The V8 engine configuration holds a special place in automotive history, delivering the perfect balance of power, smoothness, and character that enthusiasts crave.

While V8s are often celebrated for their performance credentials, certain designs have earned legendary status for an entirely different reason: their incredible durability.

These exceptional V8 engines represent the pinnacle of engineering excellence, where robust construction, conservative tuning, and intelligent design converge to create powerplants capable of astronomical mileage figures.

From American workhorses that power millions of trucks to sophisticated European and Japanese designs that combine performance with reliability, these engines demonstrate that power and longevity need not be mutually exclusive.

What separates these extraordinary V8s from their less durable counterparts? Typically, they feature overbuilt blocks with substantial cylinder wall thickness, forged internal components or high-quality cast parts with generous safety margins, well-designed oiling systems, and conservative factory tuning that keeps operating stresses well below material limits.

Many were developed during eras when manufacturers prioritized service life over maximum specific output or when commercial applications demanded bulletproof reliability.

The engines on this list have repeatedly demonstrated their durability through millions of collective miles on highways, job sites, and race tracks worldwide.

Their reputations have been built not in marketing departments but in the real world, where they continue functioning long after other vehicle components have surrendered to time and wear.

From classics that have stood the test of decades to more modern designs that carry their legacy forward, these are the ten V8 engines that have truly earned their reputation for exceptional longevity.

1. Toyota 1UZ-FE

The Toyota 1UZ-FE V8 engine, introduced in 1989 and produced in 2002, represents one of the most overengineered powerplants ever developed for production vehicles.

First appearing in the Lexus LS400, this 4.0-liter all-aluminum V8 was Toyota’s declaration of war against established German and American luxury brands.

What makes the 1UZ-FE truly exceptional is that it wasn’t merely designed to compete with the best V8s from Mercedes-Benz and BMW it was engineered to outlast them.

The 1UZ-FE’s extraordinary durability begins with its block construction. Despite being aluminum for weight savings, Toyota incorporated cast iron cylinder sleeves and six-bolt main bearing caps an unusual feature typically reserved for high-performance racing engines.

This construction provided the lightweight benefits of aluminum while maintaining the strength characteristics of traditional iron blocks.

The crankshaft, machined to aerospace tolerances, rides on these overbuilt main bearings with minimal deflection even after hundreds of thousands of miles.

What truly distinguishes the 1UZ-FE is its valvetrain design. The dual overhead camshaft layout with four valves per cylinder was advanced for its era, but Toyota’s implementation emphasized longevity alongside performance.

The timing belt, though a worn item requiring periodic replacement, was designed with substantial width and tooth engagement that virtually eliminated failures even beyond recommended service intervals.

The belt drives camshafts featuring extraordinarily durable lobes that show minimal wear even after 200,000+ miles of service.

The engine’s lubrication system deserves particular recognition, featuring a high-capacity oil pump and generous oil passages ensuring critical components receive abundant lubrication under all operating conditions.

The sophisticated electronic engine management system maintained precise fuel delivery and ignition timing, preventing the damaging lean conditions or detonation that often shortens engine life in less refined designs.

Perhaps most telling about the 1UZ-FE’s durability is that it received certification for aircraft use a testament to its reliability under sustained high-output operation.

This certification required meeting stringent standards for component durability and failure resistance far beyond typical automotive requirements.

In the real world, these engines routinely accumulate 300,000+ miles without internal repairs, while properly maintained examples frequently approach 500,000 miles with only basic servicing.

The 1UZ-FE’s combination of overbuilt components, precision manufacturing, and conservative tuning created what many consider the most reliable V8 ever mass-produced.

While the Lexus vehicles these engines power eventually succumb to transmission issues, electrical problems, or body degradation, their V8 hearts often continue beating flawlessly, frequently finding new homes in custom projects where their legendary durability continues to be appreciated by a new generation of enthusiasts.

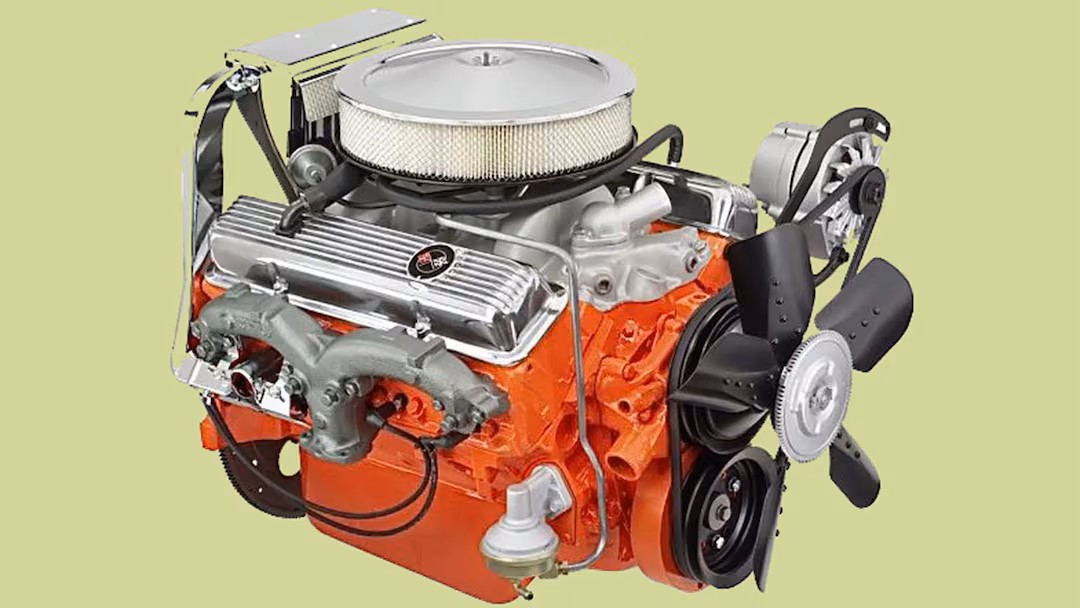

2. Chevrolet Small-Block V8 (Gen I)

The original Chevrolet Small-Block V8, introduced in 1955 and produced with minimal fundamental changes until 2003, stands as perhaps the most influential engine design in American automotive history.

This remarkably versatile powerplant, offered in displacements ranging from 262 to 400 cubic inches (4.3 to 6.6 liters), powered everything from family sedans and pickup trucks to iconic muscle cars and racing legends.

What began as the 265 cubic inch “Turbo-Fire” V8 evolved through numerous iterations while maintaining its core design principles and extraordinary durability.

The Small-Block’s exceptional longevity stems from several key attributes. Its simple and efficient design features overhead valves actuated by pushrods and a single camshaft an architecture that minimizes moving parts while providing excellent reliability.

The deep-skirt block design, where the crankcase extends well below the crankshaft centerline, provides exceptional rigidity that maintains precise bearing alignment even after decades of use.

The cast iron construction offers excellent vibration damping and thermal stability, preventing the warping that often compromises aluminum designs in severe service.

What truly distinguishes the Small-Block is its oiling system, which delivers exceptional lubrication to critical components.

The full-pressure lubrication system maintains proper oil flow to bearings and other crucial parts even at high RPMs or during extended operation.

This superior lubrication, combined with relatively conservative internal clearances in stock applications, results in minimal wear even after hundreds of thousands of miles.

The Small-Block’s timing chain design eliminates the maintenance concerns associated with timing belts, while its cast iron heads (in most variants) provide excellent heat stability.

Throughout its evolution, the basic architecture remained fundamentally sound, allowing for continuous refinement without sacrificing the inherent durability.

Even as power increased from the original 162 horsepower to 400+ in later high-performance variants, the basic structure proved more than capable of handling the additional stress.

Perhaps most significant to the Small-Block’s legendary status is its massive aftermarket support and simplicity of repair.

Nearly every component remains readily available, and most maintenance can be performed with basic tools.

This accessibility has ensured that these engines can be economically maintained and rebuilt multiple times, often outlasting several vehicle bodies.

It’s not uncommon to find original Small-Blocks with 300,000+ miles still running strong, or rebuilt examples continuing service well beyond the half-million mile mark.

The Small-Block’s influence extends far beyond its original applications, establishing design principles that informed subsequent generations of GM V8s.

Its combination of simplicity, robust construction, excellent oiling, and massive parts availability created what many consider the definitive American V8 an engine so durable and versatile that its basic architecture continued influencing engine design long after the original went out of production.

3. Mercedes-Benz M116/M117

The Mercedes-Benz M116 and M117 V8 engines, produced from 1969 to 1991, represent the pinnacle of old-school German engineering philosophy where durability took absolute precedence over manufacturing cost.

These engines powered Mercedes’ flagship models including the S-Class, SL, and SEC coupes during an era when the company’s reputation for building “over-engineered” vehicles reached its zenith.

Available in displacements ranging from 3.5 to 5.6 liters, these V8s became legendary for their ability to accumulate astronomical mileage figures while maintaining smooth, quiet operation.

The extraordinary durability of these engines begins with their basic construction.

The cast iron block features extraordinarily thick cylinder walls and main bearing supports, providing exceptional rigidity and thermal stability under all operating conditions.

The aluminum heads house single overhead camshafts per bank, driven by a duplex timing chain system designed for the lifetime of the vehicle.

This timing system, featuring two parallel chains with hydraulic tensioners, virtually eliminates the timing failures that often plague lesser designs.

What truly distinguishes the M116/M117 series is Mercedes’ meticulous engineering approach.

The crankshaft, machined from forged steel and featuring seven main bearings, provides exceptional support for the rotating assembly with minimal deflection even after hundreds of thousands of miles.

The connecting rods and pistons were similarly overbuilt, operating well below their mechanical limits in standard tune.

The oiling system features a high-capacity pump and generous oil passages ensuring critical components receive abundant lubrication even during high-speed autobahn cruising.

The fuel injection systems employed on these engines deserve particular recognition.

The Bosch mechanical fuel injection used in early versions (transitioning to electronic injection in later models) was engineered with the same no-compromise approach as the basic engine structure.

These sophisticated systems maintain precise fuel delivery under all operating conditions, preventing the damaging lean conditions that often shorten engine life in less refined designs.

Perhaps most telling about these engines’ durability is their performance in extreme environments.

From the scorching heat of Middle Eastern deserts to the bitter cold of Scandinavian winters, these powerplants maintain consistent operation regardless of conditions.

The engines’ ability to withstand thermal shock starting and operating correctly from extreme cold revealed materials selection and engineering tolerances that prioritized longevity above all else.

While the M116/M117 V8s developed modest power by modern standards (ranging from 200 to 300 horsepower depending on displacement and variant), they delivered this output with exceptional refinement and reliability.

Their combination of overbuilt components, sophisticated engineering, and conservative tuning created powerplants that routinely exceed 300,000 miles without internal repairs, with properly maintained examples frequently surpassing 500,000 miles.

These engines embody Mercedes’ golden-era engineering philosophy where longevity was considered the ultimate luxury feature an approach that earned these V8s enduring respect among enthusiasts worldwide.

4. Ford Modular V8 (4.6L 2-Valve)

The Ford 4.6-liter Modular V8 in its 2-valve configuration, introduced in 1991 and produced in 2010, represents one of the most successful transitions from traditional pushrod designs to modern overhead cam architecture.

This powerplant, which replaced the venerable Windsor V8 family, initially faced skepticism from Ford loyalists who questioned whether a more complex design could match the legendary durability of its predecessor.

Over three decades of service in everything from Crown Victoria police interceptors to F-150 trucks and Mustang GTs, the 2-valve Modular V8 definitively answered those doubts, establishing itself as perhaps the most reliable American overhead cam V8 ever produced.

The Modular’s exceptional longevity stems from several key design elements. The deep-skirt iron block provides exceptional rigidity, maintaining precise bearing alignment even after hundreds of thousands of miles.

Unlike many modern engines that prioritize weight savings over durability, Ford engineered this block with substantial material thickness in critical areas.

The aluminum heads, despite being a potential durability concern compared to traditional iron heads, feature robust construction and excellent cooling properties that prevent the warping that often compromises longevity in overhead cam designs.

What truly distinguishes the 2-valve Modular is its valvetrain design. While overhead cam arrangements typically introduce additional complexity and potential failure points compared to pushrod designs, Ford’s implementation emphasized reliability alongside performance.

The timing chains, though requiring more maintenance than the gear-driven systems of earlier Ford V8s, were engineered with substantial safety margins.

The relatively low-stress camshaft profiles used in the 2-valve design (compared to later 3-valve and 4-valve variants) further contributed to exceptional valvetrain durability.

The engine’s lubrication system deserves particular recognition, featuring a high-capacity oil pump and generous oil passages ensuring critical components receive abundant lubrication under all operating conditions.

The cooling system, with its efficient flow characteristics and substantial capacity, maintains consistent temperatures that prevent the thermal stress that often shortens engine life in less refined designs.

Perhaps most telling about the 2-valve Modular’s durability is its performance in severe-duty applications.

In police interceptors and taxi fleets, these engines routinely accumulated 300,000+ miles under the most demanding conditions imaginable extended idling, frequent high-speed operation, and often minimal maintenance.

Their ability to withstand this punishing service while maintaining reliability established the 2-valve Modular as the standard for durability in American fleet applications.

The 4.6L 2-valve Modular’s combination of robust construction, conservative tuning, and proven durability across millions of vehicles created a powerplant that successfully bridged traditional American V8 values with modern overhead cam technology.

While producing modest power by current standards (ranging from 210 to 260 horsepower depending on application and year), these engines delivered this output with exceptional reliability, frequently outlasting the vehicles they powered and establishing engineering principles that continue influencing Ford engine design today.

Also Read: 10 Forgotten Automakers That Deserve a Comeback

5. Lexus/Toyota 2UZ-FE

The Toyota 2UZ-FE V8 engine, produced from 1998 to 2011, represents Toyota’s successful adaptation of over-engineered durability principles to a larger displacement truck and SUV platform.

This 4.7-liter powerplant powered vehicles include the Toyota Land Cruiser, Tundra, and Sequoia, along with Lexus LX470 and GX470 models.

Developed as a larger companion to the legendary 1UZ-FE, the 2UZ-FE was specifically designed to deliver exceptional reliability under severe operating conditions while providing the torque characteristics needed for heavy-duty applications.

The 2UZ-FE’s extraordinary durability begins with its unique construction approach.

Unlike its all-aluminum 1UZ sibling, Toyota engineered the 2UZ with a cast iron block topped with aluminum heads a hybrid approach that combined the superior rigidity and thermal stability of iron with the weight advantages and cooling properties of aluminum.

This block features exceptional wall thickness and main bearing support structures that maintain precise alignment even after hundreds of thousands of miles of heavy-duty service.

What truly distinguishes the 2UZ-FE is its valvetrain design. The dual overhead camshaft layout with four valves per cylinder provides excellent breathing characteristics, while Toyota’s implementation emphasized longevity alongside performance.

Unlike many overhead cam engines that employ timing belts, Toyota equipped the 2UZ-FE with a timing chain designed for the lifetime of the engine.

This chain drives camshafts featuring extraordinarily durable lobes that show minimal wear even after 300,000+ miles of service.

The engine’s lubrication system deserves particular recognition, featuring a high-capacity oil pump and generous oil passages ensuring critical components receive abundant lubrication under all operating conditions.

The sophisticated cooling system maintains consistent temperatures that prevent the thermal stress that often shortens engine life in less refined designs, particularly important in heavy-duty applications where sustained loads can create challenging thermal management situations.

Perhaps most telling about the 2UZ-FE’s durability is its performance in extreme environments.

From the Australian Outback to Alaskan winters, these engines maintain consistent operation regardless of conditions.

Toyota’s testing regime for these powerplants included extended operation in the harshest environments, ensuring that the production engines incorporated substantial safety margins for all components.

The 2UZ-FE’s combination of robust construction, conservative tuning, and proven durability across global markets created a powerplant that successfully delivered on Toyota’s reputation for reliability in its most demanding applications.

While producing modest power by current standards (ranging from 230 to 270 horsepower depending on application and year), these engines delivered this output with exceptional dependability, frequently achieving 400,000+ miles without internal repairs when properly maintained.

This engine’s legacy continues influencing Toyota’s approach to truck powertrains, where the company consistently prioritizes proven durability over maximum power output or cutting-edge technology implementation a philosophy that has earned Toyota trucks their legendary status for longevity in the most challenging environments worldwide.

6. Chevrolet LS V8 Family

The Chevrolet LS engine family, introduced in 1997 and continually evolved through multiple generations, represents General Motors’ masterful reinvention of the small-block V8 concept for the modern era.

This remarkably versatile engine architecture, offered in displacements ranging from 4.8 to 7.0 liters, has powered everything from Corvettes and Camaros to Silverado trucks and Suburban SUVs.

The LS engines brilliantly combined traditional small-block virtues compact dimensions, lightweight, and simplicity with modern materials and design techniques to create what many consider the definitive American V8 of the 21st century.

The LS family’s exceptional durability stems from several key innovations. While maintaining the traditional 90-degree V8 configuration and cam-in-block architecture of its predecessors, the LS introduced a rigid aluminum block design (iron blocks in truck applications) with cross-bolted main bearing caps that provide exceptional rigidity.

This deep-skirt block design, where the crankcase extends well below the crankshaft centerline, maintains precise bearing alignment even after hundreds of thousands of miles.

The six-bolt cross-bolted main caps on performance variants provide extraordinary strength that virtually eliminates main cap walk and bearing misalignment even under extreme conditions.

What truly distinguishes the LS architecture is its cylinder head design. The symmetrical port layout with cathedral or rectangular intake ports (depending on generation) provides excellent breathing while maintaining compact dimensions.

The valvetrain, utilizing investment-cast rocker arms actuating lightweight hollow-stem valves, delivers exceptional durability compared to the stamped rocker arms of earlier small-blocks.

The timing chain system employs a single, robust chain with a hydraulic tensioner designed for the lifetime of the engine, eliminating the maintenance concerns associated with timing belts.

The oiling system deserves particular recognition, featuring improved oil passage routing and a high-capacity pump that maintains proper oil pressure even under high-RPM operation.

The improved cooling jacket design, with enhanced water flow around critical areas, prevents the hot spots that often compromise longevity in high-performance applications.

These refinements allow LS engines to handle substantial power increases while maintaining reliability that earlier generations couldn’t match.

Perhaps most remarkable about the LS family is its adaptability across diverse applications while maintaining core durability characteristics.

From low-RPM truck tuning to high-strung performance applications, the basic architecture proves exceptionally robust.

In truck applications, these engines routinely exceed 300,000 miles without internal repairs, while even performance variants demonstrate longevity that embarrasses many competitors.

The LS engine’s combination of intelligent evolution, robust construction, and exceptional engineering created a V8 architecture so successful that it has become the default choice for engine swaps across countless platforms.

Its perfect balance of traditional V8 virtues with modern engineering techniques established a durability standard that continues to influence engine design throughout the industry.

The LS family demonstrated conclusively that a modern, emissions-compliant V8 could maintain the legendary reliability characteristics that made the original small-block an American icon a remarkable achievement that ensures these engines will power vehicles for decades to come.

7. Rover V8

The Rover V8 engine, produced from 1967 to 2004, represents one of the most successful engine adaptations in automotive history.

Originally designed by General Motors as the Buick 215 V8, this lightweight aluminum powerplant gained new life when Rover acquired the design rights and refined it into what would become a British institution.

Offered in displacements ranging from 3.5 to 5.0 liters, the Rover V8 powered everything from luxury sedans and Land Rovers to sports cars like the MGB GT V8 and TVR models.

What makes this engine truly remarkable is not just its adaptability but its extraordinary longevity both in terms of production lifespan and the durability of individual engines.

The Rover V8’s exceptional durability stems from several key attributes. The all-aluminum construction radical for its era provided substantial weight savings (approximately 200 pounds lighter than equivalent iron blocks) while maintaining adequate strength for normal service.

Rover’s refinements to the original Buick design included improved cooling properties and revised oiling systems that addressed weaknesses in the original implementation.

The deep-skirt block design provides excellent rigidity, maintaining precise bearing alignment even after hundreds of thousands of miles.

What truly distinguishes the Rover V8 is its simplicity and serviceability. The overhead valve design with pushrods and a single camshaft minimizes moving parts while providing excellent reliability.

The timing chain system, while requiring periodic inspection, proved remarkably durable when properly maintained.

This mechanical simplicity made the engine extraordinarily tolerant of varying maintenance standards a significant advantage in the diverse global markets where these engines served.

The engine’s lubrication system deserves particular recognition, especially as refined in later iterations.

The improved oil pump and revised oil circulation paths ensured critical components received adequate lubrication under all operating conditions.

This refinement addressed early concerns about aluminum block durability and contributed significantly to the engine’s reputation for longevity.

Perhaps most telling about the Rover V8’s durability is its performance in extreme environments.

In Land Rover applications particularly, these engines encountered some of the most challenging conditions imaginable from scorching deserts to Arctic cold, often while being subjected to sustained high loads and challenging angles that compromised oil circulation.

Their ability to withstand these conditions while maintaining reliability established the Rover V8 as the heart of Land Rover’s legendary expedition vehicles.

The Rover V8’s combination of lightweight construction, mechanical simplicity, and continuous refinement created a powerplant that remained relevant for nearly four decades.

While producing modest power by modern standards (ranging from 130 to 300 horsepower depending on displacement, tuning, and era), these engines delivered this output with distinctive character and remarkable reliability.

Properly maintained examples routinely exceed 200,000 miles without internal repairs, with many accumulating substantially higher mileage figures.

This engine’s extraordinary production longevity spanning from the era of carburetors and points ignition through electronic fuel injection and modern engine management testifies to the fundamental soundness of its design and Rover’s successful refinement of the original Buick concept into one of the most versatile and durable V8 engines ever produced.

8. AMC/Jeep 304/360/401 V8

The American Motors Corporation (AMC) V8 engine family, produced from 1966 to 1991, represents one of the most underrated yet exceptionally durable American V8 designs.

These engines, offered in displacements of 304, 360, and 401 cubic inches (5.0, 5.9, and 6.6 liters), powered various AMC vehicles and, most notably, became the heart of Jeep’s lineup following AMC’s acquisition of the brand in 1970.

What makes these engines truly remarkable is not cutting-edge technology or extraordinary power output, but rather their anvil-like durability under the most punishing conditions imaginable.

The AMC V8’s exceptional longevity stems from its fundamental design philosophy of robust simplicity.

The cast iron block and heads feature extraordinarily thick walls and deck surfaces that resist warping even under extreme heat conditions or with compromised cooling systems.

The deep-skirt block design, where the crankcase extends well below the crankshaft centerline, provides exceptional rigidity that maintains precise bearing alignment even after decades of off-road abuse.

The seven main bearing crankshaft offers substantial support for the rotating assembly, minimizing vibration and bearing wear even under heavy loads.

What truly distinguishes the AMC V8 is its valvetrain design. The overhead valve configuration with pushrods and a single camshaft minimizes moving parts while providing excellent reliability.

The hydraulic lifters accommodate varying oil quality and maintenance intervals a significant advantage in the off-road applications where these engines frequently serve.

The timing chain system, while requiring periodic inspection, proved remarkably durable when properly maintained, with the chain and gears built to substantially heavier specifications than many competitors.

The engine’s oiling system deserves particular recognition, featuring excellent capacity and circulation properties that maintain proper lubrication under challenging conditions.

The relatively low operating RPM range (redline around 5,000 RPM) minimizes valve train stress and reciprocating mass forces, further contributing to longevity.

These characteristics made the engine particularly well-suited for the off-road duty cycles in Jeep applications, where sustained low-RPM operation under load is common.

Perhaps most telling about the AMC V8’s durability is its performance in off-road environments.

These engines earned particular acclaim for their ability to withstand the extreme conditions encountered in Jeep applications from deep water crossings that shocked hot engines with sudden cooling to sustained operation at extreme angles that challenged oil circulation.

Their ability to tolerate these conditions while maintaining reliability established the AMC V8 as the preferred powerplant for serious off-road enthusiasts.

The AMC V8’s combination of overbuilt components, mechanical simplicity, and focus on low-end torque created what many consider the definitive off-road engine of its era.

While producing modest power by modern standards (ranging from 150 to 225 horsepower depending on displacement and era), these engines delivered this output with exceptional reliability.

Properly maintained examples routinely exceed 250,000 miles without internal repairs, with many accumulating substantially higher mileage figures particularly remarkable given the punishing conditions these engines often endured in Jeep applications.

9. Audi/Volkswagen 4.2L V8

The Audi/Volkswagen 4.2L V8 engine, produced from 1994 to 2016, represents one of the most successful German luxury V8 designs in terms of longevity and refinement.

This all-aluminum powerplant powered flagship model including the Audi A8, S4, RS4, and Volkswagen Touareg/Phaeton.

What distinguishes this engine is its remarkable adaptability across diverse applications while maintaining core durability characteristics that allowed it to thrive in everything from luxury sedans to performance cars and even SUVs.

The 4.2L V8’s exceptional durability begins with its block construction. The aluminum block features cast iron cylinder liners and substantial reinforcement in critical areas, providing excellent rigidity while maintaining reasonable weight.

The five-main-bearing crankshaft rides on generously sized bearings that distribute loads effectively, minimizing wear even after hundreds of thousands of miles.

Unlike many modern aluminum engines designed primarily for weight savings, the Audi/VW unit prioritized structural integrity alongside performance.

What truly distinguishes this engine is its timing component design. Early versions employed a timing belt system that, while requiring periodic replacement, was engineered with substantial width and tooth engagement that virtually eliminated failures when properly maintained.

Later chain-driven variants (introduced around 2003) featured a sophisticated setup with auxiliary chains driving balance shafts and other components.

While more complex than some competitors, these systems demonstrated remarkable durability when serviced according to factory intervals.

The engine’s lubrication system deserves particular recognition, featuring a high-capacity oil pump and generous oil passages ensuring critical components receive abundant lubrication under all operating conditions.

The sophisticated cooling system, with its efficient flow characteristics and substantial capacity, maintains consistent temperatures that prevent the thermal stress that often shortens engine life in high-performance applications.

These characteristics were particularly important in the highly-tuned RS variants, where sustained high-output operation placed significant demands on engine systems.

Perhaps most telling about the 4.2L V8’s durability is its success across dramatically different tuning philosophies.

From the conservative, refinement-focused implementation in the A8 luxury sedan to the high-strung, 8500-RPM redline version in the RS4, the basic architecture demonstrated exceptional robustness across a wide performance spectrum.

This versatility revealed substantial engineering headroom in the design, with componentry capable of handling forces far beyond those encountered in standard applications.

The 4.2L V8’s combination of intelligent engineering, robust construction, and exceptional refinement created a powerplant that successfully delivered German precision across multiple vehicle segments.

While more complex and maintenance-intensive than some competitors, properly maintained examples routinely exceed 200,000 miles without internal repairs, with many accumulating substantially higher mileage figures.

This engine demonstrated conclusively that a sophisticated, high-performance V8 could maintain excellent longevity when engineered with appropriate safety margins a philosophy that established engineering standards still evident in German luxury powertrains today.

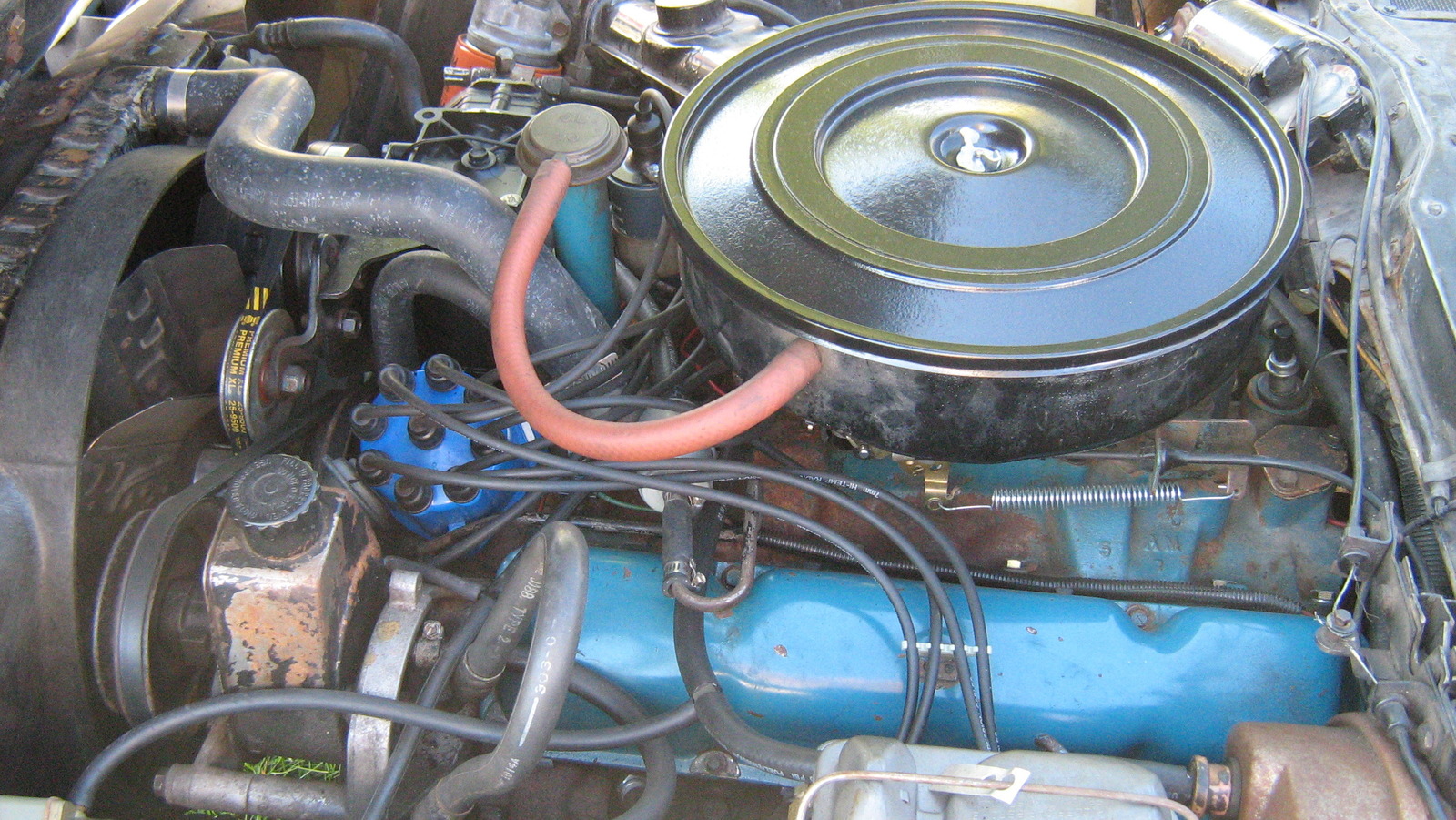

10. Dodge 5.9L Magnum V8

The Dodge 5.9L Magnum V8 (360 cubic inches), produced from 1993 to 2003, represents one of the most successful modernizations of a traditional American V8 design.

Based on the venerable LA-series small block architecture dating back to the 1960s, the Magnum refresh incorporated significant updates while maintaining the robust simplicity that made its predecessors legendary for durability.

This powerplant became the backbone of Dodge’s truck and SUV lineup, powering Ram pickups, Durango SUVs, and Dakota trucks during a transformative period when these vehicles evolved from basic workhorses to more refined, higher-capability machines.

The Magnum 5.9L’s exceptional longevity stems from its fundamentally overbuilt design inheritance.

The cast iron block and heads feature substantial material thickness that provides exceptional rigidity and thermal stability under all operating conditions.

The deep-skirt block design, where the crankcase extends well below the crankshaft centerline, maintains precise bearing alignment even after hundreds of thousands of miles of heavy-duty service.

The evolution from LA-series to Magnum retained these core strengths while improving critical components.

What truly distinguishes the Magnum V8 is Dodge’s intelligent approach to modernization.

While incorporating contemporary features like sequential multi-port fuel injection and distributorless ignition, engineers maintained the mechanical simplicity that contributed to the LA engine’s legendary durability.

The overhead valve design with pushrods and a single camshaft minimized moving parts while providing excellent reliability.

The hydraulic roller lifters introduced with the Magnum significantly reduced valvetrain wear compared to the flat tappets of earlier LA engines, addressing one of the few durability concerns in the original design.

The engine’s lubrication system deserves particular recognition, featuring improved oil passage routing and a high-capacity pump that maintains proper oil pressure even under sustained heavy loads.

The cooling system, with its large-capacity water pump and efficient flow characteristics, prevents the hot spots that often compromise longevity in truck applications where sustained towing places significant thermal demands on the engine.

Perhaps most telling about the Magnum 5.9L’s durability is its performance in severe service applications.

From commercial fleet vehicles to personal trucks regularly employed for heavy towing, these engines demonstrated remarkable resilience under conditions that would quickly compromise lesser designs.

Their ability to withstand extended operation at high loads while maintaining reliability established the Magnum V8 as the preferred powerplant for those requiring absolute dependability from their vehicles.

The Magnum 5.9L’s combination of traditional American V8 virtues with targeted modernization created a powerplant that successfully bridged automotive eras.

While producing modest power by current standards (ranging from 230 to 250 horsepower depending on application and year), these engines delivered this output with exceptional reliability.

Properly maintained examples routinely exceed 300,000 miles without internal repairs, with many accumulating substantially higher mileage figures particularly remarkable given the demanding service lives these engines often experienced in heavy-duty applications.

This engine’s legacy continues influencing how manufacturers approach truck powertrains, where proven durability must be balanced against emissions requirements and efficiency demands a challenge the Magnum V8 met with remarkable success during its decade-long production run.

Also Read: 12 Legendary Cars That Defined a Generation of Automaking