The inline-six cylinder engine configuration has long been revered in automotive circles for its inherent balance, smooth operation, and remarkable durability.

Dating back to the early days of automotive engineering, these straight-six powerplants have powered everything from luxury sedans to rugged work trucks, often accumulating hundreds of thousands of miles without major mechanical intervention.

The design’s natural primary and secondary balance eliminates the need for balance shafts, reducing complexity and potential failure points.

This mechanical harmony translates to less vibration, reduced internal stress, and ultimately, extraordinary longevity.

While V6 engines have gained popularity for their compact packaging, the inline-six continues to maintain a dedicated following among enthusiasts and manufacturers who prioritize reliability above all else.

From BMW’s legendary naturally-aspirated units to Toyota’s indestructible truck engines, these powerplants have earned their reputation through decades of service in the most demanding conditions.

The following ten engines represent the pinnacle of inline-six durability engineering marvels that have proven their mettle through millions of collective miles on roads across the globe.

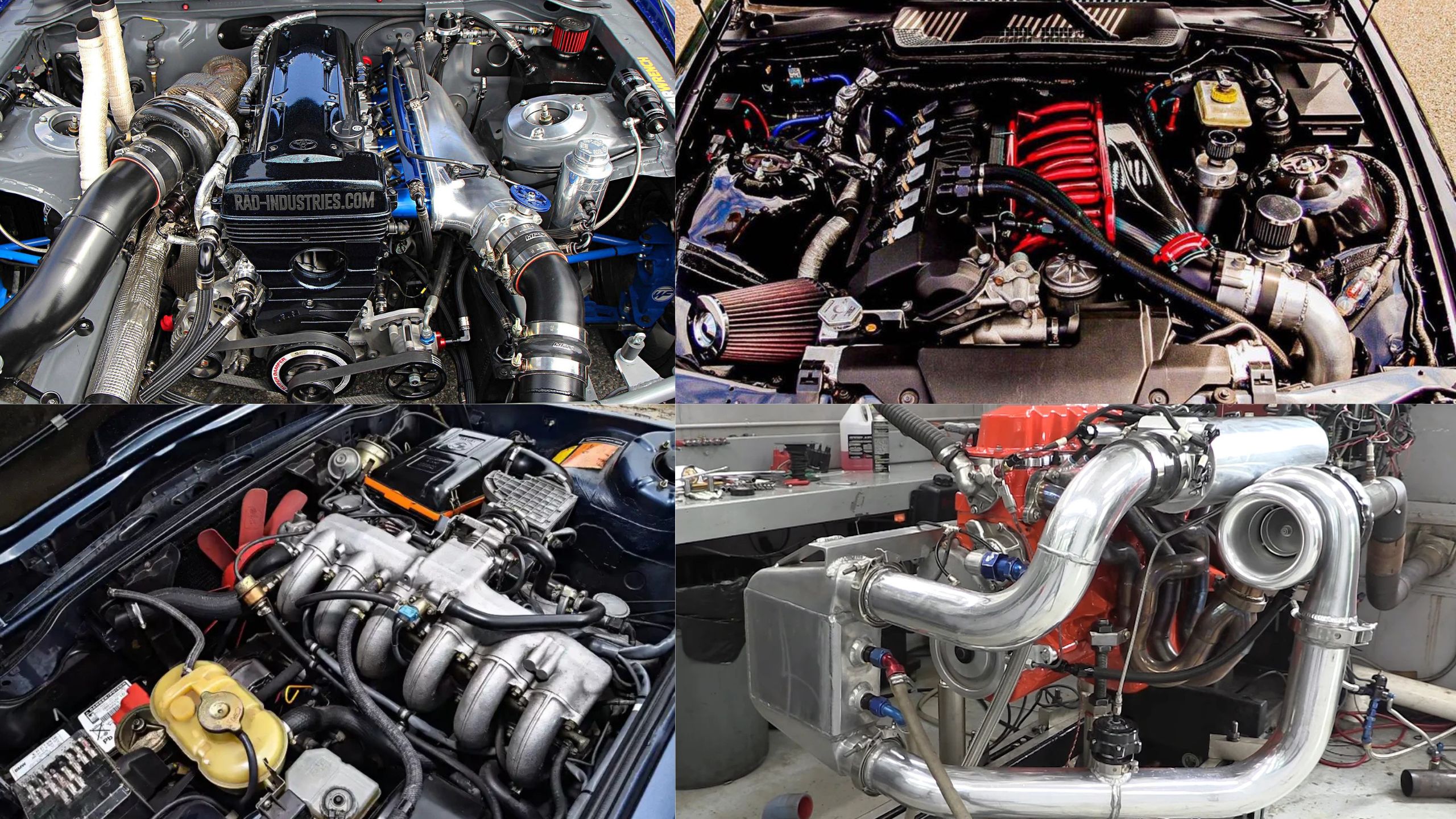

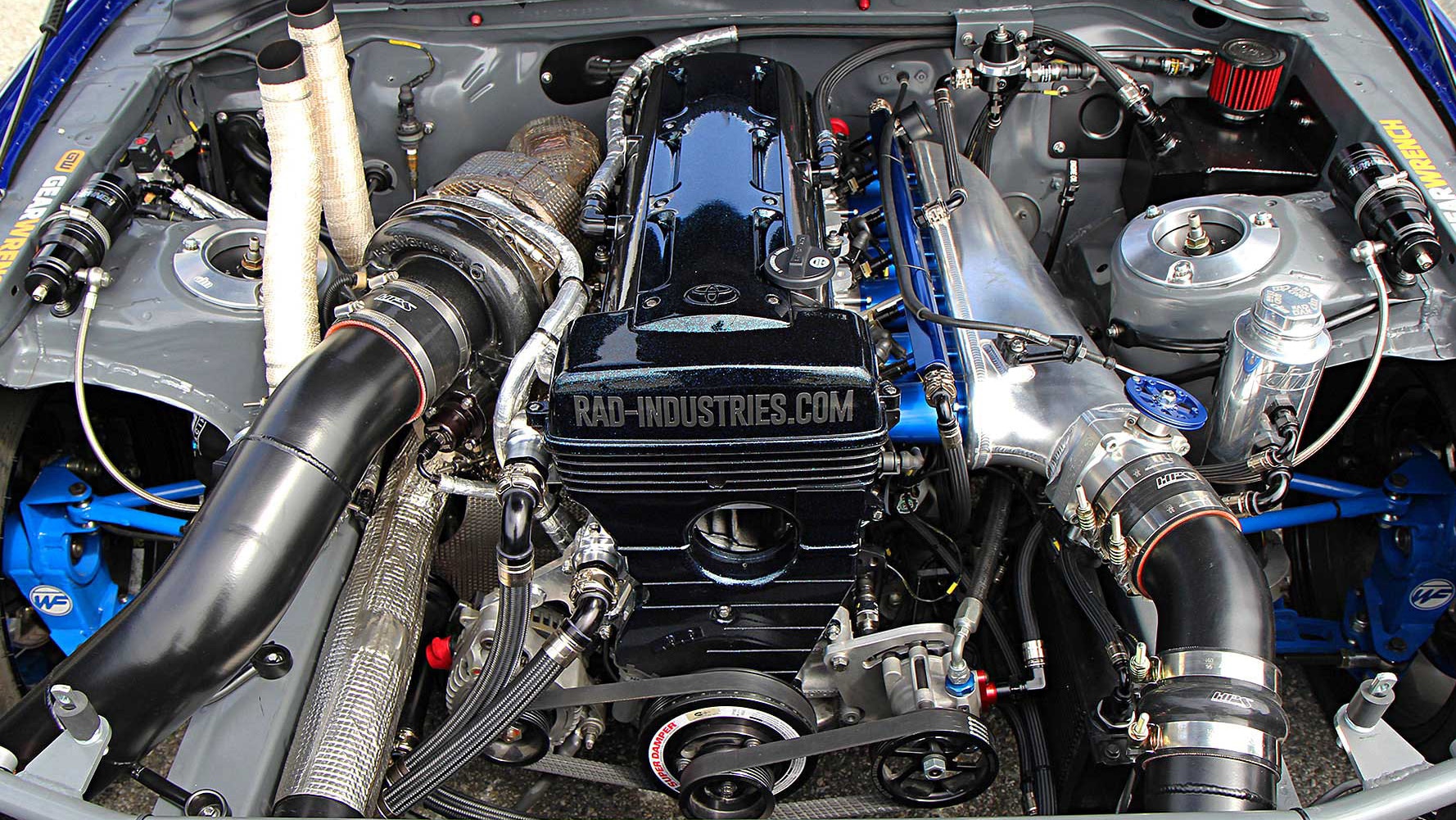

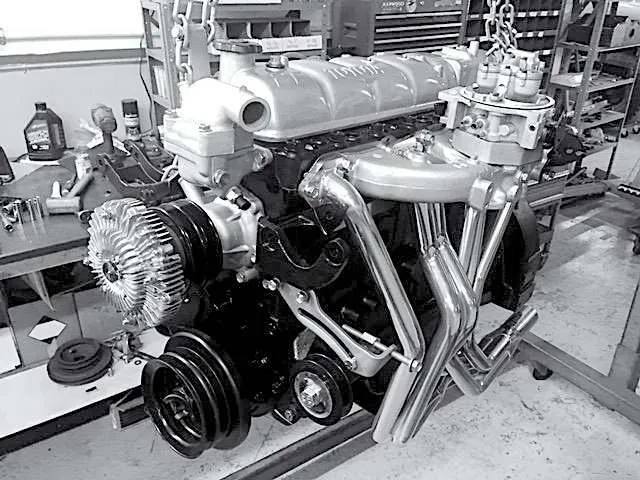

1. Toyota 2JZ-GE/2JZ-GTE

The Toyota 2JZ engine family stands as perhaps the most legendary inline-six ever produced, achieving mythical status among automotive enthusiasts worldwide.

Introduced in 1991, this 3.0-liter powerplant became famous for its incredible strength and overengineering, particularly in its turbocharged 2JZ-GTE variant found in the iconic Toyota Supra.

The engine’s closed deck design features a remarkably sturdy iron block with seven main bearings, creating an almost indestructible foundation capable of handling immense power increases.

What truly sets the 2JZ apart is its overbuilt internal components. Toyota equipped it with forged connecting rods and, in the GTE version, forged pistons designed to handle significantly more power than factory specifications.

The large oil capacity and efficient cooling systems further contribute to the engine’s legendary reliability.

Stock 2JZ-GTE engines easily handle 800+ horsepower with basic modifications, while fully built examples have been known to produce over 2,000 horsepower while maintaining reasonable reliability a testament to the engine’s engineering excellence.

Even the naturally aspirated 2JZ-GE, which powered countless Lexus models, regularly achieves 300,000+ miles with basic maintenance.

The engine’s timing belt is the only significant maintenance item, requiring replacement every 60,000-90,000 miles.

Beyond this, the 2JZ is known for trouble-free operation decade after decade. Its reputation for bulletproof reliability has kept these engines in high demand nearly three decades after their introduction, with clean examples commanding premium prices in the performance market.

The 2JZ represents Toyota engineering at its finest a powerplant designed not just to meet expectations but to vastly exceed them for the entirety of a vehicle’s lifespan.

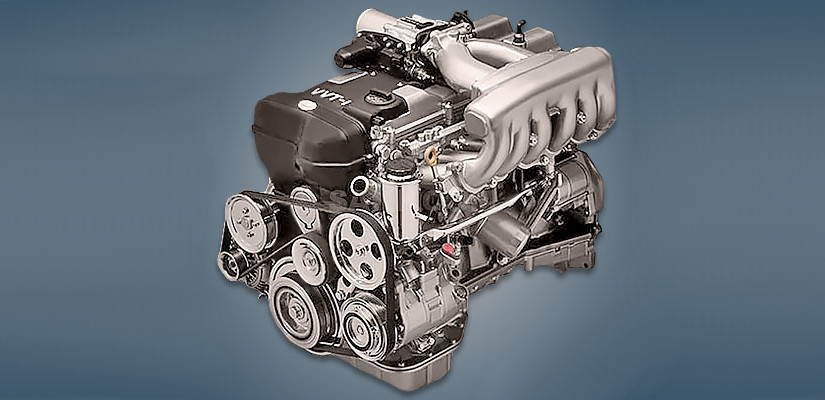

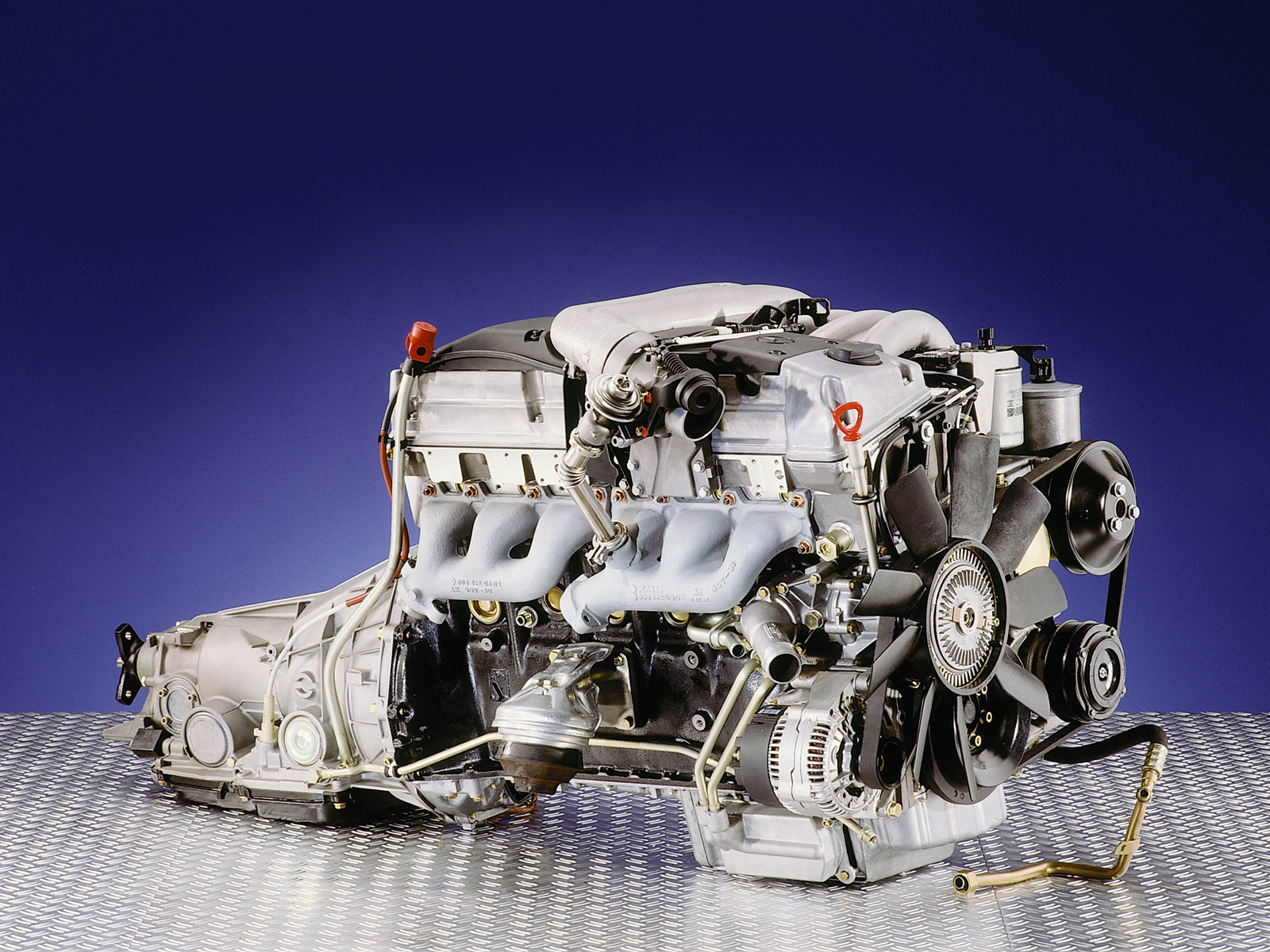

2. Mercedes-Benz M103/M104

The Mercedes-Benz M103 and its successor, the M104, represent German engineering excellence that defined Mercedes’ reputation for building exceptionally durable engines throughout the 1980s and 1990s.

The 3.0-liter M103, introduced in 1984, set a new standard for refinement and longevity in luxury vehicles, while the subsequent M104 expanded on this foundation with dual overhead cams and more advanced technology.

Built with Mercedes’ traditional conservative design philosophy, these engines feature overbuilt components throughout.

The iron block provides exceptional rigidity and stability even after hundreds of thousands of miles, while the aluminum cylinder head houses robust valve components designed for minimal wear.

The engines use a timing chain rather than a belt, eliminating a common maintenance requirement of the era and contributing to their reputation for reliability.

What truly distinguished these engines was their meticulous engineering. Mercedes utilized tight manufacturing tolerances, premium materials, and extensive testing to ensure these powerplants would withstand decades of operation.

The oiling system deserves particular recognition, with generous oil channels, excellent filtration, and sophisticated oil cooling preventing premature wear even under sustained high loads.

Countless M103 and M104 engines have surpassed 300,000 miles without internal repairs, with some documented examples exceeding 500,000 miles on original components.

Their durability became so renowned that Mercedes-Benz struggled to replicate it with later models.

The engines respond well to regular maintenance, with oil changes being the primary requirement for longevity.

Even when neglected, these engines tend to soldier on with minimal complaints a testament to their overengineered nature.

For many enthusiasts, the M103/M104 era represents the pinnacle of Mercedes-Benz’s commitment to building powerplants that could truly last a lifetime.

3. BMW M50/M52/S50/S52

BMW’s M50 family of inline-six engines, including its evolution into the M52 and the high-performance S50/S52 variants, represents some of the finest engines ever fitted to sports sedans and coupes.

Introduced in the early 1990s for BMW’s E36 3-Series and E34 5-Series models, these engines combined the company’s traditional inline-six smoothness with modern technology and remarkable durability.

The M50 established the foundation with its iron block and aluminum head design, featuring four valves per cylinder and sophisticated electronic engine management.

When BMW evolved this into the M52, they incorporated lightweight aluminum block construction (with cast iron cylinder liners in many markets) while maintaining the robust bottom end design.

The performance-oriented S50/S52 variants found in M3 models received substantial upgrades including more aggressive camshafts, higher compression ratios, and improved flowing heads.

These engines excel in durability through several key design elements. Their oiling systems maintain excellent pressure even at high RPMs, protecting crucial components during spirited driving.

The cooling systems, while sometimes requiring preventative maintenance on their plastic components, are otherwise effective at maintaining optimal operating temperatures.

Notably, these engines utilize timing chains rather than belts, which when properly maintained, can last the lifetime of the vehicle.

BMW’s engineering resulted in engines that regularly exceed 250,000 miles while maintaining their characteristic smoothness and performance.

The most common issues tend to be peripheral rather than internal cooling system plastics and VANOS variable valve timing components may require attention, but the core engine components demonstrate remarkable longevity.

Enthusiasts particularly value these engines for their combination of reliability and tuning potential, as they respond well to modifications while maintaining their fundamental durability.

For many BMW aficionados, this family of straight-sixes represents the perfect balance of performance, character, and bulletproof dependability.

4. Toyota 1JZ-GE/1JZ-GTE

The Toyota 1JZ engine series, the slightly smaller 2.5-liter sibling to the famous 2JZ, has earned its own dedicated following for exceptional durability combined with impressive performance potential.

Introduced in 1990 for the Japanese domestic market in vehicles like the Toyota Chaser, Cresta, Mark II, and Soarer, this inline-six became renowned worldwide despite limited official export markets.

Like its larger counterpart, the 1JZ features an iron block design with an aluminum cylinder head and seven main bearings, creating a tremendously strong foundation.

The turbocharged 1JZ-GTE variant initially employed a parallel twin-turbo setup before evolving to a single turbo configuration in later years.

Both naturally aspirated and turbocharged versions benefit from Toyota’s legendary build quality and engineering conservatism, resulting in engines that regularly exceed 300,000 miles with basic maintenance.

The 1JZ’s durability stems from several key design elements. Its closed deck block provides exceptional cylinder rigidity even under high boost pressure.

The oiling system delivers abundant lubrication to critical components, while the cooling system efficiently manages thermal loads.

Toyota equipped these engines with forged connecting rods capable of handling significantly more power than stock levels, providing substantial headroom for modifications.

What makes the 1JZ particularly special is its combination of reliability with excellent tuning potential.

The turbocharged variants respond exceptionally well to modifications, capable of safely producing over 500 horsepower with relatively simple upgrades while maintaining daily drivability.

Even in high-performance applications, these engines demonstrate remarkable longevity when properly maintained.

Their only significant maintenance requirement is timing belt replacement every 60,000-90,000 miles.

The 1JZ represents Toyota’s engineering philosophy at its finest overbuilt components, conservative factory specifications, and design simplicity resulting in a powerplant that continues to be sought after decades after its introduction, commanding premium prices in the performance market.

Aslo Read: 10 Street-Legal Cars That Feel Like Formula 1 Machines

5. BMW M30

The BMW M30 straight-six engine represents one of the most enduring and reliable powerplants in automotive history, serving as BMW’s flagship engine from 1968 until 1994 an astounding 26-year production run that speaks volumes about its fundamental excellence.

This 2.5-3.5 liter engine powered everything from the elegant E24 6-Series coupes to the iconic E28 5-Series sedans, becoming synonymous with BMW’s reputation for smooth, durable inline-sixes.

The M30’s remarkable durability stems from its decidedly overbuilt design. BMW constructed these engines with a sturdy cast iron block featuring seven main bearings to support the crankshaft, paired with an aluminum cylinder head.

The substantial bearing surfaces, generous oiling system, and relatively undersquare design (with stroke longer than bore) contribute to reduced cylinder wear and excellent longevity.

Unlike many modern engines designed to exact tolerances and minimal material use, the M30 embodies an old-school engineering philosophy with robust components throughout.

What truly distinguishes the M30 is its ability to accumulate astronomical mileage figures. Properly maintained examples regularly exceed 300,000 miles without internal repairs, with many documented cases surpassing 500,000 miles on original components.

The engine’s timing chain design eliminates the maintenance requirement of belt replacements, while its mechanical simplicity compared to later engines means fewer potential failure points.

The M30’s cooling system design provides excellent thermal management, preventing the warping issues that plague many other engines of its era.

BMW enthusiasts often refer to the M30 as the “eternal six” due to its remarkable toughness and serviceability.

Even with irregular maintenance, these engines tend to soldier on reliably though they reward proper care with virtually indefinite service.

While not the most powerful or technologically advanced of BMW’s inline-sixes, the M30’s bulletproof reliability and characteristic smoothness have cemented its legacy as perhaps the company’s most dependable engine ever produced, setting the standard by which all subsequent BMW straight-sixes would be judged.

6. Jeep 4.0L AMC Straight-Six

The legendary 4.0-liter inline-six engine found in Jeep vehicles from 1987 to 2006 stands as one of the most rugged and dependable powerplants ever installed in a mass-produced American vehicle.

Evolved from American Motors Corporation (AMC) designs dating back to the 1960s, this engine became synonymous with Jeep reliability during its nearly two-decade production run in vehicles like the Cherokee, Grand Cherokee, and Wrangler.

The fundamental design prioritizes simplicity and strength above all else. The engine features a cast iron block and head, creating an incredibly durable foundation resistant to warping and cracking even under severe conditions. Its oversquare design (with a bore larger than the stroke) reduces piston speeds and side loading, minimizing cylinder wall wear.

The substantial 7-main-bearing crankshaft provides exceptional support, while the hydraulic lifters eliminate the need for valve adjustments throughout the engine’s lifespan.

What truly distinguishes the Jeep 4.0L is its ability to withstand abuse and neglect that would destroy lesser engines. Its substantial oil capacity and excellent low-end torque mean it rarely needs to work hard, reducing long-term wear.

The cooling system efficiently manages heat even during demanding off-road conditions. While early models used a problematic Renix electronic control system, post-1991 engines with Chrysler’s reliable Mopar fuel injection system eliminated most electronic issues.

These engines routinely exceed 300,000 miles with basic maintenance, with many documented examples surpassing 500,000 miles.

They possess an almost tractor-like reliability they may occasionally develop external leaks or minor peripheral issues, but the core engine components demonstrate remarkable durability even when maintenance intervals are stretched.

The 4.0L’s reputation for bulletproof reliability has made it one of the most beloved engines among Jeep enthusiasts, with many considering its retirement in 2006 (due to emissions regulations rather than any design deficiency) a significant loss.

For those seeking a powerplant that prioritizes dependability above all else, the Jeep 4.0L remains the gold standard of American inline-six design.

7. Toyota F/2F/3F Series

Toyota’s F series of inline-six engines represents one of the most durable and reliable powerplants ever developed for off-road applications, powering the legendary Land Cruiser through some of the world’s most hostile environments for over three decades.

From the original F engine’s introduction in 1955 through the final 3F-E’s retirement in 1992, these engines established Toyota’s reputation for building virtually indestructible powerplants capable of thriving in extreme conditions with minimal maintenance.

The design philosophy behind these engines prioritized simplicity and robustness above all else. Built with a heavy-duty cast iron block and head, these engines feature extraordinarily thick cylinder walls, seven main bearings, and generously sized connecting rods.

The 2F (introduced in 1975) expanded displacement to 4.2 liters, while the subsequent 3F and fuel-injected 3F-E (1985-1992) maintained this displacement while incorporating modest technological updates.

Throughout their evolution, these engines maintained their fundamental design integrity with minimal complexity.

What truly distinguishes the F-series engines is their ability to withstand years of operation in punishing environments.

Land Cruisers equipped with these powerplants have traversed deserts, jungles, and arctic tundra, often accumulating hundreds of thousands of miles in regions where mechanical failures could prove life-threatening.

The engines’ low-stress design, operating at modest RPMs and compression ratios, minimizes internal wear.

Their substantial oil capacity and simple cooling systems provide excellent thermal management even in extreme temperatures.

Countless F/2F/3F engines have exceeded 300,000 miles without internal repairs, with many documented examples surpassing 500,000 miles with basic maintenance.

Their design prioritizes serviceability, with straightforward access to components and minimal specialized tools required.

While not particularly powerful or efficient by modern standards the 3F-E produces approximately 155 horsepower their tremendous torque and unparalleled durability made them ideal companions for global expeditions.

For decades, when explorers, aid workers, and militaries worldwide needed absolute mechanical reliability in remote locations, Toyota Land Cruisers with these inline-six engines were their vehicles of choice the highest possible testament to these engines’ exceptional durability.

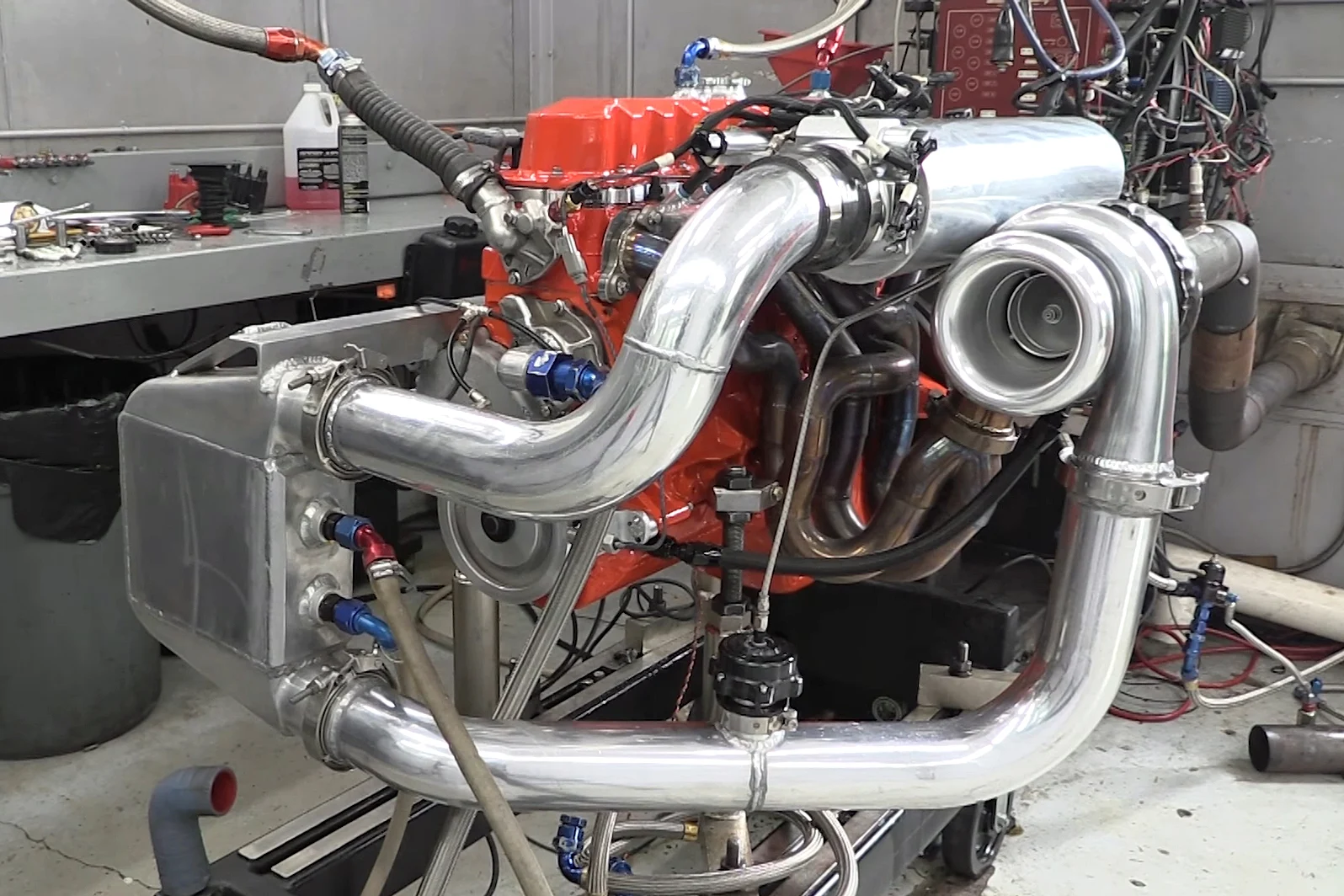

8. Nissan RB20/RB25/RB26 Series

The Nissan RB series of inline-six engines has achieved legendary status among performance enthusiasts worldwide, combining exceptional durability with tremendous power potential.

Developed through the 1980s and 1990s primarily for the Japanese domestic market, these engines especially the twin-turbocharged RB26DETT found in the iconic Skyline GT-R have earned a reputation for remarkable strength while delivering exhilarating performance.

The RB series features a cast iron block paired with an aluminum head, providing an excellent balance of strength and weight.

What truly distinguishes these engines is their overengineered design, with capabilities far exceeding their factory specifications.

The RB26DETT in particular features a closed deck block design, providing exceptional cylinder rigidity under pressure.

All RB engines utilize a seven main bearing crankshaft design providing excellent support and stability even at high RPMs, while oil channels are generously sized to ensure proper lubrication throughout.

Nissan equipped these engines with robust connecting rods capable of handling significantly more power than stock levels.

The twin-cam head design provides excellent breathing capabilities, while the ignition and fueling systems respond well to upgrades.

Even the stock turbochargers on forced-induction variants were conservatively sized, prioritizing responsiveness and reliability over maximum power.

What makes the RB series truly special is its combination of durability with modification potential.

Stock RB26DETT engines rated at 276 horsepower (due to Japan’s gentleman’s agreement limiting stated power) can reliably handle over 600 horsepower with basic supporting modifications.

Even under these raised power levels, properly maintained RB engines regularly exceed 200,000 miles, with many documented examples surpassing 300,000 miles with basic maintenance.

The RB’s timing belt represents its primary maintenance requirement, with replacement recommended every 60,000 miles, especially in high-performance applications.

The RB series’ reputation for durability becomes even more impressive considering how frequently these engines are modified for increased performance.

Even when pushed to produce double or triple their factory power outputs, these engines demonstrate remarkable longevity when properly built and maintained.

The Nissan RB series represents a perfect marriage of performance and reliability engineering powerplants designed not just to meet expectations but to vastly exceed them while delivering thrilling performance throughout their extended lifespans.

9. Mercedes-Benz OM606

The Mercedes-Benz OM606 diesel inline-six engine stands as perhaps the most durable diesel powerplant ever fitted to a passenger vehicle, earning a legendary reputation for reliability in the most demanding conditions worldwide.

Produced from 1993 to 2001 and found primarily in the W124 and W210 E-Class models, this 3.0-liter turbodiesel represents the pinnacle of Mercedes’ overengineered approach to diesel engine design.

The OM606’s exceptional durability stems from several key design elements. Its cast iron block and head provide tremendous structural integrity, while the indirect injection system reduces internal component stress compared to direct injection designs.

Mercedes equipped these engines with six substantial main bearings supporting a forged steel crankshaft, along with robust connecting rods designed to handle the substantial torque production.

The mechanical fuel injection pump, particularly in the highly regarded pre-1997 models, eliminates the complexity and potential failure points of electronic systems.

What truly distinguishes the OM606 is its absolute reliability under extreme conditions. These engines have powered vehicles across the world’s most challenging environments, from African deserts to Siberian winters, often accumulating astronomical mileages without internal repairs.

The oil cooler and large capacity cooling system provide excellent thermal management even under sustained high loads, while the oversized oil capacity protects crucial components during extended service intervals.

Properly maintained OM606 engines routinely exceed 500,000 miles without major internal work, with many documented examples surpassing 750,000 miles while maintaining their characteristic smoothness and power delivery.

The engine’s tolerance for varied fuel quality has made it particularly popular in regions where diesel fuel standards may be inconsistent.

Mercedes’ conservative factory power ratings of approximately 177 horsepower and 243 lb-ft of torque leave substantial headroom for increased performance without compromising reliability.

The OM606’s reputation for indestructibility has created enduring demand for these engines, with many being transplanted into off-road vehicles and trucks requiring ultimate dependability.

Among diesel enthusiasts, the pre-1997 OM606, in particular, is often considered the “million-mile engine” a powerplant designed to outlast virtually everything else on the vehicle, and perhaps the most durable passenger vehicle engine ever produced by any manufacturer.

10. Volvo B230

While technically not an inline-six, the Volvo B230 inline-four engine deserves honorary mention for its legendary durability, which rivals that of any straight-six ever produced.

Manufactured from 1985 to 1998 and found in the iconic 240, 740, 940, and 960 series vehicles, this 2.3-liter powerplant has earned a reputation as perhaps the most bulletproof four-cylinder engine ever created.

It commonly exceeds lifespans that match or surpass those of its six-cylinder contemporaries. The B230’s exceptional durability stems from its remarkably overbuilt design.

Volvo constructed these engines with a cast iron block featuring thick cylinder walls and substantial main bearings.

The aluminum cylinder head houses a robust valvetrain designed for minimal wear, while the timing belt drives a counterbalance shaft that reduces vibration a unique feature for a four-cylinder of its era.

The engine’s undersquare design, with a stroke longer than the bore, reduces piston speeds and promotes longevity.

What truly distinguishes the B230 is its ability to withstand neglect and abuse that would destroy lesser engines.

Its substantial oil capacity and excellent cooling system provide significant thermal stability, while the overbuilt bottom end can withstand stresses far beyond factory specifications.

The naturally aspirated variants are particularly renowned for their durability, though even the turbocharged versions demonstrate exceptional longevity when properly maintained.

These engines routinely exceed 300,000 miles without internal repairs, with countless documented examples surpassing 500,000 miles on original components.

Some have even achieved the million-mile mark with basic maintenance a testament to Volvo’s engineering excellence.

The B230’s only significant maintenance requirement is timing belt replacement every 70,000 miles, a small price to pay for such exceptional durability.

The B230’s reputation has made it a favorite among enthusiasts seeking bulletproof reliability, with many considering it the ultimate expression of Volvo’s commitment to building vehicles that outlast their owners.

While not as smooth or powerful as an inline-six, the B230’s extraordinary durability earns it a rightful place among the most reliable engines ever produced a four-cylinder that delivers a six-cylinder lifespan with even greater simplicity and dependability.

Also Read: 12 Naturally Aspirated Supercars That Sound the Best