Turbochargers have revolutionized the automotive industry by enabling smaller displacement engines to produce impressive power while maintaining efficiency.

However, forced induction traditionally introduced additional complexity and stress points that could compromise longevity.

Despite these challenges, certain turbocharged engines have established legendary reputations for reliability, often outlasting the vehicles they power.

These engineering marvels combine robust design principles, conservative tuning from the factory, and overbuilt components that withstand years of boost pressure.

From Japanese straight-sixes that routinely exceed 300,000 miles to German powerplants that maintain performance integrity through decades of use, these engines represent the pinnacle of durable forced induction design.

While proper maintenance remains essential including regular oil changes with high-quality synthetic lubricants, careful warm-up procedures, and appropriate cooling-down periods these turbocharged powerplants demonstrate that forced induction and longevity aren’t mutually exclusive.

This list celebrates ten legendary turbocharged engines that have earned their reputations through millions of collective miles, proving that with proper engineering and care, boosted engines can deliver both performance and exceptional durability.

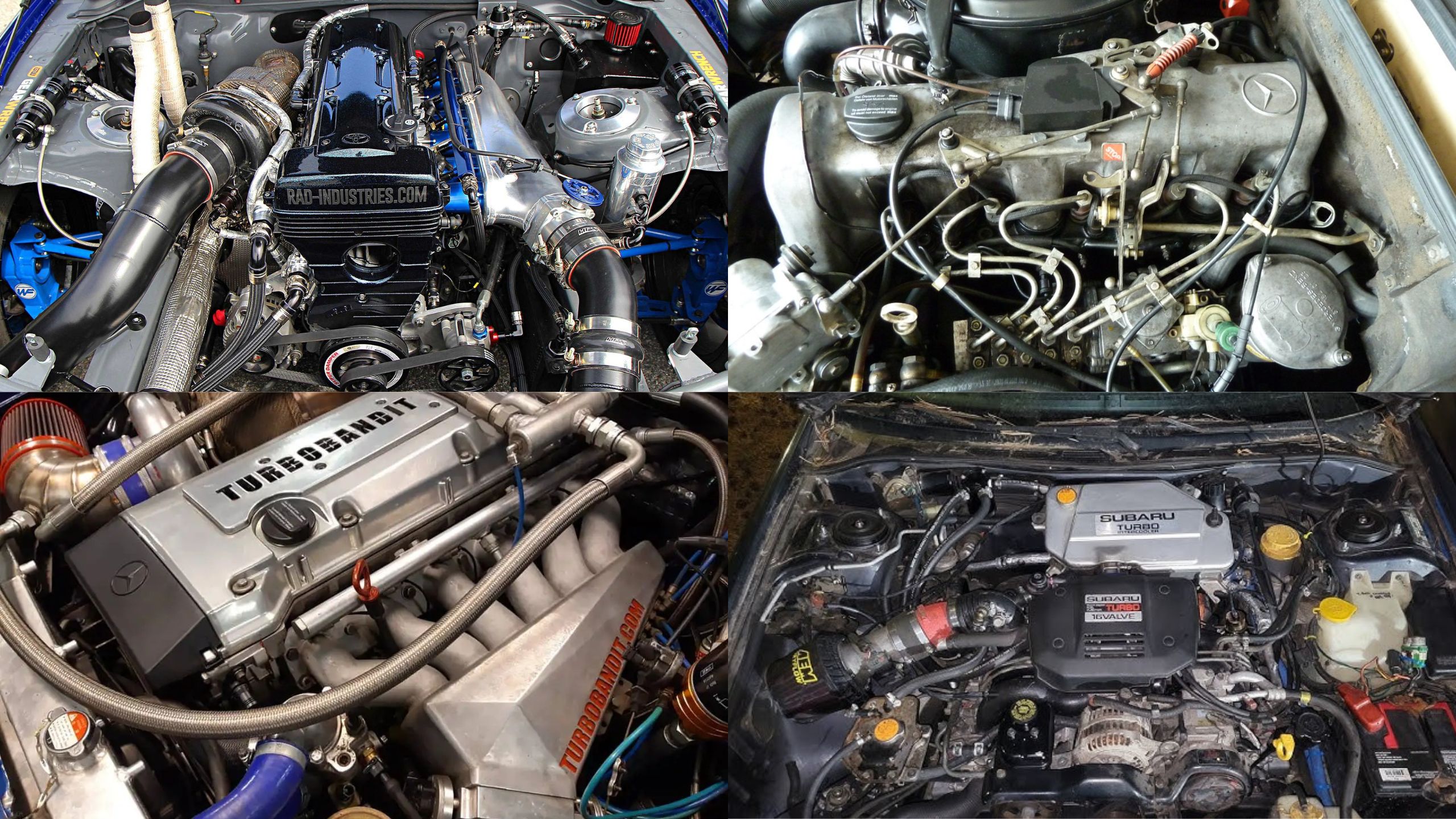

1. Toyota 2JZ-GTE

The Toyota 2JZ-GTE, immortalized in pop culture through the “Fast and Furious” franchise, represents perhaps the most legendary turbocharged inline-six ever produced.

Introduced in the 1993 Toyota Supra, this 3.0-liter twin-turbocharged masterpiece remains the benchmark for combining performance potential with unbreakable reliability.

What makes the 2JZ so exceptional is its overbuilt nature featuring a cast iron block, forged steel crankshaft, and robust connecting rods capable of handling power outputs far beyond factory specifications.

From the factory, the 2JZ-GTE produced a conservatively rated 320 horsepower, but its architecture could reliably support more than double that figure with minimal modifications.

The closed deck block design provides exceptional cylinder wall stability even under extreme boost pressure, while the sequential turbocharger system delivers responsive power delivery throughout the rev range.

Toyota’s engineering foresight included an oil system dimensioned for high-performance applications and a cooling system capable of managing heat even under sustained high-output conditions.

Many 2JZ-powered vehicles have exceeded 300,000 miles with regular maintenance, with some heavily modified examples reliably producing over 800 horsepower for extended periods.

The engine’s robustness stems from Toyota’s philosophy of engineering components to withstand stresses far beyond their rated output.

Even today, nearly three decades after its introduction, the aftermarket support for the 2JZ remains robust, with many original engines still serving as the foundation for high-performance builds.

The 2JZ-GTE stands as proof that proper engineering can create a turbocharged engine that not only survives but thrives under pressure for hundreds of thousands of miles.

2. Mercedes-Benz OM617 Turbodiesel

The Mercedes-Benz OM617 turbodiesel, introduced in the late 1970s, redefined expectations for diesel engine longevity.

This 3.0-liter inline-five turbodiesel powerplant has achieved mythical status among automotive enthusiasts, with documented examples routinely exceeding one million miles a testament to the extraordinary engineering behind this mechanical masterpiece.

Found primarily in the W123, W126, and G-Class models, the OM617 combined innovative technology with robust simplicity.

At the heart of the OM617’s longevity is its overbuilt construction, featuring a cast iron block with substantial cylinder walls, a forged steel crankshaft, and precisely machined components manufactured to exact tolerances.

Unlike many contemporary diesel engines, the OM617 utilizes an indirect injection system with pre-combustion chambers, creating a more gradual combustion process that reduces mechanical stress on critical components.

The modest factory power output typically around 120 horsepower and 170 lb-ft of torque represents significant mechanical derating, allowing the engine to operate well below its structural limits even under sustained heavy loads.

The OM617’s turbocharging system employs a conservatively sized Garrett turbocharger that provides moderate boost pressure, enhancing torque without pushing the engine’s mechanical limits.

This approach, coupled with an engine oil capacity exceeding 7 quarts and a robust oil cooling system, ensures exceptional thermal stability even during extended high-load operation.

The engine’s timing chain, rather than a belt, contributes to its maintenance-free longevity, often operating reliably for hundreds of thousands of miles without replacement.

Perhaps most impressive is the OM617’s ability to operate reliably on variable fuel quality, a characteristic that has made it popular worldwide, including in regions where fuel purity can’t be guaranteed.

With proper maintenance primarily involving regular oil changes with high-quality diesel-specific lubricants the OM617 routinely outlasts multiple vehicle bodies, with some examples being transplanted into second or even third vehicles after their original chassis succumbed to age.

3. Volvo B230FT/B234FT

The Volvo B230FT and its derivative, the B234FT, represent Scandinavian engineering at its finest turbocharged four-cylinder engines that combine impressive performance with legendary durability.

Introduced in the mid-1980s and continuing through the 1990s in various Volvo models including the iconic 240, 740, 940, and 850 series, these “redblock” engines established a reputation for exceptional longevity that persists to this day.

The secret behind the B230FT’s remarkable durability lies in its understressed design and robust construction.

The cast iron block features substantial cylinder walls and extensive water jacketing for optimal thermal management.

Unlike many contemporary turbocharged engines, Volvo engineered the B230FT with a relatively low compression ratio and conservative boost pressures, typically around 9 psi from the factory.

This approach dramatically reduced thermal and mechanical stress on critical components, allowing the engine to maintain its structural integrity through hundreds of thousands of miles of operation.

Particularly noteworthy is the B230FT’s oil system, which includes a substantial 6.1-quart capacity and efficient oil cooling provisions critical factors in preserving turbocharger longevity.

The engine’s bottom end, featuring a forged crankshaft and robust connecting rods in many versions, was substantially overbuilt for its power output, which typically ranged from 160 to 190 horsepower depending on the specific variant and model year.

Volvo’s pragmatic approach to turbocharging extended to the engine management system, which incorporated sophisticated knock detection and boost control for the era, allowing the engine to protect itself from potentially damaging conditions.

The relatively simple design, with single overhead camshaft architecture and easily accessible components, encouraged proper maintenance, further contributing to the engine’s legendary status for reliability.

Properly maintained examples regularly exceed 300,000 miles without internal repairs, with some documented cases surpassing 500,000 miles on original internal components remarkable figures for turbocharged engines of this era.

4. Cummins 5.9L 12V (6BT)

The Cummins 5.9L 12-valve inline-six turbodiesel, commonly known as the 6BT, represents one of the most durable turbocharged engines ever mass-produced.

First introduced in Dodge Ram pickups in 1989, this legendary powerplant revolutionized the consumer diesel truck market with its combination of robust construction, mechanical simplicity, and tremendous longevity.

Originally designed for commercial and agricultural applications, the 6BT brought industrial-grade durability to the consumer truck segment.

The foundation of the 6BT’s exceptional longevity is its massive cast iron block and head, featuring cylinder walls measuring nearly half an inch thick.

This substantial construction, coupled with a forged steel crankshaft and robust connecting rods, created an engine capable of withstanding internal pressures far exceeding its factory specifications.

The 12-valve 6BT’s mechanical simplicity represents another key factor in its durability utilizing a gear-driven camshaft, mechanical fuel injection pump, and minimal electronic components compared to later diesel engines.

This straightforward design eliminated numerous potential failure points while making repairs relatively straightforward when necessary.

Despite its commercial origins, the 6BT delivered an impressive performance for its era, producing 160 horsepower and 400 lb-ft of torque in its initial applications, with later versions reaching 215 horsepower and 440 lb-ft.

These figures represented significant mechanical derating, with the engine operating well below its structural limits even under sustained heavy loads.

The 6BT’s Holset turbocharger, designed for commercial durability rather than maximum performance, provided reliable boost pressure throughout the engine’s operating range while maintaining exceptional longevity.

Perhaps most impressive is the 6BT’s capacity for continuous development through the aftermarket. Many examples remain in service with substantially increased power outputs often exceeding double the factory specifications while maintaining their fundamental reliability.

With basic maintenance including regular oil changes and fuel system service, 500,000 miles represents a reasonable expectation for a 12-valve Cummins, with many properly maintained examples exceeding 750,000 miles without requiring internal repairs.

The engine’s reputation has made it a popular candidate for conversions into other vehicles requiring a durable, high-torque powerplant.

Also Read: 10 Lightweight Sports Cars That Make Every Drive Thrilling

5. BMW M57

The BMW M57 turbodiesel stands as one of the most successful and durable engines in BMW’s storied history.

This inline-six diesel powerplant, produced from 1998 through 2012, established new benchmarks for combining performance, efficiency, and extraordinary longevity in the luxury vehicle segment.

Found in numerous BMW models including the 3, 5, 7, and X series vehicles, the M57’s reputation for reliability has made it a sought-after option in the used market, with many examples continuing to deliver smooth, powerful performance well past 300,000 miles.

At the core of the M57’s exceptional durability is its robust construction, featuring a cast iron block with substantial cylinder walls and an aluminum cylinder head with exceptional thermal management properties.

The engine utilizes a chain-driven overhead camshaft system designed for the life of the vehicle, eliminating the maintenance requirements and failure points associated with timing belt systems.

Throughout its production run, the M57 received continuous refinements, eventually incorporating advanced common rail direct injection and variable geometry turbocharging technology that enhanced performance and reliability.

The M57’s cooling system deserves particular mention for its contribution to the engine’s longevity.

BMW engineered an exceptionally efficient thermal management system that maintains optimal operating temperatures even under sustained high-load conditions a critical factor in preserving turbocharger integrity and preventing the oil coking issues that plague many turbocharged engines.

The substantial oil capacity and high-efficiency oil cooling system further contribute to the engine’s ability to maintain internal component protection through hundreds of thousands of miles.

Power outputs ranged from approximately 180 horsepower in early single-turbo versions to over 280 horsepower in later twin-turbocharged variants, with torque figures exceeding 400 lb-ft in some applications.

Despite these impressive figures, the M57 maintains remarkable fuel efficiency, often delivering over 30 mpg in highway driving a combination that explains the engine’s enduring popularity.

With proper maintenance, including regular oil changes with high-quality synthetic diesel-specific lubricants and attention to the fuel system, the M57 routinely exceeds 300,000 miles without major internal repairs, with many examples continuing to provide reliable service well beyond this milestone.

6. Ford 7.3L Power Stroke (1994-2003)

The Ford 7.3L Power Stroke diesel, produced from 1994 to 2003, has earned a legendary reputation as perhaps the most reliable modern diesel truck engine ever mass-produced for the North American market.

Developed in partnership with Navistar International, this turbocharged V8 powerplant established new standards for durability in the competitive heavy-duty pickup segment.

Nearly two decades after the end of its production run, the 7.3L Power Stroke remains highly sought after, with well-maintained examples commanding premium prices in the used market.

The engine’s extraordinary longevity stems from its conservative engineering approach and robust construction.

The massive cast iron block and heads provide exceptional structural rigidity, while the hydraulically actuated, electronically controlled unit injector (HEUI) fuel system represents an innovative middle ground between mechanical simplicity and electronic precision.

Unlike later diesel engines with extremely high-pressure fuel systems, the 7.3L’s moderate injection pressures (around 21,000 psi) reduced stress on components while still delivering efficient combustion and reasonable performance.

From the factory, the 7.3L Power Stroke produced between 210 and 275 horsepower depending on model year, with torque figures ranging from 425 to 525 lb-ft.

These figures, while impressive for the era, represented significant mechanical derating, with the engine operating well below its structural limits even when towing heavy loads.

The engine’s fixed-geometry Garrett turbocharger, though less sophisticated than variable-geometry designs that would follow, provided excellent reliability and consistent boost characteristics throughout the engine’s operating range.

Perhaps most significant for the 7.3L’s longevity was its pre-emissions era design. Produced before the implementation of exhaust gas recirculation (EGR) systems, diesel particulate filters, and selective catalytic reduction technology, the 7.3L avoided the complexity and potential reliability issues associated with these emissions control systems.

This simplicity, combined with a substantial 15-quart oil capacity that provided exceptional protection for internal components, enabled the 7.3L to routinely exceed 400,000 miles with basic maintenance.

Many properly maintained examples have surpassed 500,000 miles without requiring major internal repairs, cementing the 7.3L Power Stroke’s status as the benchmark for diesel truck engine longevity.

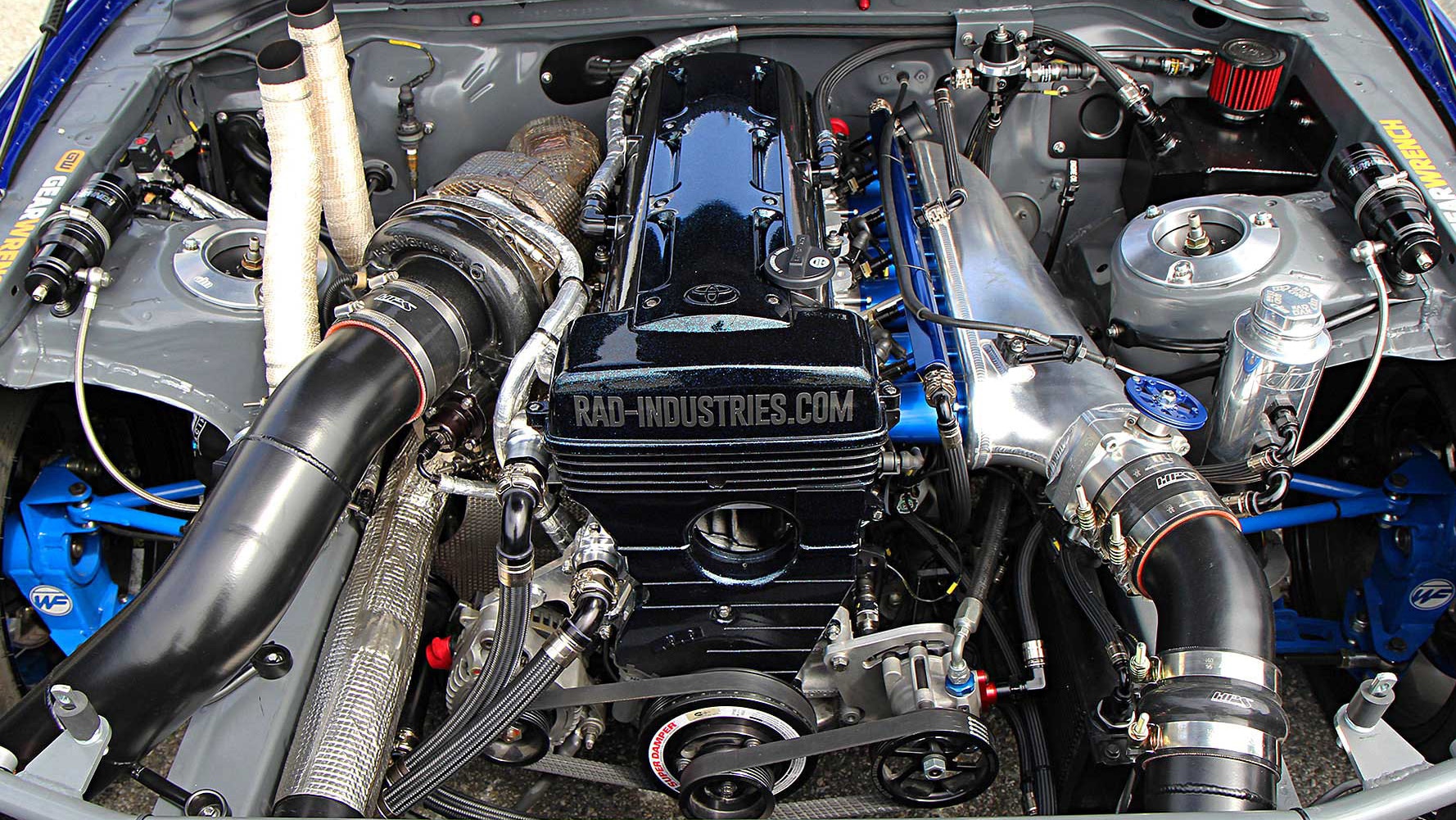

7. Mercedes-Benz M104 Turbo (Aftermarket)

Though Mercedes-Benz never officially produced a turbocharged version of its legendary M104 straight-six engine, the aftermarket-turbocharged variants have established an impressive reputation for combining increased performance with the underlying engine’s legendary durability.

The naturally aspirated M104, produced from 1989 through 1999 and featured in numerous Mercedes models including the E, C, and S-Class, provides an exceptionally robust foundation for forced induction, with many professionally turbocharged examples delivering reliable performance well beyond 300,000 miles.

The secret behind the M104’s success with aftermarket turbocharging lies in its overbuilt design and engineering.

The closed-deck cast iron block provides exceptional cylinder wall stability even under boost, while the aluminum dual overhead camshaft (DOHC) cylinder head features substantial cooling passages and robust valve train components.

The engine’s factory forged steel crankshaft and robust connecting rods, designed to support high-revving naturally aspirated operation, provide more than adequate strength for moderate boost applications without requiring replacement.

Particularly notable is the M104’s substantial oiling system, featuring a high-capacity oil pump and extensive oil pathways that maintain proper lubrication even under the increased thermal and mechanical stresses associated with turbocharging.

The engine’s sophisticated cooling system, with precisely engineered water jackets and efficient heat dissipation properties, helps maintain optimal operating temperatures even with the additional heat generated by forced induction.

Professional aftermarket turbo builds typically utilize moderate boost levels (8-12 psi) to preserve long-term reliability, with such setups commonly achieving 300-350 horsepower from the 3.2-liter variant a substantial increase over the factory output of approximately 220 horsepower while remaining well within the engine’s mechanical capabilities.

With proper tuning, high-quality fuel system components, and attention to intercooling, turbocharged M104 engines regularly deliver hundreds of thousands of reliable miles, often outlasting other vehicle components.

The engine’s continued popularity in the Mercedes enthusiast community speaks to its exceptional combination of performance potential and underlying durability, even when modified significantly beyond factory specifications.

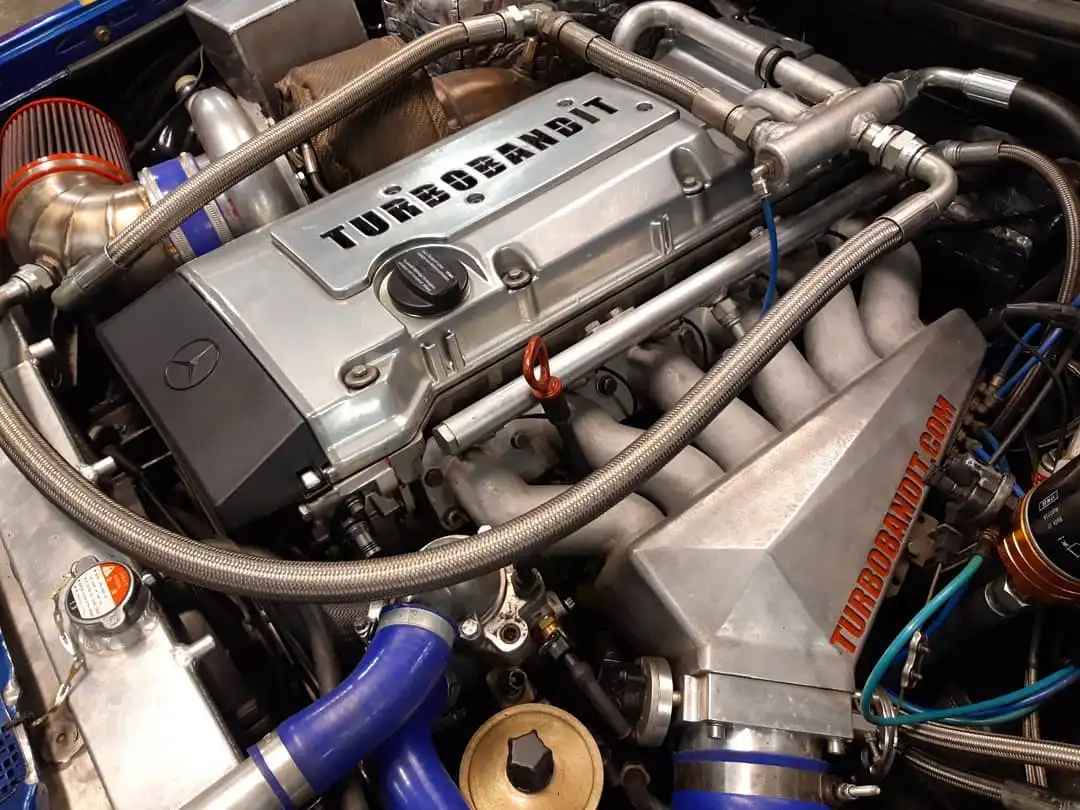

8. Subaru EJ22T

The Subaru EJ22T stands as something of an anomaly in the turbocharged engine world a powerplant that combines the traditionally opposing characteristics of forced induction and extraordinary longevity.

Produced primarily for the first-generation Subaru Legacy GT from 1991 to 1994, this 2.2-liter flat-four turbocharged engine has established a cult following for its remarkable combination of smooth power delivery and exceptional reliability, with many examples exceeding 300,000 miles without major internal repairs.

Unlike many turbocharged engines of its era, the EJ22T was conservatively tuned from the factory, producing a modest 160 horsepower and 181 lb-ft of torque.

This significant derating, combined with the engine’s robust construction, created substantial mechanical headroom that contributed directly to its legendary durability.

The closed-deck block design provides exceptional cylinder stability even under boost, while the engine’s semi-closed block with water jacketing between cylinders ensures optimal thermal management a critical factor in preserving long-term durability in turbocharged applications.

The EJ22T’s turbocharging system employs a modestly sized IHI RHB52 turbocharger that delivers mild boost pressure (typically around 7-8 psi from the factory), minimizing thermal and mechanical stress on internal components.

This conservative approach to forced induction, coupled with the engine’s efficient intercooling system, prevents the detonation issues that often plague turbocharged engines, particularly those of this era with less sophisticated engine management systems.

Perhaps most significantly, the EJ22T avoids many of the head gasket issues that affected later Subaru engines, thanks to its use of multi-layer steel head gaskets and optimal cylinder head fastening design.

The engine’s boxer configuration, with its inherently balanced operation and reduced vibration characteristics, further contributes to component longevity by minimizing mechanical stress on bearings, seals, and accessories.

While the EJ22T’s factory power output might seem modest by modern standards, its flat torque curve and responsive nature make it feel more powerful than the specifications would suggest.

With basic maintenance, including regular oil changes with high-quality synthetic lubricants and attention to cooling system integrity, the EJ22T routinely delivers 250,000 to 300,000 miles of reliable service, often outlasting the vehicle body and other components an extraordinary achievement for a turbocharged engine of its era.

9. Mercedes-Benz OM648 CDI

The Mercedes-Benz OM648 CDI represents one of the most sophisticated and durable turbodiesel engines of the early 2000s.

This 3.2-liter inline-six turbocharged diesel powerplant, introduced in 2002 and featured primarily in E-Class and S-Class models, combined advanced technology with Mercedes’ traditional emphasis on longevity, creating an engine capable of exceeding 500,000 kilometers (310,000 miles) while maintaining exceptional performance and refinement throughout its operational life.

At the heart of the OM648’s durability is its robust construction, featuring a cast iron block with substantial cylinder walls and an aluminum cylinder head with precise coolant channeling for optimal thermal management.

Unlike many contemporary diesel engines, the OM648 utilizes a timing chain rather than a belt, eliminating a common maintenance requirement and potential failure point.

The engine’s common rail direct injection system, operating at pressures up to 23,000 psi, represented cutting-edge technology for its era while maintaining the reliability expected from Mercedes-Benz powerplants.

The OM648’s variable geometry turbocharger deserves particular mention for its contribution to both performance and longevity.

This sophisticated turbocharging system provides responsive power delivery throughout the rev range while operating within its thermal and mechanical limits even under sustained high-load conditions.

The engine’s substantial oil capacity and efficient oil cooling system further ensure that the turbocharger and internal components receive adequate lubrication and thermal protection through hundreds of thousands of miles.

From the factory, the OM648 produced approximately 204 horsepower and an impressive 369 lb-ft of torque, delivering effortless acceleration and excellent highway cruising characteristics.

Despite this substantial output, the engine maintains remarkable fuel efficiency, often exceeding 30 mpg in highway driving a combination that explains its enduring popularity in the European market.

With proper maintenance, including regular oil changes with high-quality synthetic diesel-specific lubricants and attention to the fuel system, the OM648 routinely exceeds 300,000 miles without major internal repairs, with many examples continuing to provide smooth, powerful performance well beyond this milestone.

10. Nissan RB26DETT

The Nissan RB26DETT immortalized through the legendary Skyline GT-R models, represents the pinnacle of Japanese turbocharged engine design from the golden era of 1990s performance cars.

This 2.6-liter inline-six twin-turbocharged masterpiece, produced from 1989 through 2002, combined exceptional performance potential with remarkable durability, establishing a legacy that continues to influence performance engine design to this day.

Despite its high-performance orientation, properly maintained RB26DETT engines routinely exceed 150,000 miles without major issues, with many examples continuing to deliver reliable performance well beyond this milestone.

The RB26DETT’s extraordinary longevity stems from its overbuilt construction and conservative factory tuning.

The cast iron block provides exceptional rigidity and cylinder wall stability, while the aluminum dual overhead camshaft (DOHC) cylinder head features substantial cooling passages and robust valve train components.

Although officially rated at 276 horsepower due to the Japanese “gentleman’s agreement” limiting stated power outputs during that era, the engine produced closer to 310 horsepower from the factory still well below its mechanical limits.

Perhaps the most remarkable aspect of the RB26DETT’s design is its sophisticated twin-turbocharger system.

Unlike many twin-turbo setups of its era that operated sequentially, the RB26DETT employs parallel turbochargers, with each turbo serving three cylinders.

This configuration provides exceptional response throughout the rev range while preventing the thermal and mechanical stresses associated with sequential setups.

The ceramic turbine wheels in later models further enhanced turbocharger durability and responsiveness.

The engine’s oiling system deserves particular mention for its contribution to longevity. Nissan engineered the RB26DETT with a substantial oil capacity and robust oil pump, ensuring adequate lubrication even under the high-G lateral and longitudinal forces experienced during performance driving.

This attention to oiling, combined with the engine’s efficient cooling system and relatively low compression ratio (8.5:1), helps prevent the detonation issues that often plague high-performance turbocharged engines.

With basic maintenance, including regular oil changes with high-quality synthetic lubricants, attention to cooling system integrity, and proper warm-up/cool-down procedures, the RB26DETT delivers exceptional reliability despite its high-performance nature.

The engine’s continued popularity in motorsports and within the tuning community speaks to its remarkable combination of performance potential and fundamental durability, with many modified examples reliably producing over 600 horsepower with upgraded internals an extraordinary achievement for a production engine designed more than three decades ago.

Also Read: 12 Street-Legal Cars That Were Built for the Race Track