Iron has long been a symbol of strength, and this is especially true when it comes to automotive engines. 10 Classic Iron Block Engines That Are Hard to Break highlights ten engines that have earned legendary reputations for durability, reliability, and resilience under extreme conditions.

From American V8s such as the Chevrolet 350 Small-Block and Ford 4.6L Modular V8 to Japanese icons like the Toyota 2JZ and Nissan RB26DETT, these engines share a common trait: over-engineered iron blocks paired with robust internal components.

Built to handle heavy loads, high mileage, and even harsh treatment, they continue to perform where modern engines may fail.

Whether powering muscle cars, trucks, off-road vehicles, or racing machines, these engines demonstrate that careful engineering, strong materials, and conservative stress designs can produce powerplants that endure decades while remaining serviceable, tunable, and respected by enthusiasts of every generation.

1. Chevrolet 350 Small-Block: Legendary Reliability and Versatility

The Chevrolet Small-Block 350 cu in (5.7L) engine is one of the most iconic and durable engines in automotive history. Introduced in 1967 and produced for over five decades, it became the cornerstone of American muscle cars, trucks, and SUVs.

Its enduring reputation is rooted in a combination of robust materials, simple engineering, and remarkable adaptability, making it a favorite among enthusiasts, restorers, and professionals alike.

At the heart of the 350’s durability is its cast-iron construction. The grey iron block and cylinder heads resist warping and cracking under extreme heat, while many 1970s “010” blocks and later high-nickel “5419” or “96856” castings offer exceptional fatigue resistance. This robust material allows the engine to thrive in punishing conditions such as towing, racing, or overheating, making it exceptionally hard to break.

The engine’s simple overhead valve (OHV) pushrod design further contributes to reliability by minimizing failure points. Components like nodular iron cranks and, in later Vortec models (1996–2002), powdered metal connecting rods enhance bottom-end strength. The timing chain eliminates belt failures, while low-to-moderate compression reduces stress on pistons and head gaskets.

Engineered to handle heavy loads, the 350 includes optional 4-bolt mains for added durability, and Vortec upgrades such as hydraulic roller cams reduce friction and lifter wear. It is highly tolerant of misuse, including overheating or running low on oil, and repairs are straightforward thanks to global parts availability.

The massive aftermarket ecosystem addresses known weaknesses, providing high-strength bolts, upgraded gaskets, and performance modifications, effectively making the engine nearly bulletproof.

Performance varies by generation and configuration, with stock 350s producing 145–370+ horsepower and 330–350 lb-ft of torque, while high-performance variants like the 383 stroker exceed 400 horsepower. It has been widely used across GM cars, trucks, vans, and SUVs, offering versatility for daily driving, restorations, and street performance projects.

Pros include simplicity, high torque, reliability, and extensive parts support. Cons include older technology, lower fuel efficiency, and emissions limitations in early models. The Chevrolet 350 Small-Block remains a symbol of American automotive engineering, combining endurance, adaptability, and ease of maintenance with near-unmatched aftermarket support.

2. Ford 300 Inline-Six: The “Bulletproof” Workhorse

The Ford 300 Inline-Six (4.9L), often called simply the “Ford 300,” is legendary for its durability and longevity, particularly in Ford F-Series trucks from the 1960s through the 1990s. Its reputation as nearly indestructible stems from a robust, over-engineered design built for industrial applications rather than high performance.

With a focus on low-end torque, simplicity, and longevity, the Ford 300 became a favorite among truck owners, UPS fleets, and industrial operators who valued reliability above all else.

Key to its legendary toughness is its all-cast-iron construction. Both the block and cylinder head are made of cast iron, providing exceptional rigidity, heat resistance, and protection against warping or cracking under heavy loads.

The crankshaft is supported by seven main bearings, more than most engines of its era, reducing flex and dramatically strengthening the bottom end. Additionally, a gear-driven camshaft replaces timing chains or belts, eliminating a common failure point and ensuring precise valve timing for the engine’s entire lifespan.

The Ford 300’s low-stress engineering emphasizes high torque at low RPMs. Peak torque arrives around 1,600–2,000 RPM rather than horsepower, which typically ranges from 114 to 170 hp. This focus allows the engine to operate under minimal internal stress, contributing to extraordinary longevity.

Overbuilt internal components, including forged connecting rods, heavy-duty pistons, and a thick block, further enhance durability. Its inline-six layout offers straightforward maintenance and repair, making it highly serviceable even in the field.

Over decades of use, the Ford 300 has proven itself capable of exceeding 300,000 to 500,000 miles with routine maintenance. Its industrial-grade timing gears in commercial versions ensured continuous operation in tractors, generators, and cranes, further cementing its reputation as a “bulletproof” engine.

Later versions (1987–1996) incorporated fuel injection for improved efficiency, but the fundamental design remained unchanged.

Pros of the Ford 300 include unmatched reliability, exceptional low-end torque, ease of service, and extreme longevity. Its drawbacks are modest horsepower, lower fuel economy, and the weight of the cast-iron construction.

Despite these, the Ford 300 Inline-Six remains a symbol of practical engineering, designed to outlast the vehicles it powers and thrive in demanding work environments, a true working-class hero of American automotive history.

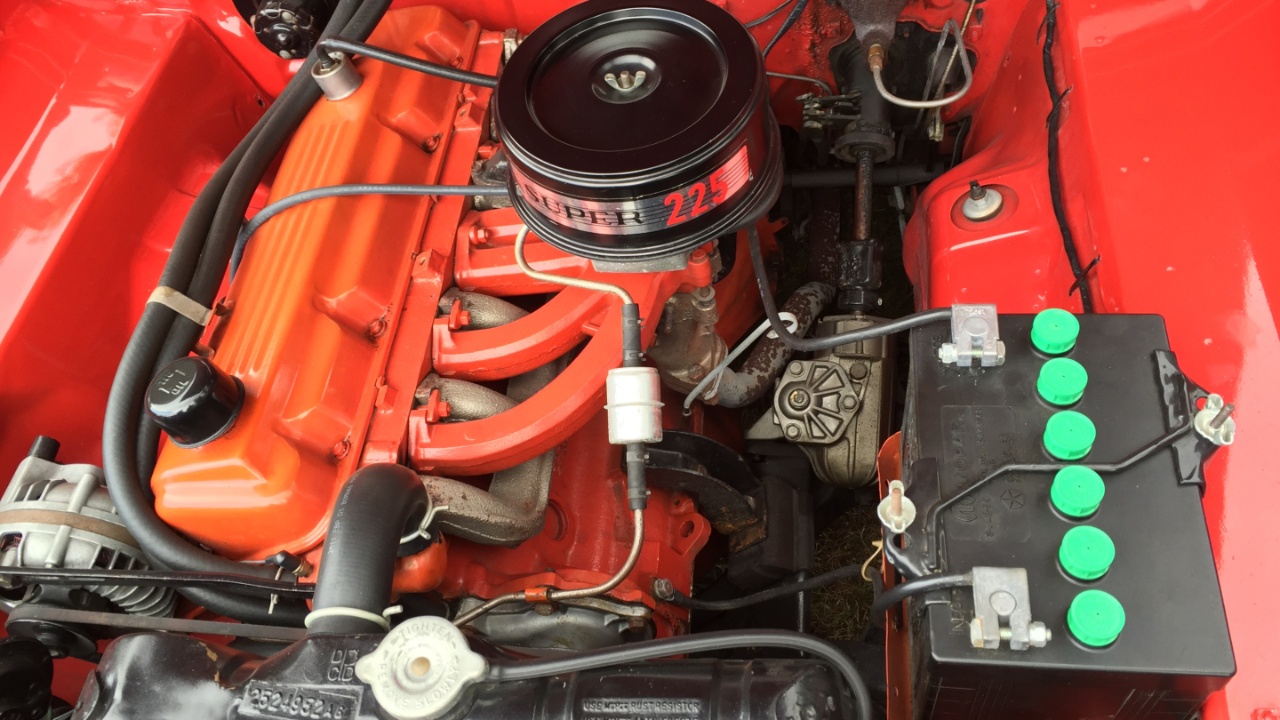

3. Chrysler 225 “Slant Six”: The Leaning Tower of Power

The Chrysler 225 cu in (3.7L) “Slant Six,” nicknamed the “Leaning Tower of Power,” is celebrated for its legendary durability and long service life. Produced between 1960 and 1983 (and later for industrial applications), this engine earned a reputation for outlasting the vehicles it powered, thanks to its overbuilt cast-iron construction, simple engineering, and conservative design philosophy.

Favored in Dodge and Plymouth cars, light trucks, and industrial equipment, the Slant Six combined reliability, torque, and ease of maintenance in a compact, low-profile package.

Durability begins with its robust cast-iron block. The engine features a thick-walled, deep-skirt block that resists cracking and flexing, paired with a forged steel crankshaft in many early models for superior bottom-end strength.

Its four-bolt main bearing design, similar to second-generation Chrysler Hemi V8s, ensures the crankshaft remains stable, while the long-stroke, low-RPM configuration focuses on torque rather than high-speed horsepower, reducing wear on internal components. Overbuilt pistons, connecting rods, and bearings further enhance its toughness, making it capable of surviving severe abuse.

The Slant Six’s simple overhead-valve pushrod design adds to its reliability. Early engines used solid lifters, later replaced by hydraulic lifters, which minimized maintenance while maintaining durability.

The 30-degree tilt allowed the engine to fit under lower hood lines and accommodated a longer intake manifold for better fuel distribution, improving efficiency and torque. Its straightforward design makes servicing easy, and parts were inexpensive and widely available, contributing to its longevity.

In real-world use, the Slant Six has a reputation for extreme resilience, with many engines exceeding 300,000–500,000 miles. It could endure extended periods without proper oil or coolant and functioned reliably in military, fleet, and industrial vehicles operating under harsh conditions or low-quality fuel.

Performance-wise, it produced roughly 145 hp and 215 lb-ft of torque, offering strong low-end power suitable for daily driving, light work, and towing rather than high-speed performance.

Pros include unmatched reliability, exceptional longevity, and simple maintenance, while cons are modest horsepower and limited high-speed performance. The Chrysler 225 “Slant Six” remains one of the most respected inline-six engines ever made, prized for its practicality, durability, and ability to withstand neglect, earning its status as a “no-nonsense” workhorse in automotive history.

4. General Motors 3800 V6: The Cockroach Engine of Reliability

The General Motors 3800 V6 (3.8L) is widely recognized as one of the most reliable engines ever produced. Nicknamed the Cockroach Engine for its ability to survive neglect and high mileage, it was manufactured from 1961 to 2008 in Series I, II, and III versions.

This pushrod, cast-iron V6 was installed in millions of GM vehicles, including Buick, Pontiac, Oldsmobile, and Chevrolet models. It often surpasses 200,000 to 300,000 miles with routine maintenance due to over-engineered components, a durable iron block, and a refined design focused on long-term durability rather than high-revving performance.

The 3800’s strength comes from its cast-iron block and cylinder heads, which resist warping, cracking, and heat-related stress. Internal components, including pistons, connecting rods, and crankshaft, are overbuilt to handle much more power than the stock output of 160–210 horsepower in naturally aspirated versions and 240–260 horsepower in supercharged models.

The simple pushrod overhead-valve design avoids the complexity of overhead cams and timing chains found in modern engines, reducing potential failure points. A balance shaft smooths vibrations in the 90-degree V6 layout, which lowers wear on internal components and engine mounts.

Designed for low-stress operation, the 3800 produces peak torque at low RPM, making it ideal for daily driving and highway use. The supercharged L67 and L32 variants were factory-built to handle increased cylinder pressures without compromising reliability. Mechanics have reported engines running after severe overheating or even on just two cylinders, demonstrating the 3800’s durability.

Known weak points include plastic upper intake manifolds, lower intake gaskets, coolant elbows, harmonic balancers, and valve cover leaks. These are minor issues that can be repaired without affecting the core engine, and parts are inexpensive and widely available.

Pros of the 3800 include extreme longevity, low maintenance requirements, excellent low- to mid-range torque, and widespread parts availability. Cons include modest high-end performance and aging plastic components that may leak.

The GM 3800 V6 remains a benchmark for durability, offering a reliable and cost-effective option for high-mileage daily drivers and commuter vehicles. Its reputation for outlasting transmissions and even chassis makes it one of the most respected iron-block engines in automotive history.

5. Toyota 2JZ Inline-Six: Bulletproof Performance and Legendary Durability

The Toyota 2JZ 3.0L inline-six engine is widely regarded as one of the most durable and over-engineered engines in modern automotive history. Produced from 1991 to 2007, it powers both performance legends like the Toyota Supra MKIV and luxury models such as the Lexus GS300 and IS300.

The engine’s cast-iron block, closed-deck design, and robust internal components make it capable of withstanding extreme stress, while its smooth inline-six configuration ensures balanced operation and long-term reliability. The 2JZ family includes two main variants: the twin-turbo 2JZ-GTE and the naturally aspirated 2JZ-GE.

The 2JZ-GTE is the high-performance flagship of the series and a favorite among tuners. Factory-rated at 276–320 horsepower with 315 lb-ft of torque, it features a sequential twin-turbo setup that minimizes lag while providing strong low-end and high-end performance.

The closed-deck cast-iron block provides exceptional rigidity, preventing cylinder wall movement or cracking under big boost. The crankshaft is forged steel, and the connecting rods and pistons are reinforced to withstand extreme pressures.

With proper modifications such as upgraded fuel systems, ECUs, and supporting hardware, the stock 2JZ-GTE bottom end can reliably handle 600–800 horsepower, and many builds have exceeded 1,000 horsepower without requiring structural changes to the block.

Oil squirters beneath the pistons and seven main bearing caps further reduce stress and improve cooling under high-power operation. The 2JZ-GTE’s robust design and massive aftermarket support make it a top choice for high-boost tuning and engine swaps.

The 2JZ-GE is the naturally aspirated sibling, designed for daily driving and reliability rather than extreme performance. Producing 212–230 horsepower and approximately 209–220 lb-ft of torque, the GE shares the same cast-iron block as the GTE, making it equally durable for long-term use.

Later VVTi versions lack factory oil squirters and forged internals, but the block is strong enough for turbocharging conversions, especially when combined with aftermarket head gaskets and internal upgrades. The GE is simpler, cheaper, and easier to maintain, making it a practical choice for daily drivers seeking smooth, linear power.

Both variants are known for their exceptional longevity, often surpassing 300,000 miles with routine maintenance. Common issues in aging engines include oil leaks at valve cover gaskets or seals, timing belt tensioner wear, and harmonic balancer deterioration. Despite these minor weaknesses, neither variant is prone to catastrophic failure, and parts remain widely available due to the engine’s popularity.

The Toyota 2JZ series combines iron-block durability, smooth inline-six operation, and an overbuilt bottom end, earning it the nickname “bulletproof.” The GTE remains the gold standard for high-boost performance builds, while the GE offers a reliable, accessible entry point with the same legendary foundation.

Its enduring reputation, strong tuning potential, and massive aftermarket support ensure the 2JZ continues to be a benchmark in automotive performance and reliability even decades after production ended.

Also Read: 10 Cars With Maintenance Schedules That Actually Matter in 2026

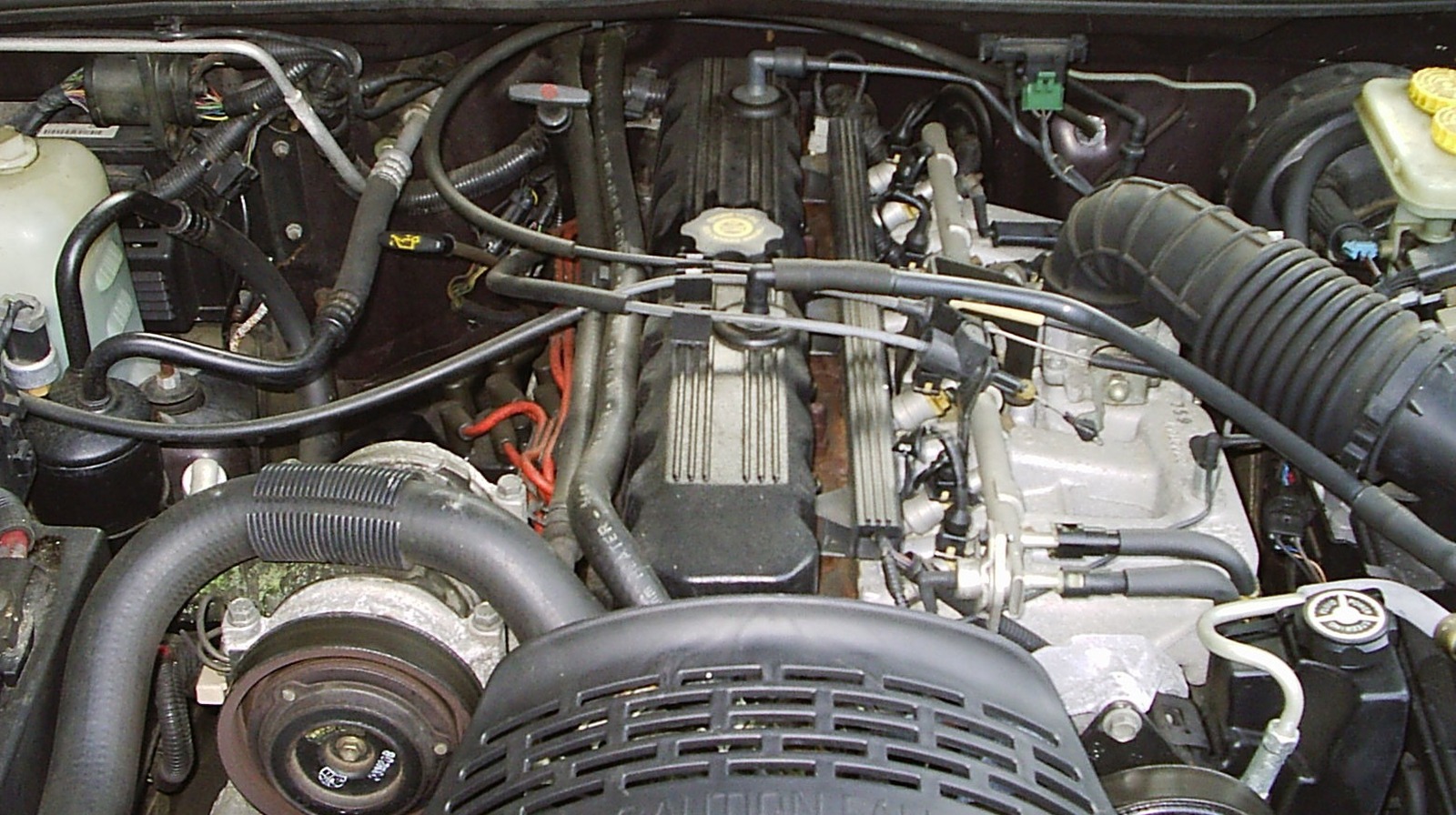

6. Jeep 4.0L Inline-Six: The Unkillable Off-Road Engine

The Jeep 4.0L Inline-Six (242 cu in) is widely regarded as one of the most durable and reliable engines ever produced. Found in Cherokee and Wrangler models from 1987 to 2006, it is celebrated for its ability to exceed 300,000 miles while handling extreme off-road conditions.

Developed by American Motors Corporation and refined by Chrysler, this engine combines an overbuilt high-nickel cast-iron block with a simple, balanced inline-six layout that focuses on low-RPM torque and long-term reliability rather than high-speed performance.

Its robust architecture is a key factor in its legendary durability. The high-nickel cast-iron block resists warping and cracking, while the crankshaft is supported by seven main bearings, providing exceptional stability and reducing bearing stress.

Heavy-duty internal components, including thick cylinder walls, a forged crankshaft, and strong connecting rods, further enhance its longevity. The engine’s slightly over-square design, with a 3.875-inch bore and 3.414-inch stroke, produces excellent low-end torque while keeping internal stresses low.

The 4.0L benefits from high-flow oil and cooling systems that maintain lubrication and prevent overheating. Its OHV pushrod configuration simplifies maintenance and reduces potential failure points compared to modern overhead-cam engines. The engine’s simplicity and durability have been refined over decades, with the High Output era from 1991 to 2006 eliminating many earlier weaknesses.

While extremely tough, the 4.0L does have minor weak points. The 0331 aluminum cylinder head on later models is prone to cracking between cylinders 3 and 4. Water pumps, plastic timing chain tensioners, and valve cover gaskets are common wear items, but failures rarely compromise the block itself. Exhaust manifold cracks and sensor issues can occur, and fuel economy is modest, typically 15–17 mpg.

Power output ranges from 173 to 195 horsepower with 220–235 lb-ft of torque, making it ideal for off-road driving, towing, and technical terrain rather than speed. Its reliable, low-RPM torque, cast-iron construction, and straightforward serviceability make it a favorite for Jeep enthusiasts and DIY mechanics.

The Jeep 4.0L Inline-Six remains a benchmark for rugged reliability. Its legendary strength, longevity, and low-end torque define the classic Jeep era, making it the preferred engine for Cherokee and Wrangler owners seeking a dependable, off-road-capable, and easy-to-maintain powerplant.

7. Ford 4.6L SOHC Modular V8 Iron Block: Durable Fleet Workhorse

The Ford 4.6L Modular V8 (SOHC, iron block) is a proven, long-lasting engine widely used in vehicles such as the Crown Victoria, Mustang, and F-150. Known for its reliability in police interceptors, taxis, and trucks, this engine combines a robust cast-iron block with a conservative internal design to handle abuse and high mileage.

Unlike aluminum-block variants, the Windsor-built iron 4.6L was engineered for endurance, making it nearly indestructible under normal operating conditions.

The engine’s strength comes from its deep-skirt cast-iron block, which extends below the crankshaft centerline to reduce flex under heavy loads. Cross-bolted main bearings further stabilize the crankshaft, while the dense, rigid cast iron resists warping under high heat or cylinder pressures.

High-tech powdered metal connecting rods and roller finger followers reduce stress on internal components, improving durability and wear resistance over hundreds of thousands of miles.

The SOHC 2-valve design contributes to reliability by keeping the valvetrain simple, with a single cam per head and basic timing chains. This design avoids the complexity of the 3-valve and 4-valve Modular engines, which introduced cam phasers and additional components prone to high-mileage failures.

The engine’s square bore and stroke configuration (3.552 × 3.543 inches) and moderate tuning prioritize longevity over peak horsepower, making it ideal for fleet and daily-use applications.

Cast iron properties further enhance the engine’s durability. The cylinder walls resist wear and maintain compression over extended use, and thermal expansion is minimal, reducing the risk of catastrophic failure if the cooling system is stressed.

Common non-structural issues include spark plug thread failure in the heads, plastic intake manifold leaks in early models, and timing chain guide wear at very high mileage. These are repairable and do not compromise the integrity of the iron block.

Power output ranges from approximately 190 hp in early models to 260 hp in late Mustang GT and Police Interceptor variants. The engine excels in work and utility roles, particularly in F-150s, Explorers, and Panther-platform sedans. The 2-valve SOHC version is considered the most reliable, durable, and easiest to maintain, while 3-valve and 4-valve variants increase complexity and require more attention.

The Ford 4.6L SOHC Modular V8 iron block remains a benchmark for fleet durability, capable of exceeding 250,000–300,000 miles with proper maintenance. Its combination of overbuilt construction, conservative design, and simple architecture makes it a practical choice for trucks, police vehicles, and any application requiring a tough, dependable V8 engine.

8. Mercedes-Benz OM617: The Bulletproof Five-Cylinder Diesel

The Mercedes-Benz OM617 3.0L inline-five diesel is widely recognized as one of the most durable engines ever built. Produced from 1974 to 1991, it powered iconic models such as the W123 300D, W116 300SD, and G-Wagen variants, earning nicknames like the “cockroach of engines” due to its incredible longevity.

Properly maintained, many OM617 engines exceed 500,000 miles, with some examples surpassing 1 million miles. Its reputation stems from a combination of over-engineered materials, conservative design, and mechanical simplicity.

The engine’s core strength lies in its heavy-duty cast-iron block and cylinder head, which resist warping under extreme heat and high compression pressures of roughly 21:1. Forged steel crankshafts and robust connecting rods further reinforce its ability to handle loads well beyond its factory output.

Power is modest, ranging from 77–88 horsepower in naturally aspirated models to 110–125 horsepower in turbocharged OM617A variants. This conservative output ensures that the engine components are rarely stressed, enhancing longevity.

Mechanical simplicity is a hallmark of the OM617. It uses a fully mechanical Bosch inline fuel injection pump and indirect pre-combustion chamber injection, avoiding complex electronics or engine control units that can fail.

The duplex double-row timing chain is exceptionally durable and rarely requires replacement. Its high-capacity oil system, holding around nine quarts, ensures effective lubrication and cooler operating temperatures for extended engine life.

The engine excels in versatility. While slow and noisy compared to modern diesels, it delivers strong, steady torque, making it ideal for off-road use, long-distance cruising, and conversions to alternative fuels like biodiesel or vegetable oil. It is commonly found in W123 and W116 sedans and wagons, G-Wagen off-road vehicles, and is a popular candidate for engine swaps into trucks, Hiluxes, and marine applications.

Weak points exist but are manageable. Turbocharged models require careful oil maintenance to protect the turbo, and all OM617 engines exhibit the characteristic diesel rattle. Despite these quirks, replacement parts remain available, and the engine’s design allows for straightforward repairs without advanced diagnostics.

The OM617 stands as a benchmark for diesel reliability, combining cast-iron durability, conservative engineering, and mechanical simplicity. It is ideal for enthusiasts seeking a low-maintenance, ultra-long-lasting engine capable of running hundreds of thousands of miles, surviving harsh conditions, and thriving on alternative fuels, making it a legend in both vintage and off-road automotive circles.

9. GM Vortec 5300: The Durable Iron-Block V8

The GM Vortec 5300 5.3L iron-block V8, part of the Gen III and Gen IV LS-series, is celebrated for its reliability, longevity, and versatility. Found in trucks and SUVs such as the Chevrolet Silverado, Tahoe, and Suburban, the LM7, L59, LY5, and LMG variants are widely regarded as “hard to break” engines.

These iron-block versions are capable of lasting 250,000 to 300,000 miles with routine maintenance and are favored for high-performance builds, often handling forced induction of 7–10 psi or more on stock internals.

The engine’s durability starts with its robust cast-iron block. The material provides superior strength and thermal stability compared to aluminum, maintaining cylinder integrity under high pressure and extreme heat.

Its deep-skirt design increases rigidity while six-bolt cross-bolted main caps prevent crankshaft flex, allowing the bottom end to withstand massive loads. The stock bottom end is well-engineered, with a strong crankshaft, rods, and pistons capable of handling high boost and extended truck duty.

The Vortec 5300’s engineering also supports longevity. Hydraulic roller lifters and rockers reduce friction and wear in the valvetrain, and efficient oiling systems, particularly in Gen IV engines, ensure consistent lubrication.

Low-RPM, high-torque tuning prioritizes truck and SUV performance, reducing stress on internal components compared to high-revving engines. The design accommodates towing, hauling, and daily driving without sacrificing reliability.

Variants include the Gen III LM7 (1999–2007) and L59 flex-fuel version, as well as Gen IV LY5 and LMG engines (2007–2014) featuring improved oiling, VVT, and head designs. Common weak points include Active Fuel Management (AFM) lifter failures and certain early 706 or 862 head castings prone to porosity or cracking. These issues are manageable and do not compromise the iron block’s structural integrity.

The Vortec 5300 is also highly mod-friendly. Bolt-on upgrades such as intakes, headers, or camshafts easily increase power, while forced induction can push the engine to 500–600+ horsepower on stock internals. Its combination of affordability, robust construction, high torque, and tuning potential makes it a favorite among truck owners, performance enthusiasts, and engine swappers.

The GM Vortec 5300 iron-block V8 represents a balance of durability, performance potential, and practicality, making it an ideal choice for heavy-duty work, daily driving, and high-power modifications alike.

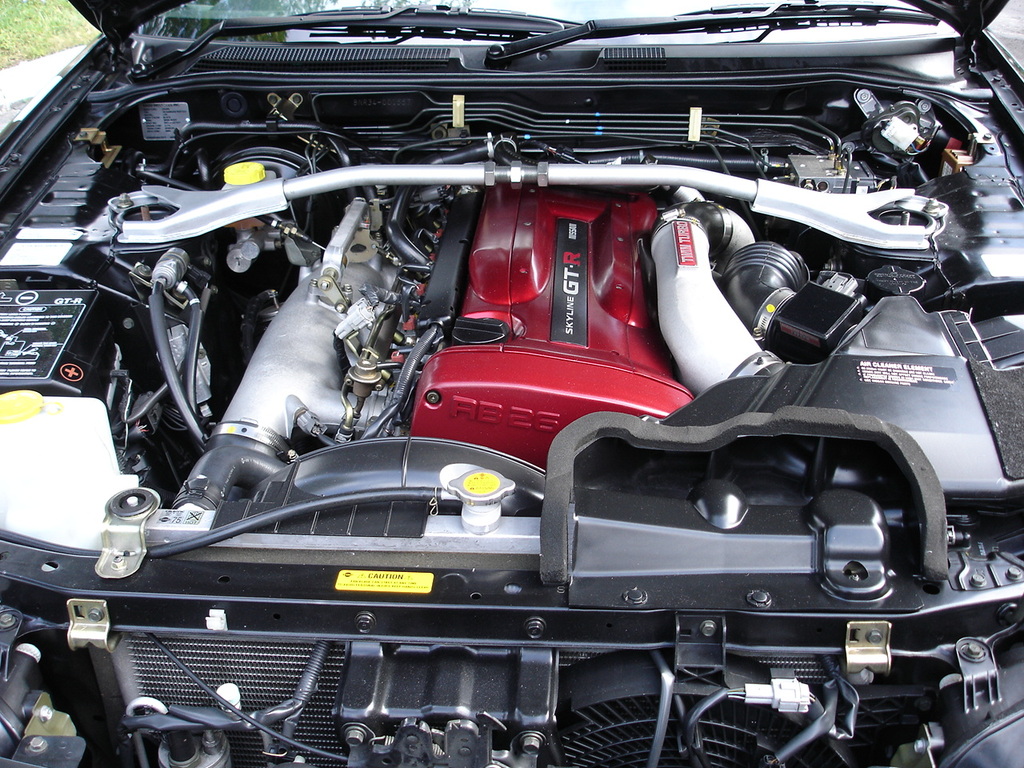

10. Nissan RB26DETT: The Iron-Bodied Inline-Six Legend

The Nissan RB26DETT 2.6-liter twin-turbo inline-six is a legendary engine, best known for powering the R32, R33, and R34 Skyline GT-Rs. Produced from 1989 to 2002, it earned a reputation as a “hard to break” performance engine thanks to its over-engineered iron block, robust internals, and racing-focused design.

Originally developed for Group A touring car homologation, the RB26 was designed to endure far more power than its stock rating, making it a favorite among tuners and enthusiasts.

At the heart of the RB26DETT is a cast-iron block with a closed-deck design. This construction provides exceptional rigidity around the cylinder walls, allowing the engine to safely handle high boost pressures without distortion.

Its iron block also resists warping under extreme heat, while the aluminum cylinder head, combined with a forged steel crankshaft and seven main bearings, ensures stability at high RPM. The engine includes piston oil squirters for cooling the pistons and reducing stress during high-performance use.

The stock RB26DETT was conservatively rated at 276 horsepower due to Japan’s voluntary “gentlemen’s agreement,” though actual output was closer to 315–330 horsepower. With this conservative rating, the engine’s components were built with a significant safety margin, enabling it to reliably handle 500–600 wheel horsepower on stock internals, and even over 800 horsepower with proper upgrades.

Racing-oriented features such as individual throttle bodies, a low compression ratio, and an inline-six configuration allow smooth high-RPM operation up to 8,000–9,000 RPM. The N1 variant further reinforced the block for endurance racing, adding thicker cylinder walls and enhanced durability.

Known weaknesses include the early R32 oil pump drive gear, which could fail at high RPM, potential oil starvation during track use, and aging cores in 30+-year-old engines. Turbocharger ceramic wheels in early models are also fragile under extreme boost, though aftermarket steel units are commonly used.

Despite these considerations, the RB26DETT remains one of the most durable Japanese performance engines of its era. Its iron-block strength, high-revving capability, and extensive aftermarket support make it a cultural icon, celebrated for raw driving feel, tuning potential, and motorsport success.

Even decades after production ended, it continues to be revered as a high-performance engine that balances reliability, power, and engineering excellence.

The ten engines presented in 10 Classic Iron Block Engines That Are Hard to Break show that durability is the result of solid engineering, quality materials, and overbuilt design. From the low-end torque of the Ford 300 Inline-Six to the high-revving performance of the RB26DETT, each engine illustrates how cast-iron construction and reinforced components can create powerplants that last hundreds of thousands of miles.

Minor issues may occur, but the core strength of these engines remains unmatched. They are ideal for long-term use, heavy-duty applications, and performance upgrades.

Together, these engines represent some of the most reliable, versatile, and enduring designs in automotive history, proving that strength and engineering excellence can create machines capable of surviving extreme conditions while continuing to deliver impressive performance.

Also read: 10 Cars With Maintenance Schedules That Actually Matter in 2026