Fuel efficiency has always been one of the biggest challenges in automotive engineering. For decades, car makers searched for ways to make engines more powerful while using less fuel.

Rising fuel prices, stricter emissions regulations, and growing environmental awareness pushed engineers to rethink how engines work. Over time, certain engines stood out because they changed the industry permanently.

These engines did not just improve efficiency slightly. They introduced ideas and technologies that reshaped how modern vehicles are built. Some brought turbocharging to the mainstream.

Others proved that small engines could replace large ones without sacrificing performance. A few showed the world that hybrid and advanced combustion technology could dramatically reduce fuel consumption.

Many of the innovations we take for granted today started as risky experiments. Engineers faced skepticism from both buyers and competitors. Some people believed small turbo engines would never last.

Others doubted that hybrid technology could be practical for everyday drivers. Despite this resistance, these groundbreaking engines proved their value and set new standards for efficiency.

Modern cars benefit from decades of progress built on these engineering milestones. Direct injection, variable valve timing, downsizing, hybrid integration, and advanced combustion cycles all trace their roots back to specific engines that pushed boundaries.

Without them, today’s vehicles would be less efficient, more expensive to run, and far less environmentally friendly.

This article highlights engines that reshaped fuel economy expectations and influenced the direction of the automotive world. Each one represents a turning point in how manufacturers approached efficiency and performance. Together, they show how innovation can transform the entire industry.

Also Read: 10 Used Dodge SUVs With Proven Long-Term Reliability

1. Toyota 1NZ FXE Hybrid Engine

The Toyota 1NZ FXE engine is one of the most influential powerplants in modern automotive history. It powered early generations of the Prius and introduced millions of drivers to hybrid technology. More importantly, it proved that hybrid cars could be reliable, practical, and incredibly efficient in everyday use.

Before this engine appeared, hybrid technology was widely viewed as experimental. Many people believed hybrids would be slow, unreliable, or too expensive to maintain. Toyota took a risk by investing heavily in hybrid development and creating an engine specifically designed to work seamlessly with an electric motor.

The 1NZ FXE uses the Atkinson cycle, a variation of the traditional combustion process. This cycle keeps the intake valves open longer during the compression stroke, reducing pumping losses and improving thermal efficiency.

The tradeoff is reduced power output, but Toyota solved this problem by pairing the engine with an electric motor that provides instant torque when needed.

This combination allowed the engine to operate in its most efficient range far more often than a conventional gasoline engine.

The electric motor handled low speed driving and assisted during acceleration, while the gasoline engine focused on efficient cruising. The result was fuel economy that shocked the world when the Prius first launched.

Another key innovation was the seamless integration of the hybrid system. The engine worked with a planetary gear transmission that allowed smooth transitions between electric and gasoline power. Drivers did not need to change their driving habits to benefit from the technology.

Reliability also played a major role in the engine’s impact. The 1NZ FXE proved that hybrid systems could last hundreds of thousands of miles with minimal maintenance. This reliability built trust and encouraged other manufacturers to invest in hybrid development.

Today, the influence of this engine can be seen in hybrid vehicles across the world. It showed that efficiency and practicality could coexist, permanently changing how the industry views fuel economy.

2. Volkswagen 1.9 TDI Diesel Engine

The Volkswagen 1.9 TDI engine changed how the world viewed diesel passenger cars. Before its arrival, diesel engines were often associated with noise, smoke, and poor performance. The 1.9 TDI proved that diesel technology could deliver strong torque, impressive efficiency, and long term durability.

The key innovation was the use of turbocharging combined with direct fuel injection. This combination allowed the engine to extract more energy from each drop of fuel while maintaining strong performance. Drivers could enjoy excellent fuel economy without sacrificing everyday usability.

The engine produced strong low end torque, which made driving effortless and relaxed. This characteristic allowed drivers to use fewer revs and shift less frequently, further improving real world fuel economy. Long distance drivers quickly recognized the advantages of diesel efficiency.

Another major advantage was durability. The 1.9 TDI became famous for reaching extremely high mileage with proper maintenance. Many examples exceeded hundreds of thousands of miles, reinforcing the idea that efficient engines could also be long lasting.

The engine also helped popularize diesel passenger cars in Europe and influenced diesel development worldwide. It demonstrated that fuel efficiency improvements could come from smarter combustion and forced induction rather than simply reducing engine size.

Its success pushed competitors to develop their own efficient diesel engines. This competition accelerated innovation across the industry and led to significant improvements in fuel economy standards.

The 1.9 TDI proved that efficiency could be practical, durable, and enjoyable to drive. Its influence is still visible in modern turbocharged and direct injection engines.

3. Honda 1.5 Litre VTEC E Engine

The Honda 1.5 liter VTEC E engine played a major role in proving that small gasoline engines could deliver exceptional fuel economy without feeling weak or underpowered. During the early 1990s, most efficient cars were slow and uninspiring to drive. Honda wanted to change that perception and make efficiency appealing to everyday drivers.

The key innovation was the VTEC E system, which stands for Variable Valve Timing and Lift Electronic Control Economy. Unlike performance focused VTEC systems, this version was designed specifically to reduce fuel consumption during light driving.

It allowed the engine to switch between different valve operation modes depending on driving conditions.

At low loads, the engine operated in a lean burn mode. This mode used a very small amount of fuel while maintaining stable combustion. Lean burn technology dramatically reduced fuel consumption during highway cruising and gentle city driving. When more power was needed, the engine switched to a conventional mode for stronger performance.

This ability to operate efficiently during real world driving conditions made the engine revolutionary. Instead of focusing only on laboratory fuel economy numbers, Honda created an engine that delivered excellent efficiency in everyday use. Drivers noticed real savings at the fuel pump.

The VTEC E engine also demonstrated that advanced valve timing could transform engine efficiency. Many modern engines now use variable valve timing as a standard feature. The idea that an engine could change its behavior depending on demand became a core principle of modern engine design.

Another important aspect was reliability. Honda engineered the engine to be simple and durable despite its advanced technology. This helped build trust in efficiency focused innovations and encouraged other manufacturers to adopt similar ideas.

The influence of this engine can be seen in modern small displacement engines that combine variable valve timing with advanced combustion strategies. It helped shift the industry toward smarter, more adaptable engines.

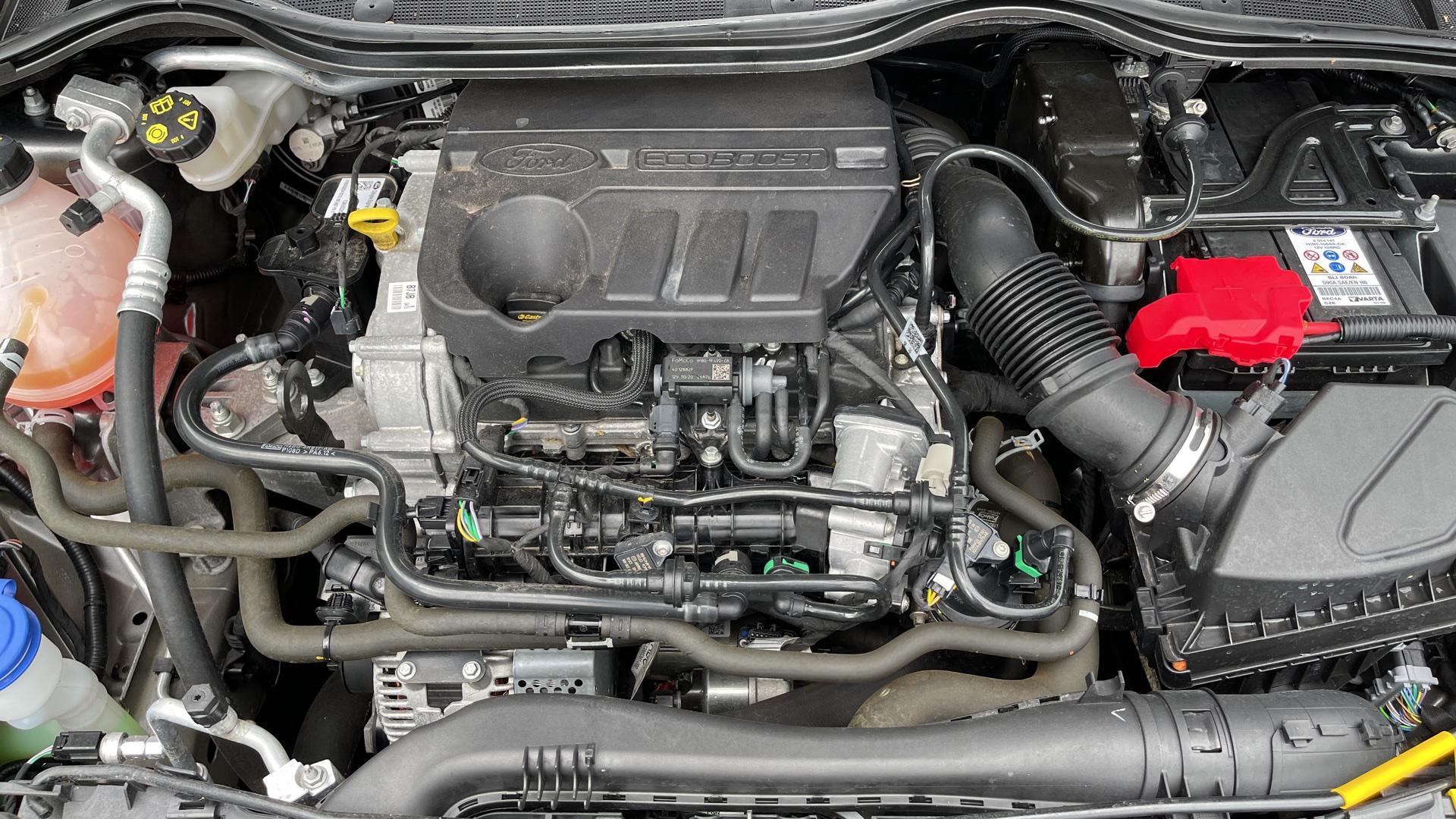

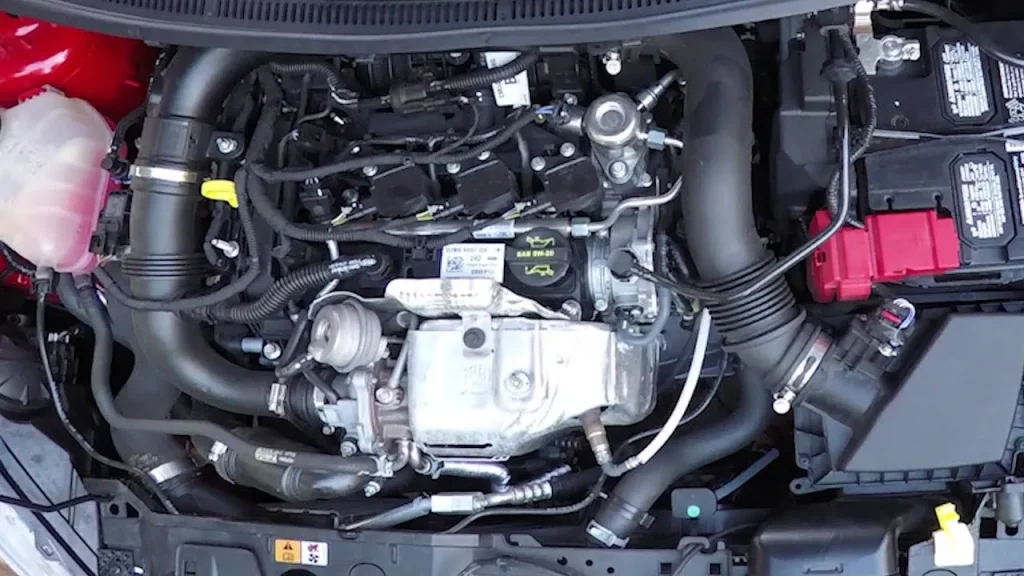

4. Ford EcoBoost 1.0 Liter Turbo Engine

The Ford EcoBoost 1.0 liter engine shocked the automotive world when it was introduced. For decades, most drivers believed small engines could never replace larger ones without sacrificing performance. Ford challenged this belief by creating a tiny turbocharged engine capable of powering everyday family cars.

The concept behind the engine is known as downsizing. Instead of using a large naturally aspirated engine, Ford used a small turbocharged engine that produced power only when needed. During gentle driving, the engine consumed very little fuel. When acceleration was required, the turbocharger provided extra power.

This approach dramatically improved fuel efficiency without making cars feel slow. Drivers could enjoy the performance of a larger engine while benefiting from the fuel economy of a smaller one. The success of this concept influenced nearly every major automaker.

The engine also introduced advanced technologies such as direct fuel injection and variable valve timing in a small package. These technologies improved combustion efficiency and reduced emissions. The combination of turbocharging and direct injection became the blueprint for modern gasoline engines.

Another important achievement was reducing friction and heat losses. Engineers focused heavily on improving thermal efficiency, allowing the engine to convert more fuel into usable energy. These improvements helped the engine achieve impressive fuel economy numbers for its size.

The EcoBoost 1.0 liter engine proved that downsized turbocharged engines could work in real world driving conditions. Its success accelerated the global shift toward smaller turbo engines and helped manufacturers meet stricter emissions regulations.

Today, the idea of replacing large engines with smaller turbocharged units is common. This engine played a major role in making that transition possible.

5. Mazda SkyActiv G 2.0 High Compression Engine

The Mazda SkyActiv G 2.0 engine changed the conversation about gasoline engine efficiency. At a time when most manufacturers focused on turbocharging and downsizing, Mazda chose a completely different path.

Instead of adding complexity, the company focused on making the traditional gasoline engine dramatically more efficient through combustion improvements.

The most revolutionary feature of the SkyActiv G engine is its extremely high compression ratio. Conventional gasoline engines usually operate around a 10:1 compression ratio.

Mazda pushed this number much higher, reaching levels once considered impossible for regular gasoline engines. Higher compression improves thermal efficiency by extracting more energy from each combustion cycle.

Achieving this required solving the problem of engine knock. High compression increases the risk of uncontrolled combustion, which can damage the engine.

Mazda engineers redesigned the piston shape, fuel injection system, and exhaust layout to control combustion precisely. These changes allowed the engine to run efficiently without sacrificing reliability.

Another important innovation involved reducing internal friction. Engineers redesigned moving components, optimized lubrication, and improved cooling to ensure more energy reached the wheels instead of being lost as heat. These improvements contributed significantly to real world fuel savings.

The SkyActiv G engine also demonstrated that efficiency could be achieved without sacrificing driving enjoyment. Unlike many small turbo engines, it delivered smooth power delivery and consistent throttle response. Drivers could enjoy efficiency without giving up the natural feel of a traditional gasoline engine.

This engine influenced the industry by showing that smarter combustion could rival turbocharging in improving fuel economy. Many manufacturers began revisiting high compression and advanced combustion techniques as a result.

The SkyActiv G engine proved that innovation does not always require forced induction or hybrid systems. Sometimes, refining the fundamentals can create groundbreaking results.

6. General Motors LS Based V8 With Cylinder Deactivation

The General Motors LS V8 engine family is famous for performance and durability, but its role in improving fuel efficiency is often overlooked. The introduction of cylinder deactivation technology transformed how large engines could balance power and efficiency.

Large V8 engines traditionally consumed significant amounts of fuel, especially during highway cruising and light driving. General Motors introduced a system that could shut down half of the engine’s cylinders when full power was not needed. This allowed the engine to operate like a smaller four cylinder engine during steady driving.

The transition between eight cylinder and four cylinder operation happens automatically and is usually unnoticeable to the driver. When more power is required, the engine instantly reactivates all cylinders. This innovation allowed large vehicles to achieve significantly better fuel economy without sacrificing performance.

Cylinder deactivation demonstrated that efficiency improvements were not limited to small engines. Even powerful performance engines could benefit from smart technology that adapts to driving conditions. This idea reshaped how manufacturers approached efficiency in trucks, SUVs, and performance cars.

The technology also influenced competitors to develop similar systems. Today, cylinder deactivation is used in many engines across different brands. It has become a standard tool for improving fuel economy in larger vehicles.

The LS engine proved that efficiency does not require giving up power. Instead, it showed that engines could intelligently adjust their behavior to match real world driving needs.

This innovation helped bridge the gap between performance and efficiency, making large engines more practical in an era of rising fuel economy standards.

7. Toyota Dynamic Force 2.5 Engine

The Toyota Dynamic Force 2.5 engine represents a modern leap forward in gasoline engine efficiency. After decades of refining hybrid systems, Toyota focused on improving the efficiency of traditional gasoline engines to work even better with and without electrification.

The result was one of the most thermally efficient mass produced gasoline engines ever created.

The most significant achievement of this engine is its extremely high thermal efficiency. Thermal efficiency measures how much energy from fuel is converted into useful power. Most gasoline engines operate around the mid thirty percent range.

The Dynamic Force engine pushed that figure beyond forty percent, which was once considered nearly impossible for a production gasoline engine.

This improvement came from a combination of advanced combustion design, high compression, and precise fuel injection. Toyota redesigned the intake and exhaust systems to improve airflow and combustion speed. Faster and more controlled combustion allows the engine to extract more energy from each drop of fuel.

Variable valve timing plays a major role in this engine’s efficiency. The engine can switch between Atkinson cycle operation for efficiency and Otto cycle operation for performance. This flexibility allows the engine to adapt to different driving conditions and maintain excellent fuel economy in real world use.

Another important innovation involves reducing energy losses. Engineers focused on minimizing friction and improving cooling efficiency. Every component was designed to ensure that more energy reaches the wheels instead of being wasted as heat.

The Dynamic Force engine also integrates seamlessly with hybrid systems. This compatibility makes it a key building block for modern hybrid vehicles. Its efficiency helps reduce fuel consumption even further when paired with electric motors.

This engine demonstrates how far gasoline engine technology has progressed. It shows that traditional engines still have room for improvement and can play a major role in reducing fuel consumption.

8. Mercedes-Benz BlueEfficiency Diesel Engine

Mercedes Benz BlueEfficiency diesel engines helped redefine the role of diesel technology in luxury and mainstream vehicles. At a time when emissions regulations were becoming stricter, Mercedes focused on making diesel engines cleaner and more efficient without sacrificing comfort or performance.

The BlueEfficiency approach involved a combination of technologies designed to reduce fuel consumption and emissions. High pressure common rail fuel injection allowed precise control of fuel delivery. This improved combustion efficiency and reduced wasted fuel.

Turbocharging played a key role in maximizing performance while maintaining efficiency. By using turbochargers, the engines could produce strong power from smaller displacement, reducing fuel consumption during normal driving.

Aerodynamic improvements and reduced internal friction also contributed to efficiency gains. Mercedes optimized engine components and vehicle systems to minimize energy losses. These changes helped improve real world fuel economy significantly.

The engines also introduced advanced emissions control systems. Technologies such as particulate filters and improved exhaust treatment allowed diesel vehicles to meet stricter environmental standards. This helped diesel remain a viable option in markets focused on fuel efficiency.

The BlueEfficiency program influenced many manufacturers to invest in cleaner diesel technology. It showed that diesel engines could deliver luxury level refinement while achieving impressive fuel economy.

These engines played a major role in improving long distance fuel efficiency and demonstrated that innovation could make traditional engine types more environmentally friendly.

9. Hyundai Smartstream 1.6 Hybrid Engine

The Hyundai Smartstream 1.6 hybrid engine represents a major step forward in making hybrid technology more accessible and efficient for mainstream drivers.

Hyundai invested heavily in improving combustion efficiency while designing the engine specifically to work seamlessly with electric motors. The goal was to create a hybrid system that delivered excellent fuel economy without increasing cost or complexity too much.

One of the most important innovations in this engine is the use of a continuously variable valve duration system. Traditional engines control when valves open and close, but this system also adjusts how long they stay open. This allows the engine to optimize combustion for both power and efficiency depending on driving conditions.

The engine also uses a high efficiency combustion chamber design that improves how fuel mixes with air. Better mixing leads to more complete combustion, which means more energy extracted from each drop of fuel. This directly improves fuel economy and reduces emissions.

Another key feature is the integration with a hybrid transmission. Unlike many hybrids that use a planetary gear system, Hyundai designed a system that feels familiar to drivers while still delivering strong efficiency. This helped make hybrid vehicles more appealing to buyers transitioning from traditional gasoline cars.

Thermal efficiency improvements played a major role in the engine’s success. Engineers focused on reducing heat loss and friction within the engine. These changes allow more energy to be converted into usable power, which improves fuel economy in real world driving.

The Smartstream hybrid engine helped Hyundai and Kia become serious competitors in the hybrid market. It demonstrated that advanced hybrid technology could be produced at scale and offered in affordable vehicles.

This engine represents the modern era of hybrid development and shows how manufacturers continue to refine efficiency using smarter combustion and electrification.

10. Nissan Variable Compression Turbo Engine

The Nissan Variable Compression Turbo engine introduced one of the most ambitious innovations in modern engine design.

For decades, engineers dreamed of creating an engine that could change its compression ratio depending on driving conditions. Nissan turned this idea into reality with a production ready design.

Compression ratio plays a huge role in fuel efficiency and performance. High compression improves efficiency but increases the risk of engine knock under heavy load. Low compression reduces knock but sacrifices efficiency. Traditionally, engineers had to choose one compromise.

Nissan solved this problem by creating a mechanical system that can physically change the compression ratio while the engine is running. During gentle driving, the engine uses high compression for maximum efficiency. When strong acceleration is needed, the compression ratio lowers to allow higher boost from the turbocharger.

This innovation allows the engine to behave like two engines in one. It delivers the efficiency of a small high compression engine during cruising and the power of a turbocharged engine during acceleration. This adaptability dramatically improves real world fuel economy.

The engine also uses direct fuel injection and advanced turbocharging to maximize efficiency. These technologies work together to improve combustion and reduce fuel consumption across different driving conditions.

The Variable Compression Turbo engine represents a major engineering breakthrough. It proves that internal combustion engines still have room for innovation and efficiency improvements.

This engine closes the list as one of the most advanced examples of how engineering creativity can transform fuel efficiency for future vehicles.

The history of automotive fuel efficiency is defined by a series of engines that challenged conventional thinking and pushed engineering boundaries. These engines did not simply improve fuel economy slightly.

They introduced ideas that permanently reshaped how manufacturers design powertrains. From hybrid systems to advanced combustion techniques, each engine on this list contributed to the evolution of modern efficiency.

One of the most important themes is the shift toward smarter combustion. Engines such as the Toyota 1NZ FXE and Toyota Dynamic Force 2.5 showed how refining the combustion process can dramatically improve efficiency.

By using the Atkinson cycle, higher compression, and advanced airflow design, engineers found ways to extract more energy from every drop of fuel. These innovations proved that fuel economy gains could come from improving fundamentals rather than relying only on electrification.

Downsizing and turbocharging also played a major role. The Ford EcoBoost 1.0 demonstrated that small engines could replace larger ones without sacrificing everyday usability. This concept quickly spread across the industry and became the standard approach for meeting stricter emissions and fuel economy regulations.

The Nissan Variable Compression Turbo engine took this idea even further by allowing one engine to adapt its compression ratio depending on driving conditions.

Hybrid technology represents another major turning point. The Toyota 1NZ FXE and Hyundai Smartstream hybrid engine showed how combining electric motors with efficient gasoline engines can produce impressive real world fuel savings.

These systems helped hybrids move from niche experiments to mainstream vehicles trusted by millions of drivers.

Diesel technology also contributed significantly to fuel efficiency progress. Engines such as the Volkswagen 1.9 TDI and Mercedes BlueEfficiency diesel proved that turbocharging and precise fuel injection could deliver excellent mileage and long distance efficiency.

These engines reshaped public perception of diesel passenger cars and influenced global fuel economy standards.

Another important lesson is that efficiency improvements are not limited to small engines. The General Motors LS V8 with cylinder deactivation demonstrated that even large performance engines can adapt to save fuel during light driving.

This technology helped bridge the gap between performance and efficiency in trucks and larger vehicles.

Overall, these engines highlight the creativity and persistence of automotive engineers. They show how innovation, experimentation, and competition have driven decades of progress. The technologies introduced by these engines continue to influence modern vehicles and will shape the future of transportation for years to come.

Also Read: 10 Affordable Used Pickup Trucks With Impressive Towing Power