For most American drivers, hitting 200,000 miles already feels like a major victory. But quietly, a select group of modern engines keeps going far beyond that milestone often reaching 300,000 miles or more with nothing exotic in terms of maintenance.

No engine is immortal, of course. Oil changes still matter. Cooling systems still fail. Timing components still wear out. But some powerplants are simply engineered with wider tolerances, conservative tuning, and materials that age gracefully.

These aren’t hand-built race motors or ultra-expensive luxury units. They’re everyday engines found in commuter sedans, family SUVs, and work trucks across the U.S.

What they share is a reputation for durability, strong aftermarket support, and predictable failure points that owners can manage before catastrophe strikes.

Below are 12 modern engines that mechanics routinely see in their bays at 250k–300k miles and sometimes far beyond provided they receive basic care like regular oil changes, coolant service, and timely belt or chain inspections.

1. Toyota 2GR-FE 3.5L V6

Built by Toyota, the 2GR-FE is one of the most respected V6 engines of the past two decades. It uses a timing chain instead of a belt, avoids direct injection complexity, and runs relatively low boost (none, actually it’s naturally aspirated).

Owners regularly report mileage well past 300,000 when oil changes are done on schedule. The water pump is a known weak spot, but it usually fails gradually, giving plenty of warning. Otherwise, this engine is famous for smooth operation and long internal life.

You’ll find it in everything from midsize sedans to three-row SUVs, making it one of the most common high-mileage V6s on American roads.

Toyota introduced its 3.5-liter V6 gasoline engine designed for transverse installation in 2004. Designated the 2GR-FE, it succeeded both the earlier 1MZ-FE V6 and the renowned 2JZ inline-six engines.

The 2GR-FE quickly became a widely adopted powerplant across Toyota’s high-volume models, including the Toyota Camry, Toyota RAV4, and Highlander.

Similar in construction philosophy to the 1GR-FE, the 2GR-FE employs an open-deck cast aluminum alloy cylinder block fitted with spiny-type cast iron cylinder liners. The V configuration features a 60-degree bank angle, with the liners cast directly into the block material.

Internally, the engine is equipped with a forged steel crankshaft incorporating five counterweights, along with forged connecting rods. The aluminum alloy pistons feature resin-coated skirts to minimize friction during operation.

Each cylinder head is constructed as a three-piece assembly consisting of the main cylinder head casting, a separate camshaft housing, and a valve cover, all manufactured from aluminum alloy.

Steel-laminate head gaskets seal the interface between the cylinder banks and heads. The valvetrain features dual overhead camshafts per bank, driven by a chain system. A primary timing chain operates the intake camshafts, while secondary chains link the intake camshafts to the exhaust camshafts.

Variable valve timing is managed by Toyota’s Dual VVT-i system. Valve actuation occurs via roller rocker arms, and hydraulic lash adjusters automatically maintain proper valve clearance, eliminating the need for periodic manual adjustment.

The 2GR-FE incorporates a plastic variable-geometry intake manifold. Toyota’s ACIS (Acoustic Control Induction System) adjusts the effective intake runner length by opening and closing an intake air control valve in response to engine speed.

Throttle operation is governed by the ETCS-I (Electronic Throttle Control System – intelligent), which eliminates a direct mechanical linkage between the accelerator pedal and throttle body, instead relying on position sensors and electronic signals.

Fuel delivery is handled by an L-type sequential fuel injection system, while ignition duties are managed by Toyota’s DIS system.

Each spark plug is paired with an individual ignition coil integrated into the plug cap. Exhaust gases are routed through stainless-steel exhaust manifolds and pass through three-way catalytic converters positioned on both banks.

The 2GR-FSE variant is primarily found in Lexus models and select Japanese domestic market vehicles. This version features Toyota’s D-4S twin injection system, combining direct fuel injection with traditional port injection.

The integration of both injection methods necessitates separate low- and high-pressure fuel delivery systems. The engine is equipped with revised cylinder heads designed to accommodate high-pressure direct injectors positioned on the outer side of the intake valves.

The pistons are reshaped and constructed from hypereutectic aluminum alloy to withstand elevated thermal and mechanical stresses.

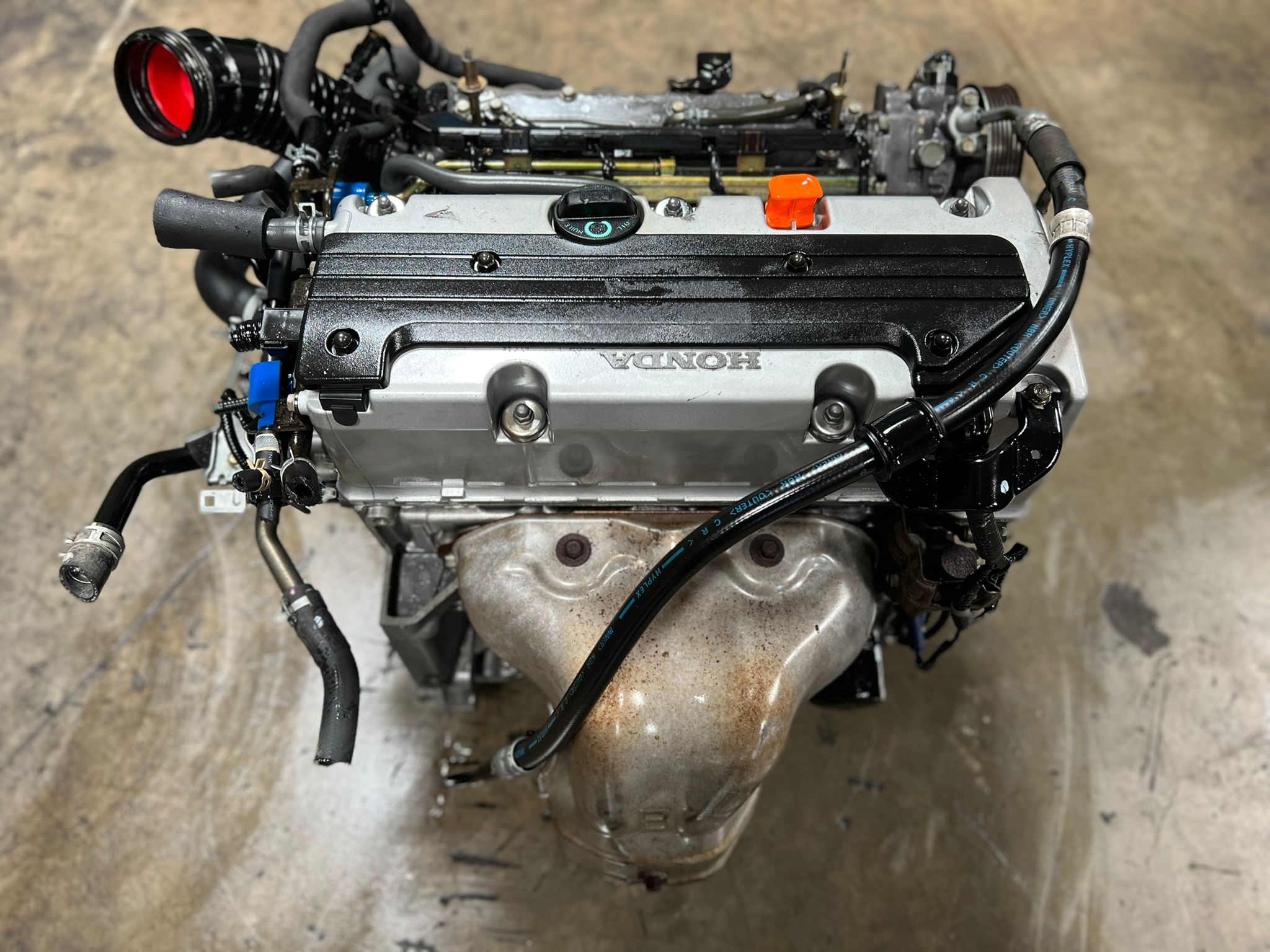

2. Honda K24 2.4L Inline-Four

Honda’s K-series engines earned legendary status, and the K24 may be the most durable of the bunch. It’s simple, naturally aspirated, and lightly stressed.

Timing chains last a long time, valve trains are robust, and parts availability is excellent.

With basic maintenance, these engines routinely reach 250k–300k miles. Some go much farther, especially in highway-driven vehicles.

Oil consumption can appear late in life, but rarely enough to threaten the bottom end.

3. Toyota 1NZ-FXE (Hybrid 1.5L)

Another win for Toyota, the 1NZ-FXE powers early hybrid models and benefits enormously from electric assistance. Because the engine isn’t always running, internal wear is dramatically reduced.

Taxi fleets have proven this engine’s durability repeatedly, with many examples exceeding 300,000 miles. Cooling system upkeep and EGR cleaning are critical, but mechanically the engine itself is remarkably tough.

The Toyota 1NZ-FXE is a 1.5-liter (1,497 cc, 91.35 cubic-inch) naturally aspirated inline four-cylinder gasoline engine developed as part of Toyota’s NZ engine family and engineered specifically for hybrid applications.

It operates on a four-stroke cycle and is widely recognized for its role in Toyota’s hybrid powertrains.

Structurally, the 1NZ-FXE utilizes a lightweight aluminum cylinder block paired with an aluminum cylinder head. The valvetrain features a dual overhead camshaft (DOHC) configuration with four valves per cylinder, for a total of 16 valves.

Toyota characterizes the 1NZ-FXE as operating on an “Atkinson cycle.” In practical terms, this means the compression stroke is effectively shortened while the expansion stroke is extended.

Although the engine’s physical compression ratio is 13.0:1, the delayed closing of the intake valve reduces the effective compression ratio to 9.5:1. The cylinder bore measures 75.0 mm (2.95 inches), and the piston stroke is 84.7 mm (3.34 inches).

In terms of output, the 1NZ-FXE delivers a maximum power rating of 76 PS (56 kW; 75 HP) at 5,000 rpm and produces peak torque of 110 Nm (11.2 kg·m; 81.2 lb-ft) at 4,000 rpm. The firing order follows a 1-3-4-2 sequence, typical for inline four-cylinder engines.

From a general specification standpoint, the 1NZ-FXE features a displacement of 1.5 liters (1,497 cm³), utilizes Electronic Fuel Injection (EFI), and does not incorporate forced induction. The engine has been in production since 1997. It weighs approximately 87 kg (191.2 pounds), reflecting its lightweight construction.

The cylinder block is constructed from aluminum and incorporates a five-bearing crankshaft support system along with thin-walled cast-iron cylinder liners.

With a 75.0 mm bore and an 84.7 mm stroke, the engine’s internal design prioritizes efficiency and thermal management. Each piston is fitted with two compression rings and a single oil control ring, contributing to effective sealing and lubrication control within the combustion chamber.

4. Ford 2.5L Duratec (Naturally Aspirated)

This old-school four-cylinder from Ford avoids turbochargers and direct injection, two features that often shorten engine life.

Its conservative design and iron block make it heavier than newer alternatives, but also far more forgiving. These engines commonly cross 250k miles with little drama, and many keep going with only routine servicing.

5. GM 5.3L V8 (Gen IV LS Family)

General Motors refined the LS architecture for years, and the Gen IV 5.3L V8 remains one of its most durable variants. Built by General Motors, this engine balances strong power with mechanical simplicity.

Active Fuel Management lifters can fail, but once addressed, the core engine routinely reaches 300k miles in trucks and SUVs that see regular highway use.

The LS4 is a 5.3-liter naturally aspirated gasoline V8 from GM’s Gen IV small-block family, constructed entirely from aluminum and installed in full-size front-wheel-drive passenger cars between 2005 and 2009.

What distinguishes the LS4 from other LS variants is its transverse configuration, making it the only LS engine specifically engineered for front-wheel-drive applications.

It also marked a milestone for the Small Block lineup as the first to incorporate GM’s Active Fuel Management system, which enables cylinder deactivation for improved fuel efficiency. The 5.3L LS4 powered vehicles such as the Pontiac Grand Prix GXP, Chevrolet Impala SS, Chevrolet Monte Carlo SS, and Buick LaCrosse Super.

The LS4 is derived from the fourth-generation Small Block architecture and shares its 5.3-liter displacement with engines such as the Vortec 5300 (LH6, LC9, LY5). However, unlike those truck-oriented variants that typically use iron blocks, the LS4 employs an aluminum cylinder block fitted with iron sleeves.

The block maintains the traditional 90-degree V configuration, features 4.40-inch (111.8 mm) bore spacing, and utilizes six-bolt main bearing caps for bottom-end strength. Internally, the engine is equipped with a cast-iron crankshaft, forged powdered-metal connecting rods, and aluminum flat-top pistons.

To accommodate transverse installation, the crankshaft was shortened by 13 mm compared with conventional longitudinal LS engines, reducing overall engine length and enabling fitment within front-wheel-drive engine bays.

The cylinder heads are aluminum overhead-valve (OHV) units with two valves per cylinder. They incorporate cathedral-style intake ports and D-shaped exhaust ports, and their design is closely related to the LS6 heads.

Intake valves measure 2.000 inches (50.8 mm) in diameter, while exhaust valves measure 1.575 inches (40.0 mm). As a traditional pushrod V8, the LS4 employs a single hollow steel hydraulic roller camshaft located within the engine block. Valve actuation is managed through 7.385-inch pushrods and die-cast roller rocker arms.

Beginning in 2007, GM updated the LS4 with a revised camshaft featuring a one-bolt cam gear attachment instead of the earlier three-bolt configuration.

The revised camshaft specifications were 196/201 degrees of duration (intake/exhaust), 0.481-inch lift on both intake and exhaust valves, and a 116-degree lobe separation angle.

6. Subaru FB25 2.5L Boxer

Subaru improved oil consumption and head gasket issues with the FB series. While earlier boxer engines struggled long-term, the FB25 has proven far more stable.

Owners who stay on top of oil levels and cooling system maintenance frequently see these engines approach or exceed 300,000 miles.

The FB-series represents an entirely new generation of engines developed by Subaru. Among them, the 2.5-liter FB25 is a naturally aspirated gasoline flat-four (boxer) engine introduced to replace the long-serving EJ25 in models such as the Legacy and Forester. Production of the FB25 began in 2010.

Like its smaller-displacement sibling, the FB20, this engine incorporates a range of updated engineering solutions intended to improve efficiency, refinement, and emissions performance. A closer examination of its construction highlights both its strengths and its compromises.

The FB25 (also referred to as the FB25B in certain applications) is derived from the FB20’s aluminum cylinder block, which uses cast-iron cylinder liners. To increase displacement, Subaru enlarged the bore to 94 mm while retaining the same stroke dimension as the 2.0-liter variant.

The cylinder heads are aluminum dual overhead camshaft (DOHC) units with four valves per cylinder, operated via roller rocker arms. Each head is constructed in two sections: the main cylinder head casting and a separate camshaft carrier. This modular approach reduces overall material thickness and weight.

The FB25 utilizes maintenance-free timing chains rather than belts, improving long-term durability. Both intake and exhaust camshafts are equipped with Subaru’s dual AVCS (Active Valve Control System), providing variable valve timing on each side for enhanced flexibility and efficiency

The exhaust system was also redesigned, incorporating new exhaust manifolds with optimized pipe diameters to accelerate catalytic converter warm-up and marginally enhance power output.

Compared with the older EJ25, the FB25 delivers improved performance at lower engine speeds. Although peak horsepower figures remain similar, torque output at lower RPM is increased, resulting in better drivability and improved real-world fuel efficiency.

These characteristics make the FB25 a more economical and practical choice for drivers prioritizing reduced fuel consumption and smoother low-speed response.

7. Mazda Skyactiv-G 2.5L

Mazda’s Skyactiv philosophy focused on efficiency without forced induction. From Mazda, the 2.5L Skyactiv-G uses high compression but avoids turbos, keeping thermal stress low.

These engines age slowly, with few chronic mechanical problems reported even at high mileage.

8. Lexus 2UR-GSE 5.0L V8

Built under Lexus, this naturally aspirated V8 is overengineered by modern standards. Forged internals, conservative tuning, and excellent cooling allow it to rack up enormous mileage when serviced properly.

It’s proof that performance engines don’t have to be fragile.

If you are an automotive enthusiast looking for a high-performance engine upgrade, or a workshop sourcing premium Toyota powerplants, the Toyota 2UR-GSE stands out as one of the most accomplished modern V8 engines available.

Whether your interest lies in motorsport applications, custom engine swaps, or securing a reliable replacement for a Lexus IS F, RC F, GS F, or LC 500, this 5.0-liter naturally aspirated V8 delivers a compelling balance of output, durability, and advanced engineering.

In this comprehensive overview, we examine the 2UR-GSE in detail, covering its technical specifications, performance characteristics, common applications, and the reasons it continues to maintain strong appeal among enthusiasts and professional mechanics worldwide.

The Toyota 2UR-GSE is a 5.0-liter naturally aspirated V8 developed by Toyota’s performance engineering division. It made its debut in 2007 in the Lexus IS F and has since powered several high-performance Lexus models, including:

As a member of Toyota’s UR-series V8 family, the 2UR-GSE was engineered specifically for luxury performance vehicles. It is recognized for its high-revving nature, dual overhead camshaft (DOHC) configuration, and advanced dual-injection fuel system that combines both direct and port injection.

The engine was designed to provide strong horsepower output, immediate throttle response, and the long-term reliability traditionally associated with Toyota powertrains.

9. Hyundai 2.4L Theta II (Later Revisions)

Earlier Theta II engines had serious issues, but later revisions from Hyundai corrected many failures. Properly maintained examples now regularly exceed 250k miles, and some reach 300k.

The key is frequent oil changes and prompt attention to any knocking or warning lights.

10. Toyota 5.7L i-Force V8 (3UR-FE)

Designed for heavy trucks, this Toyota V8 is massively understressed in daily driving. With proper maintenance, 300,000 miles is well within reach.

Fleet operators prize this engine for its predictable wear patterns and strong bottom end.

The 3UR-FE belongs to Toyota’s modern UR engine family and represents its largest-displacement variant. This 5.7-liter V8 features an aluminum cylinder block and aluminum cylinder heads, and it was engineered primarily for use in larger Toyota SUVs and trucks, including the Toyota Tundra, Sequoia, Land Cruiser, and the Lexus LX570.

As with other UR-family engines, such as the 1UR-FE/FSE and 2UR-GSE/FSE, the 3UR-FE utilizes an aluminum block configured at a 90-degree V-angle.

The bore pitch measures 105.5 mm, and the cylinder banks are offset by 21.0 mm. All UR engines share a 94 mm bore diameter, while the 3UR-FE increases displacement through a longer 102.0 mm stroke, bringing total capacity to 5.7 liters.

Internally, the engine is equipped with a forged steel crankshaft featuring six counterweights, forged connecting rods, and aluminum alloy pistons coated with resin to reduce friction. Four oil jets integrated into the block spray oil onto the undersides of the pistons to manage heat and improve durability.

The cylinder heads follow a consistent UR-series design. They are constructed from aluminum alloy and incorporate integrated camshaft housings.

Each cylinder is fitted with four valves, two intake and two exhaust, operated by dual overhead camshafts. Valve actuation is handled by roller rocker arms, and the 3UR-FE includes hydraulic lifters for automatic valve clearance adjustment.

Timing duties are managed by two primary chains that drive the intake camshafts, while secondary chains link each intake camshaft to its corresponding exhaust camshaft.

All chains are maintained under tension by oil-pressure-assisted, spring-loaded tensioners. Valve timing is controlled through Toyota’s Dual Variable Valve Timing – intelligent system (Dual VVT-i), allowing independent adjustment of both intake and exhaust camshaft timing.

The intake system features a plastic intake manifold equipped with Toyota’s Acoustic Control Induction System (ACIS), which varies intake runner length according to engine speed to optimize torque and efficiency.

Fuel delivery is handled by a sequential fuel injection (SFI) system; this engine does not utilize direct injection. Airflow is monitored by a slot-in type mass airflow sensor that incorporates an integrated intake air temperature sensor.

Ignition duties are managed by Toyota’s Direct Ignition System (DIS), employing individual ignition coils for each cylinder. The engine uses iridium-tipped spark plugs designed for extended service intervals.

Exhaust gases exit through 4-2-1 stainless steel exhaust manifolds. This semi-dual configuration reduces exhaust pulse interference and enhances mid-range torque output.

11. Nissan QR25DE 2.5L

Modern versions of this engine from Nissan are far improved over early models. When paired with regular oil service and cooling system care, the QR25DE has proven capable of long life in commuter vehicles.

The 2.5-liter QR25DE engine is essentially derived from the QR20DE, with several key modifications distinguishing it from the smaller-displacement version.

The primary difference lies in the crankshaft design. The QR25DE uses a revised crankshaft that increases the stroke to 100 mm, compared to the 80.3 mm stroke of the 2.0-liter engine.

To accommodate this longer stroke while retaining the same 89 mm cylinder bore, the connecting rods were shortened. These changes raised total displacement to 2.5 liters and resulted in improved torque output.

However, the longer stroke configuration also increases mechanical stress on the cylinder walls, piston rings, and connecting rods.

As a consequence, the QR25DE has a shorter warranty period compared to its 2.0-liter counterpart, and elevated oil consumption is a more common issue with this engine.

In 2007, Nissan introduced a series of updates to improve durability and performance. The intake receiver (manifold) was revised, and the engine received updated pistons along with strengthened connecting rods.

12. Ford 3.7L Cyclone V6

The naturally aspirated 3.7L Cyclone is one of Ford’s quiet success stories. It avoids turbo complexity and uses a strong timing chain setup.

High-mileage examples are common, especially in fleet vehicles and base-model pickups.

No engine reaches 300,000 miles by accident. But these powerplants give owners a significant head start. Their designs favor mechanical simplicity, conservative output, and proven materials exactly what matters for longevity.

If you’re shopping used or hoping to keep your current vehicle on the road for the long haul, engines like these offer something increasingly rare in modern cars: predictable durability.

With routine oil changes, cooling system service, and attention to early warning signs, crossing the 300,000-mile mark isn’t fantasy anymore. For many American drivers, it’s simply a matter of time.