When it comes to mechanical reliability, certain engines stand as marvels of engineering built to withstand decades of use with minimal maintenance.

These powerplants represent the pinnacle of durability in their respective categories, from automobile engines to industrial workhorses.

Their longevity stems from overbuilt designs, simple mechanical principles, and engineering that prioritizes robustness over cutting-edge performance.

While no engine is truly maintenance-free, these examples require significantly less attention than their counterparts, often running reliably for 30+ years with basic care.

They’ve earned reputations in professional circles as “buy it for life” options, with many examples still operating well beyond their expected service lives.

This collection spans various applications and technologies, from naturally aspirated gasoline engines to diesel workhorses and even specialized industrial units.

What unites them is exceptional build quality, thoughtful engineering, and proven track records of survival in demanding conditions.

For those seeking true mechanical dependability, these engines represent the gold standard of long-term reliability.

1. Toyota 2JZ-GE Inline-6 Engine

The Toyota 2JZ-GE stands as a testament to the Japanese engineering excellence of the 1990s, representing perhaps the ultimate expression of Toyota’s overbuilt philosophy.

This 3.0-liter inline-six engine first appeared in the Lexus SC300 and Toyota Supra, quickly establishing itself as one of the most bulletproof powerplants ever produced for a passenger vehicle.

What makes the 2JZ-GE exceptional is its iron block construction unusual for its era when many manufacturers were switching to aluminum for weight savings.

This cast iron foundation provides exceptional rigidity and heat management, allowing the engine to maintain precise tolerances even under extreme conditions.

Toyota paired this with a remarkably strong forged steel crankshaft that could handle forces far beyond what the factory output required.

The engine features a simple yet effective dual overhead cam design with sequential fuel injection that operates with remarkable consistency.

The cooling system is generously proportioned, preventing the hot spots that often lead to premature failure in other engines.

Even the oil passages are oversized compared to contemporary designs, ensuring proper lubrication throughout the engine’s long life.

Perhaps most importantly, Toyota engineered the 2JZ with extremely conservative internal clearances and operating parameters.

While many manufacturers pushed their engines to the limit for maximum performance, Toyota built significant safety margins into every component.

This means that even when subjected to decades of use, the engine typically shows minimal wear.

The naturally aspirated 2JZ-GE regularly achieves 300,000-400,000 miles without internal repairs, with many examples exceeding 500,000 miles with just basic maintenance.

This legendary durability has made it a favorite among enthusiasts and professionals alike, with demand remaining high even 25+ years after production.

The engine’s reputation for reliability is so strong that many owners report needing nothing more than routine oil changes, occasional timing belt replacements, and basic tune-ups over decades of ownership.

2. Cummins 5.9L 12-Valve Diesel

The Cummins 5.9L 12-valve diesel engine (officially the 6BT) represents the pinnacle of mechanical diesel simplicity and durability.

Introduced in 1989 for Dodge Ram trucks, this straight-six turbodiesel powerplant has earned a legendary reputation for reliability in both commercial and consumer applications.

What sets the 12-valve Cummins apart is its incredibly simple design philosophy. Unlike modern diesel engines with complex electronic controls, the 12-valve uses a straightforward mechanical fuel injection system with a Bosch P7100 injection pump.

This mechanical system operates without electronic sensors or computers, eliminating countless potential failure points.

The engine’s mechanical injection timing means it can run even under conditions that would cripple electronically controlled diesels.

The engine block is made of cast iron with exceptional wall thickness, providing tremendous strength and stability.

The forged steel crankshaft and connecting rods are massively overbuilt for the factory power output, which explains why these engines can handle significant power increases without internal modifications.

The cylinder head features just two valves per cylinder (hence the “12-valve” designation), reducing complexity compared to later 24-valve versions.

Cooling is another area where the 5.9L excels. The engine utilizes a gear-driven water pump and a thermostat housing designed for maximum flow, preventing the overheating issues that plague many diesel engines.

The oil system features a large-capacity oil pump and generous oil passages that ensure proper lubrication throughout the engine’s service life.

These engines regularly achieve 500,000 miles without major repairs, with many documented cases exceeding 1 million miles with just basic maintenance.

The maintenance requirements are remarkably simple regular oil changes, occasional valve adjustments, and fuel filter replacements are typically all that’s needed for decades of service.

When issues do arise, they’re usually limited to external components like water pumps or fuel lines, while the core engine remains intact.

The Cummins 5.9L 12-valve’s reputation for reliability has made it one of the most sought-after diesel engines on the secondary market, with many examples commanding premium prices even with high mileage.

Its ability to run for decades with minimal attention represents the gold standard for diesel engine longevity.

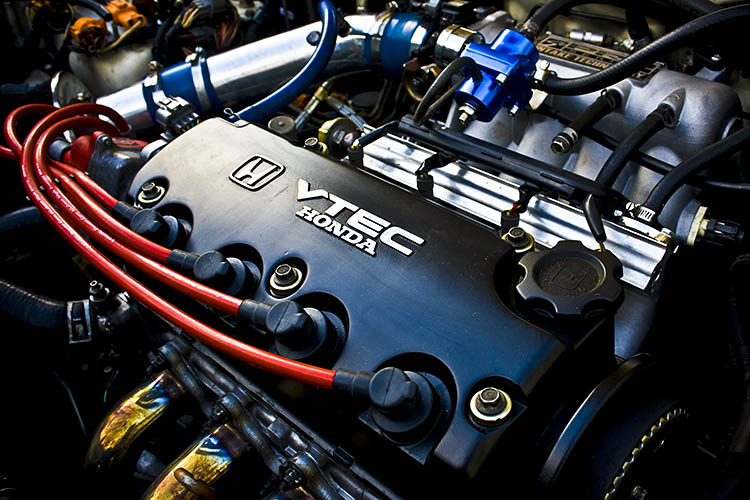

3. Honda D-Series SOHC Engines

Honda’s D-series single overhead cam (SOHC) engines represent the epitome of a reliable, economical four-cylinder design.

First introduced in the late 1980s and produced through the early 2000s, these engines powered millions of Civic, Accord, and other Honda models worldwide, earning a reputation for exceptional longevity with minimal maintenance.

The most famous variants, including the D15B, D16A, and D16Z6, share a fundamental architecture that prioritizes simplicity and durability.

Honda engineered these engines with precision manufacturing tolerances that were years ahead of their time, creating engines that maintain their efficiency and performance characteristics even after hundreds of thousands of miles.

The D-series features a cast iron cylinder block paired with an aluminum head, providing an ideal balance of strength and weight.

The oil passages are generously sized and precisely placed to ensure proper lubrication under all operating conditions.

Perhaps most importantly, Honda designed these engines to operate with remarkable mechanical harmony the valvetrain components, pistons, and rotating assembly work together with minimal stress or vibration.

One of the D-series’ most impressive features is its timing belt system. While timing belts are typically considered maintenance items, Honda engineered their system with such precision that many D-series engines run for 200,000+ miles on the original timing belt without failure (though replacement at 90,000-mile intervals is recommended).

The interference design means a failure would be catastrophic, yet these belts rarely break when properly maintained.

The cooling system is another engineering triumph, with excellent flow characteristics and a thermostat housing designed to prevent air pockets.

This system allows the engine to maintain consistent operating temperatures even under extreme conditions, preventing the thermal cycling that often leads to head gasket failures in other engines.

Maintenance requirements are remarkably simple regular oil changes every 5,000-7,500 miles, occasional valve adjustments (which can be performed without special tools), and timing belt replacement at recommended intervals.

With this basic care, D-series engines regularly surpass 300,000 miles without internal repairs, with many documented cases exceeding 500,000 miles on original components.

The D-series’ remarkable longevity is perhaps best illustrated by their prevalence in high-mileage fleets and developing countries, where they continue to operate reliably decades after manufacture.

Their combination of simplicity, precision engineering, and thoughtful design has created a legacy of four-cylinder engines that outlast many vehicles they power.

4. Mercedes-Benz OM617 Diesel

The Mercedes-Benz OM617 five-cylinder diesel engine stands as perhaps the most legendary diesel powerplant ever installed in a passenger vehicle.

Produced from 1974 to 1991, this naturally aspirated (and later turbocharged) diesel engine powered numerous Mercedes models, including the iconic W123 chassis that many consider the most durable automobile ever manufactured.

The OM617’s reputation for longevity begins with its massively overbuilt block and rotating assembly.

The cast iron block features extraordinary wall thickness and cylinder reinforcement, making it virtually impervious to the stresses of diesel combustion.

The forged steel crankshaft rotates on seven main bearings (unusual for a five-cylinder design), providing exceptional stability and load distribution throughout the engine’s service life.

Mercedes engineered the OM617 with pre-chamber indirect injection, a design that sacrifices some efficiency for remarkable durability.

This system operates with significantly lower cylinder pressures than modern direct injection diesel, reducing stress on components and extending service life.

The injection pump itself is a Bosch mechanical unit renowned for its precision and longevity, often operating flawlessly for 500,000+ miles without service.

The cooling system features a thermostat housing designed for maximum flow and a water pump with exceptional durability.

The oil system is equally robust, with a large-capacity sump and generous oil galleries that ensure proper lubrication under all conditions.

Perhaps most importantly, Mercedes designed the OM617 with conservative operating parameters, never pushing the engine to its limits for the sake of performance or efficiency.

Maintenance requirements are remarkably simple oil changes every 5,000-7,500 miles, occasional valve adjustments and timing chain inspection at high mileage are typically all that’s needed.

The timing chain itself is a massive, overbuilt component that rarely requires replacement before 300,000 miles.

The engine’s valvetrain is similarly robust, with many examples showing minimal wear even after 500,000 miles of service.

The OM617’s legendary durability is best demonstrated by its prevalence in high-mileage applications worldwide.

Numerous examples have surpassed 1 million miles with minimal internal work, with many taxi services and commercial operators choosing these engines specifically for their longevity.

The 617’s reputation is so strong that even decades after production ended, these engines command premium prices in the secondary market.

Mercedes’ commitment to engineering excellence was created in the OM617 a diesel engine that outlasts virtually every other component in the vehicles it powers, often remaining in service for 40+ years with just basic maintenance.

Also Read: 10 Performance Cars That Come With a Factory Roll Cage

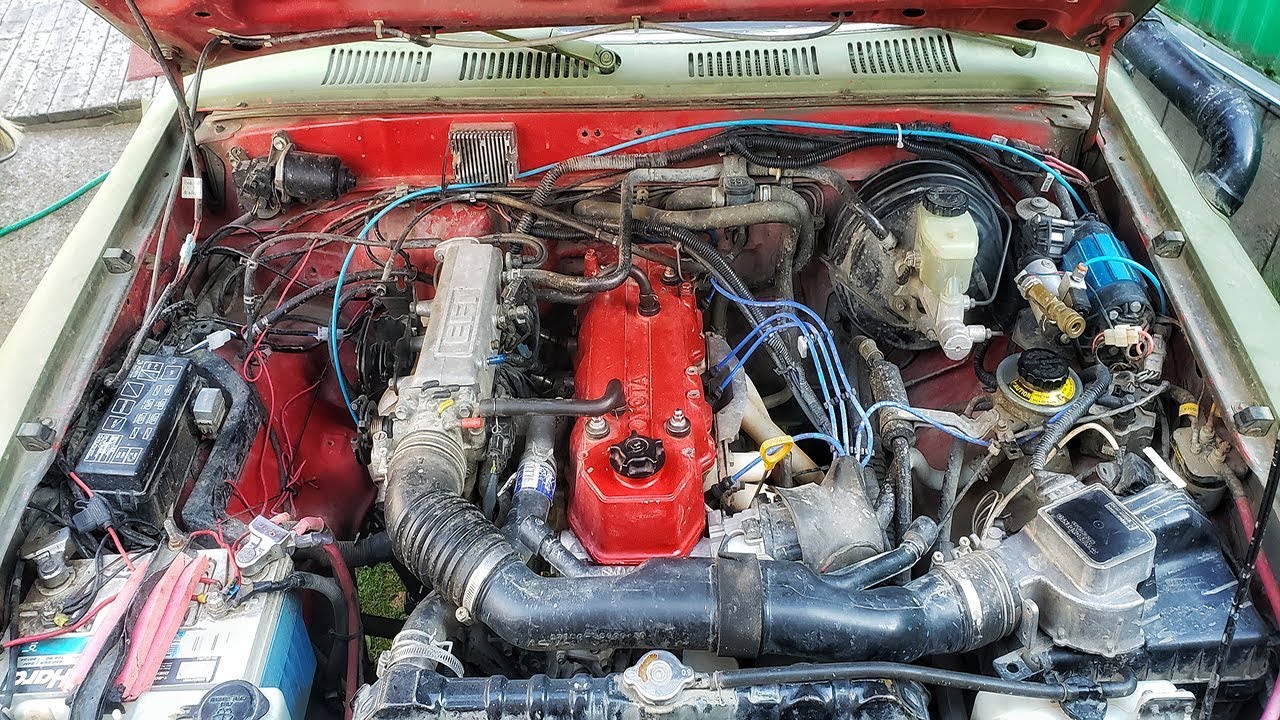

5. Toyota 22R/22RE Four-Cylinder Engine

The Toyota 22R and its fuel-injected evolution, the 22RE, represent the pinnacle of reliable four-cylinder truck engines.

Produced from 1981 to 1997, these engines powered Toyota’s legendary pickup trucks and 4Runners through their most reputation-building years, establishing a legacy of reliability that continues to influence consumer perceptions today.

What makes the 22R/22RE exceptional is its architectural simplicity combined with Toyota’s fanatical attention to manufacturing precision.

The engine features a cast iron block with unusually thick cylinder walls and main bearing supports, providing exceptional rigidity and heat management.

The cylinder head is made of aluminum for weight savings but is designed with generous material thickness around critical areas like valve seats and combustion chambers.

The engine’s valvetrain employs a single overhead cam design with a timing chain that’s among the most durable ever produced.

Unlike many timing chains that require replacement at regular intervals, the 22R’s chain and guides routinely last 300,000+ miles before showing significant wear.

The chain tensioner is mechanically actuated rather than hydraulic, eliminating a common failure point in other engines.

Cooling is another area where Toyota’s engineering shines. The water pump is externally mounted and driven by the timing chain, making it both reliable and easily serviceable.

The cooling passages are generously sized and strategically placed to prevent hot spots that could lead to head gasket failures.

The oil system features a high-capacity pump and large oil galleries that ensure proper lubrication even under extreme conditions.

Perhaps most importantly, Toyota designed the 22R/22RE with extreme conservatism in its operating parameters.

The engine typically operates well below its mechanical limits, with combustion pressures, valve spring tensions, and bearing loads all maintained at levels that promote longevity over maximum performance.

These engines regularly achieve 300,000-400,000 miles without internal repairs, with many documented cases exceeding 500,000 miles with just basic maintenance.

The maintenance requirements are remarkably simple – regular oil changes, occasional valve adjustments, and timing chain inspection at high mileage are typically all that’s needed for decades of reliable service.

The 22R/22RE’s reputation for reliability has made it one of the most sought-after engines in the used market, with many examples commanding premium prices even with high mileage.

Its ability to run virtually indefinitely with minimal attention represents the gold standard for truck engine longevity and explains why these decades-old Toyota trucks continue to command strong resale values worldwide.

6. Caterpillar 3406 Diesel Engine

The Caterpillar 3406 diesel engine stands as one of the most respected and longest-lasting powerplants in the heavy-duty industry.

Introduced in the early 1980s and produced through several evolutionary stages until the early 2000s, this inline-six diesel engine became the benchmark for reliability in commercial trucking, marine applications, and industrial power generation.

The 3406’s remarkable durability begins with its massive cast iron block, featuring cylinder walls significantly thicker than industry standards and extraordinary reinforcement around the main bearings.

The crankshaft is forged from high-grade steel and precision-balanced, running on seven main bearings that distribute loads evenly throughout the engine’s operating range.

The connecting rods are similarly overbuilt, designed to handle forces far beyond what the factory output requires.

Caterpillar engineered the 3406 with a gear-driven camshaft system rather than using chains or belts, eliminating a common failure point in other engines.

These precision-machined hardened steel gears typically last the entire service life of the engine without replacement.

The valvetrain employs massive pushrods and rocker arms that maintain precise valve timing even after millions of miles of operation.

The fuel system varies by generation but generally features Caterpillar’s proprietary mechanical injection systems (pre-HEUI models) that operate with remarkable consistency decade after decade.

Unlike modern electronic systems with numerous potential failure points, these mechanical injection systems can run virtually indefinitely with basic maintenance.

Perhaps most importantly, Caterpillar designed the 3406 with significantly larger cooling and lubrication systems than strictly necessary.

The cooling system features a large-capacity radiator and water pump, while the oil system utilizes a high-volume pump and massive oil galleries.

These oversized systems ensure proper cooling and lubrication even under extreme conditions, preventing the accelerated wear that plagues many other heavy-duty engines.

The 3406’s legendary durability is best illustrated by its service record. These engines regularly achieve 1-2 million miles before requiring a major overhaul, with many marine and industrial applications running 60,000+ hours without internal repairs.

The maintenance requirements are straightforward regular oil changes, fuel filter replacements, and occasional valve adjustments are typically all that’s needed for decades of service.

Even after Caterpillar ceased production in favor of emissions-compliant designs, the 3406 remains highly sought after in the secondary market.

Many operators specifically seek out these engines for their renowned reliability, often paying premium prices for well-maintained examples.

The 3406’s reputation for durability made it the engine of choice for applications where downtime is simply not an option.

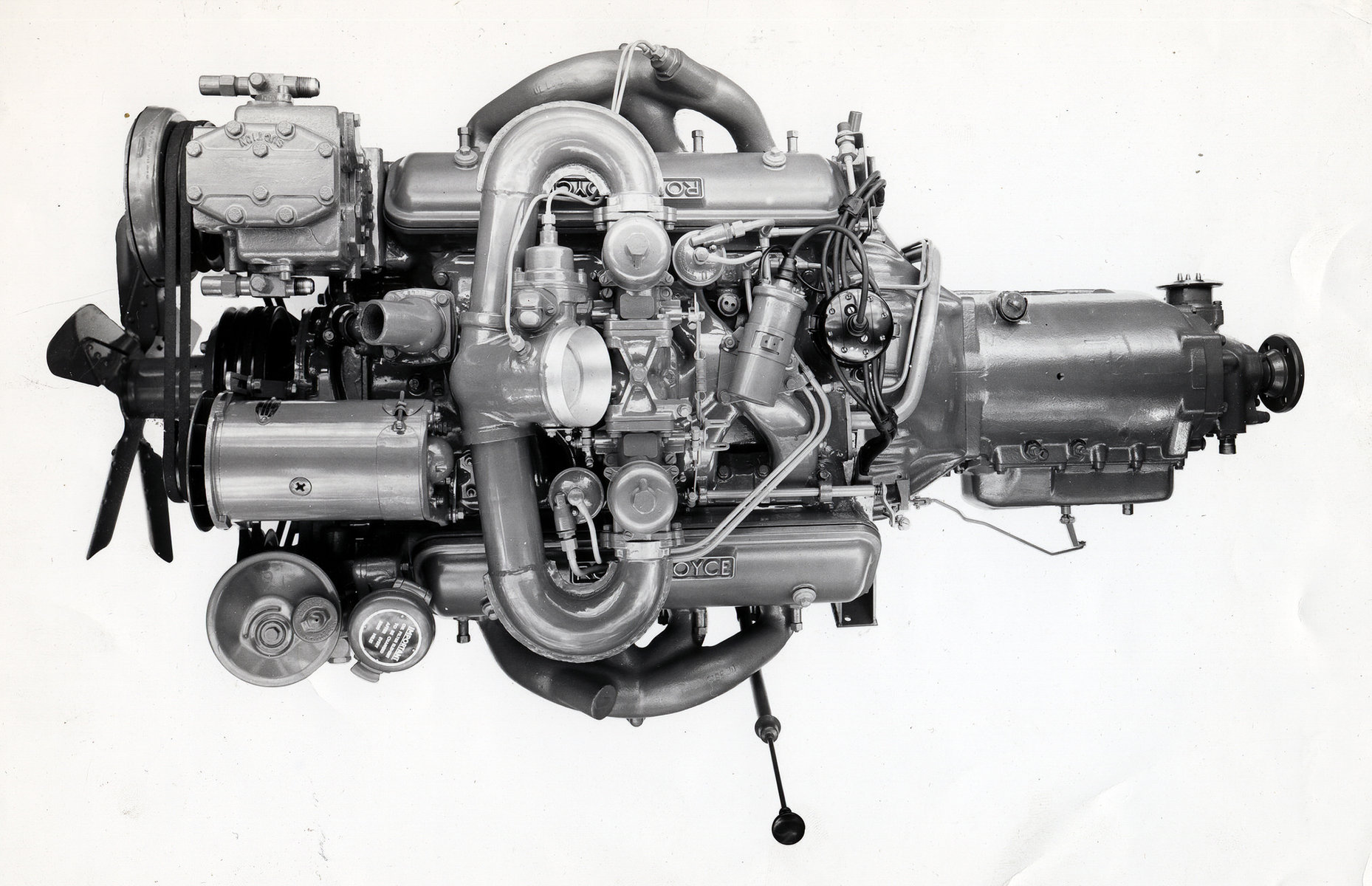

7. Rolls-Royce/Bentley L-Series V8

The Rolls-Royce/Bentley L-Series V8 stands as one of the longest-running production engines in automotive history, with a production span from 1959 to 2020.

This remarkable 61-year production run speaks volumes about the engine’s fundamental durability and timeless design, powering some of the world’s most prestigious luxury automobiles across multiple generations.

What makes the L-Series V8 exceptional is its extraordinary overbuilt nature. The engine block is cast from aluminum with exceptionally thick walls and massive reinforcement around the cylinder bores and main bearings.

Unlike many aluminum blocks that suffer from durability issues, Rolls-Royce engineered this block with cast-in iron cylinder liners of significant thickness, providing the wear resistance of iron with the weight advantages of aluminum.

The crankshaft is a masterpiece of engineering, forged from high-grade steel and featuring counterweights that extend well beyond what’s strictly necessary for balancing.

This massive crankshaft runs on five main bearings with bearing surfaces significantly larger than industry standards.

The connecting rods are similarly overbuilt, designed to handle forces far beyond what the engine would experience in normal operation.

Perhaps most importantly, Rolls-Royce designed the L-Series with extremely conservative internal clearances and operating parameters.

While many manufacturers pushed their engines to the limit for maximum performance, Rolls-Royce prioritized smoothness and longevity above all else.

The engine typically operates well below its mechanical limits, with combustion pressures, valve spring tensions, and bearing loads all maintained at levels that promote longevity over maximum performance.

The cooling system features precision-machined water jackets and a thermostat housing designed for optimal flow distribution.

The oil system employs a large-capacity sump and oil pump, with generous oil galleries that ensure proper lubrication throughout the engine’s long life.

Even the auxiliary components like the water pump and alternator are engineered to last far longer than industry standards.

These engines regularly achieve 300,000+ miles without internal repairs, with many examples exceeding 500,000 miles with just basic maintenance.

What’s perhaps most remarkable is that they achieve this longevity while powering extremely heavy luxury vehicles, often operating in stop-and-go traffic and other demanding conditions.

The maintenance requirements are straightforward regular oil changes, occasional valve adjustments, and timing chain inspection at high mileage are typically all that’s needed.

The L-Series V8’s extraordinary durability is best illustrated by its prevalence in vintage Rolls-Royce and Bentley models from the 1960s and 1970s that continue to operate flawlessly today.

Many of these vehicles have been in continuous service for 50+ years, with their original engines still running smoothly after decades of use.

This exceptional longevity, combined with the engine’s legendary smoothness and refinement, explains why Rolls-Royce continued producing variations of this basic design for over six decades testament to engineering that was decades ahead of its time.

8. Detroit Diesel 71 Series Two-Stroke Diesel

The Detroit Diesel 71 Series represents perhaps the most durable two-stroke diesel engine ever produced for commercial applications.

Developed by General Motors’ Detroit Diesel division in the 1930s and produced through the 1990s, these engines powered everything from buses and trucks to marine vessels, generators, and military equipment through some of America’s most productive decades.

What makes the “Screaming Jimmy” (as it was affectionately known due to its distinctive sound) exceptional is its remarkably simple yet robust design.

Unlike four-stroke diesels with complex valve trains, the two-stroke 71 Series uses ports in the cylinder walls and simple butterfly valves in the exhaust manifold.

This radical simplification eliminates countless potential failure points, resulting in an engine that can run virtually indefinitely with basic maintenance.

The engine block is constructed from cast iron with extraordinary wall thickness and reinforcement. The crankshaft is forged from high-grade steel and runs on massive bearings designed for continuous heavy-duty operation.

Perhaps most importantly, Detroit designed these engines with individual replaceable cylinder liners, allowing for simple rebuilds without major disassembly.

The fuel system employs Detroit’s proprietary unit injector design, with mechanically actuated injectors operated directly by the camshaft.

This system eliminates the high-pressure fuel lines and complex injection pumps that often cause issues in other diesel engines.

The injectors themselves are built with remarkable precision and durability, often lasting 500,000+ miles before requiring service.

The blower system (a defining feature of these two-stroke diesels) uses massive Roots-type lobes manufactured to extraordinarily tight tolerances.

These precision-machined components maintain their efficiency even after decades of operation, ensuring proper air delivery throughout the engine’s service life.

The cooling system features generously sized water jackets and external cooling components designed for continuous heavy-duty use.

These engines regularly achieve 1-2 million miles before requiring a major overhaul, with many industrial and marine applications running 100,000+ hours without internal repairs.

The maintenance requirements are remarkably simple regular oil changes, fuel filter replacements, and occasional blower inspections are typically all that’s needed for decades of continuous service.

The 71 Series’ legendary durability is best illustrated by its continued presence in infrastructure around the world.

Many of these engines remain in emergency power generation service 50+ years after manufacture, still ready to provide reliable power when called upon.

Their combination of mechanical simplicity and robust construction created a diesel engine that could withstand decades of continuous operation with minimal attention.

9. General Electric J47 Turbojet Engine

The General Electric J47 turbojet engine represents one of the most reliable jet engines ever produced.

First introduced in 1948 and manufactured through the 1960s, this remarkable powerplant powered numerous military aircraft including the F-86 Sabre, B-45 Tornado, and B-47 Stratojet during a critical period in American aviation history.

What makes the J47 exceptional is its remarkable simplicity compared to modern turbine engines.

The engine features a centrifugal compressor rather than the more complex axial compressors found in later designs.

This simpler compressor uses massive impellers manufactured to extraordinary precision, maintaining their aerodynamic efficiency even after thousands of operating hours.

The combustion chamber employs a can-annular design with individual flame tubes that can be inspected and replaced individually without engine disassembly.

General Electric engineered the J47 with remarkable metallurgical innovation for its era. The turbine blades are manufactured from high-temperature alloys that maintain their structural integrity even when operating at temperatures approaching their limits.

The main shaft bearings are designed for extraordinary durability, with multi-redundant lubrication systems ensuring proper operation even under extreme conditions.

Perhaps most importantly, General Electric designed the J47 with significant operational margins.

Unlike many modern engines that operate near their design limits for maximum efficiency, the J47 typically operates well below its mechanical and thermal limits.

This conservative approach allowed these engines to run reliably even in the harsh conditions of military service, where maintenance might be less than ideal.

The engine’s control system employs simple mechanical governor mechanisms rather than the complex electronic controls found in modern turbines.

These mechanical systems can operate reliably for decades with minimal adjustment, eliminating countless potential failure points.

The fuel delivery system is similarly straightforward, with robust mechanical pumps and simple metering systems that maintain consistency throughout the engine’s long service life.

These engines regularly achieved 4,000-5,000 operating hours between major overhauls, with many examples accumulating 20,000+ total hours over decades of service.

The maintenance requirements are remarkably straightforward regular oil changes, filter replacements, and borescope inspections are typically all that’s needed between major service intervals.

The J47’s extraordinary durability is perhaps best illustrated by its continued presence in museum collections worldwide, where many examples can still operate safely decades after manufacture.

The engine’s combination of design simplicity, material innovation, and conservative operating parameters created a turbine powerplant that could withstand decades of demanding service with remarkable reliability.

10. Continental O-200 Aircraft Engine

The Continental O-200 air-cooled aircraft engine stands as one of the most reliable powerplants ever produced for light aircraft.

Introduced in the 1940s and still in production today, this four-cylinder horizontally opposed engine has powered countless Cessna 150s, Aeronca Champions, and other iconic training aircraft that have introduced generations of pilots to flight.

What makes the O-200 exceptional is its fundamental simplicity combined with extraordinarily precise manufacturing.

The engine features horizontally opposed cylinders that naturally balance reciprocating forces, reducing vibration and extending component life. Each cylinder is individually replaceable, allowing for simple maintenance without complete engine disassembly.

The cylinder heads are made from aluminum with deep cooling fins, providing excellent heat dissipation without the complexity of liquid cooling systems.

Continental engineered the O-200 with a remarkably robust crankshaft and connecting rods, manufactured to tolerances that were decades ahead of their time.

The crankshaft runs on massive main bearings designed for continuous operation at relatively high RPMs.

The connecting rods feature a simple but exceptionally strong design that has remained largely unchanged for decades, demonstrating the fundamental soundness of the original engineering.

The engine’s valvetrain employs push rods and rocker arms rather than overhead cams, creating a system that’s both simple to maintain and extraordinarily reliable.

The valve guides and seats are manufactured from hardened materials that maintain their dimensions even after thousands of hours of operation.

The valve springs are designed to provide proper valve control without creating excessive stress on other components.

Perhaps most importantly, Continental designed the O-200 with significant operational margins.

While the engine is rated for continuous operation at 100 horsepower, its internal components are engineered to handle significantly greater loads.

This conservative approach allows these engines to run reliably even when operated near their rated capacity for extended periods.

These engines regularly achieve 2,000 hours between overhauls, with many examples accumulating 10,000+ total hours over decades of service.

What’s particularly impressive is that they achieve this longevity despite the harsh operating environment of aircraft use, with rapid temperature changes, varying load conditions, and critical safety requirements.

The maintenance requirements are straightforward regular oil changes, spark plug replacements, and valve adjustments are typically all that’s needed between major overhaul intervals.

The engine’s simple design allows much of this maintenance to be performed with basic tools, making it ideal for operation in remote locations.

The O-200’s extraordinary durability is best illustrated by its continued production after more than 75 years with relatively minor changes to the fundamental design.

Few engineered products can claim such longevity, particularly in an application where reliability is quite literally a matter of life and death.

Continental’s commitment to engineering excellence created an aircraft engine that pilots continue to trust with their lives generation after generation.

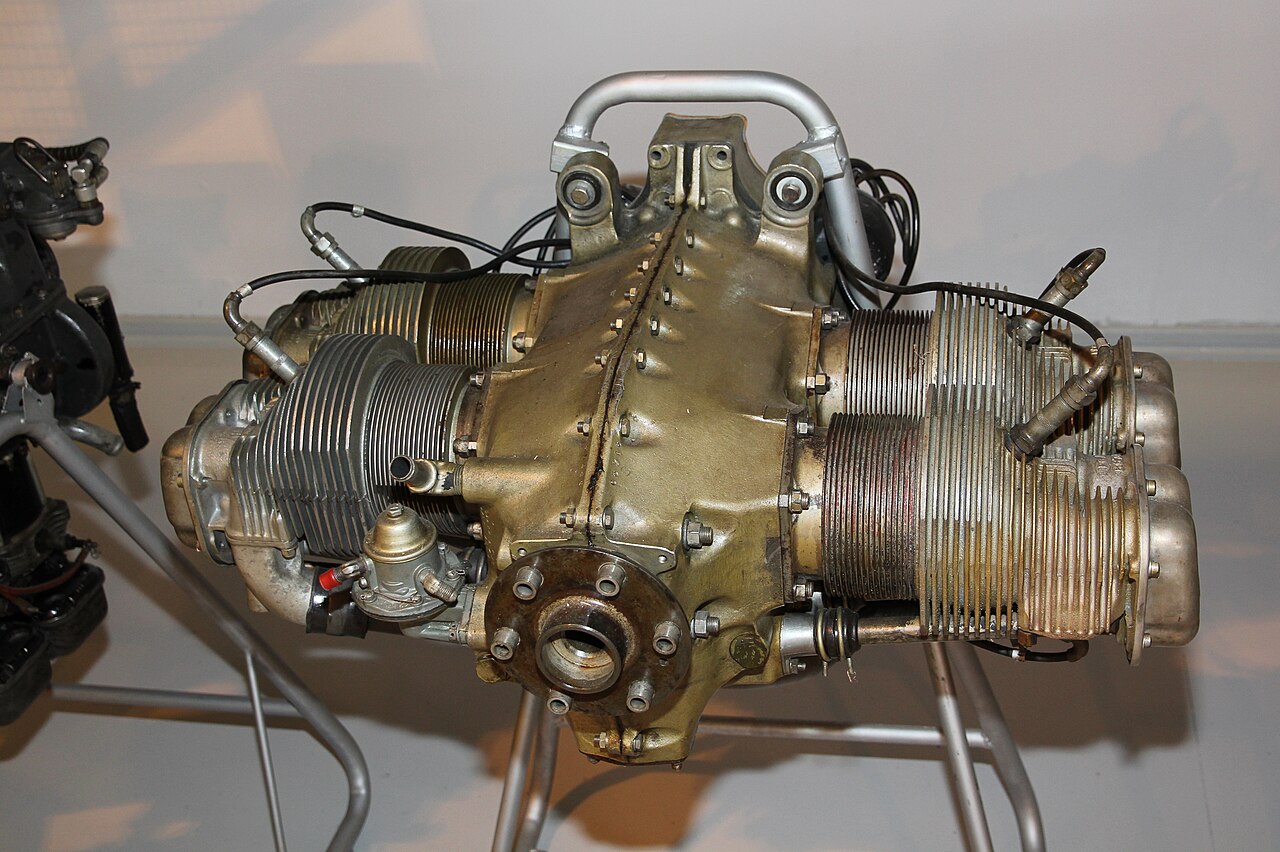

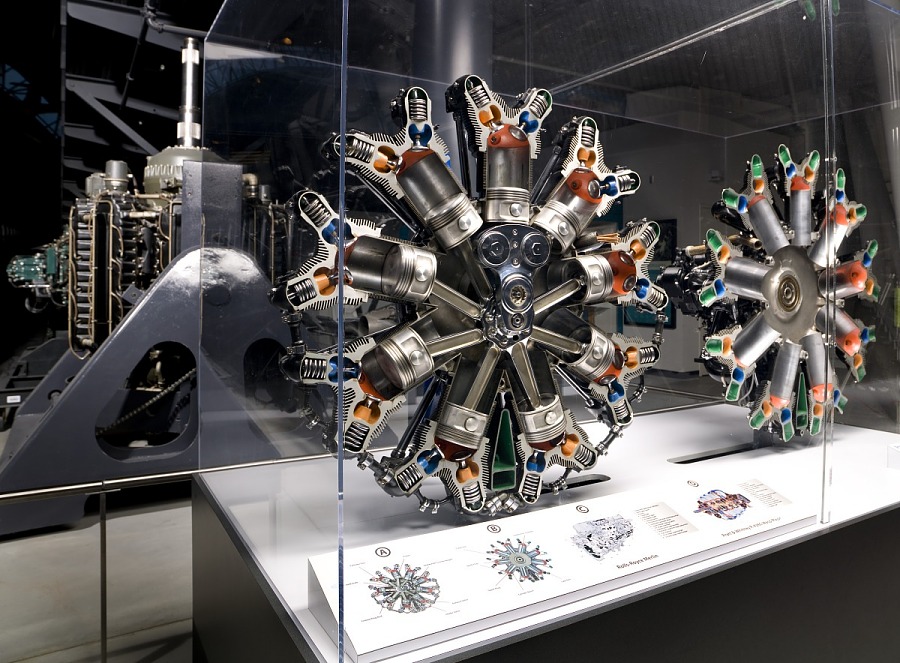

11. Pratt & Whitney R-985 Wasp Junior Radial Engine

The Pratt & Whitney R-985 Wasp Junior stands as one of the most reliable radial aircraft engines ever produced.

First introduced in 1929 and manufactured through the 1950s, this nine-cylinder air-cooled radial engine powered numerous civilian and military aircraft through some of aviation’s most formative decades, including the Beechcraft Model 18, de Havilland Beaver, and various military trainers.

What makes the R-985 exceptional is its remarkable simplicity combined with Pratt & Whitney’s fanatical attention to manufacturing precision.

The engine features nine cylinders arranged radially around a central crankcase, creating natural cooling airflow and even distribution of forces.

Each cylinder is individually replaceable, allowing for simple maintenance without complete engine disassembly.

The cylinder heads are made from aluminum with deep cooling fins, providing excellent heat dissipation without the complexity of liquid cooling systems.

Pratt & Whitney engineered the R-985 with a remarkably robust master rod and articulating rod system.

The master rod connects directly to the crankshaft, while the remaining eight cylinders connect to the master rod through articulating rods.

This design distributes forces evenly throughout the engine while minimizing reciprocating masses.

The crankshaft itself is a masterpiece of engineering, manufactured from high-grade steel with massive journals designed for continuous heavy-duty operation.

The engine’s valvetrain employs push rods and rocker arms actuated by a single-piece cam ring inside the crankcase.

This simple but effective system provides precise valve timing while minimizing complexity. The valve guides and seats are manufactured from hardened materials that maintain their dimensions even after thousands of hours of operation.

Perhaps most importantly, Pratt & Whitney designed the R-985 with significant operational margins.

While the engine is rated for output between 300-450 horsepower (depending on the variant), its internal components are engineered to handle significantly greater loads.

This conservative approach allows these engines to run reliably even when operated near their rated capacity for extended periods.

These engines regularly achieve 1,200-1,500 hours between overhauls, with many examples accumulating 20,000+ total hours over decades of service.

What’s particularly impressive is that they achieve this longevity despite operating in some of aviation’s most demanding environments, from bush flying in remote Alaska to military training operations.

The R-985’s extraordinary durability is best illustrated by its continued presence in working aircraft worldwide, many of which continue daily operations 70+ years after manufacture.

Numerous air tour operators and bush pilots specifically seek out aircraft powered by these engines for their legendary reliability in remote operations where mechanical failures could have catastrophic consequences.

Even in the modern era with countless technological advancements, the fundamental design virtues of the R-985 Wasp Junior’s simplicity, redundancy, and conservative engineering continue to make it a benchmark for aircraft engine reliability and longevity.

12. Volvo Redblock Inline-4 and Inline-5 Engines

The Volvo Redblock engines, produced from 1974 to 1998, represent some of the most durable four-cylinder and five-cylinder automotive powerplants ever created.

Available in both naturally aspirated and turbocharged variants, these engines powered Volvo’s legendary 240, 740, 940, and other models through the Swedish manufacturer’s most reputation-building decades.

What makes the Redblock exceptional is its extraordinarily overbuilt design philosophy combined with Volvo’s uncompromising manufacturing standards.

The engine block is cast from iron with unusually thick cylinder walls and main bearing supports, providing exceptional rigidity and heat management.

The block earned its “Redblock” nickname from the distinctive red paint applied at the factory, but owners came to associate the name with the engine’s remarkable toughness.

Volvo engineered the Redblock with a massive five-main-bearing crankshaft even for the four-cylinder variants unusual for its era when many manufacturers used fewer bearings to reduce costs.

This overbuilt crankshaft provides exceptional stability and load distribution throughout the engine’s service life.

The connecting rods and pistons are similarly robust, and designed with significant safety margins above their operating requirements.

The cylinder head features a crossflow design with excellent port geometry that promotes efficient combustion and heat dissipation.

The valvetrain employs a single overhead cam with robust rocker arms and valve springs that maintain precise valve timing even after hundreds of thousands of miles.

The timing belt system is generously proportioned, with most examples reliably exceeding their recommended replacement intervals (though prudent owners still follow the maintenance schedule).

Perhaps most importantly, Volvo designed the Redblock with extremely conservative internal clearances and operating parameters.

While many manufacturers pushed their engines to the limit for maximum performance, Volvo prioritized longevity above all else.

The engine typically operates well below its mechanical limits, with combustion pressures, valve spring tensions, and bearing loads all maintained at levels that promote durability over maximum output.

These engines regularly achieve 300,000-400,000 miles without internal repairs, with many documented cases exceeding 500,000 miles with just basic maintenance.

What’s perhaps most remarkable is that even the turbocharged variants which subject components to significantly greater stresses maintain exceptional reliability when properly maintained.

The maintenance requirements are straightforward regular oil changes, timing belt replacement at recommended intervals, and occasional valve adjustments are typically all that’s needed for decades of service.

The Redblock’s legendary durability is best illustrated by its prevalence in high-mileage Volvos worldwide. Many of these vehicles continue daily operation with 30+ year old engines that show no signs of significant wear.

This exceptional longevity, combined with the engine’s smooth operation and respectable performance, has made Redblock-equipped Volvos some of the most sought-after vehicles for those prioritizing long-term reliability above all else.

Also Read: Top 12 Supercars That Were Built With Jet Engine Technology Offering Unmatched Performance