Electric pickups are storming the automotive market with promises of unprecedented torque, zero emissions, and cutting-edge technology. Manufacturers showcase impressive towing capacities, lightning-fast acceleration, and futuristic features that make traditional gas-powered trucks seem antiquated.

The marketing materials paint a compelling picture: you can have your cake and eat it too enjoying the utility of a full-size pickup while saving the planet and your wallet.

However, beneath the glossy advertisements and enthusiastic reviews lies a more complex reality that many potential buyers discover only after signing on the dotted line.

While electric pickups represent genuine technological progress and offer real advantages, they also come with significant trade-offs that aren’t always immediately apparent during a showroom test drive or online research session.

The transition from internal combustion to electric power in the pickup segment introduces unique challenges that differ substantially from electric sedans or SUVs.

Pickups are workhorses designed for hauling, towing, and tackling demanding jobs tasks that push electric vehicle technology to its limits. Understanding these limitations isn’t about dismissing electric pickups as inferior; it’s about making an informed decision based on realistic expectations rather than marketing hype.

This article cuts through the promotional noise to examine ten hard truths about electric pickups that dealerships, manufacturers, and even some enthusiast publications prefer to downplay.

Whether you’re considering a Ford F-150 Lightning, Rivian R1T, Chevrolet Silverado EV, or any other electric truck, these insights will help you understand what you’re really getting into.

1. Towing Decimates Your Range

Electric pickup manufacturers love to advertise impressive towing capacities often matching or exceeding their gas-powered counterparts. The Ford F-150 Lightning can tow up to 10,000 pounds, while the Rivian R1T handles 11,000 pounds, and the Silverado EV boasts a massive 20,000-pound capacity in certain configurations.

These numbers look fantastic on paper and make for compelling marketing materials. However, what manufacturers rarely emphasize is the catastrophic impact towing has on your driving range.

When you hook up a substantial trailer to an electric pickup, your range can plummet by 50-70% or even more, depending on trailer weight, aerodynamics, and terrain. Real-world testing has shown the F-150 Lightning’s range dropping from around 300 miles unloaded to barely 100 miles when towing 6,500 pounds.

Some owners report even worse results in challenging conditions. The Rivian R1T experiences similar dramatic reductions, with range sometimes halving when towing moderate loads.

This isn’t just an inconvenience it fundamentally changes how you use the vehicle. A trip that would require one fuel stop in a gas truck might need three or four charging stops in an electric pickup while towing.

Each charging session takes significantly longer than filling a gas tank, potentially turning a six-hour journey into an all-day affair. The situation worsens because many charging stations aren’t designed for vehicles with trailers, forcing you to disconnect, park the trailer, charge, then reconnect adding considerable hassle to an already time-consuming process.

The physics behind this limitation are straightforward: towing dramatically increases aerodynamic drag and requires substantially more energy to accelerate and maintain speed.

While gas engines also lose efficiency when towing, they can quickly refuel anywhere, making the impact less noticeable. For electric pickups, this represents a fundamental use-case limitation that won’t improve significantly until battery technology makes revolutionary advances.

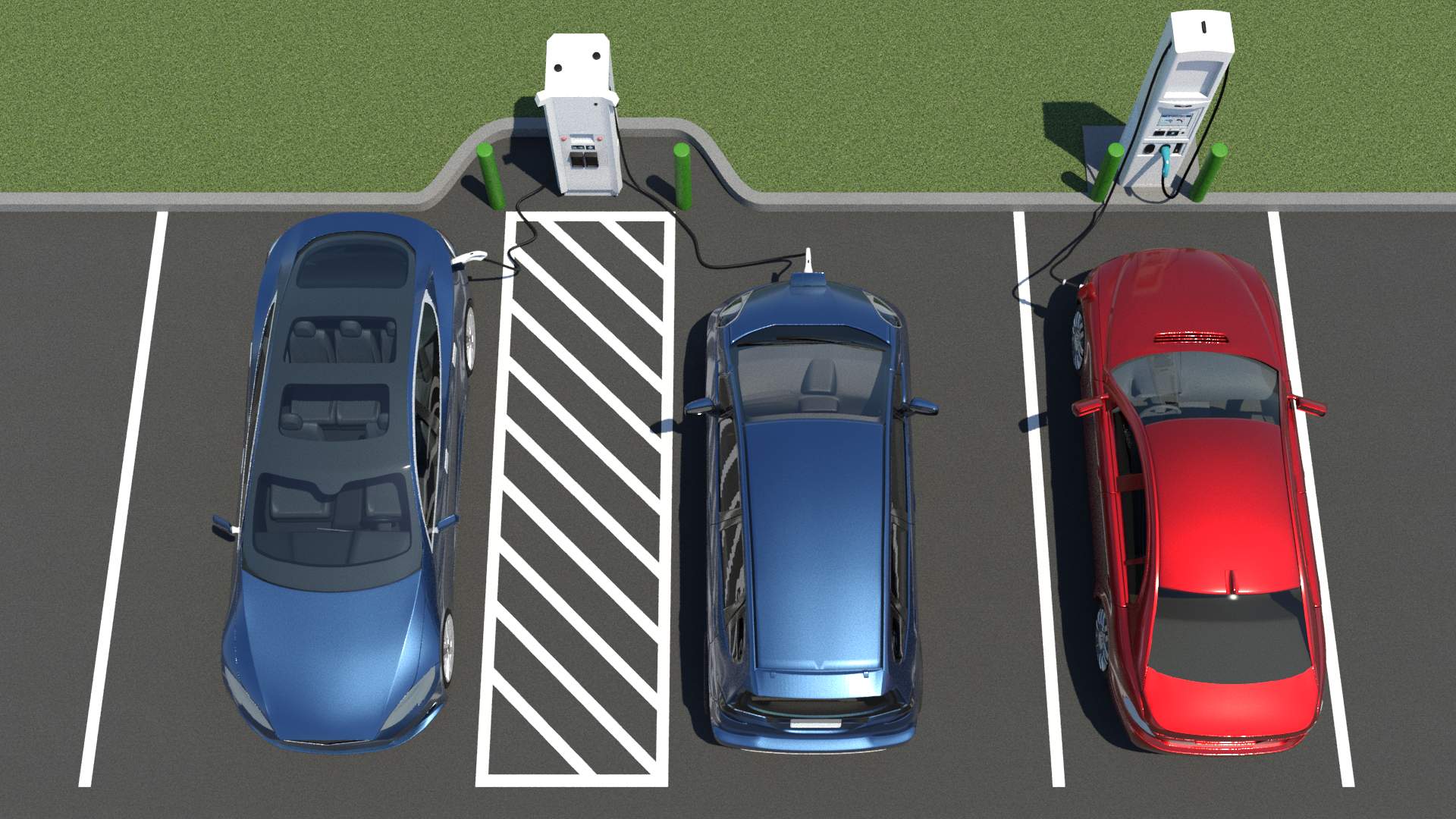

2. Charging Infrastructure Isn’t Truck-Friendly

The charging infrastructure across North America has expanded considerably, with thousands of DC fast-charging stations now available.

However, this network was primarily designed with sedans and SUVs in mind, not full-size pickups, especially those towing trailers. This oversight creates numerous practical challenges that electric pickup owners encounter regularly and that significantly complicate the ownership experience.

Most charging stations feature parking spaces barely large enough for a standard sedan, with charge cables only a few feet long. An F-150 Lightning or Silverado EV measures over 19 feet long already tight for many charging spaces.

Add a trailer, and you’re looking at a combined length of 35-45 feet or more. Very few charging stations can accommodate this length, and those with the charge port in specific locations may find the cable won’t reach without blocking multiple spaces or parking awkwardly.

This design oversight forces many electric pickup owners towing trailers to disconnect before charging a significant hassle involving unhitching, parking the trailer safely (often in spaces not designed for this), moving the truck to charge, waiting 30-60 minutes, then reconnecting everything.

This process might add 15-30 minutes to each charging stop, and if you need three or four stops on a long towing journey, you’re adding hours to your trip.

Furthermore, charging stations in rural areas where pickup trucks are often most popular and necessary remain sparse. While urban and suburban charging networks continue growing, vast stretches of rural America have limited fast-charging options.

This creates range anxiety for anyone traveling off the beaten path, particularly when towing reduces your effective range to 100-150 miles between charges.

3. Cold Weather Performance Is Significantly Compromised

Electric vehicle performance in cold weather is a well-documented challenge, but for pickups often used for work regardless of conditions this limitation becomes particularly problematic.

When temperatures drop below freezing, electric pickups can lose 30-50% of their range, and in extreme cold (below 0°F), losses can exceed 60%. This isn’t a minor inconvenience; it fundamentally alters the vehicle’s capability during winter months.

The range reduction comes from multiple factors. Lithium-ion batteries operate less efficiently in cold temperatures, with chemical reactions slowing down and internal resistance increasing.

Simultaneously, the battery heating system draws substantial power to maintain optimal operating temperature. Cabin heating which uses battery power rather than waste heat from an engine further drains the battery. When you combine cold-weather battery performance with heating demands, the energy consumption skyrockets.

For someone in Minnesota, Montana, or Canada using their electric pickup for winter work, this creates serious practical challenges. A truck that provides 300 miles of summer range might deliver only 150 miles or less in January.

If you’re also towing or hauling heavy loads, you might see that drop to under 100 miles. This makes previously routine trips suddenly require charging stops, and charging in extreme cold takes longer as the battery must warm up before accepting maximum charge rates.

Many electric pickup owners in cold climates report needing to charge almost daily during winter, even with moderate use. Pre-conditioning the battery and cabin while still plugged in helps, but it’s another task to remember and plan for.

For contractors, farmers, or anyone who needs their truck to work reliably in all conditions, this seasonal performance variation represents a genuine limitation that gas trucks simply don’t share.

4. The True Cost of Ownership Isn’t Always Lower

One of the primary selling points for electric vehicles is lower operating costs no oil changes, less brake maintenance, cheaper “fuel,” and fewer moving parts to fail. While these advantages are real, the cost equation for electric pickups proves more complicated than many buyers anticipate, especially when considering the total ownership experience over five to seven years.

Electric pickups carry substantial price premiums over comparable gas models. The F-150 Lightning starts around $50,000-$60,000, while a similarly equipped gas F-150 might cost $40,000-$45,000. The Rivian R1T starts over $70,000, and top-tier configurations easily exceed $90,000. While federal tax credits can offset some of this ($7,500 currently), they don’t eliminate the price gap, and not all buyers qualify for the full credit.

Electricity costs, while lower than gasoline per mile, aren’t always as cheap as advertised. Home charging at off-peak rates might cost $0.03-$0.04 per mile, compared to $0.12-$0.15 per mile for gas (at $3.50/gallon).

However, public DC fast-charging can cost $0.10-$0.15 per mile or more, approaching or even exceeding gas costs. If you frequently road-trip or lack home charging, your fuel savings shrink considerably.

Insurance for electric pickups often costs more due to higher vehicle values, expensive battery replacement costs, and specialized repair requirements.

Tire wear can be accelerated due to the heavy weight of these vehicles most electric pickups weigh 6,000-7,000 pounds or more, significantly heavier than gas equivalents. These tires are also more expensive, and you’ll replace them more frequently.

Battery degradation represents another long-term cost consideration. While manufacturers offer warranties (typically 8 years/100,000 miles), batteries do lose capacity over time, and replacement costs remain extremely high potentially $10,000-$20,000 or more when outside warranty coverage.

Also Read: 10 Used SUVs Known to Cross 500,000 Miles

5. Payload Capacity Takes a Significant Hit

Pickups are prized for their ability to haul cargo in the bed, whether that’s construction materials, landscaping supplies, camping gear, or recreational equipment.

However, the massive batteries required for electric pickups consume much of the vehicle’s weight budget, resulting in surprisingly limited payload capacities compared to gas-powered alternatives. This represents one of the most significant practical compromises in electric pickup design.

A standard F-150 with a gas engine can offer payload capacities of 2,000-3,000 pounds depending on configuration. The F-150 Lightning’s payload capacity ranges from about 1,800 to 2,235 pounds maximum a reduction of 25-40% in many configurations.

The Rivian R1T offers only about 1,760 pounds of payload in most configurations. When you consider that the average American weighs around 180 pounds, just adding four passengers consumes over 700 pounds of that capacity before you put anything in the bed.

This limitation becomes particularly problematic for contractors, landscapers, or anyone regularly hauling heavy materials. A pallet of shingles weighs about 2,100-2,800 pounds; a cubic yard of gravel weighs approximately 3,000 pounds; a pallet of sod weighs around 2,000-3,000 pounds.

Many common work loads either max out an electric pickup’s payload or exceed it entirely, something that wouldn’t be an issue with a gas-powered equivalent.

The weight problem compounds when considering accessories. Adding a bed cap, toolbox, or tonneau cover consumes additional payload capacity.

Aftermarket modifications like lift kits, larger tires, or heavy-duty bumpers further reduce what you can legally carry. For many professionals who depend on their trucks for work, these payload limitations represent a genuine dealbreaker that makes electric pickups unsuitable for their needs, regardless of other benefits.

6. Home Charging Installation Can Be Expensive and Complicated

Electric pickup manufacturers tout the convenience of home charging waking up every morning with a “full tank.” While this advantage is real, achieving it requires electrical infrastructure many homes simply don’t have, and the installation costs can add thousands of dollars to your electric pickup purchase.

This hidden expense catches many first-time electric vehicle buyers off guard. Electric pickups require 240-volt charging to be practical for daily use.

While you can technically charge on a standard 120-volt outlet, the charge rate is so slow (typically 3-5 miles of range added per hour) that it’s impractical except for emergency situations.

Installing a Level 2 (240-volt) charging station requires a dedicated circuit, typically 40-80 amps, running from your electrical panel to wherever you park.

For many homes, particularly older ones, this installation isn’t straightforward. Your electrical panel might already be near capacity, requiring an expensive panel upgrade ($1,500-$3,000 or more).

If your parking area is far from the panel such as a detached garage or street parking you’ll need extensive electrical work, potentially including trenching.

Total installation costs commonly range from $1,000-$3,000 for simple installations but can easily exceed $5,000-$10,000 for complex situations requiring panel upgrades, long wire runs, or significant electrical work.

Renters or apartment dwellers face even bigger challenges. Many landlords won’t approve electrical modifications, and even if they do, you’re investing in infrastructure you’ll leave behind when you move.

Condo associations may resist installation or restrict charging equipment locations. Urban residents with street parking may have no practical home charging option at all, forcing reliance on more expensive and less convenient public charging.

7. Battery Replacement Costs Are Astronomical

Electric vehicle advocates correctly point out that EVs have fewer moving parts than gas vehicles, potentially reducing maintenance costs over the vehicle’s life. However, this analysis overlooks the elephant in the room: the battery pack.

Electric pickup batteries are massive, expensive, and eventually need replacement a cost that can exceed the entire value of the vehicle if you keep it long enough.

Electric pickup battery packs typically range from 98-200+ kWh capacity, containing thousands of individual battery cells. These packs cost $10,000-$25,000 or more to replace, depending on the vehicle and battery size.

While manufacturers offer warranties (commonly 8 years/100,000 miles), batteries degrade over time, and you’ll eventually face this cost if you keep the vehicle beyond the warranty period.

Battery degradation is inevitable. Most electric pickup batteries retain about 90% capacity after three years and 80-85% after eight years under normal use. Aggressive use frequent DC fast-charging, towing, extreme temperatures accelerates degradation.

While 80% capacity might be acceptable for city commuting, it’s problematic for a pickup truck. Your 300-mile range becomes 240 miles, and when towing cuts that in half, you’re looking at 120-mile effective range barely usable for serious truck work.

The financial risk is substantial. If you own an electric pickup after warranty expiration and the battery degrades significantly, you face an impossible choice: pay $15,000-$25,000 to replace the battery in a vehicle that might only be worth $20,000-$30,000, or sell it at a massive loss because buyers won’t pay much for an EV with degraded battery capacity.

This residual value uncertainty makes electric pickups risky long-term investments compared to gas trucks that remain functional for 200,000-300,000 miles with relatively minor repairs.

8. Repair Costs and Service Availability Are Major Concerns

Electric pickup owners often discover that routine repairs and service present unique challenges compared to traditional trucks. The specialized nature of electric vehicles, combined with their relative newness to the market, creates a situation where finding qualified technicians, getting parts, and managing repair costs can be significantly more difficult and expensive than anticipated.

Many traditional mechanics lack the training, certification, and specialized equipment to work on electric vehicles. High-voltage systems require special safety protocols, diagnostic tools, and expertise that most neighborhood repair shops simply don’t have.

This forces electric pickup owners toward dealerships or specialized EV service centers, which are far fewer in number and often charge premium rates. If you live in a rural area or small town, the nearest qualified service center might be hours away.

When damage involves the battery pack or high-voltage systems even minor damage repair costs skyrocket. A seemingly minor accident that damages the undercarriage where the battery sits can total the vehicle because insurance companies often won’t risk approving battery pack repairs.

They mandate complete replacement instead, pushing repair costs beyond the vehicle’s value. This has led to insurance companies totaling relatively new electric vehicles for damage that would be minor repairs on a gas truck.

Parts availability represents another challenge. Electric pickups are newer models with lower production volumes than established gas trucks. When you need a replacement part, it might be on backorder for weeks or months.

For someone who depends on their truck for work, having it sit at a dealership for extended periods waiting for parts is unacceptable. Ford, Rivian, and GM are building out service networks, but they’re years behind the infrastructure supporting gas-powered trucks.

9. Off-Road and Remote Use Is Severely Limited

Pickups have always been synonymous with adventure exploring remote areas, hunting and fishing trips, backcountry camping, and accessing off-grid work sites.

Electric pickups market themselves as equally capable, featuring impressive off-road specs like adjustable air suspension, locking differentials, and robust underbody protection.

However, the reality of using an electric pickup for genuine remote or off-road adventures reveals serious limitations that gas trucks don’t face.

The fundamental problem is energy availability. In a gas truck, you can carry extra fuel in jerry cans, extending your range indefinitely. Remote areas often have gas stations, even if they’re far apart. If you run out in the backcountry, someone can bring you a few gallons to get to the nearest station.

None of these solutions exist for electric pickups. You can’t carry extra electricity, charging infrastructure doesn’t exist in remote areas, and if you run out, you need a flatbed tow truck to haul you dozens or hundreds of miles to the nearest charger.

Off-road driving is extremely energy-intensive. Crawling over rocks, through mud, or up steep inclines at low speeds consumes far more energy than highway driving. The battery range optimistically estimated for highway use can be cut in half or more during challenging off-road conditions.

That 300-mile range might become 100-150 miles when rock crawling, mud bogging, or going through the difficult terrain, and there’s nowhere to recharge once you’re deep in the wilderness.

Recovery and rescue scenarios become complicated. If you’re stuck in mud, sand, or snow, running the motors to free yourself drains the battery quickly.

Unlike a gas truck that can idle indefinitely while winching or using power tools, an electric pickup’s battery drains continuously. Extended recovery situations can leave you stranded even after getting unstuck, with insufficient charge to reach civilization.

10. Resale Value Uncertainty Creates Financial Risk

When purchasing any vehicle, resale value is a crucial consideration it represents a significant portion of your total ownership cost. With gas-powered pickups, decades of market history provide reliable depreciation curves. Everyone understands roughly what a three-year-old or five-year-old F-150, Silverado, or Ram will sell for.

Electric pickups, being new to the market, offer no such certainty, and early indicators suggest their resale values may be problematic.

Battery degradation creates unique depreciation challenges. Unlike a gas engine that either works or doesn’t, batteries degrade gradually, and potential buyers have no easy way to assess remaining battery health.

A three-year-old electric pickup might have 90% battery capacity or 80%, dramatically affecting its utility and value. This uncertainty makes buyers nervous, depressing resale prices.

Additionally, as battery technology improves rapidly, older electric vehicles become obsolete faster than gas vehicles, much like smartphones or computers.

The used electric-vehicle market has exhibited concerning depreciation trends. Some electric vehicles lose 40-50% of their value in just two to three years, significantly worse than comparable gas vehicles.

While pickup trucks traditionally hold value better than sedans, it’s unclear whether electric pickups will follow traditional truck depreciation patterns or steeper EV patterns. Early Rivian R1T listings are showing substantial depreciation, though the sample size remains small.

Tax credits complicate the equation. A new electric pickup might qualify for a $7,500 federal tax credit, effectively reducing its price. This means used buyers might pay nearly the same for a used electric pickup as they would for a new one after factoring in the credit, destroying the first owner’s equity. As more manufacturers qualify for credits and production increases, this situation could worsen.

Also Read: 10 Inline-Six SUVs That Offer Serious Value