The automotive engineering, engine longevity stands as the ultimate testament to design excellence and manufacturing quality.

While many modern vehicles fall victim to electrical issues, transmission failures, or body corrosion, certain powerplants have earned legendary status for their ability to keep running long after other components have surrendered to time and wear.

These extraordinary engines often continue their service life even as the vehicles around them deteriorate, sometimes finding new homes in restoration projects or custom builds.

Built with superior materials, conservative engineering tolerances, and simple yet effective designs, these motors represent the pinnacle of automotive durability.

From naturally aspirated inline-sixes to bulletproof V8s, the engines on this list share common traits: overbuilt components, adequate cooling systems, timing chains instead of belts, and designs that prioritize reliability over maximum power output.

Many were developed during eras when manufacturers valued longevity as a primary selling point, rather than the horsepower-per-liter metrics that dominate modern marketing.

This collection spans decades of automotive history and represents diverse engineering philosophies from around the globe.

Whether powering workhorses or luxury vehicles, these engines have earned their reputations through millions of collective miles on roads worldwide.

Let’s explore the dozen most resilient powerplants ever to grace an engine bay motors so durable they regularly outlive the vehicles they were designed to power.

1. Toyota 22R/22RE

The Toyota 22R series of engines, first introduced in 1981, represents perhaps the most bulletproof four-cylinder engine ever mass-produced.

This 2.4-liter powerplant became the backbone of Toyota’s reputation for reliability, powering everything from Hilux pickups and 4Runners to Celicas and Corona sedans throughout the 1980s and early 1990s.

What makes the 22R exceptional is its straightforward design and robust construction.

The iron block features thick cylinder walls that resist warping even under severe heat conditions, while its timing chain setup eliminates the maintenance concerns of timing belts.

Toyota’s conservative approach to performance meant these engines were significantly underfunded, producing modest power (around 105-120 horsepower depending on the variant) but creating minimal internal stress.

The engine’s oiling system deserves particular recognition, featuring generous oil passages and excellent flow characteristics that maintain lubrication even in extreme environments.

This became particularly evident in the Middle East and Australia, where 22R-equipped vehicles routinely accumulated over 500,000 miles in harsh desert conditions without major mechanical issues.

The fuel-injected 22RE variant, introduced in 1983, further improved reliability while enhancing performance and fuel economy.

The injection system itself proved remarkably trouble-free compared to many contemporary systems, functioning reliably long after other engine components began showing signs of age.

Perhaps most telling about the 22R’s durability is how frequently these engines continue running despite neglect.

Stories abound of these motors surviving severe oil change neglect, overheating incidents, and even coolant loss conditions that would catastrophically damage most engines.

While the transmissions, differentials, and body panels of their host vehicles often succumb to time, the 22R heart frequently keeps beating, ready to be transplanted into another platform.

This engine’s combination of simple design, overbuilt components, and balanced performance created a power unit that didn’t just meet expectations it rewrote them, setting standards for reliability that manufacturers still strive to match four decades later.

2. Mercedes-Benz OM617 Diesel

The Mercedes-Benz OM617 turbodiesel stands as one of the most indestructible engines ever produced in automotive history.

This 3.0-liter inline-five cylinder diesel, manufactured from 1974 to 1991, powered legendary Mercedes models including the 300D, 300TD, and 300SD.

Its reputation for exceptional longevity is evidenced by the significant number of these engines still in service today, many having accumulated mileage figures exceeding one million kilometers.

The OM617’s remarkable durability stems from its overengineered design philosophy.

Mercedes constructed these engines with extraordinarily thick cylinder walls and robust internal components that were designed to withstand the higher compression ratios and forces inherent to diesel operation.

The cast iron block and aluminum head combination provided both strength and effective heat dissipation, while the indirect injection system favored reliability over maximum power output.

What truly distinguished the OM617 was its meticulous manufacturing process. Each engine component was precision-machined to exacting tolerances, creating a powerplant that, when properly maintained, could function almost indefinitely.

The timing chain was designed for the lifetime of the vehicle, eliminating the maintenance intervals required by timing belt systems.

Additionally, the engine’s oil capacity and circulation system ensured excellent lubrication even under extreme conditions.

Although modest by modern standards with approximately 120 horsepower in turbocharged form, the OM617’s abundant torque delivery (170 lb-ft) provided satisfying performance while operating well below its engineering stress limits.

This conservative tuning meant minimal wear on internal components, contributing significantly to its legendary longevity.

Perhaps most impressive is the OM617’s ability to adapt to alternative fuels, with many examples successfully running on biodiesel, waste vegetable oil, and other alternative diesel fuels with minimal modifications.

This versatility has contributed to the engine’s enduring popularity among enthusiasts seeking sustainability alongside reliability.

The OM617’s longevity often outpaces the vehicles it powers, with many Mercedes bodies succumbing to corrosion or electrical issues while the engine remains perfectly serviceable.

This has created a thriving market for engine swaps, with OM617s finding new homes in everything from Land Rovers to custom off-road vehicles, ensuring these mechanical masterpieces continue their service long after their original vehicles have retired.

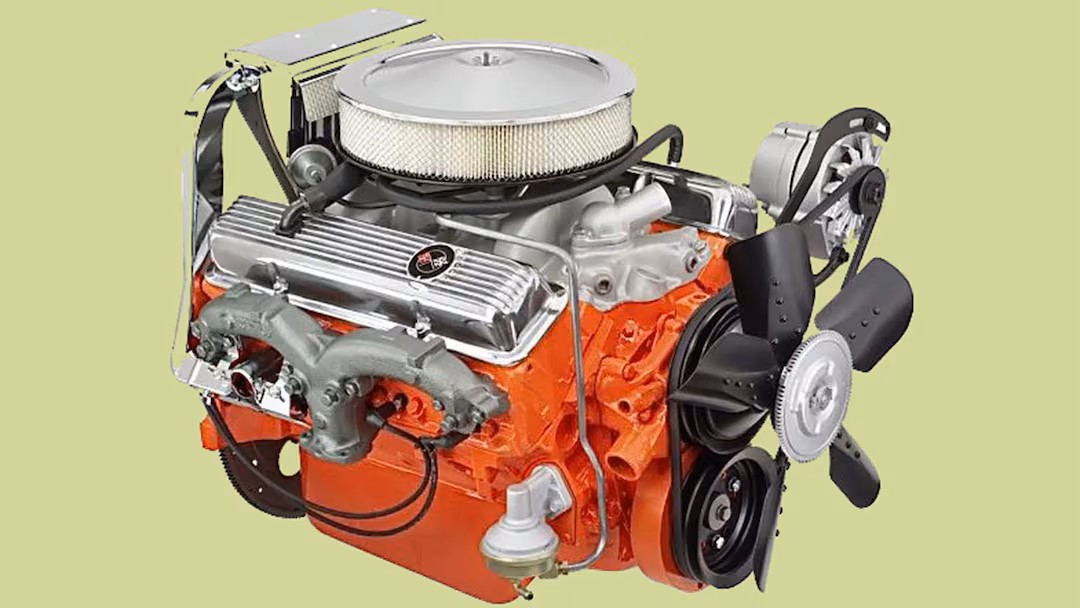

3. Chevrolet Small-Block V8

The Chevrolet Small-Block V8 represents one of the most enduring engine architectures in automotive history, with a production run spanning from 1955 to 2003.

This remarkably versatile powerplant, produced in displacements ranging from 262 to 400 cubic inches, has powered everything from family sedans and pickup trucks to muscle cars and racing legends.

What began as the 265 cubic inch “Turbo-Fire” V8 evolved through numerous iterations while maintaining its core design principles.

The Small-Block’s exceptional longevity stems from several key attributes. Its simple and efficient design features a 90-degree V configuration with overhead valves (pushrod architecture), allowing for compact dimensions and straightforward maintenance.

The engine block’s robust cast iron construction provides excellent strength and vibration damping, while its efficient cooling passages ensure consistent temperature regulation even under heavy loads.

Perhaps the Small-Block’s greatest strength lies in its oiling system, which delivers exceptional lubrication to critical components.

The full-pressure lubrication system maintains proper oil flow to bearings and other crucial parts even at high RPMs or during extended operation.

This superior lubrication, combined with relatively conservative internal clearances, results in minimal wear even after hundreds of thousands of miles.

The Small-Block’s timing chain design eliminates the maintenance concerns associated with timing belts, while its cast iron heads (in earlier versions) and block provide excellent heat stability.

Later iterations featuring aluminum heads maintained reliability while reducing weight.

Throughout its evolution, the basic architecture remained fundamentally sound, allowing for continuous refinement without sacrificing the inherent durability.

What truly distinguishes the Small-Block is its massive aftermarket support and simplicity of repair.

Nearly every component remains readily available, and most maintenance can be performed with basic tools.

This accessibility has ensured that these engines can be economically maintained and rebuilt multiple times, often outlasting several vehicle bodies.

It’s not uncommon to find original Small-Blocks with 300,000+ miles still running strong, or rebuilt examples continuing service well beyond the half-million mile mark.

The Small-Block’s conservative engineering created substantial safety margins in standard tune, allowing these engines to withstand considerable abuse.

Even when neglected, they often continue functioning long after more complex designs have failed.

This combination of simplicity, robust construction, excellent oiling, and massive parts availability created what many consider the definitive American V8 an engine so durable it frequently finds itself transplanted into new vehicles after its original host has succumbed to age.

4. BMW M20 Inline-Six

The BMW M20 inline-six engine, produced from 1977 to 1993, earned its reputation as “the engine that wouldn’t die” through a combination of elegant engineering and robust construction.

This 2.0-3.2 liter powerplant powered numerous BMW models including the E30 3-Series, E28 5-Series, and E24 6-Series, becoming the backbone of BMW’s product lineup during a pivotal period in the company’s history.

What distinguishes the M20 is its perfect balance of performance and durability.

The inherently balanced inline-six configuration minimizes vibration and internal stress, creating a smooth operation that reduces wear on bearings and other critical components.

BMW’s precision engineering ensured tight manufacturing tolerances while maintaining adequate clearances for thermal expansion and oil circulation.

The M20’s cast iron block provides exceptional rigidity and heat stability, while its aluminum head offers efficient cooling and reduced weight.

Unlike many engines of its era, the M20 features a timing belt rather than a chain theoretically a reliability concern.

However, BMW engineered this component with significant safety margins, and when maintained at the recommended 60,000-mile replacement interval, it rarely causes issues.

More importantly, the M20 employs a non-interference design, meaning that even in the rare event of timing belt failure, the valves and pistons won’t collide, preventing catastrophic engine damage.

The oiling system deserves particular recognition, featuring generous oil capacity and excellent circulation even under high-performance driving conditions.

This robust lubrication, combined with the moderate specific output (horsepower per liter) of most M20 variants, creates an engine that operates well within its mechanical limits during normal use, contributing significantly to its longevity.

What truly sets the M20 apart is its ability to handle neglect while continuing to function reliably.

Numerous examples have surpassed 300,000 miles with only basic maintenance, while properly maintained versions frequently exceed 400,000 miles before requiring significant rebuilding.

The engine’s relatively simple design allows for straightforward servicing, with most components accessible without specialized tools.

While the bodies of E30s and other M20-powered vehicles often succumb to rust in harsh climates, the engines frequently outlive multiple chassis, finding new homes in restoration projects, kit cars, and even boats.

The M20’s combination of smooth operation, adequate power, and exceptional durability created a powerplant that exemplifies BMW’s engineering excellence an engine so reliable that many enthusiasts consider it BMW’s finest hour, despite more powerful options developed in subsequent decades.

Also Read: 12 Pickup Trucks That Will Last Over 20 Years With Basic Maintenance

5. Toyota 1UZ-FE V8

The Toyota 1UZ-FE V8 engine, introduced in 1989 and produced in 2002, represents one of the most overengineered powerplants ever created for production vehicles.

Developed initially for the Lexus LS400 and subsequently used in various Toyota luxury and performance models, this 4.0-liter aluminum V8 was designed to compete directly with the finest engines from Mercedes-Benz and BMW.

Toyota’s engineering team, given virtually unlimited resources, created an engine so robust that it received certification for use in aircraft applications a testament to its exceptional reliability.

What makes the 1UZ-FE extraordinary is its construction quality. The aluminum block features cast iron cylinder sleeves and six-bolt main bearing caps that provide strength comparable to traditional iron blocks while maintaining significantly lower weight.

The aluminum heads house four valves per cylinder and dual overhead camshafts, driven by a timing belt designed with extraordinary safety margins.

Unlike many overhead cam engines, the 1UZ-FE uses an interference design but compensates with a belt of such quality and thickness that failures are exceedingly rare, even beyond recommended replacement intervals.

The engine’s internal components reveal Toyota’s commitment to durability.

Forged steel connecting rods, hypereutectic pistons with short skirts for reduced friction, and a crankshaft manufactured to aerospace tolerances create an assembly capable of withstanding forces far beyond those experienced in normal operation.

The oiling system, featuring a high-capacity pump and large oil passages, ensures critical components receive abundant lubrication even under extreme conditions.

Perhaps most impressive is the 1UZ-FE’s electronic control systems. The sequential fuel injection and sophisticated engine management were revolutionary when introduced, providing exceptional reliability when many competitors struggled with electronic complexity.

The distributor-less ignition system with individual coils eliminated a common failure point in earlier engines.

These engineering choices resulted in an engine capable of astronomical mileage figures.

Numerous documented examples have exceeded 500,000 miles without internal repairs, while properly maintained versions frequently approach the million-mile mark with only basic service.

The 1UZ-FE’s resilience became legendary among luxury car enthusiasts and has made it a popular choice for engine swaps into everything from sports cars to off-road vehicles.

While the Lexus and Toyota vehicles these engines power eventually succumb to transmission issues, electrical problems, or body deterioration, the 1UZ-FE hearts often continue beating flawlessly, ready for transplantation into new hosts.

This combination of overengineered components, precision manufacturing, and conservative tuning created what many consider the most reliable V8 ever mass-produced an enduring legacy of Toyota’s golden era of engineering excellence.

6. Cummins 5.9L Diesel (12-Valve)

The Cummins 5.9L 12-valve diesel engine (6BT) represents the gold standard of heavy-duty diesel reliability. Introduced in Dodge Ram pickups in 1989, this inline-six turbodiesel was originally designed for agricultural and industrial applications before finding its way into consumer vehicles.

This commercial heritage immediately distinguished it from purpose-built automotive diesel, endowing it with durability characteristics more commonly associated with engines meant to run 24/7 in tractors and generators than those designed for highway use.

The 12-valve Cummins’ exceptional longevity stems from its remarkably simple and overbuilt design.

The cast iron block and head feature extraordinarily thick walls that resist warping even under extreme heat conditions.

Its massive forged steel crankshaft, connecting rods with substantial cross-sections, and robust wrist pins create a bottom end capable of handling stresses far beyond those encountered in normal operation.

The gear-driven camshaft eliminates timing belt or chain concerns, while the direct mechanical fuel injection system operates without complex electronics that might fail over time.

What truly sets the 12-valve Cummins apart is its mechanical simplicity. The engine uses a Bosch P7100 injection pump (commonly called the “P-pump”) that requires no electronic control it’s purely mechanical, using simple hydraulic principles to deliver precisely measured fuel.

This straightforward design makes it extraordinarily resistant to environmental conditions that would cripple more sophisticated systems.

The lack of complex electronics also means fewer potential failure points over the engine’s lifespan.

The 5.9L Cummins’ oiling system deserves particular recognition, featuring a high-capacity oil pump and generous oil passages that ensure critical components receive abundant lubrication.

The engine’s 12-quart oil capacity provides excellent thermal stability and dilution resistance during extended operation.

These factors contribute significantly to the engine’s legendary durability, with many examples exceeding 600,000 miles without internal repairs, while properly maintained versions regularly surpass the million-mile threshold.

Perhaps most telling about the 12-valve Cummins’ durability is its ability to handle significant performance modifications without sacrificing reliability.

While factory-rated at a modest 160-215 horsepower (depending on the year), simple adjustments to the injection pump can safely increase output to over 300 horsepower while maintaining exceptional longevity.

This mechanical tunability has made it extraordinarily popular among enthusiasts seeking both power and reliability.

While Dodge Ram trucks of this era frequently experience transmission failures, body rust, and electrical issues, their Cummins engines often outlive multiple chassis, eventually finding new homes in custom builds, off-road vehicles, or even marine applications.

This combination of industrial-grade construction, mechanical simplicity, and massive overdesign created what many consider the definitive American diesel engine a powerplant of such remarkable durability that it frequently outlives everything around it.

7. Honda B-Series VTEC

The Honda B-Series VTEC engines, produced from 1989 to 2001, represent a masterclass in combining high-performance capabilities with exceptional durability.

Offered in displacements ranging from 1.6 to 1.8 liters, these four-cylinder powerplants became legendary among enthusiasts for their ability to deliver motorcycle-like revving capabilities and impressive specific output while maintaining Honda’s reputation for bulletproof reliability.

What distinguishes the B-Series is its perfect balance of advanced technology and fundamental engineering excellence.

At its core, the B-Series features an aluminum block with cast iron cylinder sleeves providing exceptional strength and heat management.

The aluminum cylinder head houses Honda’s Variable Valve Timing and Electronic Lift Control (VTEC) system, which effectively provides two separate cam profiles one optimized for efficiency at low RPMs and another for maximum power at high RPMs.

This innovative approach allowed the engine to deliver impressive power without sacrificing low-end tractability or reliability.

Unlike many high-performance engines that sacrifice longevity for maximum output, Honda engineered the B-Series with substantial safety margins.

The forged crankshaft, robust connecting rods, and precisely engineered pistons create a rotating assembly capable of sustaining repeated high-RPM operation without accelerated wear.

The oil system features generous capacity and excellent circulation properties, ensuring critical components receive abundant lubrication even when consistently operated near the 8,000+ RPM redline.

What truly sets the B-Series apart is its timing belt design and valvetrain durability.

While timing belts are traditionally considered wear items, Honda’s implementation features exceptional quality and conservative replacement intervals.

More importantly, despite being an interference design, properly maintained B-Series engines rarely experience timing belt failures, and the valvetrain components rocker arms, valve springs, and the VTEC switching mechanism maintain proper function well beyond 200,000 miles with basic maintenance.

The B-Series’ durability becomes particularly evident in modified applications. These engines routinely withstand significant increases in power through forced induction, handling 300+ horsepower with stock internals when properly tuned.

This substantial headroom in the design has made them favorites among performance enthusiasts seeking reliable power.

While the Civic, Integra, and Del Sol models these engines eventually succumb to transmission issues, rust, or collision damage, their B-Series hearts often continue operating flawlessly, frequently finding new homes in custom builds, track cars, or even motorcycle-engined kit cars.

The combination of high-technology features, precision manufacturing, and fundamentally sound engineering created powerplants that not only defined an era of Japanese performance but established standards for reliability that few high-revving engines have matched since.

8. Volvo Redblock (B230)

The Volvo Redblock engine family, particularly the B230 variant produced from 1985 to 1998, epitomizes Scandinavian engineering principles where durability takes absolute precedence.

This 2.3-liter inline-four earned its legendary status powering vehicles like the 240, 740, 940, and other boxy Volvo models that became synonymous with safety and longevity.

The Redblock’s reputation is so formidable that finding examples with 300,000+ miles is commonplace, while properly maintained versions regularly exceed 500,000 miles without major internal repairs.

The extraordinary durability of the B230 stems from its fundamentally overbuilt design.

The cast iron block features remarkably thick cylinder walls and main bearing support structures that resist warping and maintain precision even after decades of thermal cycling.

The five main bearing crankshaft design provides exceptional support for the rotating assembly, minimizing vibration and bearing wear even under sustained load.

The forged steel connecting rods used in certain variants (particularly the turbocharged models) provide massive safety margins, often capable of handling twice the factory power output without failure.

What distinguishes the Redblock is Volvo’s commitment to evolutionary rather than revolutionary development.

Each refinement is built upon proven design elements, with changes implemented only after extensive testing.

This conservative approach resulted in an engine that benefited from continuous improvement while maintaining its fundamental reliability.

The implementation of fuel injection systems exemplifies this philosophy Volvo incorporated electronic injection while maintaining mechanical simplicity that ensured long-term functionality.

The oiling system deserves particular recognition, featuring excellent oil capacity and circulation properties that maintain proper lubrication under all operating conditions.

The engine’s relatively low operating RPM range (redline around 5,500 RPM) minimizes valve float and reciprocating mass stress, further contributing to longevity.

The timing belt design, while requiring periodic replacement, features generous dimensions and conservative replacement intervals that virtually eliminate catastrophic failures when properly maintained.

Perhaps most telling about the B230’s durability is its performance in extreme climates.

These engines earned particular acclaim in Scandinavia, Canada, and northern Russia, where their ability to start reliably in temperatures approaching -40°F and operate consistently in these conditions demonstrated engineering excellence that transcended the theoretical.

The engines’ resilience to thermal shock starting and operating correctly from extreme cold revealed materials selection and engineering tolerances that prioritized longevity above all else.

While the Volvo vehicles these engines powered eventually succumb to body corrosion, transmission issues, or electrical failures, their Redblock hearts frequently continue operating flawlessly, often finding new homes in custom projects, rally cars, or even marine applications.

This combination of overbuilt components, conservative engineering, and evolutionary refinement created what many consider the definitive expression of Swedish automotive engineering an engine so durable it frequently outlasts everything around it.

9. Nissan RB Series (RB25/RB26)

The Nissan RB series engines, particularly the RB25DET and legendary RB26DETT variants produced from 1985 to 2002, represent pinnacles of Japanese inline-six engineering.

These 2.5 and 2.6-liter twin-cam powerplants achieved fame powering iconic models like the Skyline GT-R and GTS-T, combining exceptional performance capabilities with remarkable durability that has endeared them to enthusiasts worldwide.

What makes these engines particularly noteworthy is their ability to deliver supercar-level performance while maintaining reliability which puts many ordinary commuter engines to shame.

The RB’s exceptional longevity stems from its fundamentally overbuilt design. The cast iron block features substantial cylinder walls and main bearing supports, providing extraordinary rigidity even under extreme boost pressures.

The seven-main-bearing crankshaft an unusual feature compared to the more common five-bearing design in many inline-sixes delivers exceptional support for the rotating assembly, minimizing flex and bearing wear even at high RPMs.

The aluminum cylinder head houses dual overhead camshafts driving four valves per cylinder, with timing belt drives designed with significant safety margins.

What distinguishes the RB series is Nissan’s engineering approach that prioritized strength alongside performance.

The oil system features exceptional capacity and circulation properties, with the RB26DETT, in particular, utilizing a complex oil channel arrangement that ensures abundant lubrication even during sustained high-G cornering.

The water cooling system, with its large capacity and efficient flow characteristics, maintains consistent temperatures even under track conditions.

These factors collectively enable the engine to withstand the substantial thermal and mechanical stresses associated with turbocharged performance applications.

The RB26DETT deserves particular recognition for its unique parallel twin-turbo setup, where each turbocharger serves three cylinders independently.

While complex by 1980s standards, this arrangement provided exceptional throttle response and thermal management advantages over single-turbo designs.

Despite this complexity, the system demonstrates remarkable reliability when properly maintained, often functioning flawlessly for hundreds of thousands of miles.

Perhaps most telling about the RB series’ durability is its capacity for power increases.

While factory-rated at 276 horsepower due to Japan’s “Gentleman’s Agreement” limiting official output figures, the RB26DETT in particular was engineered to handle substantially more.

Stock internal components routinely withstand 500+ horsepower with proper tuning, while moderately reinforced examples frequently operate reliably at 700+ horsepower a testament to the massive engineering headroom built into the design.

While the Nissan vehicles these engines powered eventually succumb to body corrosion, transmission issues, or electrical failures, their RB hearts frequently continue operating flawlessly, often finding new homes in custom projects, drift cars, or even world-record-setting drag vehicles.

This combination of overbuilt components, sophisticated engineering, and substantial performance headroom created what many consider the definitive expression of Japanese straight-six excellence engines of such remarkable durability that they frequently outlive everything around them while continuing to deliver exceptional performance decades after their manufacture.

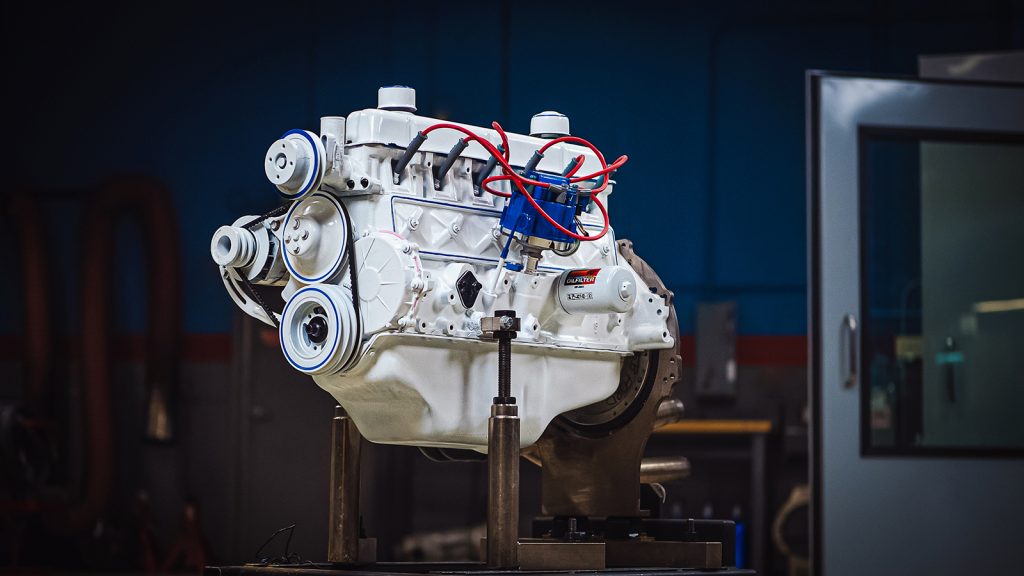

10. Ford 300 Inline-Six

The Ford 300 cubic inch (4.9-liter) inline-six engine, produced from 1965 to 1996, stands as perhaps the most indestructible American truck engine ever manufactured.

This remarkably long-lived powerplant served primarily in F-Series trucks and E-Series vans, becoming legendary among farmers, contractors, and fleet operators for its ability to soldier on through conditions that would destroy lesser engines.

Its production span of over three decades with minimal fundamental changes speaks volumes about the fundamental soundness of its design.

What distinguishes the Ford 300 is its focus on low-end torque and absolute reliability rather than maximum horsepower.

The long-stroke design produces abundant torque at low RPMs perfect for work applications while operating well below its mechanical limits during normal use.

The cast iron block and head feature extraordinarily thick walls that resist warping even under extreme heat conditions or with compromised cooling systems.

The seven main bearing crankshaft provides exceptional support for the rotating assembly, minimizing vibration and bearing wear even under heavy loads.

The 300’s oiling system deserves particular recognition, featuring an oil pump with capacity far beyond what’s theoretically necessary and generous oil galleries that ensure critical components receive abundant lubrication.

The engine’s relatively low operating RPM range (redline around 4,500 RPM) minimizes valve train stress and reciprocating mass forces, further contributing to longevity.

The timing gear setup using cast iron gears rather than a belt or chain virtually eliminates timing-related failures.

What truly sets the Ford 300 apart is its carburetion simplicity (in earlier versions) and robust fuel injection system (in later models).

The feedback electronic fuel injection introduced in 1987 maintained the engine’s fundamental reliability while improving efficiency and emissions.

Unlike many engines that suffered from early fuel injection complexity, Ford’s implementation proved remarkably trouble-free, frequently functioning properly for hundreds of thousands of miles.

Perhaps most telling about the 300’s durability is its performance under severe neglect.

These engines earned particular acclaim for their ability to withstand extended oil change intervals, cooling system neglect, and even brief periods of overheating without catastrophic failure.

Stories abound of these motors continuing to run despite cracked radiators, slipped timing, or severely degraded oil conditions that would immediately destroy most engines.

While the Ford trucks and vans these engines powered eventually succumb to frame rust, transmission issues, or differential failures, their inline-six hearts frequently continue operating flawlessly, often finding new homes in custom projects, boats, or even stationary power applications.

This combination of overbuilt components, mechanical simplicity, and focus on low-RPM torque created what many consider the definitive American work engine a powerplant of such remarkable durability that it frequently outlives multiple vehicle bodies while continuing to deliver reliable service decades after manufacture.

11. Toyota 1JZ/2JZ

The Toyota JZ series engines, particularly the 1JZ-GTE (2.5L) and 2JZ-GTE (3.0L) twin-turbocharged variants produced from 1990 to 2007, represent the pinnacle of Japanese inline-six engineering.

These powerplants achieved global recognition powering vehicles like the Toyota Supra, Chaser, and Aristo, combining exceptional performance potential with reliability that has become almost mythical among enthusiasts.

What makes these engines truly remarkable is their ability to handle power levels several times their factory rating while maintaining longevity that embarrasses many ordinary commuter engines.

The JZ’s extraordinary durability stems from massive overengineering. The closed-deck cast iron block features substantial cylinder walls and the main bearing supports provide exceptional rigidity even under extreme boost pressures.

The seven-main-bearing crankshaft delivers outstanding support for the rotating assembly, minimizing flex and bearing wear even at high RPMs.

The forged steel connecting rods (particularly in the 2JZ-GTE) offer strength far beyond factory power requirements, routinely handling double or triple the stock output without failure.

What distinguishes the JZ series is Toyota’s no-compromise approach to engineering.

The oil system features exceptional capacity with large oil passages ensuring abundant lubrication throughout the engine.

The water cooling system employs large capacity and excellent flow characteristics, maintaining consistent temperatures even under track conditions.

The belt-driven dual overhead camshafts feature timing components with significant safety margins, while the non-interference design prevents catastrophic damage even in the rare event of timing belt failure.

The sequential twin-turbo setup in these engines deserves particular recognition for its reliability despite its complexity.

The sophisticated arrangement (especially in the 2JZ-GTE) where one turbocharger operates at lower RPMs with the second joining at higher RPMs provides exceptional throttle response and thermal management.

Despite this complexity, the system demonstrates remarkable durability when properly maintained, often functioning flawlessly for hundreds of thousands of miles.

Perhaps most telling about the JZ series’ durability is its capacity for power increases.

While factory-rated between 276-320 horsepower (depending on market and variant), these engines were engineered with enormous headroom.

Stock internal components routinely withstand 500-600 horsepower with proper tuning, while the 2JZ-GTE in particular has become famous for reliably producing 800+ horsepower with only moderate reinforcement a testament to the massive engineering margins built into the design.

While the Toyota vehicles these engines powered eventually succumb to body corrosion, transmission issues, or electrical failures, their JZ hearts frequently continue operating flawlessly, often finding new homes in everything from drift cars and drag racers to luxury performance builds.

The combination of overbuilt components, sophisticated engineering, and substantial performance headroom created what many consider the definitive modern straight-six engines of such remarkable durability that their values have increased decades after production, with good examples commanding premium prices for engine swaps into an endless variety of vehicles worldwide.

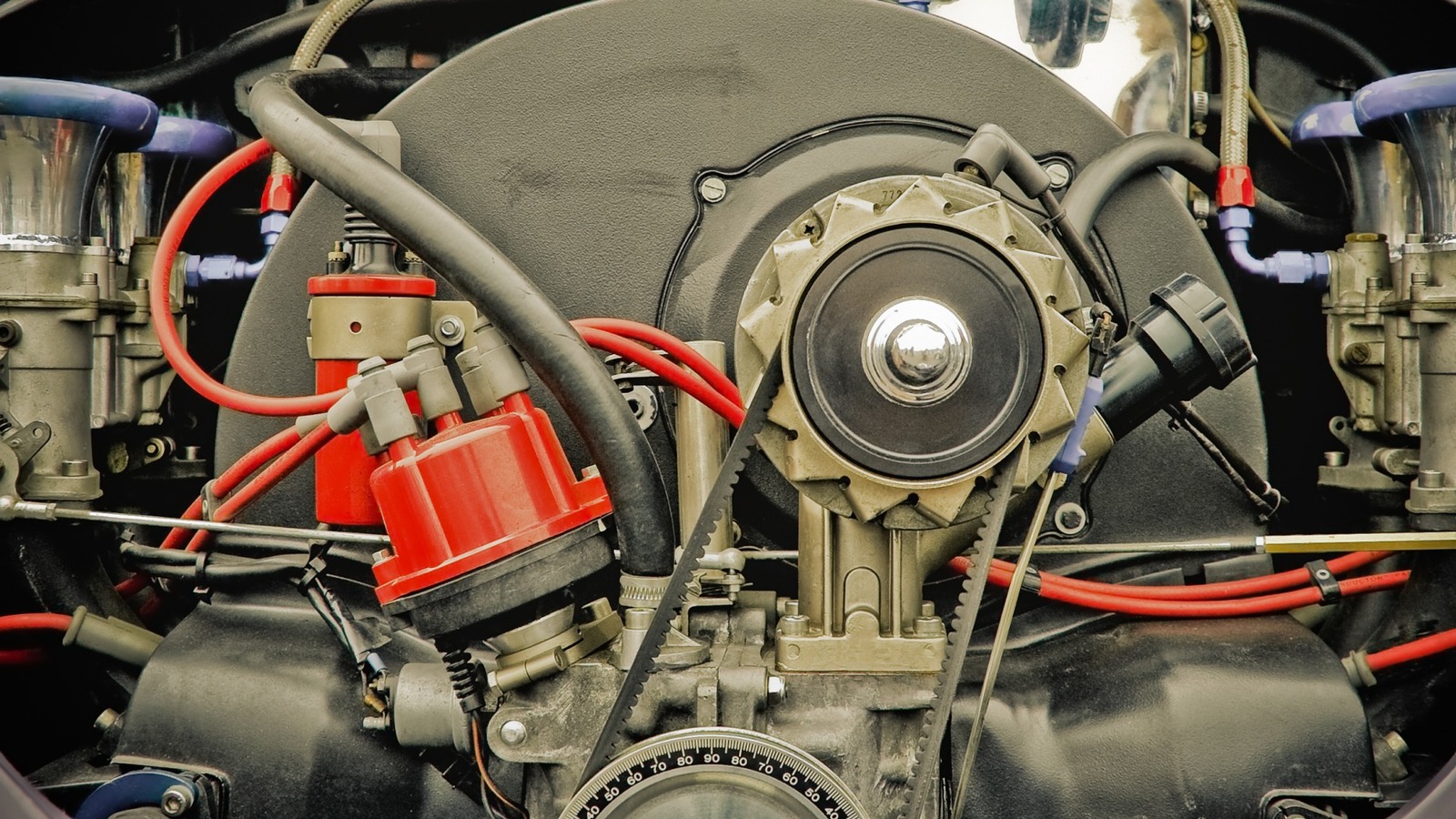

12. Volkswagen Air-Cooled Flat-Four

The Volkswagen air-cooled flat-four engine, produced from 1938 to 2003 with minimal fundamental changes, represents one of the most enduring engine designs in automotive history.

This remarkably simple boxer engine powered everything from the iconic Beetle and Bus to the Karmann Ghia and countless dune buggies, establishing itself as perhaps the most recognizable engine silhouette ever created.

Its production span of over six decades across multiple continents speaks volumes about the fundamental soundness of its design.

What distinguishes the VW flat-four is its radical simplicity. The horizontally opposed configuration provides natural balance with minimal vibration, while the air-cooled design eliminates the entire water cooling system and its potential failure points.

The engine block and heads, constructed from magnesium-aluminum alloy, provide excellent heat dissipation while reducing weight.

The pushrod valve actuation system, while not as sophisticated as overhead cam designs, offers exceptional reliability with minimal complexity.

The VW flat-four’s durability stems largely from its conservative output. Early versions produced merely 25-40 horsepower, eventually reaching 50-70 horsepower in later variants.

This modest specific output (horsepower per liter) means internal components operate well below their mechanical limits during normal use.

The engine’s relatively low operating RPM range minimizes valve train stress and reciprocating mass forces, further contributing to longevity.

What truly sets the VW flat-four apart is its serviceability. Nearly every component can be accessed and replaced with basic hand tools, making field repairs possible even in remote areas.

This accessibility, combined with the engine’s fundamental simplicity, created a powerplant that could be maintained almost indefinitely with basic mechanical knowledge.

The absence of water cooling eliminated freeze damage concerns in cold climates, while air cooling proved remarkably effective in hot environments, though less efficient than water cooling in extreme conditions.

Perhaps most telling about the flat-four’s durability is its performance in developing nations.

These engines earned particular acclaim in regions with limited access to replacement parts or specialized service facilities.

In Brazil, Mexico, and numerous African countries, VW engines frequently accumulated astronomical mileage figures, continuing to operate despite maintenance practices that would destroy more complex designs.

The engines’ ability to run (albeit roughly) even with one cylinder not functioning properly further demonstrated their fundamental resilience.

While Volkswagen vehicles eventually succumb to body rust, transmission issues, or suspension failures, their flat-four hearts frequently continue operating reliably, often finding new homes in custom projects, kit cars, or even aircraft conversions.

This combination of balanced design, mechanical simplicity, and straightforward serviceability created what many consider the definitive people’s engine a powerplant of such remarkable durability and repairability that it enabled motorization for millions worldwide while establishing a cult following that persists long after production ended.

Also Read: 10 Used SUVs That Are Worth Every Penny Due to Durability