connecting rods, while the HEUI system, although electronically controlled, has far fewer failure points than later diesel engines.

Factory horsepower and torque were modest, ranging from roughly 210 horsepower and 425 pound-feet of torque in 1994 models to 275 horsepower and 525 pound-feet of torque in 2003 models. This conservative tuning helps protect internal components.

The engine also benefits from a robust externally mounted oil-to-fluid cooler and a deep-skirt block that provides strength for towing and heavy-duty work. These features create an engine built for consistent high-mileage use rather than peak performance.

The engine has a few predictable maintenance concerns. The camshaft position sensor is the most notable issue because a failure will cause the engine to stop running immediately, although replacements are inexpensive and easy to keep on hand.

Other minor issues include leaking turbo pedestals, brittle under valve cover harnesses, and occasional injection pressure regulator problems. Transmission compatibility is also a consideration.

The 4R100 automatic transmission may struggle if the engine is modified for higher power, while the ZF-6 manual transmission remains highly durable. Despite these concerns, the 7.3L is easy to service, and most repairs do not require removing the cab.

The greatest advantage of the 7.3L Power Stroke is its simplicity. With no EGR, diesel particulate filters, or diesel exhaust fluid systems, the engine avoids the common failures that affect modern diesels.

It delivers strong low-end torque for towing and hauling while remaining highly reliable. For drivers who value longevity, mechanical simplicity, and ease of maintenance, the Ford 7.3L Power Stroke stands as one of the most dependable engines ever installed in a heavy-duty truck and continues to dominate the used diesel market.

3. Mercedes-Benz OM617: The Million-Mile Diesel

The Mercedes-Benz OM617 is widely celebrated for its exceptional reliability and longevity. Produced from 1974 to 1991 and most famously installed in the 1976–1985 W123 chassis, this 3.0-liter inline-five diesel is known to reach over 400,000 miles without a rebuild.

Its robust construction features a cast-iron block and cylinder head, a forged steel crankshaft supported by six main bearings, and over-engineered components that prioritize durability over performance.

The engine uses a purely mechanical Bosch fuel injection pump, eliminating the risk of electronic failures, and its indirect injection system reduces stress on internal components, allowing it to withstand decades of continuous operation.

Mechanical simplicity is a cornerstone of the OM617’s longevity. With no electronic control units, sensors, or delicate wiring harnesses, the engine requires only air, fuel, and oil to operate once started.

The fuel system is lubricated by engine oil, and the double-row timing chain, along with gear-driven oil and vacuum pumps, ensures that critical components rarely fail unexpectedly.

Early naturally aspirated versions produced 79–87 horsepower, while the turbocharged variant introduced in the late 1970s increased output to roughly 121–125 horsepower and 184 pound-feet of torque. These modest figures reflect a conservative power density that minimizes stress on pistons, rods, and bearings, contributing to the engine’s reputation for durability.

The OM617 is also notable for its versatility and practicality. Its pre-chamber indirect injection design makes it tolerant of alternative fuels such as waste vegetable oil or biodiesel. Combined with simple maintenance procedures, including regular valve adjustments every 15,000 miles, the engine can continue to perform reliably for hundreds of thousands of miles.

While the W123 chassis may experience rust in certain climates, the engine itself is largely immune to common failures, and its rugged design allows it to maintain highway speeds comfortably despite its “agricultural” idle noise.

The Mercedes-Benz OM617 exemplifies a bygone era of over-engineered engineering focused on longevity and serviceability. It is not a high-performance engine but a workhorse designed for owners who value reliability and mechanical integrity.

Vehicles equipped with the OM617, including the 300D sedan and 300TD wagon, continue to inspire admiration for their ability to endure high mileage and harsh conditions. The OM617 stands as a benchmark in automotive history for durability, representing the philosophy that cars can be built to last a lifetime.

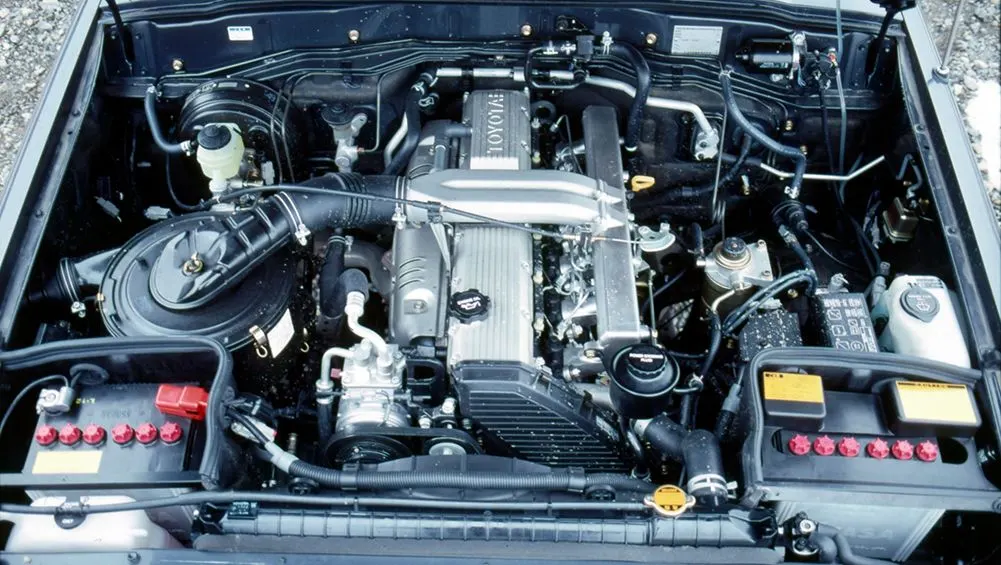

4. Toyota 1HZ: The Bulletproof Diesel

The Toyota 1HZ is a 4.2-liter naturally aspirated inline-six diesel renowned worldwide for its legendary reliability and mechanical simplicity. Produced from 1990, it powers the Toyota Land Cruiser 70 and 80 Series and has become a global benchmark for durability in harsh environments.

With no turbocharger, no electronic control unit, and a straightforward mechanical indirect injection system, the 1HZ can run virtually anywhere and on low-quality diesel, making it the engine of choice for UN fleets, aid agencies, and off-road adventurers. Well-maintained examples regularly exceed 500,000 kilometers, and many surpass 700,000 kilometers without a major rebuild.

Mechanical simplicity is at the core of the 1HZ’s reputation. Its purely mechanical fuel system, lack of complex sensors, and absence of electronics make it highly resistant to failure, even in remote locations. The engine is naturally aspirated, which reduces heat stress and removes potential turbo-related failure points.

Its simple design allows for in-field maintenance and repairs using basic tools, a critical advantage for operators in regions with limited infrastructure. The single overhead cam valvetrain, indirect injection, and robust components combine to deliver smooth, low-end torque ideal for crawling, towing, and utility work rather than high-speed performance.

Durability is reinforced by heavy-duty engineering and overbuilt internal components. The 1HZ features a cast-iron block and cylinder head, a forged crankshaft supported by seven main bearings, and a long-stroke design that emphasizes torque at low RPMs. Its power output of around 129 horsepower and 285 newton-meters of torque is intentionally modest, keeping internal stresses low and ensuring longevity.

The engine tolerates poor fuel quality, high heat, and high-altitude operation, making it well-suited for deserts, mines, and remote off-road regions. Regular maintenance, including timing belt replacement every 100,000 to 120,000 kilometers and cooling system upkeep, is essential to prevent overheating or catastrophic failures.

Owners consistently praise the 1HZ for its “unstoppable reliability” and confidence-inspiring performance under extreme conditions. While its highway speed and acceleration are limited and fuel consumption is higher than modern diesels, its resilience and ease of maintenance outweigh these drawbacks for overlanders and fleet operators.

Aftermarket turbocharger kits exist, but can compromise longevity if not carefully supported. The Toyota 1HZ exemplifies an engineering philosophy that prioritizes simplicity, durability, and field-serviceability, cementing its status as one of the most dependable diesel engines ever built.

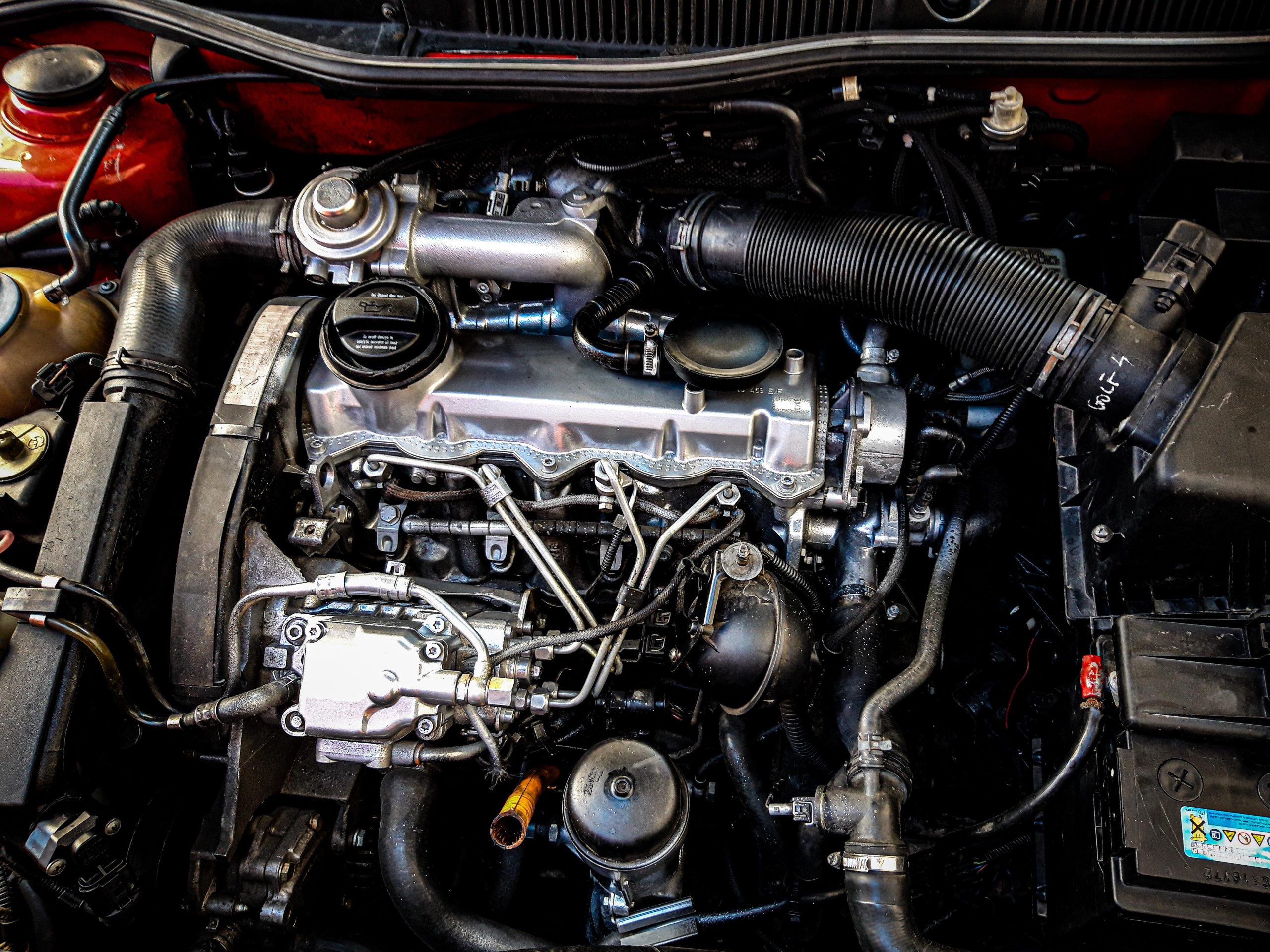

5. Volkswagen 1.9L TDI ALH: The Bulletproof Diesel

The Volkswagen 1.9L TDI ALH is widely celebrated for its longevity, reliability, and exceptional efficiency. Produced between 1998 and 2003, it powered the Mk4 Jetta and Golf, earning a reputation as a “gold standard” for diesel engineering.

Unlike later Pumpe Düse or common rail TDIs, the ALH uses a mechanical Bosch VP37 rotary injection pump, a cast-iron block, and a simple SOHC eight-valve head.

Its lack of complex electronics, restrictive emissions equipment, and sensitive injectors makes it highly robust and forgiving, allowing many engines to exceed 400,000 miles with proper maintenance. Some examples have even surpassed 700,000 miles, a testament to its over-engineered durability.

Mechanical simplicity is central to the ALH’s design. The rotary injection pump is less sensitive to fuel quality than later high-pressure systems, while the direct injection layout produces peak torque at low RPMs, providing strong drivability without stressing internal components.

The engine’s naturally aspirated feel, combined with low-end grunt, makes it responsive for city and highway driving. Its interference design requires careful timing belt and water pump maintenance every 100,000 miles to avoid catastrophic damage. High-quality, VW 505.00 spec synthetic oil and regular intake cleaning for the EGR system are critical for maintaining the engine’s performance over hundreds of thousands of miles.

The ALH’s performance is modest by modern standards, producing roughly 90 horsepower and 155 pound-feet of torque in stock form. However, its charm lies in efficiency, often achieving 45–50 miles per gallon in real-world driving, with some hyper-milers exceeding 55 miles per gallon.

The engine’s durability, combined with its simple design, allows enthusiasts and fleet operators to perform almost all repairs using standard tools, without relying on complex diagnostics. It tolerates slightly irregular maintenance better than modern, high-pressure diesel engines, making it an ideal choice for drivers who prioritize reliability and economy over outright performance.

Enthusiasts also appreciate the ALH for its tunability and longevity. Mild ECU remaps and larger injectors can increase output to 140–150 horsepower without compromising the engine’s legendary reliability. Its straightforward mechanical layout and overbuilt components make it a favorite for DIY repairs and long-term ownership.

The Volkswagen 1.9L TDI ALH represents a rare combination of efficiency, durability, and mechanical honesty, standing as one of the most dependable diesel engines of its era and a defining example of Volkswagen’s pre-2003 engineering philosophy.

Also Read: 5 Cars With Strong Heating Systems vs 5 With Weak Ones

5 That Have Emissions System Faults

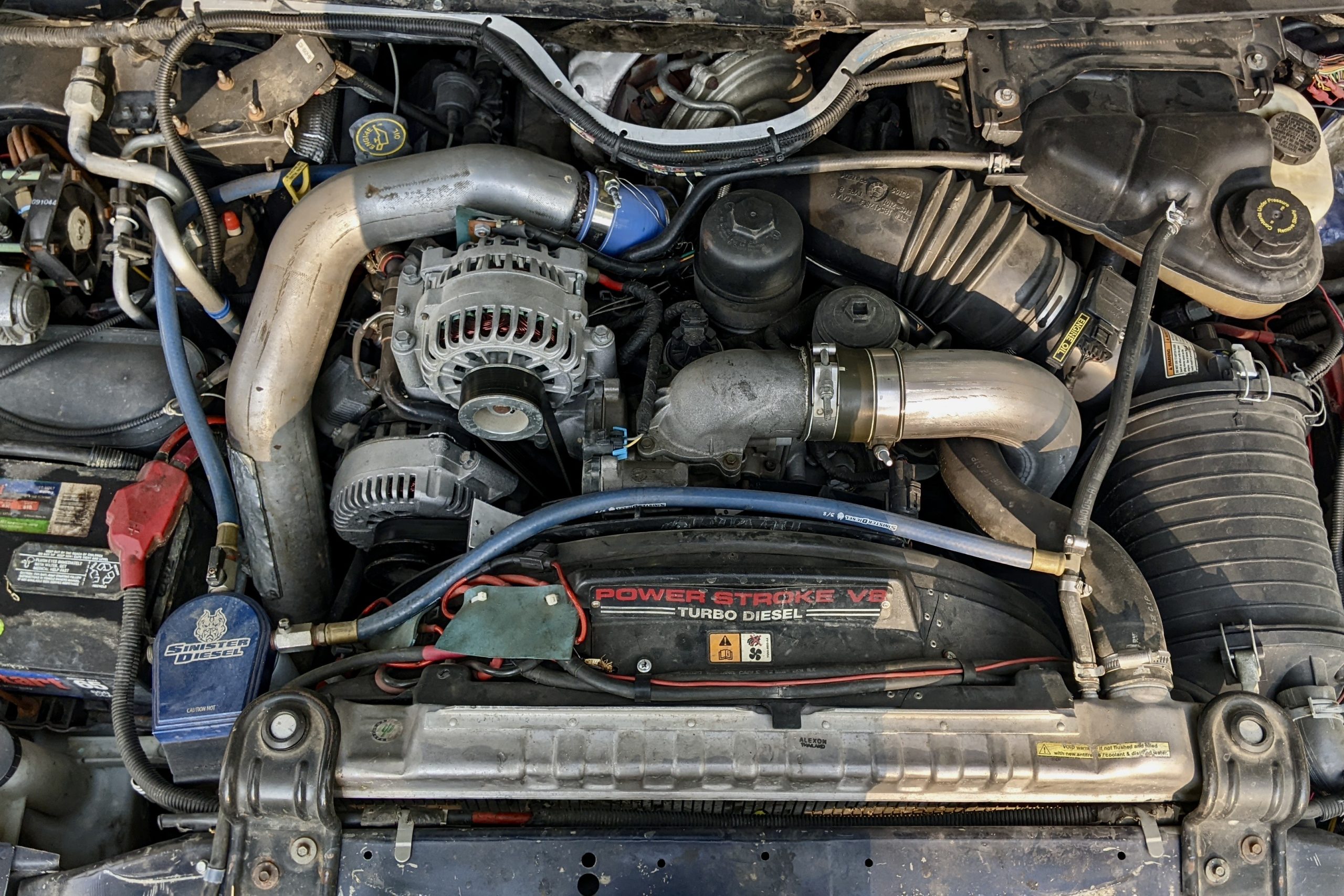

1. Ford 6.4L Power Stroke: The Troublesome Emissions Diesel

The Ford 6.4L Power Stroke is widely regarded as one of Ford’s most problematic diesel engines. Introduced to meet stricter federal emissions standards, it features complex, first-generation emissions hardware that frequently fails, earning it a reputation for being “disposable.”

The engine is especially prone to Diesel Particulate Filter (DPF) problems, as the filter clogs easily during short trips or city driving when the exhaust does not reach high enough temperatures. Failed or frequent regeneration cycles force the engine into limp mode, reduce fuel economy, and generate excessive heat, contributing to further mechanical stress.

A key issue is the dual Exhaust Gas Recirculation (EGR) coolers. Unlike previous engines with a single cooler, the 6.4L’s dual setup doubles the potential for failure. Clogged or cracked EGR coolers allow coolant into the exhaust or engine, causing white smoke, warning lights, and potential catastrophic failure. Coolant loss is a common symptom, and repairs are often complex and expensive.

Another critical problem is oil dilution. During active DPF regeneration, diesel fuel is injected into the exhaust to burn off soot. On the 6.4L, fuel frequently leaks past the piston rings into the oil, thinning it and washing cylinder components.

This “cylinder washing” can destroy bearings, pistons, and other engine internals, often within 150,000 miles. Additional issues include cracked up-pipes and failing Exhaust Gas Temperature sensors, both of which contribute to constant emissions faults and sensor warnings.

In practice, the 6.4L Power Stroke requires extensive maintenance to manage these emissions-related failures. Many owners resort to aftermarket upgrades or deleting emissions components entirely to improve reliability, although this is illegal in many jurisdictions.

While powerful on paper, the 6.4L’s first-generation emissions hardware and design flaws make it a high-maintenance engine that struggles to reach the longevity of previous Ford Power Stroke models.

2. Ford 6.0L Power Stroke: The Troublesome Six-Oh

The Ford 6.0L Power Stroke is notorious for emissions-related failures caused by a combination of design flaws and early EGR system implementation. Introduced to meet stricter NOx standards, the engine relies heavily on its oil-to-EGR cooler system, which is prone to clogs and ruptures.

Small casting debris or coolant sediment often blocks passages in the oil cooler, starving the EGR cooler of vital cooling. Without proper cooling, the EGR cooler cracks, allowing coolant to enter the intake manifold, leading to white smoke, coolant loss, and even potential hydrolock.

Carbon buildup and soot accumulation further exacerbate the engine’s problems. The high levels of soot can seize the EGR valve, preventing proper exhaust flow. A stuck valve triggers fault codes such as P0401 and P0402, causing rough idling, hesitation, and noticeable power loss. Regular physical cleaning of the EGR valve every 15,000 to 20,000 miles is essential to prevent these issues.

Additionally, the engine’s Variable Geometry Turbocharger (VGT) is susceptible to vane sticking from soot and rust, particularly if the vehicle is used for short trips or idle-heavy driving. This can cause overboost or underboost conditions, leading to excessive smoke and “limp mode” errors.

The 6.0L Power Stroke also suffers from inherent head gasket weaknesses. Torque-to-Yield head bolts, four per cylinder, can stretch under high cylinder pressures, causing blown gaskets. This allows combustion gases to enter the cooling system, compounding EGR cooler failures and generating a confusing mix of cooling and emissions problems.

Despite its reputation, the 6.0L can be made reliable through “bulletproofing.” Upgrades such as ARP head studs, enhanced EGR coolers, and Mishimoto coolant filtration kits address the core failure points, transforming the engine into a durable, high-performance powerplant.

Without these modifications, however, the stock 6.0L remains a high-maintenance engine with a precarious emissions setup prone to catastrophic failures.

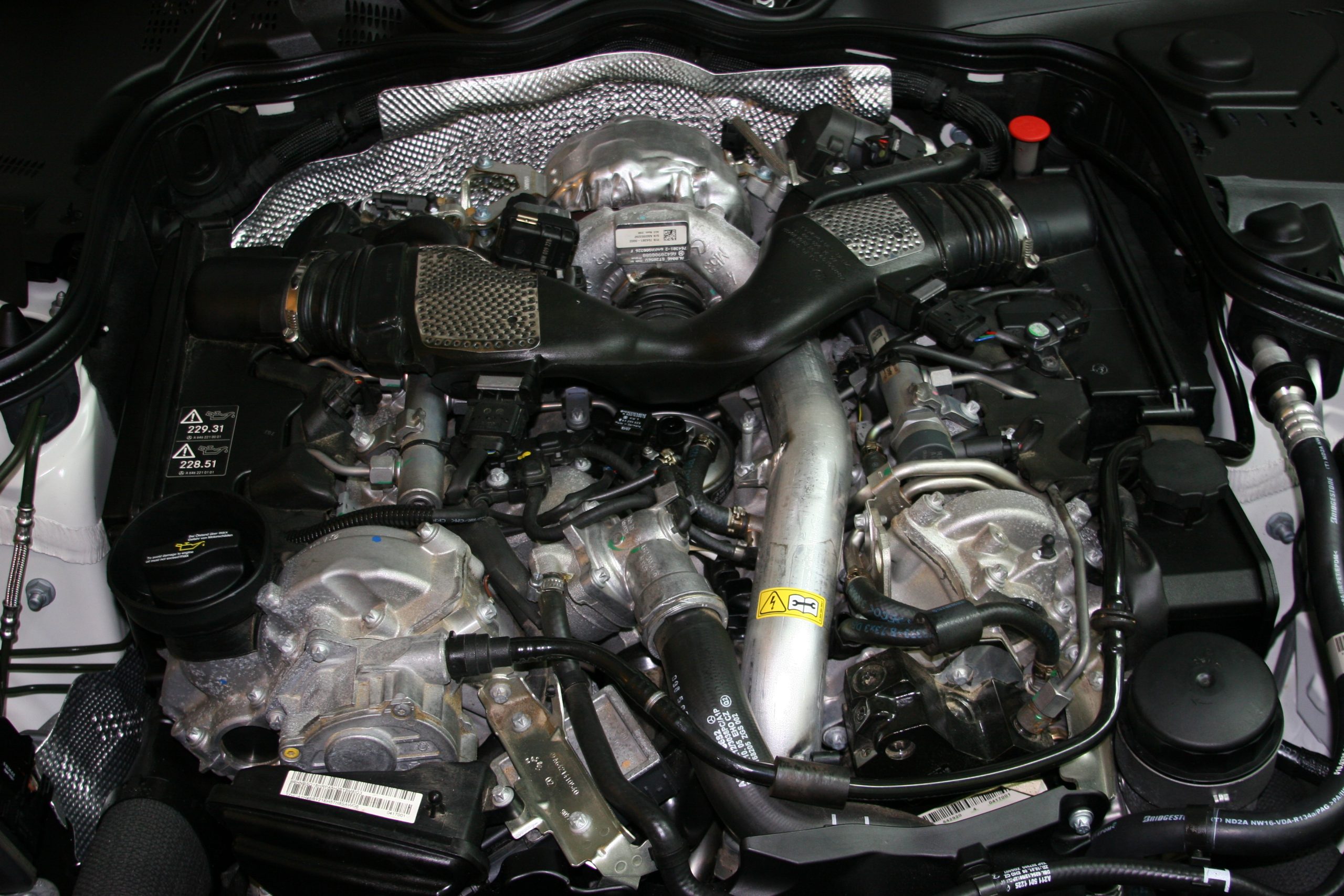

3. Mercedes-Benz OM642 BlueTEC: The Complex Emissions Diesel

The Mercedes-Benz OM642 BlueTEC is notorious for persistent emissions-related faults, largely due to the complexity of its BlueTEC system. Designed to meet strict NOx regulations, the engine incorporates Selective Catalytic Reduction (SCR), Diesel Particulate Filters (DPF), and Exhaust Gas Recirculation (EGR), all of which rely on precise operation and perfect air-fuel ratios.

Minor mechanical issues often trigger a cascade of failures that affect downstream components, creating frequent service alerts and “10 Starts Remaining” warnings.

One of the primary problems is oil cooler seal failure. Located deep in the engine “V,” these seals degrade from extreme heat, causing oil to leak into the intake valley. This contamination can short the swirl flap motor and coat the intake manifold with sludge, disrupting airflow and leading to incomplete combustion.

The resulting excess soot overloads the DPF and clogs the EGR valve. Vehicles used for short trips or city driving often fail to reach the high exhaust temperatures needed for DPF regeneration, creating permanent blockages and triggering limp mode.

The AdBlue (Diesel Exhaust Fluid) system adds another layer of complexity. Its heaters frequently burn out, NOx sensors are sensitive to moisture and soot, and the fluid itself can crystallize in cold climates or during infrequent use.

Any single failure in these components can prevent the vehicle from restarting once the “10-start” limit is reached. Combined with DPF and EGR issues, these factors make the OM642 highly maintenance-intensive, especially in delivery or urban environments.

The OM642 BlueTEC is a sophisticated but fragile engine. Heat-induced oil leaks, swirl flap contamination, soot buildup, DPF clogging, and DEF system failures all interact in a chain reaction that can disable the vehicle.

While technologically advanced and emissions-compliant, it requires meticulous care, regular long-distance operation, and constant monitoring to avoid costly repairs, making it less suitable for drivers seeking a low-maintenance diesel platform.

4. GM 6.6L Duramax LML: The Emissions-Heavy Diesel

The GM 6.6L Duramax LML represents GM’s attempt to bridge traditional diesel reliability with modern EPA emissions standards. Mechanically, the engine’s rotating assembly and block are robust, but the addition of first-generation Selective Catalytic Reduction (SCR) and Diesel Particulate Filter (DPF) systems introduced a range of vulnerabilities.

While durable in principle, the LML’s emissions hardware often fails under typical North American operating conditions, creating expensive repairs and frequent service warnings.

A major source of problems is the DEF (Diesel Exhaust Fluid) system. Submerged heaters in the tank frequently burn out, and the NOx sensors upstream and downstream of the SCR catalyst are highly sensitive to soot, moisture, and minor fuel quality variations.

When these components fail or drift out of calibration, the engine’s ECM interprets it as a system fault, triggering warnings, speed limitations, and often requiring a professional data reset to clear.

DPF regeneration logic compounds the issue. The LML is optimized for long highway drives; short trips prevent the exhaust from reaching sufficient temperatures to burn off soot.

This leads to clogged filters, backpressure on the turbo, and limp mode. The 9th hydrocarbon injector, used to heat the exhaust for passive regen, is also prone to carbon buildup. When it fails, the DPF cannot regenerate, causing cascading failures throughout the emissions system.

Finally, the Bosch CP4.2 high-pressure fuel pump represents a critical weak point. Designed for higher rail pressures to improve emissions compliance, it is sensitive to low-lubricity US diesel.

Failures often shed metal shards into fuel lines and injectors, contaminating the entire fuel and emissions system and resulting in repair costs exceeding $10,000. While the 6.6L Duramax LML is otherwise a strong engine, the combination of emissions complexity and fuel system vulnerabilities makes it high-maintenance and costly to own in its stock form.

5. Ram 6.7L Cummins: The Early Emissions Challenge

The Ram 6.7L Cummins marked Dodge’s first attempt to meet modern EPA emissions standards without Diesel Exhaust Fluid (DEF). Instead, it relied heavily on Exhaust Gas Recirculation (EGR) to reduce NOx emissions. This approach required running a richer air-fuel mixture, which produced excessive soot.

The soot accumulation created a cascade of failures affecting the Variable Geometry Turbocharger (VGT), Diesel Particulate Filter (DPF), and EGR system, making this generation of 6.7L Cummins prone to frequent and costly maintenance.

The DPF is particularly vulnerable. It captures soot during combustion and requires high-temperature regeneration to burn it off. Trucks used for short trips or idling often fail to reach the necessary exhaust heat, resulting in clogged filters.

A blocked DPF triggers limp mode and may require professional cleaning or replacement, which can cost thousands. Meanwhile, excessive soot coats the EGR valve and cooler, causing sticking, rough idling, stalling, and repeated check engine warnings.

High soot levels also affect the VGT turbocharger. The internal sliding vanes seize or stick, reducing boost and power delivery. Over time, this can lead to full turbo failure. Additionally, the DPF regeneration process injects fuel into the exhaust, and unburned fuel can leak past the piston rings into the crankcase, diluting the engine oil. Thinned oil reduces lubrication, accelerating wear on critical engine components.

These failures are often exacerbated by typical daily driving. Unlike hard work cycles for which the truck was designed, short commutes prevent the engine from achieving sufficient temperatures to manage soot effectively.

This creates a domino effect where a partially clogged DPF increases backpressure, pushing more soot into the EGR system and accelerating the degradation of the engine’s emissions hardware.

Later 6.7L models equipped with DEF and Selective Catalytic Reduction (SCR) resolved many of these issues, but the 2007.5–2012 models remain a challenge for owners who do not follow high-load driving routines or perform regular manual maintenance of the emissions system.

The comparison between these engines shows a clear pattern. Simple, overbuilt designs promote longevity, while engines burdened by complex emissions systems are more prone to failure.

The Cummins 5.9L 12-Valve, Ford 7.3L Power Stroke, and Toyota 1HZ demonstrate that strong materials, straightforward fuel systems, and minimal electronics can provide decades of reliable service. In contrast, the Ford 6.4L Power Stroke, GM 6.6L Duramax LML, and early Ram 6.7L Cummins often face soot accumulation, sensor malfunctions, and DPF or EGR issues that require frequent maintenance.

For diesel owners, these differences affect reliability, cost of ownership, and peace of mind. Engines designed for durability with minimal complexity deliver dependable performance and low-maintenance operation.

Emissions-heavy designs demand constant attention, careful driving, and proactive servicing to prevent costly failures. By comparing engines known for longevity with those prone to emissions faults, it becomes clear that simplicity, robust construction, and practical engineering remain the most effective keys to a long-lasting diesel engine.

Also read: Top 10 Cars That Hit the Depreciation Sweet Spot at 5 Years Old