In the demanding world of pickup trucks, engine longevity represents the ultimate measure of engineering excellence.

While most modern vehicles are designed with planned obsolescence in mind, certain exceptional truck engines have established reputations for extraordinary durability, routinely surpassing 500,000 miles and occasionally reaching the mythical million-mile mark.

These mechanical marvels share common traits: overbuilt bottom ends, conservative factory tuning, efficient cooling systems, and designs that prioritize durability over maximum performance.

Their longevity isn’t merely theoretical it’s documented through countless real-world examples of high-mileage trucks still performing their duties decades after leaving the factory.

From American workhorses like the Ford 7.3L Power Stroke and Cummins 5.9L inline-six to Japanese stalwarts like Toyota’s 22R and Nissan’s VK56DE, these engines have earned legendary status among truckers, fleet managers, and mechanical enthusiasts.

Their ability to endure punishing work cycles, extreme temperatures, and neglected maintenance schedules demonstrates engineering principles that transcend mere transportation and enter the mechanical art.

These engines don’t just power vehicles they build legacies and livelihoods through their unwavering reliability mile after million miles.

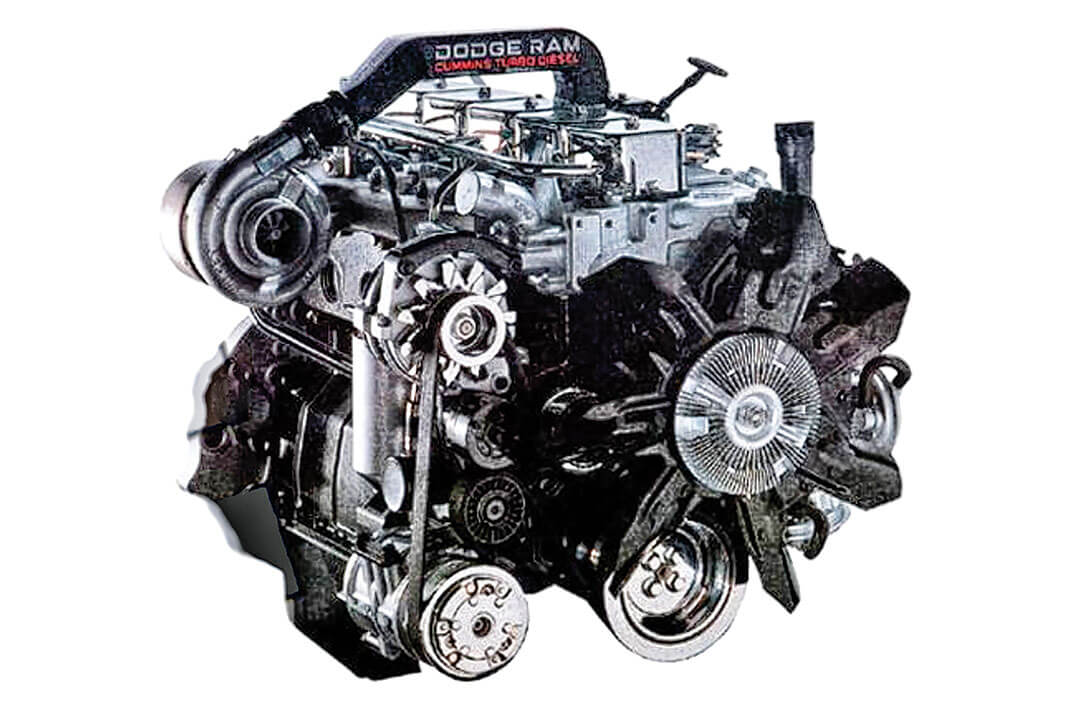

1. Cummins 5.9L Inline-Six Diesel

The Cummins 5.9L inline-six diesel engine stands as perhaps the most legendary pickup truck powerplant ever created.

First introduced in the 1989 Dodge Ram and continued through 2007, this remarkable engine established new standards for durability and longevity that competitors struggled to match.

What makes the 5.9L Cummins truly exceptional is its fundamental architecture, which borrowed heavily from commercial applications where million-mile service intervals were expected.

At the heart of the Cummins’ extraordinary durability is its robust iron block and head, which provide exceptional strength and thermal stability.

The engine features a forged steel crankshaft supported by seven main bearings an overbuilt design that ensures minimal flex even under extreme loads.

The connecting rods and pistons are similarly robust, with the 12-valve versions (1989-1998) featuring particularly overbuilt components that could handle significantly more power than factory settings.

The Cummins’ legendary reliability is further enhanced by its mechanical simplicity. The 12-valve versions utilized a straightforward Bosch P7100 mechanical injection pump that operated reliably with minimal maintenance.

Even as the engine evolved to incorporate electronic controls and more sophisticated fuel delivery systems in the 24-valve iterations, the fundamental mechanical integrity remained intact.

Perhaps most impressively, the 5.9L Cummins maintained its reliability despite being routinely modified for increased performance.

While factory configurations produced between 160-325 horsepower depending on the model year, owners frequently doubled these figures with relatively simple modifications.

The engine’s ability to handle these power increases while maintaining longevity speaks to the substantial engineering margins built into the design.

Cooling system integrity plays a crucial role in the Cummins’ longevity. The engine features generous coolant passages and efficient flow patterns that prevent hot spots, even under heavy loads.

This thermal management, combined with the inherently balanced nature of an inline-six configuration, contributes to exceptional head gasket longevity a common failure point in many diesel engines.

Documented examples of 5.9L Cummins engines exceeding one million miles are numerous, with many achieving this milestone without major internal repairs.

The engine’s longevity is particularly impressive considering the demanding applications these trucks often serve, from heavy towing to commercial use.

For many owners, rebuilding a high-mileage Cummins is less about necessity and more about preventative maintenance, as the core components often show minimal wear even after hundreds of thousands of miles of service.

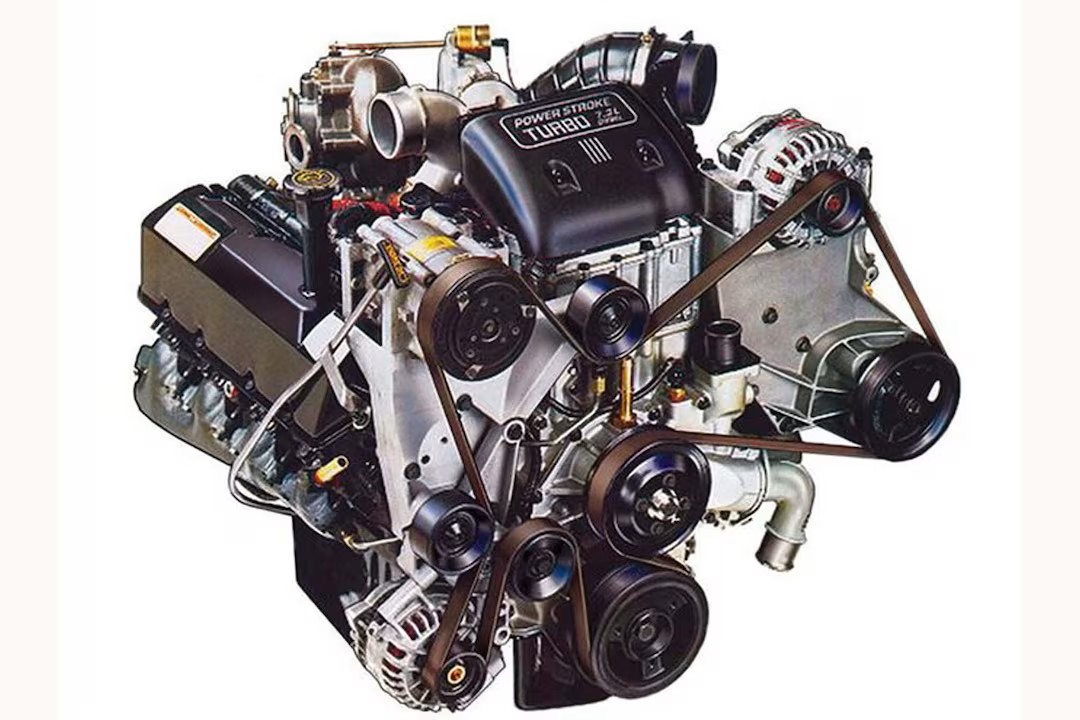

2. Ford 7.3L Power Stroke Diesel

The Ford 7.3L Power Stroke diesel engine represents one of the most respected and durable powerplants ever installed in a production pickup truck.

Manufactured by International Navistar and used in Ford trucks from 1994 to 2003, this legendary engine established a reputation for million-mile reliability that continues to influence how diesel engines are judged today.

What makes the 7.3L Power Stroke truly exceptional is its conservative design philosophy that prioritizes longevity over maximum performance.

At the foundation of the Power Stroke’s durability is its robust iron block and heads, which provide exceptional strength and thermal stability.

The engine features a forged steel crankshaft supported by substantial main bearings that ensure minimal flex even under extreme loads.

The connecting rods and pistons are similarly overbuilt, with generous material throughout the reciprocating assembly.

This fundamental strength allows the engine to withstand the punishing conditions often encountered in heavy-duty truck applications.

The 7.3L’s legendary reliability is further enhanced by its relatively low-pressure hydraulic electronic unit injector (HEUI) fuel system.

While advanced for its time, this system operated at significantly lower pressures than later diesel designs, reducing stress on components.

The maximum factory injection pressure of 21,000 psi modest by modern standards helped ensure exceptional injector longevity while still providing adequate fuel atomization.

Perhaps most impressively, the 7.3L Power Stroke maintained its reliability despite being used in the most demanding conditions.

These engines powered ambulances, utility vehicles, delivery trucks, and personal vehicles engaged in heavy towing.

The engine’s conservative factory tuning producing between 210-275 horsepower depending on the model year ensured substantial thermal margins even under sustained high-load operation.

Cooling system integrity played a crucial role in the Power Stroke’s longevity. The engine features an oil cooler, a large capacity oil system, and efficient coolant flow patterns that prevent hot spots.

This thermal management, combined with the inherently balanced nature of a V8 configuration, contributes to exceptional head gasket longevity a common failure point in many diesel engines.

Documented examples of 7.3L Power Stroke engines exceeding one million miles are numerous, with many achieving this milestone with only minor repairs.

The engine’s longevity is particularly notable considering Ford rated these trucks for 500,000 miles of service life a figure regularly exceeded by well-maintained examples.

The 7.3L’s legendary status is further cemented by the continuing strong demand for these engines in the used market, with many buyers specifically seeking out 1999-2003 trucks for their million-mile potential.

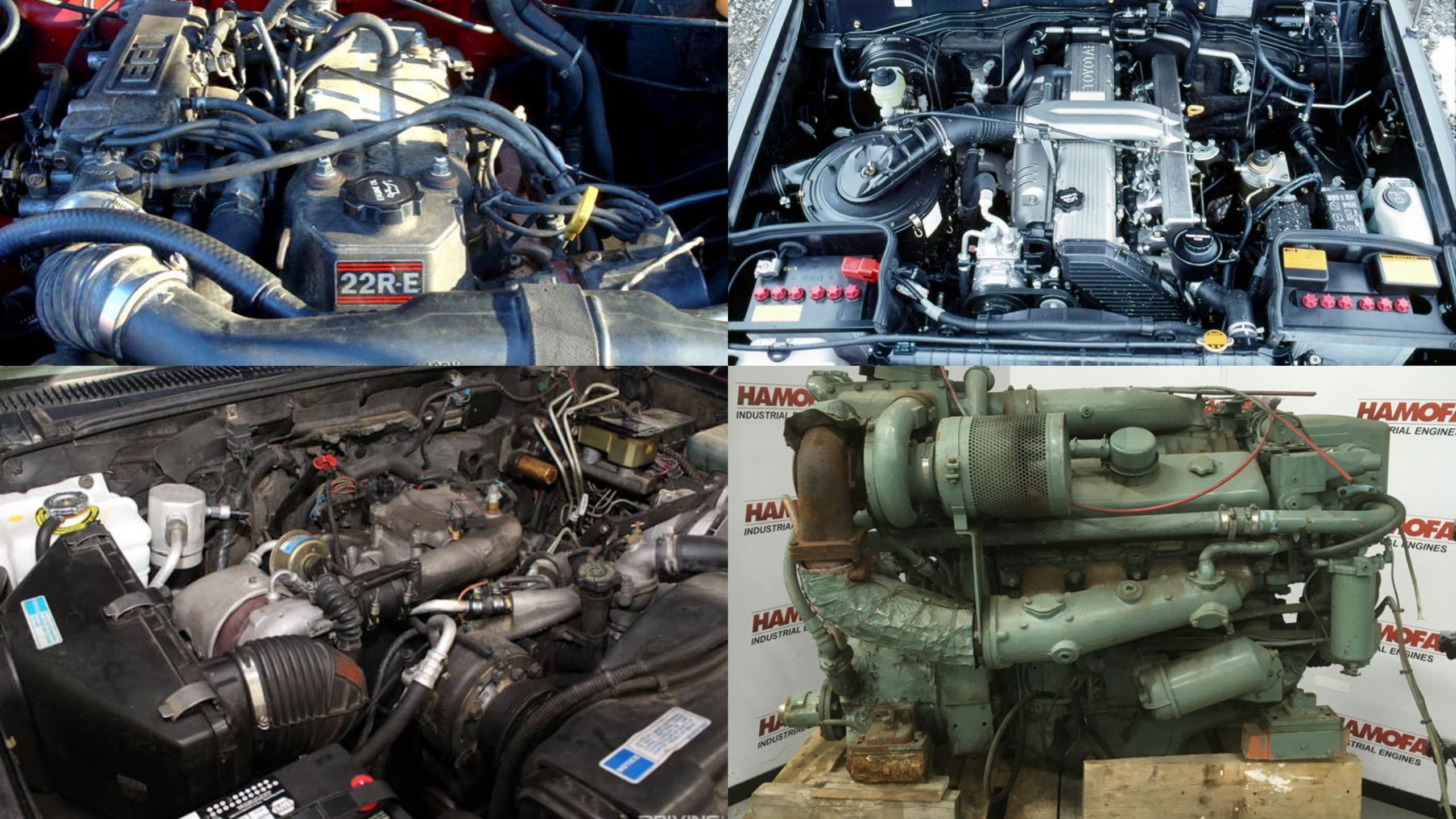

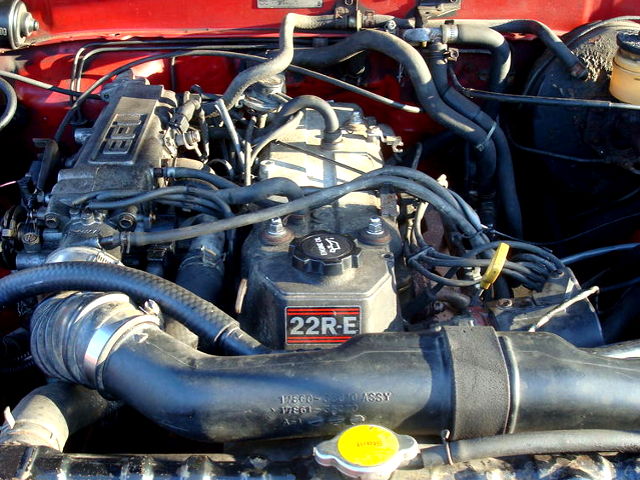

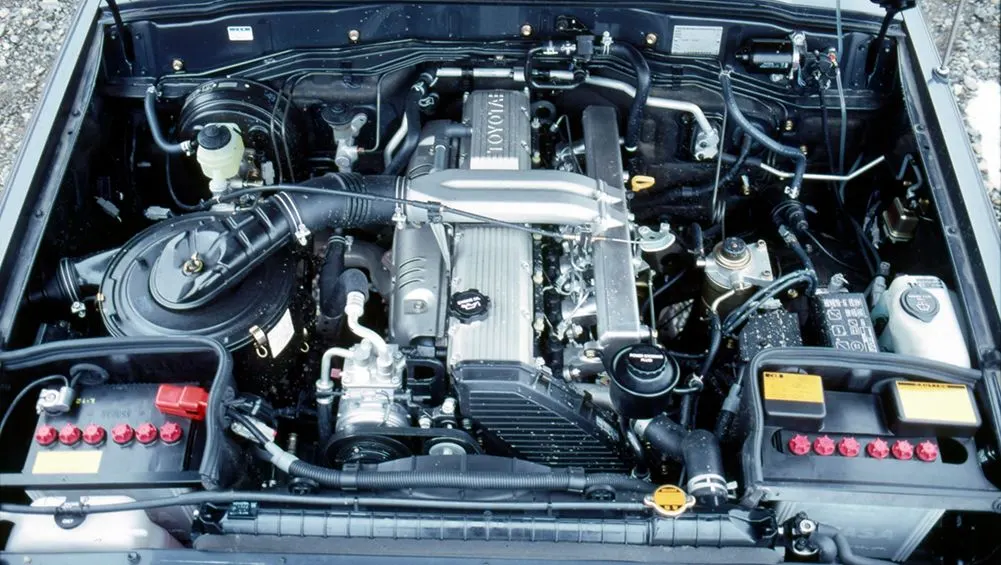

3. Toyota 22R/22RE Inline-Four

The Toyota 22R and fuel-injected 22RE inline-four engines represent perhaps the most indestructible pickup truck powerplants ever created.

First introduced in 1981 and produced through 1995, these remarkable engines powered Toyota’s compact trucks and 4Runners through multiple generations, establishing a reputation for bulletproof reliability that has become an automotive legend.

What makes the 22R/22RE truly exceptional is its fundamental simplicity combined with Toyota’s meticulous engineering and manufacturing standards.

At the heart of the 22R’s extraordinary durability is its robust cast iron block and head, which provide exceptional strength and thermal stability.

The engine features a forged steel crankshaft supported by five main bearings an overbuilt design for a four-cylinder that ensures minimal flex even under extreme loads.

The connecting rods and pistons are similarly robust, with generous material throughout the reciprocating assembly.

This fundamental strength allows the engine to withstand abuse that would destroy lesser designs.

The 22R’s legendary reliability is further enhanced by its mechanical simplicity. The engine utilizes a timing chain rather than a belt, eliminating a common failure point in many engines.

The chain drive itself is overbuilt, with dual rows in most applications providing redundancy and extended service life.

Even when these chains stretch after hundreds of thousands of miles, they rarely fail catastrophically, instead producing a recognizable rattle that serves as an early warning system.

Perhaps most impressively, the 22R/22RE maintained its reliability despite being used in the most demanding conditions worldwide.

These engines powered vehicles in the Australian Outback, African deserts, and Arctic tundra, routinely operating in extreme temperatures and dusty environments.

The engine’s relatively low compression ratio and conservative tuning producing between 97-116 horsepower depending on the model year ensured it could run on poor-quality fuel often found in remote regions.

Cooling system integrity plays a crucial role in the 22R’s longevity. The engine features efficient coolant flow patterns that prevent hot spots, even under heavy loads.

This thermal management contributes to exceptional head gasket longevity a common failure point in many engines.

The engine’s oil system is similarly robust, with a high-capacity pump and generous oil galleries ensuring adequate lubrication under all conditions.

Documented examples of 22R/22RE engines exceeding one million miles are numerous, with many achieving this milestone with minimal repairs.

The engine’s longevity is impressive considering the demanding off-road applications these trucks often serve.

For many owners, rebuilding a high-mileage 22R is less about necessity and more about preventative maintenance, as the core components often show minimal wear even after hundreds of thousands of miles of service.

4. Duramax 6.6L LB7/LLY Diesel

The Duramax 6.6L LB7 and LLY diesel engines represent General Motors’ entrance into the modern diesel pickup truck market and quickly established themselves as million-mile capable powerplants.

First introduced in 2001 and continued through 2006, these engines were developed in partnership with Isuzu and powered Chevrolet and GMC heavy-duty trucks.

What makes the early Duramax engines truly exceptional is their robust design and advanced technology that provided both power and extraordinary longevity.

At the foundation of the Duramax’s durability is its deep-skirt cast iron block and aluminum heads, which provide an excellent balance of strength and weight.

The engine features a forged steel crankshaft supported by six main bearings with substantial journals that ensure minimal flex even under extreme loads.

The connecting rods and pistons are similarly overbuilt, with the Duramax utilizing fractured-cap connecting rods that provide superior strength and precise alignment.

This fundamental strength allows the engine to withstand the punishing conditions often encountered in heavy-duty truck applications.

The Duramax’s legendary reliability is further enhanced by its advanced common-rail fuel injection system, which was revolutionary for its time in American diesel pickups.

While the LB7’s injectors (mounted under the valve covers) proved somewhat problematic, the underlying architecture of the fuel system was sound, providing precise fuel delivery and excellent atomization.

The LLY addressed many of the LB7’s shortcomings while maintaining the fundamental durability of the design.

Perhaps most impressively, the early Duramax engines maintained their reliability despite being used in the most demanding conditions.

These engines powered commercial vehicles, farm trucks, and personal vehicles engaged in heavy towing.

The engine’s factory tuning producing between 235-310 horsepower depending on the model year ensured substantial thermal margins even under sustained high-load operation.

Cooling system integrity played a crucial role in the Duramax’s longevity. The engine features an efficient coolant flow design, an integrated oil cooler, and a robust water pump that prevents overheating even under extreme conditions.

This thermal management, combined with the inherently balanced nature of a V8 configuration, contributes to exceptional head gasket longevity a common failure point in many diesel engines.

Documented examples of early Duramax engines exceeding one million miles are numerous, with many achieving this milestone with only minor repairs.

The engine’s longevity is particularly notable considering the high power output and torque figures these engines produced.

With proper maintenance and timely repairs to known weak points (particularly the injectors on LB7 models), these engines routinely exceed 500,000 miles and can reach the seven-figure milestone with careful operation.

Also Read: 12 Underrated Supercars That Perform Like Hypercars

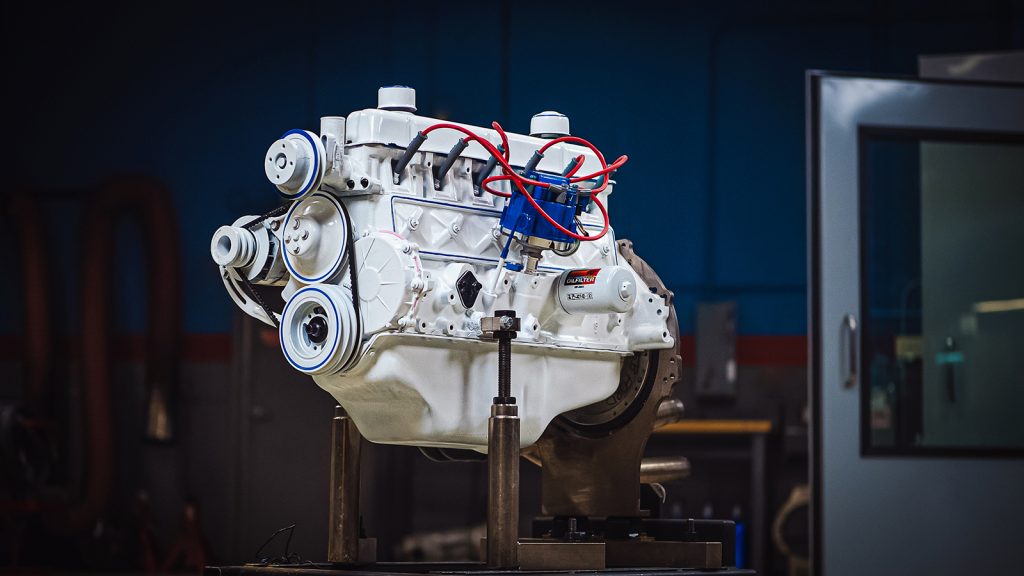

5. Ford 300 Inline-Six

The Ford 300 cubic inch (4.9L) inline-six engine stands as perhaps the most understated yet incredibly durable pickup truck powerplant ever created.

Produced from 1965 to 1996, this remarkable engine powered Ford’s F-Series trucks through three decades of service, establishing a reputation for bulletproof reliability that has become legendary among truck enthusiasts.

What makes the Ford 300 truly exceptional is its fundamental simplicity combined with substantial overengineering that prioritized longevity above all else.

At the heart of the 300’s extraordinary durability is its robust cast iron block and head, which provide exceptional strength and thermal stability.

The engine features seven main bearings supporting the crankshaft an overbuilt design that ensures minimal flex even under extreme loads.

The connecting rods and pistons are similarly robust, with generous material throughout the reciprocating assembly.

This fundamental strength allows the engine to withstand abuse that would destroy lesser designs.

The 300’s legendary reliability is further enhanced by its mechanical simplicity. The engine utilizes a timing gear rather than a chain or belt, eliminating a common failure point in many engines.

This gear-driven camshaft design is virtually indestructible and requires no maintenance throughout the life of the engine.

The overhead valve pushrod design, while not as efficient as overhead cam configurations, provides excellent durability and straightforward serviceability.

Perhaps most impressively, the Ford 300 maintained its reliability despite being used in the most demanding commercial applications.

These engines powered utility company trucks, construction vehicles, farm equipment, and delivery vans often running 24/7 in severe conditions.

The engine’s modest power output ranging from 105 to 150 horsepower depending on the model year ensured it operated well within its mechanical limits, contributing to its extraordinary longevity.

Cooling system integrity plays a crucial role in the 300 million-mile potential. The engine features generous coolant passages and efficient flow patterns that prevent hot spots, even under heavy loads.

This thermal management contributes to exceptional head gasket longevity a common failure point in many engines.

The engine’s oil system is similarly robust, with a high-capacity pump and generous oil galleries ensuring adequate lubrication under all conditions.

Documented examples of Ford 300 engines exceeding one million miles are numerous, with many achieving this milestone with minimal repairs.

The engine’s longevity is particularly impressive considering these trucks often received indifferent maintenance in commercial applications.

For many owners, rebuilding a high-mileage 300 is less about necessity and more about preventative maintenance, as the core components often show minimal wear even after hundreds of thousands of miles of service.

6. Toyota 1HZ Diesel

The Toyota 1HZ diesel engine represents one of the most durable and reliable powerplants ever created for pickup trucks and commercial applications.

Produced from 1990 to 2019, this remarkable 4.2-liter inline-six diesel powered Toyota Land Cruisers, Coaster buses, and HiLux trucks across the globe, establishing an unparalleled reputation for million-mile reliability under the most extreme conditions.

What makes the 1HZ truly exceptional is its mechanical simplicity combined with Toyota’s meticulous engineering and manufacturing standards.

At the foundation of the 1HZ’s extraordinary durability is its robust cast iron block and head, which provide exceptional strength and thermal stability.

The engine features seven main bearings supporting the crankshaft an overbuilt design that ensures minimal flex even under extreme loads.

The connecting rods and pistons are similarly robust, with generous material throughout the reciprocating assembly.

This fundamental strength allows the engine to withstand the punishing conditions often encountered in remote and harsh environments.

Unlike virtually every other diesel engine of its era, the 1HZ maintained a fully mechanical indirect injection system with no electronic components.

This deliberate choice by Toyota engineers prioritized reliability over emissions or maximum performance, resulting in an engine that could operate flawlessly in areas where electronic diagnostics and repairs were impossible.

The mechanical injection pump, manufactured by Denso, has proven incredibly durable, with many examples operating faultlessly for hundreds of thousands of miles.

Perhaps most impressively, the 1HZ maintained its reliability despite being used in the most demanding conditions on Earth.

These engines powered vehicles in the Australian Outback, African deserts, and Arctic tundra, routinely operating in extreme temperatures, dust, and humidity.

The engine’s modest power output approximately 129 horsepower and 210 lb-ft of torque ensured it operated well within its mechanical limits, contributing to its extraordinary longevity.

Cooling system integrity plays a crucial role in the 1HZ’s million-mile potential. The engine features generous coolant passages and efficient flow patterns that prevent hot spots, even under heavy loads in extreme ambient temperatures.

This thermal management contributes to exceptional head gasket longevity a common failure point in many diesel engines.

The engine’s oil system is similarly robust, with a high-capacity pump and generous oil galleries ensuring adequate lubrication under all conditions.

Documented examples of 1HZ engines exceeding one million kilometers (621,371 miles) are numerous, with many achieving this milestone with minimal repairs.

The engine’s longevity is particularly impressive considering the punishing conditions these vehicles often endure in commercial, military, and remote operations.

For many owners in developing nations, where vehicle replacement is economically challenging, the 1HZ’s durability represents not just a mechanical achievement but a crucial economic advantage.

7. Nissan VK56DE V8

The Nissan VK56DE V8 engine stands as one of the most underrated yet incredibly durable pickup truck powerplants available in the modern era.

Introduced in 2004 and still in production with evolutionary improvements, this 5.6-liter engine powers the Nissan Titan, Armada, NV commercial vans, and global Patrol/Infiniti QX56 models.

What makes the VK56DE truly exceptional is its robust design and construction that prioritizes longevity while delivering impressive performance.

At the heart of the VK56DE’s durability is its deep-skirt aluminum block with cast iron cylinder liners, providing an excellent balance of strength and weight.

The engine features a forged steel crankshaft supported by five main bearings with substantial journals that ensure minimal flex even under extreme loads.

The connecting rods and pistons are similarly overbuilt, with generous material throughout the reciprocating assembly.

This fundamental strength allows the engine to withstand the punishing conditions often encountered in heavy-duty truck applications.

The VK56DE’s legendary reliability is further enhanced by its double overhead camshaft design with four valves per cylinder.

While this configuration is more complex than pushrod arrangements, Nissan’s engineering team created a remarkably robust valvetrain that rarely develops issues.

The timing chain system, often a weakness in modern engines, utilizes a dual-chain design with exceptionally durable components that routinely last beyond 300,000 miles without replacement.

Perhaps most impressively, the VK56DE maintains its reliability despite delivering substantial performance.

With 317-400 horsepower (depending on the application and model year), this engine produces significantly more power than many million-mile engines of the past.

The engine’s conservative factory tuning ensures it operates with substantial thermal margins even under heavy loads, contributing to its extraordinary longevity.

Cooling system integrity plays a crucial role in the VK56DE’s million-mile potential. The engine features microfinished cylinder bores, efficient coolant flow patterns, and a high-capacity cooling system that prevents hot spots, even under heavy loads.

This thermal management contributes to exceptional head gasket longevity

a common failure point in many engines. The engine’s oil system is similarly robust, with a high-capacity pump and generous oil galleries ensuring adequate lubrication under all conditions.

Documented examples of VK56DE engines exceeding 500,000 miles are increasingly common, with many commercial users reporting minimal internal wear at this milestone.

The engine’s longevity is particularly impressive considering the demanding applications these trucks often serve, from heavy towing to commercial delivery operations.

For many owners, the VK56DE’s durability has made it a viable million-mile engine, especially in the first-generation Titan pickups and NV commercial vans where the engine is routinely subjected to severe-duty cycles.

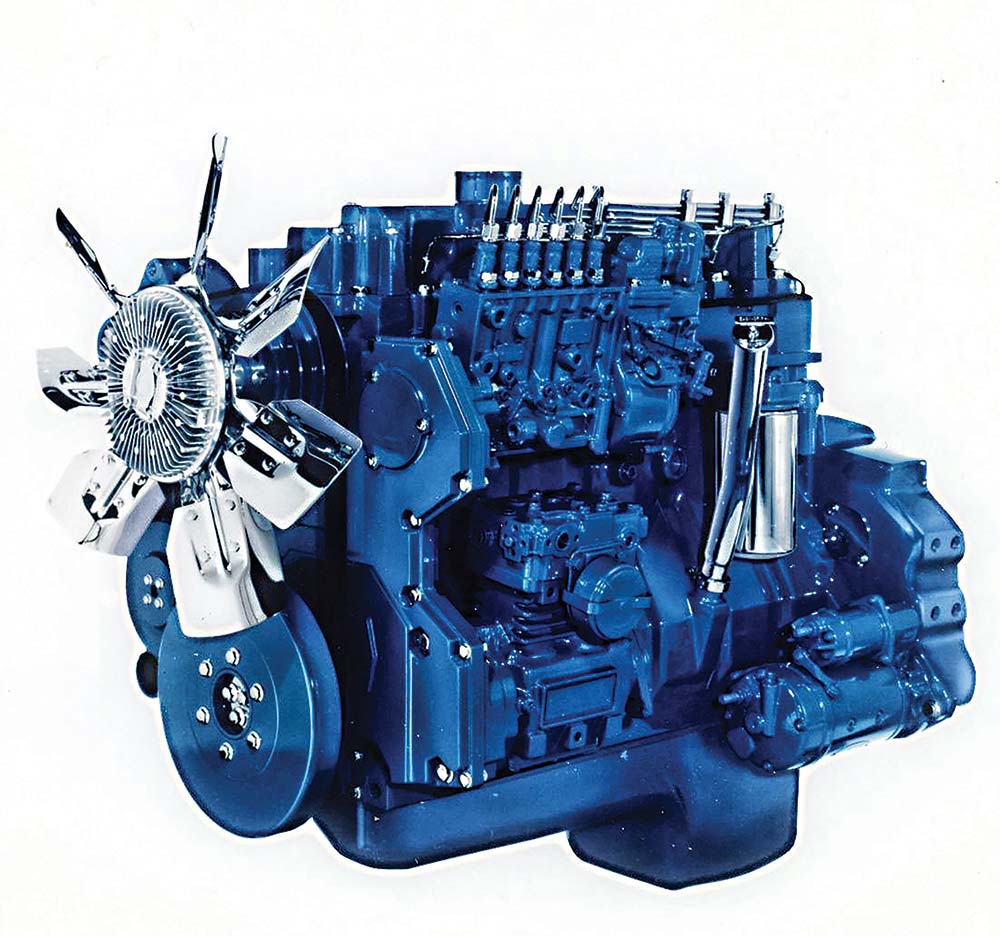

8. International/Navistar DT466 Inline-Six Diesel

The International/Navistar DT466 inline-six diesel engine represents perhaps the most legendary million-mile engine ever created for medium-duty truck applications.

First introduced in 1971 and produced in various evolved forms until 2016 (when it was replaced by the A26), this remarkable 7.6-liter powerplant powered everything from delivery trucks to school buses and municipal vehicles.

What makes the DT466 truly exceptional is its robust design and construction that prioritizes longevity above all else.

At the foundation of the DT466’s extraordinary durability is its massive wet-sleeve cylinder design, which allows for engine rebuilds without removing the block from the vehicle.

The engine features a substantial cast iron block with replaceable cylinder liners that can be serviced individually.

The crankshaft rides on seven main bearings with enormous journals that ensure minimal flex even under extreme loads.

The connecting rods and pistons are similarly massive, with generous material throughout the reciprocating assembly.

The DT466’s legendary reliability is further enhanced by its mechanical simplicity, particularly in pre-electronic versions.

The engine utilizes a gear-driven camshaft rather than a timing chain or belt, eliminating a common failure point in many engines.

This gear-driven design is virtually indestructible and requires no maintenance throughout the life of the engine.

Even as the engine evolved to incorporate electronic controls, the fundamental mechanical integrity remained unchanged.

Perhaps most impressively, the DT466 maintained its reliability despite being used in the most demanding commercial applications.

These engines powered dump trucks, cement mixers, school buses, and delivery vehicles often running continuously for decades in severe conditions.

The engine’s modest power output by modern standards ranging from 170-300 horsepower depending on the model year ensured it operated well within its mechanical limits, contributing to its extraordinary longevity.

Cooling system integrity plays a crucial role in the DT466’s million-mile potential. The engine features generous coolant passages and efficient flow patterns that prevent hot spots, even under heavy loads.

This thermal management contributes to exceptional head gasket longevity a common failure point in many diesel engines.

The engine’s oil system is similarly robust, with a high-capacity pump and generous oil galleries ensuring adequate lubrication under all conditions.

Documented examples of DT466 engines exceeding two million miles are numerous, with many achieving this milestone with minimal internal repairs.

The engine’s longevity is particularly impressive considering these trucks often received only basic maintenance in commercial applications.

For fleet operators, the DT466’s durability represented a significant economic advantage, with many engines outlasting multiple truck bodies and transmissions.

9. Detroit Diesel 6.2L/6.5L V8

The Detroit Diesel 6.2L and 6.5L V8 engines represent some of the most durable and reliable powerplants ever installed in light and medium-duty trucks. Introduced in 1982 and produced through 2000, these engines powered GM’s full-size pickups, Suburban/Tahoe SUVs, and military HMMWV (Humvee) vehicles.

What makes these engines truly exceptional is their robust design and construction that prioritizes longevity over maximum performance.

At the heart of these engines’ durability is their massive cast iron block and heads, which provide exceptional strength and thermal stability.

The engines feature a forged steel crankshaft supported by five main bearings with substantial journals that ensure minimal flex even under extreme loads.

The connecting rods and pistons are similarly overbuilt, with generous material throughout the reciprocating assembly.

This fundamental strength allows the engines to withstand punishing conditions that would destroy lesser designs.

The 6.2L/6.5L’s legendary reliability is further enhanced by their mechanical simplicity. These engines utilize a gear-driven camshaft rather than a timing chain or belt, eliminating a common failure point in many engines.

This gear-driven design is virtually indestructible and requires no maintenance throughout the life of the engine.

The indirect injection system, while less efficient than direct injection, provides excellent durability and tolerance for poor-quality fuel.

Perhaps most impressively, these engines maintained their reliability despite being used in the most demanding military and commercial applications.

The 6.2L/6.5L powered vehicles in desert warfare, Arctic conditions, and harsh off-road environments often run continuously for days in extreme conditions.

The engines’ modest power output ranging from 130 to 190 horsepower depending on the model year ensured they operated well within their mechanical limits, contributing to their extraordinary longevity.

Cooling system integrity plays a crucial role in these engines’ million-mile potential. The engines feature generous coolant passages and efficient flow patterns that prevent hot spots, even under heavy loads.

This thermal management contributes to exceptional head gasket longevity a common failure point in many diesel engines.

The engines’ oil systems are similarly robust, with high-capacity pumps and generous oil galleries ensuring adequate lubrication under all conditions.

Documented examples of 6.2L/6.5L engines exceeding one million miles are numerous, with many achieving this milestone with minimal repairs.

The engines’ longevity is particularly impressive considering the demanding applications these trucks often serve, from military operations to commercial delivery and towing.

For many owners, these engines’ durability has made them viable million-mile powerplants, especially in applications where reliability trumps maximum performance.

10. Isuzu 4BD1T/4HE1T Diesel

The Isuzu 4BD1T and 4HE1T diesel engines represent some of the most durable and reliable four-cylinder powerplants ever created for light and medium-duty truck applications.

Produced from the 1980s through the 2000s, these engines powered Isuzu NPR, NQR, and NRR commercial trucks, as well as numerous GMC and Chevrolet medium-duty vehicles through the companies’ partnership.

What makes these engines truly exceptional is their robust design and construction that prioritizes longevity above all else.

At the foundation of these engines’ extraordinary durability is their massive cast iron block and head, which provide exceptional strength and thermal stability.

The engines feature a forged steel crankshaft supported by five main bearings with substantial journals that ensure minimal flex even under extreme loads.

The connecting rods and pistons are similarly overbuilt, with generous material throughout the reciprocating assembly.

This fundamental strength allows the engines to withstand punishing conditions that would destroy lesser designs.

The 4BD1T/4HE1T’s legendary reliability is further enhanced by their mechanical simplicity, particularly in earlier versions.

The engines utilize robust timing gear systems rather than chains or belts, eliminating a common failure point in many engines.

This gear-driven design is virtually indestructible and requires no maintenance throughout the life of the engine.

Even as the engines evolved to incorporate electronic controls, the fundamental mechanical integrity remained unchanged.

Perhaps most impressively, these engines maintained their reliability despite being used in the most demanding commercial applications.

These engines powered delivery trucks, box trucks, and municipal vehicles often running continuously for decades in stop-and-go urban environments.

The engines’ modest power output ranging from 110 to 175 horsepower depending on the model ensured they operated well within their mechanical limits, contributing to their extraordinary longevity.

Cooling system integrity plays a crucial role in these engines’ million-mile potential. The engines feature generous coolant passages and efficient flow patterns that prevent hot spots, even under heavy loads.

This thermal management contributes to exceptional head gasket longevity a common failure point in many diesel engines.

The engines’ oil systems are similarly robust, with high-capacity pumps and generous oil galleries ensuring adequate lubrication under all conditions.

Documented examples of 4BD1T/4HE1T engines exceeding one million miles are numerous in commercial applications, with many achieving this milestone with minimal internal repairs.

The engines’ longevity is particularly impressive considering these trucks often received only basic maintenance in fleet operations.

For delivery companies and municipalities, these engines’ durability represented a significant economic advantage, with many engines outlasting multiple truck bodies and transmissions.

11. GMC/Detroit Diesel 6-71/8V-71 Diesel

The GMC/Detroit Diesel 6-71 and 8V-71 diesel engines represent perhaps the most legendary million-mile powerplants ever created for heavy-duty truck applications.

Developed in the 1930s and produced for decades, these remarkable two-stroke diesel engines powered everything from highway trucks to buses, marine vessels, and industrial equipment.

What makes these engines truly exceptional is their robust design and construction that prioritizes longevity above all else.

At the heart of these engines’ extraordinary durability is their unique two-stroke architecture with unit injectors and roots-type blowers.

The engines feature massive cast iron blocks with replaceable cylinder liners that can be serviced individually.

The crankshaft rides on substantial main bearings that ensure minimal flex even under extreme loads.

The connecting rods and pistons are similarly overbuilt, with generous material throughout the reciprocating assembly.

This fundamental strength allows the engines to withstand punishing conditions that would destroy lesser designs.

The 6-71/8V-71’s legendary reliability is further enhanced by its mechanical simplicity and serviceability.

The engines utilize gear-driven camshafts rather than timing chains or belts, eliminating a common failure point in many engines.

This gear-driven design is virtually indestructible and requires no maintenance throughout the life of the engine.

The engines’ design allows for in-frame overhauls, meaning major components can be replaced without removing the entire engine from the vehicle.

Perhaps most impressively, these engines maintained their reliability despite being used in the most demanding commercial applications.

These engines powered long-haul trucks, city buses, and construction equipment often running continuously for decades in severe conditions.

The engines’ modest power output by modern standards ranging from 165-318 horsepower depending on the model ensured they operated well within their mechanical limits, contributing to their extraordinary longevity.

Cooling system integrity plays a crucial role in these engines’ million-mile potential. The engines feature generous coolant passages and efficient flow patterns that prevent hot spots, even under heavy loads.

This thermal management contributes to exceptional block and head integrity a common failure point in many diesel engines.

The engines’ oil systems are similarly robust, with high-capacity pumps and generous oil galleries ensuring adequate lubrication under all conditions.

Documented examples of 6-71/8V-71 engines exceeding two million miles are numerous, with many achieving this milestone with periodic rebuilds.

The engines’ longevity is particularly impressive considering these trucks often operated around the clock in commercial applications.

For fleet operators, these engines’ durability represented a significant economic advantage, with many engines being rebuilt multiple times and continuing to operate reliably for decades.

12. Mercedes-Benz OM617 Diesel

The Mercedes-Benz OM617 diesel engine represents one of the most durable and reliable powerplants ever created for passenger vehicles and light commercial applications.

Produced from 1974 to 1991, this remarkable 3.0-liter inline-five diesel powered Mercedes sedans, wagons, and the iconic G-Wagen off-road vehicle.

What makes the OM617 truly exceptional is its robust design and construction that prioritizes longevity above all else.

At the foundation of the OM617’s extraordinary durability is its massive cast iron block and aluminum head, which provide an excellent balance of strength and weight.

The engine features a forged steel crankshaft supported by six main bearings that ensure minimal flex even under extreme loads.

The connecting rods and pistons are similarly overbuilt, with generous material throughout the reciprocating assembly.

This fundamental strength allows the engine to withstand punishing conditions that would destroy lesser designs.

The OM617’s legendary reliability is further enhanced by its mechanical simplicity. The engine utilizes a robust timing chain system rather than a belt, eliminating a common failure point in many engines.

This chain-driven design is virtually indestructible and requires no maintenance throughout the life of the engine.

The indirect injection system, featuring a Ricardo Comet pre-combustion chamber design, provides excellent durability and smooth operation.

Perhaps most impressively, the OM617 maintained its reliability despite being used in the most demanding commercial and personal applications.

These engines powered taxis, delivery vehicles, and personal cars often accumulating astronomical mileage in diverse conditions.

The engine’s modest power output ranging from 80 to 125 horsepower depending on the model year ensured it operated well within its mechanical limits, contributing to its extraordinary longevity.

Cooling system integrity plays a crucial role in the OM617’s million-mile potential. The engine features generous coolant passages and efficient flow patterns that prevent hot spots, even under heavy loads.

This thermal management contributes to exceptional head gasket longevity a common failure point in many diesel engines.

The engine’s oil system is similarly robust, with a high-capacity pump and generous oil galleries ensuring adequate lubrication under all conditions.

Documented examples of OM617 engines exceeding one million miles are numerous, with many achieving this milestone with minimal internal repairs.

The engine’s longevity is particularly impressive considering these vehicles often received only basic maintenance in taxi and commercial applications.

For many owners, the OM617’s durability has made it a viable million-mile engine, especially in W123 chassis sedans and G-Wagen vehicles where the engine is routinely subjected to severe duty cycles yet continues to operate flawlessly decade after decade.

Also Read: 10 Luxury SUVs That Can Outrun Supercars with Blistering Speed and Power