The ultimate measure of an engine’s quality isn’t horsepower, torque, or even fuel efficiency it’s longevity.

While the average engine might struggle to reach 200,000 miles, some extraordinary powerplants have established legendary reputations for reliability, regularly surpassing the 500,000-mile mark with proper maintenance.

These mechanical marvels represent the pinnacle of automotive engineering, combining robust design, quality materials, and meticulous manufacturing processes.

They’ve earned their reputations through decades of real-world performance in everything from family sedans to commercial trucks, proving their worth in the most demanding conditions.

What makes these engines truly special isn’t just their ability to keep running, but to do so without requiring major overhauls or sacrificing performance.

For owners, these powerplants offer the ultimate peace of mind a vehicle that can be handed down through generations rather than traded in after a few years.

Let’s explore ten of the most durable engines ever created, each an engineering triumph that has earned its place in automotive history through sheer longevity and reliability.

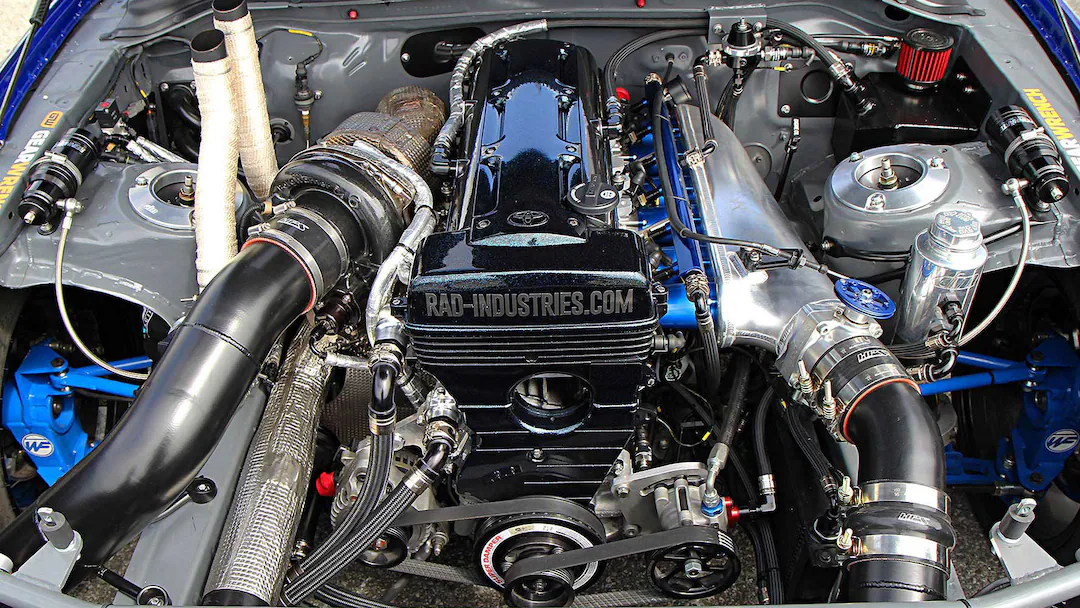

1. Toyota 2JZ-GE/GTE

The Toyota 2JZ engine family stands as perhaps the most revered inline-six configuration ever produced. Introduced in 1991, this 3.0-liter powerplant became famous worldwide through the Toyota Supra, but its legendary status stems from its virtually indestructible design.

The engine features a cast-iron block with exceptional wall thickness, providing incredible structural integrity even under extreme pressure.

Its seven main bearings ensure crankshaft stability at high RPMs, while the over-engineered connecting rods can withstand forces far beyond factory specifications.

The 2JZ-GE (naturally aspirated) version delivers smooth, reliable power for hundreds of thousands of miles in vehicles like the Lexus GS300 and IS300.

However, it’s the twin-turbocharged 2JZ-GTE variant that achieved mythical status in performance circles.

With stock internals, these engines have demonstrated the ability to handle double or even triple their factory-rated 320 horsepower without failure.

This remarkable headroom explains why so many examples have survived brutal tuning regimens while still accumulating astronomical mileage.

What truly sets the 2JZ apart is its uncompromising build quality. Toyota’s engineers incorporated features like a girdle-reinforced block, oil-cooled pistons, and a sophisticated sequential turbocharger system in the GTE model.

The timing belt system, often a weak point in engines, was designed with exceptional durability, requiring replacement only at 100,000-mile intervals. Even the head gasket, a common failure point in many high-performance engines, rarely causes issues in the 2JZ.

With proper maintenance, these engines regularly exceed 500,000 miles while maintaining their original performance characteristics.

Many taxi companies in Japan specifically sought out 2JZ-powered Toyotas for their fleets, with documented examples surpassing 1,000,000 kilometers.

The engine’s reputation for reliability has made it a popular swap candidate for everything from drift cars to luxury sedans, ensuring its legacy will continue for decades to come.

2. Mercedes-Benz OM617

The Mercedes-Benz OM617 diesel engine stands as a monument to German engineering excellence and mechanical durability.

Produced from 1974 to 1991, this 3.0-liter five-cylinder turbodiesel powerplant has earned a reputation as perhaps the most reliable diesel engine ever manufactured for passenger vehicles.

Its robust cast-iron construction formed the foundation of its legendary status, with numerous documented examples surpassing one million miles on their original components.

The OM617’s design prioritized longevity at every turn. Its forged steel crankshaft, supported by seven main bearings, provided exceptional stability and wear resistance.

The indirect injection system, while not as fuel-efficient as modern direct injection setups, created less mechanical stress and contributed significantly to the engine’s durability.

Mercedes engineered the cylinder head with exceptional cooling properties, preventing the warping issues that plagued many diesel engines of the era.

What truly distinguished the OM617 was its ability to operate reliably under virtually any conditions. From the blistering heat of the Sahara to the frigid winters of northern Europe, these engines started faithfully and ran smoothly.

The legendary W123 chassis 300D and 300TD models equipped with this engine became the vehicles of choice for taxi operators worldwide, with many accumulating over 500,000 miles in punishing stop-and-go service.

The OM617’s maintenance requirements were remarkably simple regular oil changes with proper diesel-rated lubricants, periodic valve adjustments, and timing chain inspections.

The engine’s mechanical fuel injection system, while lacking the precision of modern electronic systems, could be maintained indefinitely with basic tools and skills.

This serviceability factor contributed enormously to the engine’s longevity in developing countries, where complex electronic components were difficult to source.

Even decades after production ceased, enthusiasts continue to seek out vehicles equipped with the OM617, particularly the turbocharged variant found in later models.

Its combination of reasonable power (up to 125 horsepower in factory form), excellent fuel economy, and unmatched reliability has made it a favorite for long-distance travelers and those seeking a truly lifetime vehicle.

3. Cummins 5.9L 12-Valve

The Cummins 5.9L 12-valve diesel engine represents the pinnacle of mechanical simplicity and brute durability in the heavy-duty truck market.

Introduced in 1989 for Dodge Ram pickups, this straight-six turbodiesel powerplant revolutionized the consumer diesel truck segment with its combination of massive torque and commercial-grade reliability.

The engine’s design originated from industrial applications, bringing genuine heavy equipment durability to the consumer market.

At the heart of the 12-valve’s legendary status is its remarkably simple design. With a cast-iron block featuring cylinder walls nearly twice as thick as comparable engines, and a forged-steel crankshaft rotating on seven main bearings, the engine was built to withstand decades of punishment.

The mechanical Bosch P7100 injection pump eliminated complex electronics that could fail while providing exceptional fuel delivery precision and easy serviceability.

The 12-valve Cummins achieved its extraordinary longevity through several key design elements. Its gear-driven camshaft eliminated timing belt or chain issues.

The direct injection system advanced for its era and delivered excellent combustion efficiency without the high-pressure components that cause problems in modern diesel engines.

Perhaps most importantly, the engine operated at significantly lower RPMs than its competitors, typically running between 1,600-2,700 RPM, dramatically reducing wear on critical components.

This engine’s reputation for reliability made it the preferred choice for commercial applications, from agricultural equipment to delivery vehicles.

Many examples have documented lifespans exceeding 800,000 miles on original internals, with some surpassing the million-mile mark with only regular maintenance.

The engine’s substantial torque output up to 440 lb-ft in later versions allowed it to perform demanding tasks like heavy towing while operating well within its mechanical limits.

The 12-valve Cummins remains highly sought after decades after its production ended, with many enthusiasts specifically seeking out 1994-1998 model year trucks equipped with this engine.

Its combination of mechanical simplicity, massive torque, and unparalleled durability has created a legacy that continues to influence diesel engine design today.

For many owners, the 12-valve Cummins isn’t just an engine it’s an investment that appreciates with time.

4. Toyota 22R/22RE

The Toyota 22R and its fuel-injected counterpart, the 22RE, epitomize the engineering philosophy that established Toyota’s global reputation for reliability.

Introduced in 1981, this 2.4-liter inline-four engine powered everything from Toyota pickup trucks and 4Runners to Celicas and Coronas, becoming the cornerstone of Toyota’s lineup throughout the 1980s and early 1990s.

Its reputation for durability wasn’t built on exceptional power producing a modest 105-115 horsepower but rather on its ability to run virtually forever with minimal maintenance.

The 22R’s architecture featured a cast-iron block with a simple overhead cam design, utilizing a chain-driven valvetrain that proved remarkably resistant to wear.

Toyota’s engineers focused on creating ideal thermal characteristics, with excellent cooling passages and oil circulation that prevented the hot spots and uneven expansion that typically lead to head gasket failures in four-cylinder engines.

The cylinder head itself was designed with exceptional rigidity to maintain proper sealing even after hundreds of thousands of miles.

What truly distinguished the 22R/22RE was its ability to tolerate abuse and neglect that would destroy lesser engines.

The robust bottom end featured a forged steel crankshaft and strong connecting rods that could withstand significant overloading.

Even the engine’s timing chain system, typically a wear item in many engines, was engineered with dual-row chains and overbuilt guides and tensioners in early models.

While Toyota later switched to single-row chains that proved somewhat less durable, even these routinely lasted well beyond 200,000 miles.

The 22RE variant, introduced in 1982, added electronic fuel injection that enhanced both performance and efficiency while maintaining the engine’s legendary reliability.

This fuel delivery system proved remarkably tolerant of poor-quality fuel and continued to function properly even as components aged, a critical factor in the engine’s global success.

In developing countries with limited access to quality parts and services, the 22R/22RE developed a reputation as virtually unkillable.

Documented cases of these engines exceeding 500,000 miles are commonplace, with many surpassing 700,000 miles on original internals.

The engine’s simplicity made it easy to rebuild when necessary, contributing to its continued presence in Toyota trucks decades after production ended.

For many owners worldwide, the 22R/22RE represents the gold standard of reliability against which all other engines are measured.

Also Read: 12 Most Powerful Cars That Come With a Manual Transmission

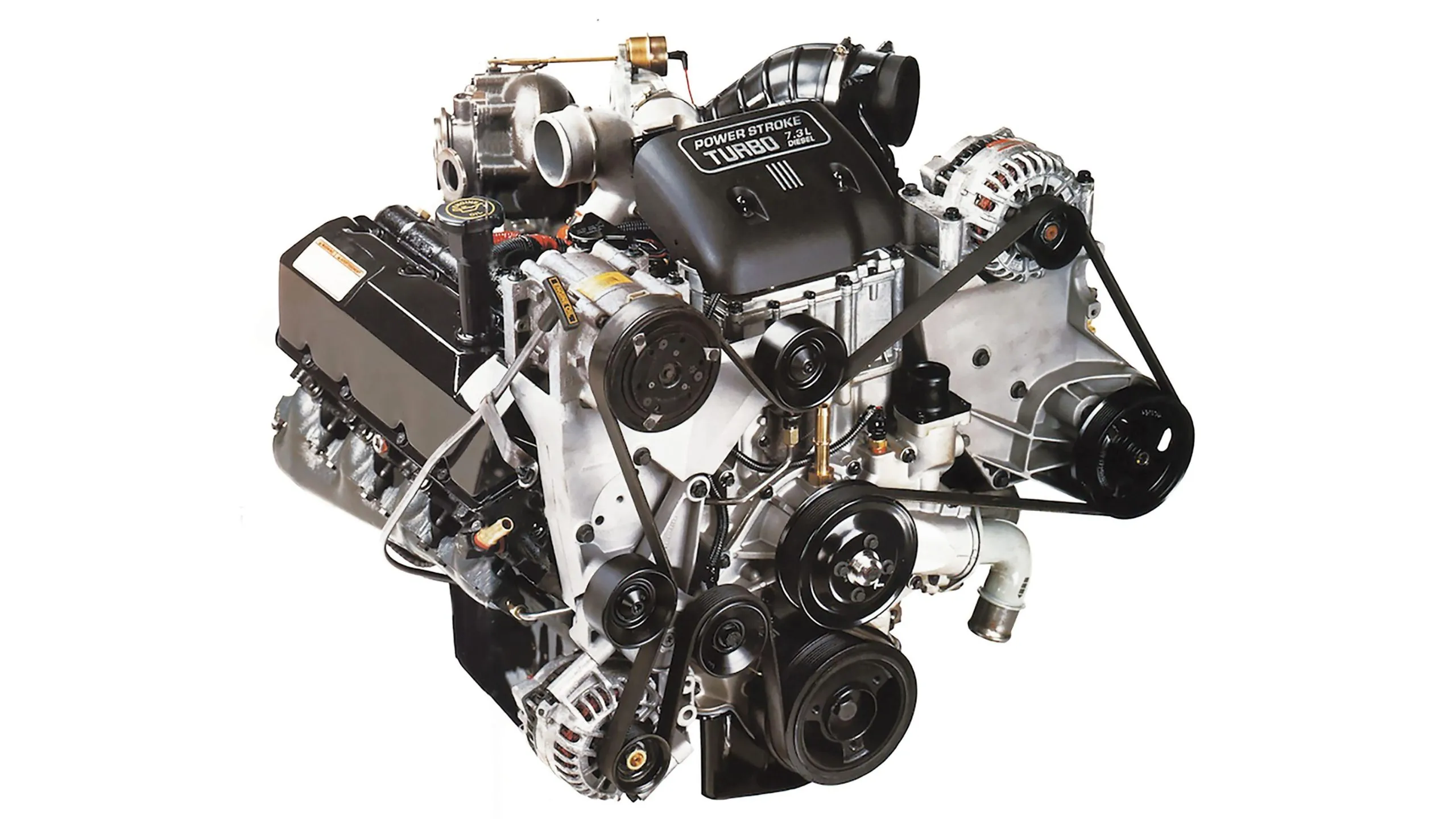

5. Navistar/International 7.3L Power Stroke

The 7.3L Power Stroke diesel engine, produced by Navistar International for Ford trucks from 1994 to 2003, earned its place in automotive history as one of the most reliable heavy-duty diesel engines ever manufactured.

This 444 cubic inch V8 turbodiesel powerplant transformed Ford’s heavy-duty truck lineup, delivering the perfect combination of power, efficiency, and legendary durability that owners still celebrate decades after its production ended.

The engine’s foundation was an exceptionally robust cast-iron block with cross-bolted main caps and a forged steel crankshaft.

Unlike many diesel engines of its era, the 7.3L Power Stroke utilized hydraulic lifters, eliminating the need for periodic valve adjustments while maintaining excellent reliability.

The engine’s HEUI (Hydraulically-activated Electronically-controlled Unit Injection) system represented a technological middle ground electronically controlled for precision but hydraulically actuated for durability that proved far more reliable than the fully electronic systems that followed.

What truly distinguished the 7.3L Power Stroke was its conservative engineering. While rated at 210-275 horsepower and 425-525 lb-ft of torque depending on the model year, the engine operated well below its mechanical limits.

This substantial design margin allowed it to handle heavy loads and extreme conditions without approaching the stress thresholds that cause premature failure.

The engine’s relatively low operating pressure compared to modern diesels reduced strain on head gaskets and other critical components.

The 7.3L’s cooling system deserves special mention, as it was designed to maintain optimal operating temperatures even under the most demanding conditions.

This prevented the heat-related issues that often plague diesel engines used for heavy towing or in extreme climates.

The engine’s oil system was equally robust, with excellent filtration and cooling capacity that preserved critical internal components.

Among truckers and fleet operators, the 7.3L Power Stroke earned a reputation for reaching extraordinary mileage milestones.

Properly maintained examples routinely exceed 500,000 miles, with many documented cases surpassing 800,000 miles on original internals.

The engine’s longevity created a unique phenomenon in the used truck market, where well-maintained 7.3L-equipped trucks often command premium prices even with high mileage.

For many Ford truck enthusiasts, the 7.3L Power Stroke represents the pinnacle of diesel reliability a reputation that subsequent engines have struggled to match.

6. Lexus/Toyota 1UZ-FE

The Toyota 1UZ-FE V8 engine represents the pinnacle of Japanese luxury engineering, combining silky-smooth operation with extraordinary longevity.

Introduced in 1989 for the first-generation Lexus LS400, this 4.0-liter quad-cam V8 was designed to compete directly with the finest engines from Mercedes-Benz and BMW.

What Toyota created, however, was an engine that not only matched its German counterparts in refinement but utterly surpassed them in reliability and durability.

The 1UZ-FE’s architecture featured an aluminum block and heads unusual for an engine known for longevity but Toyota’s engineers compensated with exceptional design features.

The block incorporated cast-iron cylinder liners and six-bolt main bearing caps securing a forged steel crankshaft.

The timing belt system, typically a weak point in overhead cam engines, was engineered to last 100,000 miles in an era when 60,000-mile intervals were standard.

Most impressively, the engine utilized a timing belt to drive four camshafts without any history of interference issues or belt failures.

What truly distinguished the 1UZ-FE was its perfect balance of performance and durability. Producing 250-290 horsepower (depending on the generation) and revving smoothly to 6,500 RPM, the engine delivered luxury-car performance while maintaining commercial-grade reliability.

The engine’s internals were so overbuilt that many examples have been supercharged or turbocharged to produce twice their original power output without sacrificing longevity.

Toyota’s obsessive attention to detail extended to the engine’s ancillary systems. The variable-length intake manifold enhanced torque across the power band while reducing stress on internal components.

The electronic throttle control system pioneered in later versions eliminated mechanical linkages that could wear out.

Even the engine’s cooling system was designed with durability in mind, featuring optimal coolant flow that prevented the hot spots that typically lead to head gasket failures in aluminum engines.

The 1UZ-FE’s reputation for reliability made it the preferred engine for luxury taxis in many countries, with documented examples exceeding 1,000,000 kilometers in commercial service.

Even in these demanding applications, the engines rarely required more than routine maintenance.

This combination of refinement and durability has made 1UZ-FE-equipped vehicles highly sought after in the used market, with many enthusiasts specifically seeking out first-generation Lexus LS400s for their legendary powerplant.

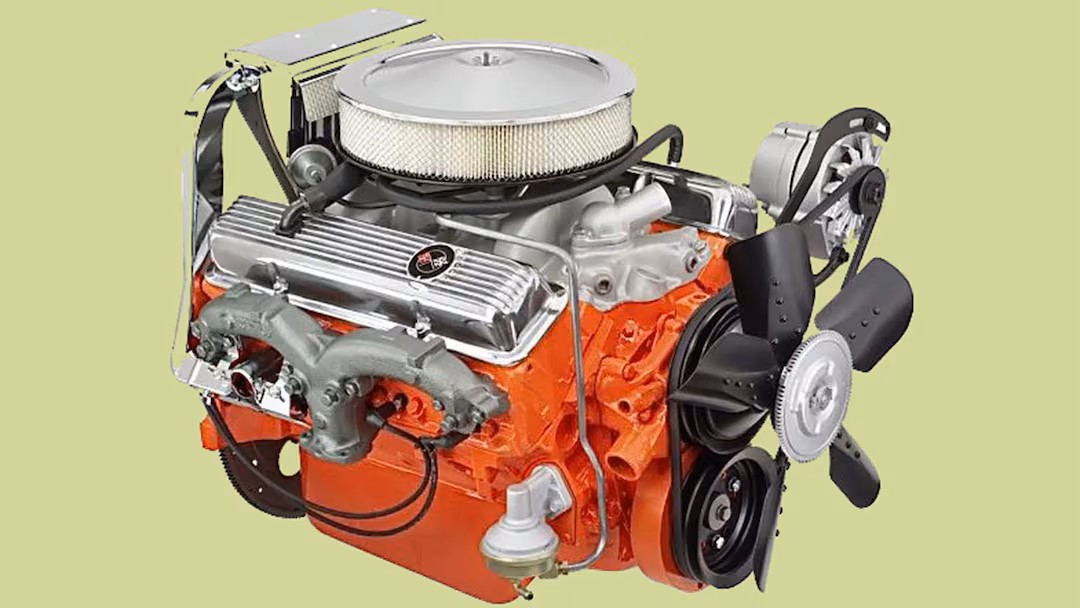

7. Chevrolet Small-Block V8 (350 cubic inch/5.7L)

The Chevrolet small-block V8, particularly the ubiquitous 350 cubic inch (5.7L) variant, stands as America’s most iconic engine, combining simplicity, power, and remarkable longevity.

Introduced in 1955 and produced in various forms until 2003, this pushrod V8 powered everything from family sedans and pickup trucks to sports cars and boats, becoming the backbone of General Motors’ lineup for nearly half a century.

While many versions were produced, the 350 cubic inch displacement became the most popular, with a reputation for reliability that has achieved near-mythical status.

The small block’s durability stems from its fundamentally sound design. Its cast-iron block and heads provided excellent thermal stability, while the simple overhead valve configuration eliminated the complexity and potential failure points of overhead cam systems.

The engine’s relatively low-stress valvetrain, with hydraulic lifters that required no adjustment, contributed significantly to its longevity.

Even the timing chain system, often a weak point in many engines, was designed with robust components that routinely lasted well beyond 200,000 miles.

What truly distinguished the Chevy small-block was its adaptability and ease of maintenance. The engine’s design allowed for straightforward repairs using basic tools, making it accessible to shade-tree mechanics and professional technicians alike.

This serviceability factor meant that these engines could be maintained indefinitely at a reasonable cost, contributing enormously to their reputation for exceeding 500,000 miles in commercial applications.

The small-block’s cooling system deserves special mention, as it was designed with excellent water flow through the block and heads, preventing the hot spots that often lead to head gasket failures in V8 engines.

Oil circulation was equally well-engineered, with ample pressure and volume to protect critical components even under extreme conditions.

These fundamental design elements gave the small block exceptional resilience even when subjected to the rigors of towing, high-performance driving, or commercial use.

Throughout its production run, the 350 small block underwent numerous refinements while maintaining its core architecture.

Later versions incorporated electronic fuel injection, more efficient combustion chambers, and improved sealing technologies, all while preserving the durability that made the engine famous.

The TBI (Throttle Body Injection) 350 engines of the late 1980s and early 1990s are particularly renowned for their longevity, with many examples in trucks and SUVs exceeding 300,000 miles with minimal issues.

The Chevy small-block’s reputation for durability created a massive aftermarket industry and a knowledge base unmatched by any other engine.

This ecosystem of parts and expertise has allowed countless examples to remain in service decades after their manufacture, with many reaching the 500,000-mile mark through periodic rebuilds and maintenance.

For millions of Americans, the distinctive rumble of a Chevy 350 remains the sound of dependable power that keeps on running long after other engines have failed.

8. Volvo Redblock (B230FT)

The Volvo Redblock engine family, particularly the turbocharged B230FT variant, epitomizes Swedish engineering philosophy: robust, practical, and built to outlast the vehicle it powers.

Introduced in the late 1970s and produced until 1998, this 2.3-liter inline-four became synonymous with Volvo’s reputation for safety and durability.

While not the most powerful or sophisticated engine of its era, the Redblock’s extraordinary longevity has created a devoted following among those who prioritize reliability above all else.

The Redblock’s durability begins with its massive cast-iron block, featuring cylinder walls significantly thicker than comparable engines of the period.

This substantial construction provided exceptional rigidity and thermal stability, creating an ideal foundation for long-term reliability.

The engine’s crossflow cylinder head design, with intake and exhaust on opposite sides, ensured optimal cooling and breathing efficiency.

Even the head bolts were engineered for longevity, using a special design that prevented the loosening that often leads to head gasket failures.

What truly distinguished the B230FT was its ability to handle the additional stresses of turbocharging without compromising reliability.

Volvo’s engineers incorporated numerous strengthening features, including reinforced main bearings, oil-cooled pistons, and a robust forged crankshaft.

The turbocharging system itself was conservatively tuned, prioritizing longevity over maximum power output.

This approach resulted in an engine that delivered satisfying performance while maintaining the exceptional durability expected of a Volvo.

The Redblock’s oiling system deserves special mention, as it was designed with capacity far beyond the engine’s requirements.

This generous oil supply, combined with an efficient cooling system, allowed the engine to operate under extreme conditions without accelerated wear.

Even the timing belt system, often a weakness in interference engines, was designed with ample safety margins and a straightforward replacement procedure.

Among Volvo enthusiasts, the B230FT has achieved legendary status for its ability to exceed 500,000 miles with basic maintenance.

Many examples have surpassed 750,000 miles on original internals, with some documented cases exceeding one million miles.

This extraordinary longevity has made Redblock-equipped Volvos popular choices for those seeking truly durable vehicles, with many 1980s and early 1990s models still in daily service decades after their manufacture.

9. BMW M20

The BMW M20 straight-six engine represents the perfect synthesis of German engineering precision and long-term durability.

Produced from 1977 to 1993, this inline-six powerplant powered numerous BMW models, including the iconic E30 3-Series and E28 5-Series.

While BMW has created many extraordinary engines over the decades, the M20 stands apart for its remarkable longevity and mechanical resilience, routinely exceeding 300,000 miles and capable of reaching 500,000 miles with proper maintenance.

The M20’s architecture featured a cast-iron block paired with an aluminum cylinder head, creating an ideal balance between strength and weight.

BMW’s engineers incorporated seven main bearings to support the crankshaft, providing exceptional stability and wear resistance.

The simple single overhead cam design, with two valves per cylinder, prioritized reliability over maximum power output.

This conservative approach to performance resulted in an engine that operated well within its mechanical limits, contributing significantly to its longevity.

What truly distinguished the M20 was BMW’s fanatical attention to detail in its manufacturing.

The engine’s components were produced to exceptionally tight tolerances, resulting in optimal operating clearances that minimized wear.

The oiling system provided abundant lubrication to critical components, while the cooling system maintained ideal operating temperatures under all conditions.

Even the engine’s accessories, often a weak point in many designs, were engineered for exceptional service life.

The M20’s timing belt system, usually a reliability concern in interference engines, was designed with substantial safety margins and a straightforward replacement procedure.

When maintained according to BMW’s 60,000-mile replacement interval, belt failures were virtually unknown.

This reliability extended to the engine’s fuel and ignition systems, which proved remarkably durable even as they aged.

Among BMW enthusiasts, the M20 is celebrated for its tractable power delivery and extraordinary serviceability.

The engine’s design allowed for straightforward maintenance with reasonable access to most components.

This accessibility, combined with excellent parts availability, has allowed countless M20 engines to remain in service decades after their manufacture.

For many BMW owners, the M20 represents the perfect combination of driving pleasure and pragmatic reliability an engine that delivers the “ultimate driving machine” experience without the maintenance headaches often associated with European performance cars.

10. Honda F-Series (F22B/F23A)

The Honda F-Series engines, particularly the F22B and F23A variants found in the fourth, fifth, and sixth-generation Accord models, represent the pinnacle of Honda’s engineering philosophy: efficient, refined, and extraordinarily durable.

Introduced in the early 1990s, these 2.2-2.3 liter inline-four SOHC engines weren’t designed to wow with impressive horsepower figures but rather to provide smooth, efficient power delivery and exceptional longevity that would keep owners satisfied for decades.

The F-Series architecture featured a cast-iron block paired with an aluminum SOHC cylinder head, creating an ideal balance of strength and weight.

Honda’s engineers incorporated design elements specifically targeting long-term durability, including a rigid crankshaft supported by five main bearings, a robust connecting rod design, and pistons with perfect thermal characteristics.

The engine’s valvetrain utilized Honda’s proven rocker arm system, which proved remarkably resilient even after hundreds of thousands of miles.

What truly distinguished the F-Series engines was Honda’s legendary manufacturing precision. Components were produced to extraordinarily tight tolerances, resulting in optimal operating clearances that minimized wear.

The engine’s oiling system provided abundant lubrication even under extreme conditions, while the cooling system maintained ideal operating temperatures to prevent the thermal stress that often leads to head gasket failures in aluminum heads.

The F-Series engines featured Honda’s non-interference design, meaning that even if the timing belt failed, the pistons wouldn’t contact the valves a significant reliability advantage over many competitors.

While Honda recommended timing belt replacement at 90,000-mile intervals, many F-Series engines operated well beyond this point without issues.

This reliability extended to the engine’s fuel and ignition systems, which proved remarkably durable even as they aged.

Among Honda enthusiasts, the F-Series engines are celebrated for their perfect balance of efficiency, refinement, and durability.

With basic maintenance, these engines routinely exceeded 300,000 miles without major issues, with many documented examples surpassing 500,000 miles on original internals.

This extraordinary longevity has made F-Series-equipped Accords popular choices for those seeking truly reliable transportation.

Many 1990s models are still in daily service decades after their manufacture. For countless owners worldwide, the Honda F-Series engine represents the gold standard of four-cylinder reliability an engine that simply refuses to die.

Also Read: 10 Cars That Feel More Like an Aircraft Than a Vehicle