Automatic transmissions are engineered to withstand years of commuting, highway cruising, school runs, and weekend road trips. Yet across the US, transmission replacement remains one of the most expensive repairs drivers face.

What surprises many owners is that these failures are rarely caused by manufacturing defects. Instead, they’re usually the result of everyday driving habits.

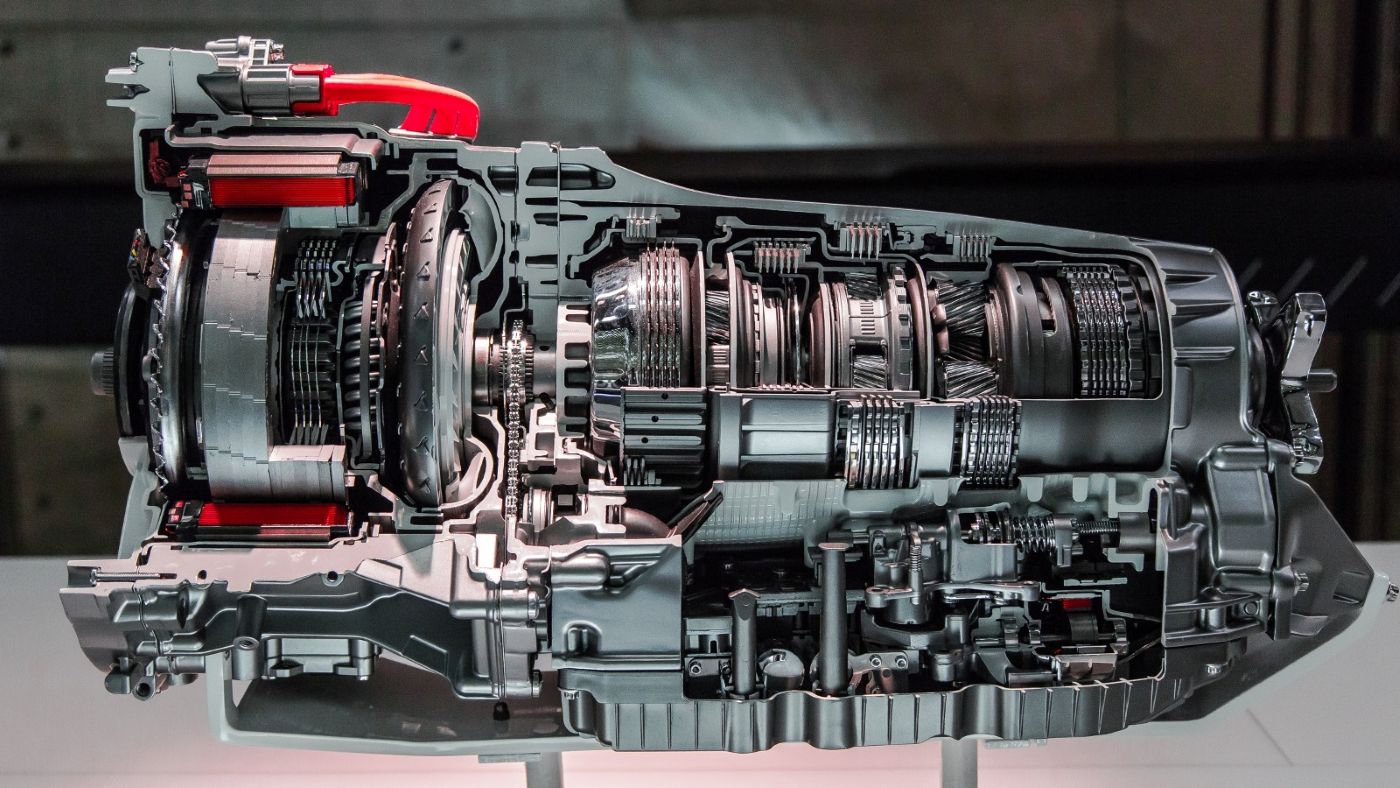

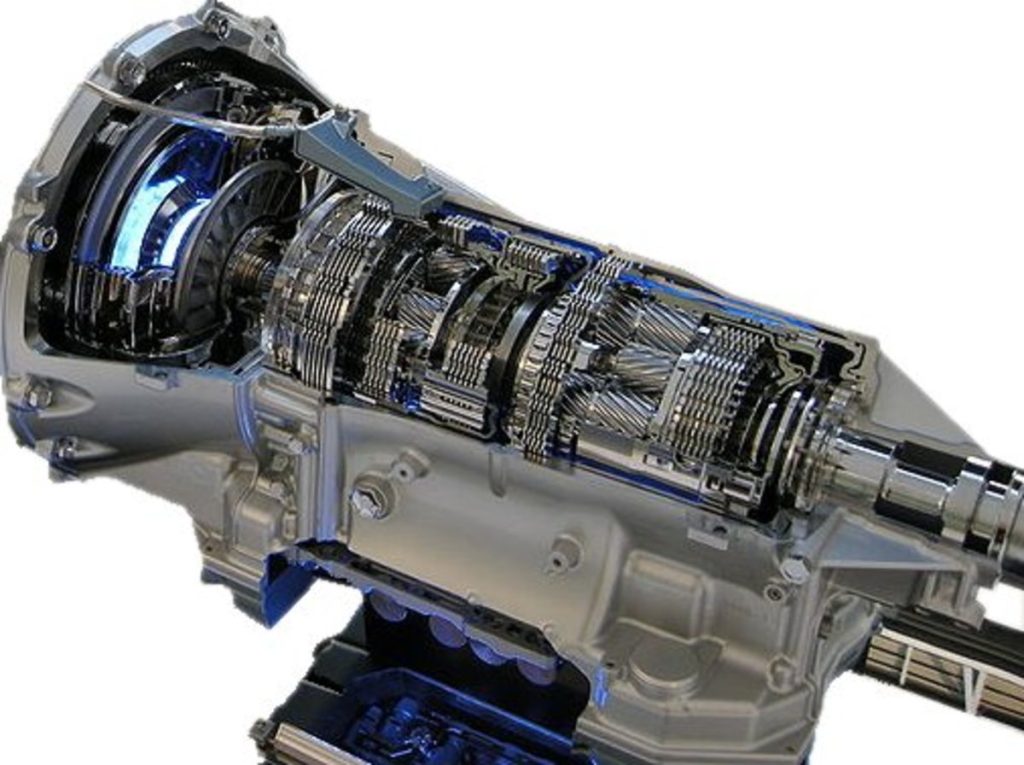

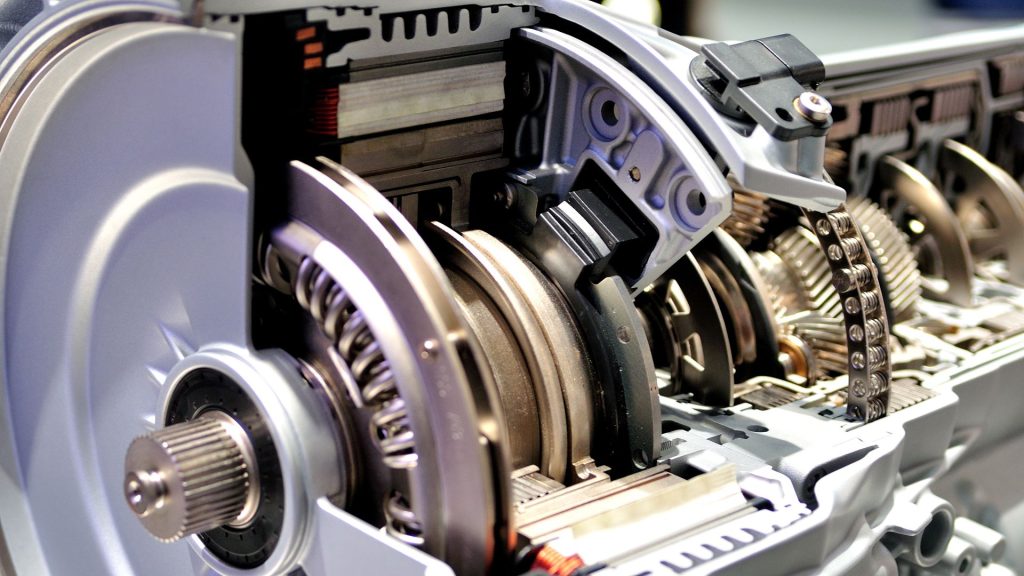

Modern automatics rely on hydraulic pressure, electronic controls, clutch packs, and clean transmission fluid working together in tight tolerances.

They are incredibly efficient, but also sensitive to heat, shock loads, and neglected maintenance. Small behaviors repeated thousands of times slowly degrade internal components until slipping, rough shifts, or total failure appear.

Understanding what not to do is one of the simplest ways to protect your vehicle and avoid a repair bill that can easily exceed several thousand dollars.

Below are ten common driving habits that quietly destroy automatic transmissions, along with practical context for American driving conditions.

1. Shifting Between Drive and Reverse Before Stopping

Changing from Drive to Reverse while the car is still rolling, even slightly, places enormous stress on internal clutch packs.

These components are designed to engage when the vehicle is stationary, not while momentum is still present.

When you shift too early, the clutches are forced to absorb that motion, creating shock loads and excessive heat.

This habit is common in parking lots and tight driveways. Over time, it leads to glazed friction surfaces, delayed engagement, and premature clutch failure. Always allow the car to come to a complete stop before changing direction.

2. Riding the Brake While Accelerating

Many drivers unknowingly press the brake pedal lightly while applying throttle, especially in stop-and-go traffic or on hills. This creates constant resistance against the drivetrain. The transmission compensates by slipping more to maintain speed, which generates heat.

Heat is the number-one killer of automatic transmissions. Elevated temperatures break down fluid, harden seals, and accelerate internal wear. In heavy metro traffic, think Los Angeles, Atlanta, or Dallas, this habit quietly shortens transmission life every single day.

When a driver habitually rides the brake, the sustained friction and heat buildup create several mechanical consequences. Continuous contact between the brake pads and rotors accelerates wear on both components, shortening their service life.

The effects extend beyond those primary friction surfaces. Excessive heat can raise brake fluid temperatures to the point of boiling, while also contributing to premature deterioration of hoses and calipers.

Prolonged braking can also lead to “brake pedal fade,” a condition in which stopping performance diminishes and greater distance is required to slow or halt the vehicle. In some cases, heat accumulation may cause gas to form between the pads and rotors, reducing effective friction and further lengthening stopping time. Over time, these factors can culminate in partial or complete brake failure.

Repeated brake riding typically results in more frequent replacement of pads and rotors or drums. These components may also develop glazing, a hardened surface condition that reduces friction efficiency. When glazing occurs, the affected rotor or drum must be resurfaced or replaced to restore proper braking performance.

Beyond mechanical wear, riding the brake introduces additional concerns. It can create uncertainty for other motorists who may struggle to determine whether you intend to stop.

Persistent brake application can also negatively affect fuel economy. The practice becomes particularly hazardous on downhill grades, where overheating risk increases, and overall accident probability rises due to reduced braking effectiveness.

Drivers who frequently navigate hills or mountainous terrain should rely more heavily on engine braking by selecting lower gears. To minimize strain on the braking system, shift into a lower gear before descending an incline.

If vehicle speed begins to increase, apply the brakes in short intervals, generally no longer than five seconds at a time, rather than maintaining constant pressure.

Keep your foot off the accelerator while traveling downhill so the engine and transmission can absorb much of the load. Depending on the vehicle, disengaging overdrive may further assist with speed control. During this process, the anti-lock braking system (ABS) may activate intermittently to prevent wheel lockup.

In winter conditions, particularly when roads are covered with snow or ice, some brake application may be necessary while descending. Maintain increased following distance and apply light, steady pressure to preserve a slow and controlled speed. If the vehicle begins to fishtail or lose traction, the ABS will engage to help maintain steering control and directional stability.

3. Skipping Transmission Fluid Service

Transmission fluid isn’t truly “lifetime,” despite what some marketing suggests. Over time, it becomes contaminated with clutch material and metal particles and loses its ability to lubricate and cool.

Many US drivers never service their transmission until symptoms appear. By then, damage has often already occurred.

Fresh fluid helps maintain proper hydraulic pressure, keeps components cool, and prevents solenoids from sticking. Regular service, especially for vehicles used in traffic-heavy areas or for towing,is one of the most effective ways to extend gearbox life.

4. Towing Without Proper Cooling

Towing campers, boats, or trailers puts extreme strain on automatic transmissions. Without an auxiliary transmission cooler, fluid temperatures can rise dramatically under load. Every increase in temperature shortens fluid life and weakens internal seals.

SUV and truck owners often assume that having a hitch means their vehicle is fully tow-ready. In reality, towing packages typically include upgraded cooling and gearing. Pulling heavy loads without this equipment essentially cooks the transmission from the inside.

When a vehicle tows a trailer or heavy load, the engine must exert additional effort to overcome the increased mass and aerodynamic drag. That added demand places greater strain on the transmission, which must manage higher torque loads and sustained operation under stress. The resulting friction within the transmission generates elevated heat levels.

A useful comparison is the difference between completing a marathon and taking a casual walk. The marathon runner’s body works at a much higher intensity, producing more heat and requiring greater cooling. In the same way, a vehicle engaged in towing operates under heavier stress, leading to increased thermal buildup within the transmission assembly.

Transmission fluid serves as the critical operating medium of the transmission system. It lubricates internal components, dissipates heat, and enables hydraulic pressure necessary for gear changes. Over time, this fluid deteriorates, gradually losing its lubricating and cooling effectiveness. The elevated temperatures associated with towing accelerate that degradation process.

Routine inspection and maintenance of transmission fluid are essential. The vehicle owner’s manual specifies the correct fluid type and recommended service intervals. Fluid condition should also be assessed visually and by odor.

An auxiliary transmission cooler is an add-on cooling component designed to enhance the capacity of the factory-installed system. It functions by circulating transmission fluid through a separate heat exchanger, where airflow reduces fluid temperature before it returns to the transmission. This additional cooling loop significantly improves the system’s ability to manage heat under load.

Installing an auxiliary cooler is among the most effective preventative measures against transmission overheating during towing. Available designs include tube-and-fin and stacked-plate configurations. Stacked-plate coolers generally provide superior heat dissipation compared to tube-and-fin models.

Selection should be based on anticipated towing weight and operating environment. Vehicles used for heavier loads or in hotter climates typically benefit from larger-capacity coolers.

Maintaining awareness of transmission temperature is critical to avoiding thermal damage. Many vehicles are not equipped with a factory-installed transmission temperature gauge. Adding an aftermarket gauge enables real-time monitoring, allowing the driver to intervene if temperatures approach unsafe thresholds.

Transmission temperature can be tracked using analog or digital gauge systems. Alternatively, a scan tool or diagnostic device can access temperature data through the vehicle’s onboard computer. For accurate readings, consult a repair manual or a qualified technician to determine the proper sensor placement and installation procedure.

5. Using Park Instead of the Parking Brake

On slopes, many drivers shift into Park and skip the parking brake. When this happens, the vehicle’s entire weight rests on a small metal component inside the transmission called the parking pawl.

Over time, this causes hard engagement when shifting out of Park and adds stress to internal gearsets.

On steep driveways or hilly streets, the damage accumulates faster. Applying the parking brake first and then selecting Park transfers the load to the brake system, which is designed to handle it.

6. Driving Aggressively on Cold Starts

Transmission fluid thickens in cold temperatures, reducing lubrication and slowing hydraulic response. Flooring the accelerator immediately after startup forces the transmission to shift while poorly lubricated.

In colder parts of the US, this habit is especially damaging during winter months. Allowing the car a few minutes of gentle driving gives fluid time to circulate and reach operating temperature, significantly reducing wear on clutches and valve bodies.

7. Constant Creeping in Traffic

In congested urban traffic, many drivers inch forward continuously instead of letting gaps form. This means the transmission is constantly engaging and disengaging first gear, creating repeated low-speed slipping.

That constant engagement generates heat and wears clutch packs prematurely. Over years of commuting, the damage becomes substantial. Leaving a small buffer and moving in larger increments reduces engagement cycles and lowers internal temperatures.

8. Resting Your Hand on the Gear Selector

It seems harmless, but resting your hand on the shifter applies small amounts of pressure to shift mechanisms or electronic selector components. In older vehicles, this can cause gradual linkage misalignment. In newer cars, it can stress sensors and selector assemblies.

While this habit alone won’t destroy a transmission, combined with others it adds unnecessary wear over time.

A vehicle’s transmission is a precisely engineered assembly intended to operate without unnecessary external load. Habitually resting your hand on the gearshift introduces continuous pressure into the shift linkage and internal components. Over time, that added force can accelerate wear and contribute to avoidable mechanical failures. Several specific effects are associated with this practice.

Placing steady pressure on the gearshift transfers force to internal transmission components, particularly the synchronizers and supporting bearings. Synchronizers are engineered to align gear speeds during shifts, enabling smooth engagement.

Because they are designed for intermittent load rather than constant pressure, even modest additional force can increase wear rates. Premature degradation may manifest as notchy shifting, gear engagement difficulty, or ultimately the need for costly transmission repairs.

Resting a hand on the shifter can also create slight but continuous internal contact within the transmission assembly. While friction is inherent to gear operation, unnecessary load amplifies contact stress between moving parts. Over time, this can accelerate wear on gear teeth and related components, reducing overall transmission efficiency and durability.

The cumulative effect of sustained pressure on bearings, elevated friction, and synchronizer wear is a shortened service life for the transmission. A unit subjected to chronic external load is more likely to require major repair or full replacement earlier than one operated according to proper driving practices.

Safe driving principles emphasize maintaining both hands on the steering wheel to ensure maximum control. When one hand remains on the gearshift, steering input becomes less stable, particularly in situations requiring abrupt maneuvering, such as obstacle avoidance or sudden braking.

In emergency scenarios, rapid and precise steering adjustments are critical. If a driver’s hand is positioned on the gearshift instead of the wheel, the transition to full steering control may be delayed, reducing responsiveness in time-sensitive situations.

Diminished steering control and delayed reactions can heighten accident risk, particularly during unexpected events. Drivers who do not consistently maintain both hands on the wheel are more susceptible to control errors, which can compromise their own safety as well as that of other road users.

9. Flooring the Throttle at Low Speeds in High Gear

Pressing hard on the accelerator while cruising in a high gear forces the transmission to either lug the engine or perform a sudden kickdown.

Repeated aggressive throttle inputs at low RPM strain clutch packs and torque converters, especially in heavier vehicles with smaller engines.

Progressive acceleration or allowing the transmission time to downshift smoothly reduces this stress and improves long-term reliability.

10. Ignoring Early Warning Signs

Automatic transmissions almost always provide warning before failure. Delayed engagement, rough or slipping shifts, unusual noises, burning smells, or dashboard warning lights are signals that something is wrong.

Many drivers continue driving for months after these symptoms appear. What could have been fixed with a fluid service or minor repair often turns into a full rebuild. Early attention saves money and prevents catastrophic damage.

Automatic transmissions rarely fail suddenly. They wear out gradually, one bad habit at a time. By becoming more mindful of how you drive, you can protect one of the most expensive components in your vehicle.

In a country where replacement costs routinely climb into the thousands, smart driving isn’t just about mechanical sympathy, it’s a practical investment in long-term reliability.