A team of mechanics took apart a high-performance Ford Coyote V8 engine used for drag racing to see how well it held up under intense competition.

Building a powerful engine takes time to ensure efficiency and reliability.

Experienced drag racer Brett Lasala examines his twin-turbocharged Coyote V8 engine with expert help.

Upgrading head gasket components and crankshaft is crucial for increasing the power output of the Coyote V8 without risking failure.

Developing a high-power engine like the Coyote V8, capable of reaching around 3,000 horsepower, requires careful engineering to ensure it can handle the stress of racing without breaking down.

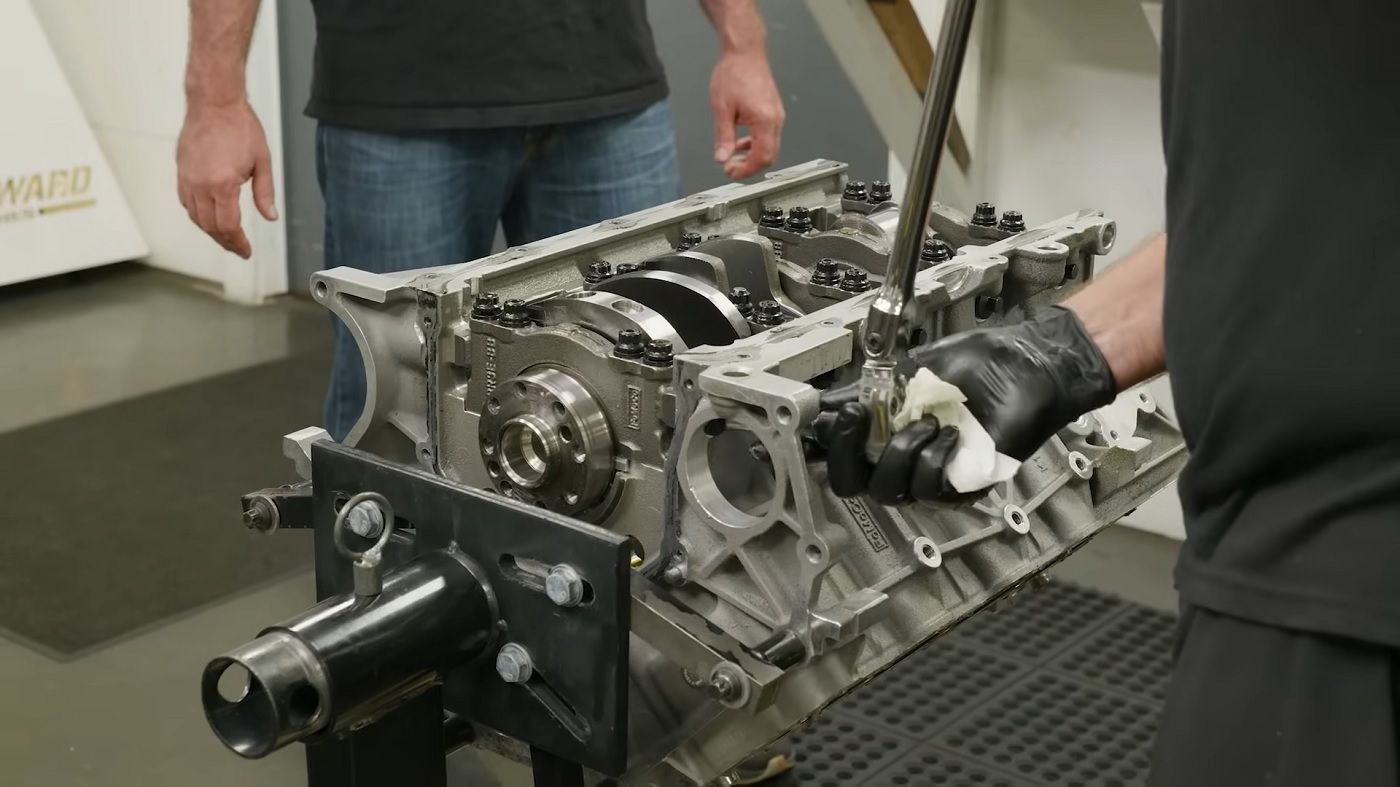

Brett Lasala, a seasoned drag racer, runs a Ford Mustang equipped with a twin-turbocharged Coyote V8 engine. He decided to dismantle one of his racing engines to assess its performance and make necessary improvements.

Brett encountered some issues during previous racing seasons, particularly noticing excessive wear on the main bearings towards the end of the campaign.

He suspected that the stock crankshaft provided with the Ford crate motor was partly to blame. To investigate further, he turned to expert builders who explained that engine development is an ongoing process, with occasional setbacks inevitable as they strive to increase power output.

Disassembling the engine after multiple races allowed them to observe how it responded to stress. They identified areas for improvement to prevent potential engine failure. Brett revealed that they had pushed the engine to nearly 3,000 horsepower on the dyno and around 2,700 horsepower in competition.

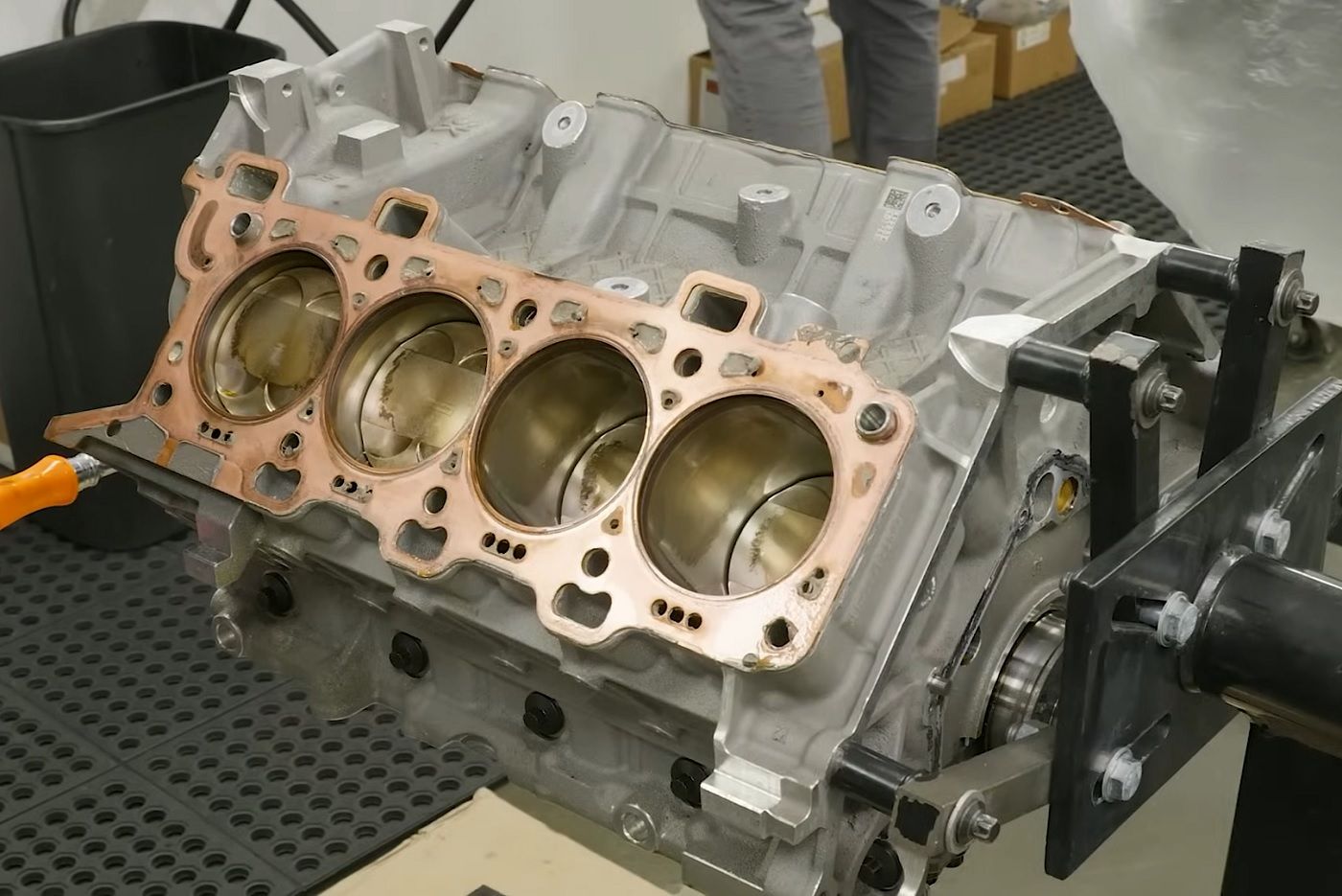

However, increasing the boost to reach these power levels posed challenges, causing issues such as head gasket failure.

The mechanics first inspected the engine’s heads and noticed areas for enhancement, particularly with the head stud and washer types. Upgraded studs and textured washers were recommended to better withstand the engine’s high pressure. They also observed signs of head gasket damage, likely caused by coolant leaks, which could lead to costly failures if left unaddressed.

Brett also discovered debris in the oil filter after races, indicating internal issues within the engine. Problems with the crankshaft, such as flexing and thrust bearing displacement, further prompted the need for upgrades to ensure long-term reliability.

Despite these challenges, the mechanics found the engine’s pistons in good condition, suggesting that additional coatings could enhance their durability. They planned to upgrade the crankshaft and implement a revised head gasket sealing system to prevent future coolant leaks.

Moving forward, Brett aims to address issues with head stability and continue optimizing the engine for maximum power output. By identifying weaknesses and making strategic upgrades, he hopes to achieve peak performance on the racetrack without compromising reliability.