In the automotive world, reliability is the gold standard that separates merely good vehicles from truly exceptional ones.

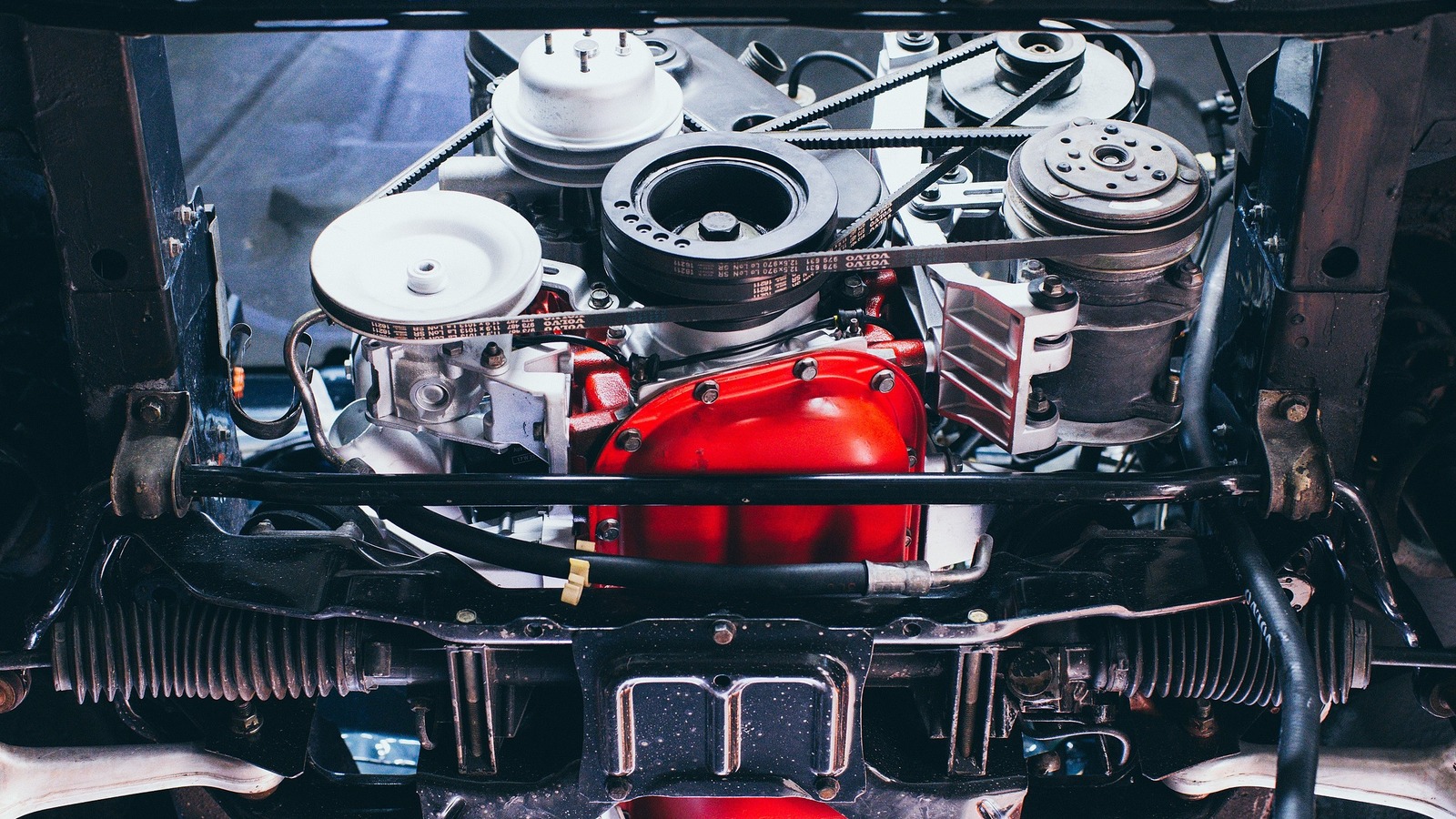

While many components contribute to a car’s longevity, the engine remains the heart of the vehicle and some small displacement powerplants have earned legendary status for their ability to keep running long after other parts have deteriorated.

These compact engineering marvels often continue purring while suspension components fail, body panels rust, and interiors crumble around them.

Their resilience comes from thoughtful engineering, conservative tuning, and simple, robust design philosophies that prioritize durability over maximum power.

From Japanese inline-fours that routinely cross the 300,000-mile threshold without major service to European diesels that power taxis well into seven-figure mileages, these engines represent the pinnacle of reliability in compact form.

This collection highlights ten remarkable small-displacement engines that have proven they can outlast the vehicles they power often requiring only basic maintenance and oil changes to soldier on decade after decade.

1. Toyota 22R/22RE (2.4L Inline-4)

The Toyota 22R and its fuel-injected evolution, the 22RE, stand as monuments to Toyota’s legendary reliability.

Introduced in 1981, this 2.4-liter workhorse powered everything from the humble Celica to the rugged Hilux pickup trucks that gained fame for their indestructibility on BBC’s Top Gear.

The secret to the 22R’s longevity lies in its deliberately conservative engineering: with a simple overhead cam design, a cast iron block with generous cylinder wall thickness, and forged steel connecting rods, Toyota built this engine to withstand abuse rather than chase horsepower figures.

What makes the 22R truly remarkable is its tolerance for neglect. Stories abound of these engines running with minimal maintenance, surviving low oil conditions, and continuing to operate despite timing chain issues that would kill lesser motors.

The engine’s overbuilt nature is evident in its robust bottom end, which rarely experiences bearing failure even at extreme mileage.

Toyota’s decision to utilize a gear-driven oil pump rather than a chain-driven one eliminated a common failure point in many engines.

Mechanically simple with easily accessible components, the 22R allows even novice mechanics to perform maintenance, contributing to its reputation for serviceability.

The engine’s power output ranging from 97 to 114 horsepower depending on the year and application might seem modest by modern standards, but this conservative tuning means the engine rarely operates under stress, extending its operational life dramatically.

Many 22R-powered vehicles have recorded over 400,000 miles without internal engine repairs, with some well-maintained examples reportedly crossing the 700,000-mile mark.

It’s common to find these engines still running smoothly even when the truck bodies around them have succumbed to rust, particularly in coastal or road-salt regions.

This exceptional durability cemented Toyota’s reputation for reliability in the 1980s and 1990s, creating a legacy that continues to influence consumer perception of the brand today.

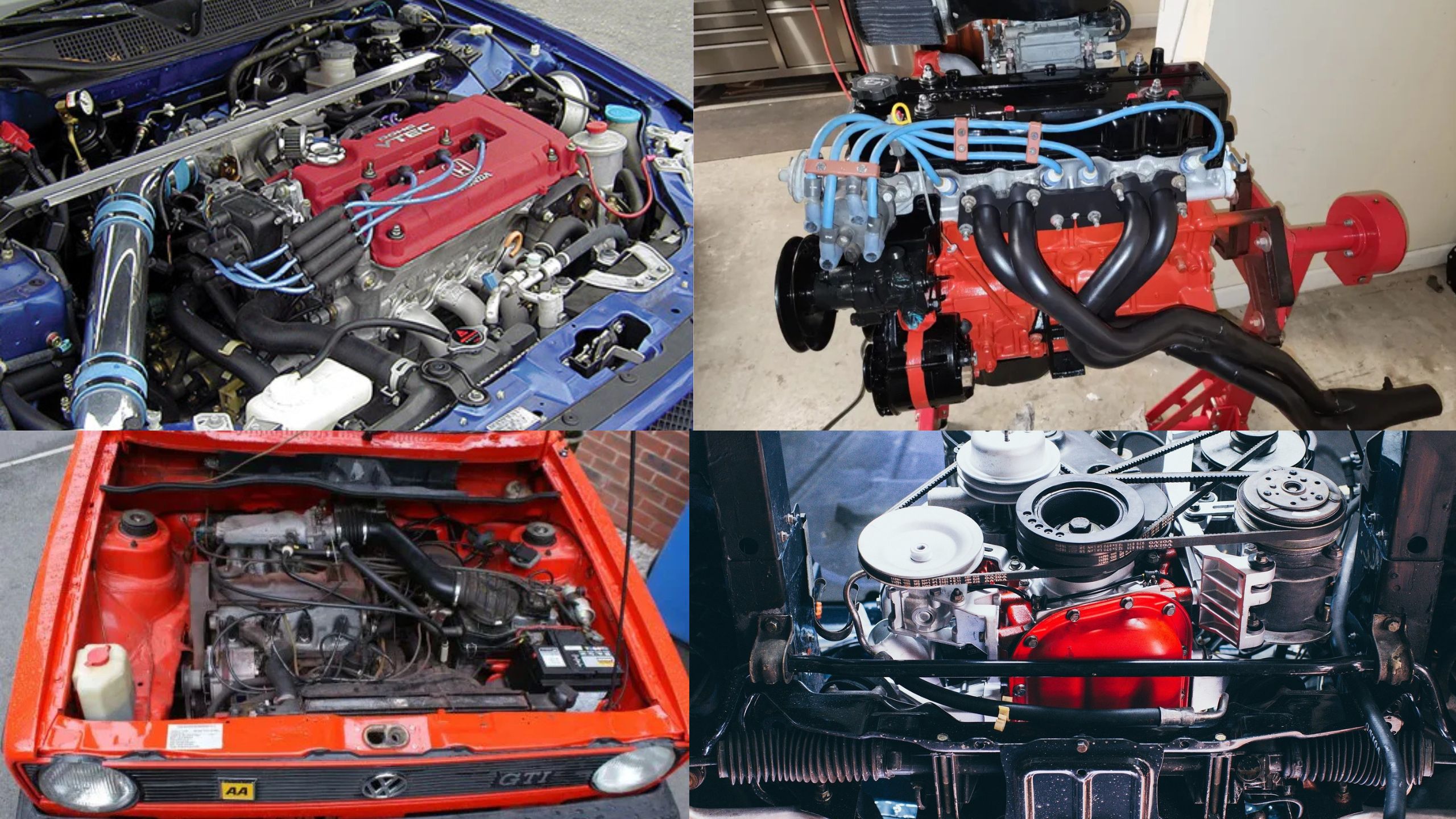

2. Honda B-Series (1.6-1.8L Inline-4)

Honda’s B-series engines, particularly the B16 and B18 variants, represent the perfect marriage of reliability and performance that defined Honda’s golden era from the late 1980s through the early 2000s.

These compact powerplants found homes in Civic and Integra models worldwide, earning devoted followings for their ability to deliver sports car performance while maintaining economy car dependability.

The B-series’ signature attribute is its extraordinary rev capability with redlines reaching 8,000 RPM while still offering the durability to exceed 300,000 miles with proper maintenance.

The core of the B-series’ longevity comes from Honda’s revolutionary VTEC (Variable Valve Timing and Lift Electronic Control) system, which allowed the engine to operate efficiently at low RPMs while delivering performance at higher revs.

Unlike many contemporary variable valve timing systems, Honda’s implementation used robust mechanical components with minimal failure points.

The engines feature precision-machined aluminum blocks with cast iron cylinder sleeves, providing lightweight construction without sacrificing durability.

Perhaps most impressive is the B-series’ tolerance for modification and performance tuning. While many engines suffer reliability issues when pushed beyond factory specifications, properly built B-series motors can withstand significant power increases while maintaining their legendary durability.

The engines use forged crankshafts in many applications, oversized rod bearings, and oil systems designed to perform under high-RPM operation all contributing to their robust nature.

These engines frequently outlast their host vehicles, with many B16 and B18 motors being transplanted into multiple chassis over their operational lives.

A well-documented phenomenon among Honda enthusiasts is finding high-mileage B-series engines with minimal wear when opened for inspection.

The timing belts, water pumps, and tensioners require regular service, but the internal components often show remarkable resistance to wear even after hundreds of thousands of miles.

The B-series’ combination of bulletproof reliability, high-performance potential, and widespread availability has cemented its status as one of the most beloved four-cylinder engines ever produced, with many examples still powering vehicles decades after manufacture.

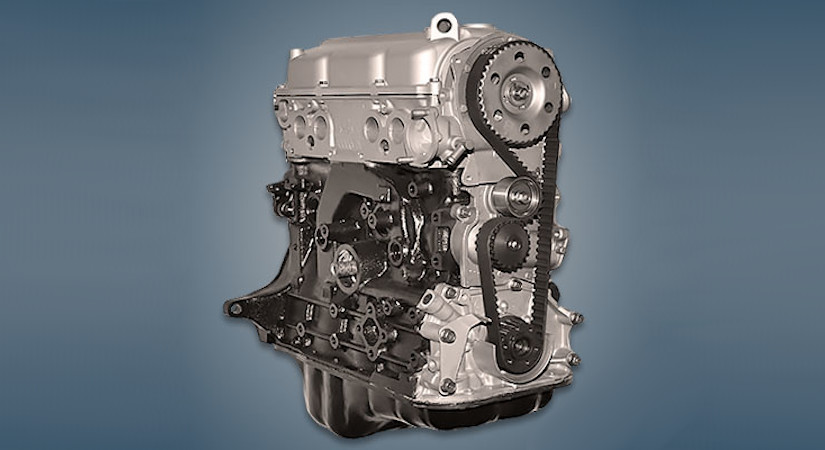

3. Volkswagen EA827 (1.6-2.0L Inline-4)

The Volkswagen EA827 engine family might be the most prolific yet underappreciated workhorse in automotive history.

Developed in the early 1970s, this inline-four design became VW Group’s standard-bearer for decades, powering everything from humble Golfs and Jettas to Audi and SEAT models across Europe.

While initially designed as a modest family car engine, the EA827’s architecture proved so fundamentally sound that it remained in production with various updates until 2013 a production run exceeding 40 years.

What distinguishes the EA827 is its incredibly overbuilt bottom end for an economy car engine. The block features five main bearings supporting a forged steel crankshaft specifications typically reserved for performance engines.

This robust foundation allows many EA827 variants to accumulate over 300,000 miles without internal repairs.

The engine’s cast iron block provides excellent thermal stability and resistance to warping, while its relatively low compression ratios in most applications reduce stress on internal components.

Particularly noteworthy are the diesel variants of the EA827 platform, which achieved legendary status as nearly unkillable powerplants.

These naturally aspirated and early turbocharged diesel engines powered countless European taxis through million-kilometer journeys, often requiring nothing more than regular timing belt replacements and fuel filter changes.

The mechanical simplicity of these engines particularly the non-electronically controlled versions contributed significantly to their longevity.

Volkswagen’s continuous development of the platform addressed many early weaknesses without fundamentally altering the core design.

Even when these engines do require repair, their ubiquity means parts remain widely available and affordable.

The engine bay accessibility in most applications also makes maintenance straightforward, encouraging owners to perform timely service.

Perhaps most impressively, many EA827 engines outlive multiple vehicle bodies, particularly in regions where road salt accelerates chassis corrosion.

It’s not uncommon to find these engines being transplanted into their second or third vehicle, continuing to provide reliable service long after their original cars have been scrapped.

This combination of robust engineering, mechanical simplicity, and parts availability has made the EA827 one of the most enduring engine designs in automotive history.

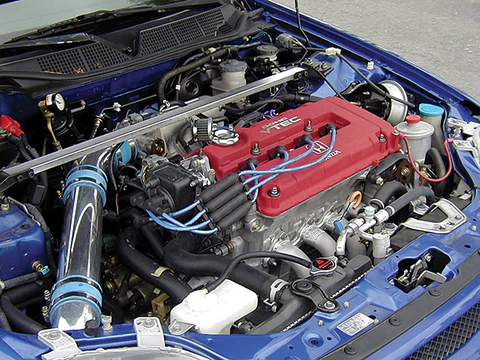

4. Mazda F/FE-Series (2.0-2.2L Inline-4)

Mazda’s F-series engines, particularly the FE-DOHC 2.0L variant, represent one of Japan’s most underrated engineering achievements of reliable powerplants.

Introduced in the late 1980s and powering everything from the MX-6 to the 626 and various Ford Probe models (through Mazda’s partnership with Ford), these engines established a reputation for exceptional durability that frequently saw them outlasting their host vehicles’ transmissions, suspension components, and body integrity.

The secret to the F-series’ extraordinary longevity lies in its conservative internal design. Mazda engineers opted for a cast iron block paired with an aluminum head a combination that provides excellent thermal stability while managing weight.

Unlike many manufacturers who pushed for maximum power from small displacements, Mazda detuned these engines in most applications, allowing them to operate well below their stress thresholds.

The result was modest horsepower ratings (typically 110-130hp) but exceptional reliability even under neglectful maintenance regimes.

Particularly notable is the engine’s oil control system, featuring larger-than-necessary oil passages that resist clogging even with extended oil change intervals.

The timing belt system, while requiring maintenance every 60,000 miles, is non-interference in most applications meaning that even if the belt fails, the pistons won’t contact the valves, preventing catastrophic engine damage that plagues many competitors.

The F-series’ cooling system design deserves special mention for its role in the engine’s longevity.

With a cross-flow radiator design and carefully engineered water passages, these engines rarely experience the head gasket failures common to many aluminum-head engines of the era.

Even in hot climates or under heavy loads, the F-series maintains excellent temperature control, preserving internal components from heat-related wear.

Many F-series engines have documented histories exceeding 400,000 miles with only routine maintenance, with some well-preserved examples approaching the 500,000-mile mark.

It’s not uncommon to find these engines being salvaged from otherwise deteriorated vehicles for transplantation into project cars a testament to their ability to outlast virtually every other component of the vehicle.

While they may lack the performance pedigree of some competitors, few engines can match the F-series’ combination of reliability, efficiency, and sheer determination to keep running decade after decade.

Also Read: 10 Affordable Sports Cars That Offer Supercar-Level Performance Without the High Price

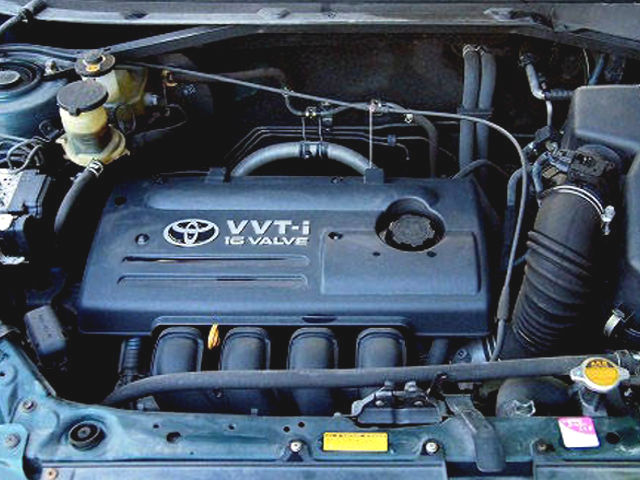

5. Toyota 1ZZ-FE (1.8L Inline-4)

The Toyota 1ZZ-FE 1.8-liter engine represents one of Toyota’s most widely deployed powerplants, finding its way into everything from the Corolla and Matrix to the Celica and MR2 Spyder between 1998 and 2008.

While it followed Toyota’s legendary 4A-GE engine, the 1ZZ-FE established its reputation for exceptional longevity through a blend of advanced manufacturing techniques and deliberately conservative engineering that prioritized reliability over maximum performance.

Unlike many of its contemporaries, the 1ZZ-FE featured an aluminum block with cast iron cylinder liners a departure from Toyota’s previous use of cast iron blocks in economy cars.

This aluminum construction represented a significant engineering challenge, but Toyota’s solution was ingenious: the MMC (Metal Matrix Composite) cylinder liners provided exceptional wear resistance while allowing for the weight savings of aluminum.

Combined with the engine’s relatively undersquare design (longer stroke than bore), this architecture created a powerplant that operated with minimal internal friction and stress.

The 1ZZ-FE’s variable valve timing system (Toyota’s VVT-i) offered a significant advancement over fixed timing engines, improving both efficiency and power delivery.

Unlike more complex dual-stage systems, Toyota’s single-stage implementation prioritized simplicity and reliability, with very few documented failures even at extreme mileages.

The timing chain design eliminated the maintenance requirement of timing belt replacements, with many engines exceeding 300,000 miles on their original timing chains and tensioners.

Oil consumption became an issue in some early examples (particularly 1998-2000 models), but Toyota addressed this with improved piston ring designs in later production.

Even with this early weakness, properly maintained 1ZZ-FE engines routinely exceed 250,000 miles without requiring internal repairs.

The engine’s overbuilt bottom end, featuring substantial main bearing supports and a rigid crankcase design contributes significantly to its longevity.

Perhaps most impressively, the 1ZZ-FE demonstrates exceptional resistance to overheating damage.

While many aluminum engines suffer fatal warping or head gasket failures after even brief overheating episodes, the 1ZZ-FE shows remarkable tolerance for thermal stress.

This forgiveness for occasional maintenance neglect has helped countless examples survive in the hands of owners who might not adhere to strict service schedules, cementing the engine’s reputation as one that will likely outlast the vehicle it powers.

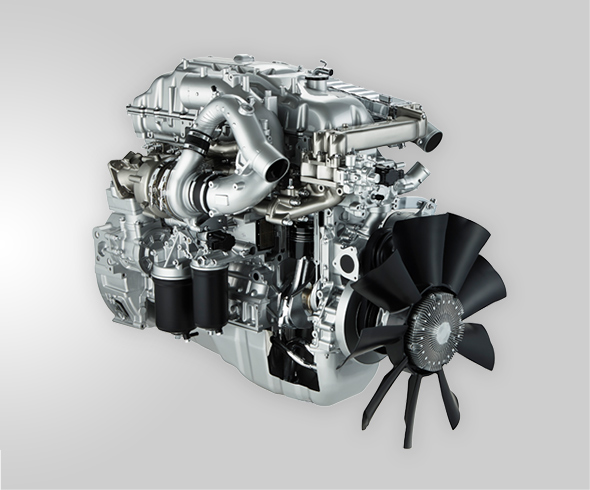

6. Mercedes-Benz OM617 (3.0L Inline-5 Diesel)

Though slightly larger than most engines on this list, the Mercedes-Benz OM617 3.0-liter inline-five diesel warrants inclusion as perhaps the most durable production automobile engine ever manufactured.

Developed in the 1970s, this cast iron behemoth powered the W123, W126, and W460 chassis Mercedes vehicles, creating a legacy of reliability that remains unmatched nearly five decades later.

With properly documented examples exceeding 1.5 million miles without internal rebuilds, the OM617 stands as the benchmark against which all claims of engine longevity must be measured.

The OM617’s legendary durability stems from deliberately overengineered components and conservative operational parameters.

The engine block features extraordinarily thick cylinder walls, seven main bearings supporting a forged crankshaft (two more than strictly necessary for a five-cylinder), and gallery-cooled pistons that minimize thermal distortion.

While these features added considerable weight the engine alone weighs approximately 330 pounds they created an almost indestructible foundation.

In naturally aspirated form (producing 80 horsepower), these engines rarely operate under stress in normal driving conditions.

The later turbocharged variants, while increasing output to a still-modest 123 horsepower, maintained similar reliability through careful boost limiting and robust connecting rods designed to handle significantly more power than factory specifications.

The indirect injection system, while less efficient than modern direct injection, provides exceptional resistance to poor fuel quality allowing these engines to run on virtually anything diesel-adjacent, including various vegetable oils with minor modifications.

The OM617’s mechanical simplicity contributes significantly to its longevity. With no electronic controls in most versions, minimal emissions equipment, and fully mechanical fuel delivery, there are simply fewer components to fail.

Regular maintenance requires nothing more exotic than oil changes, fuel filter replacements, and occasional valve adjustments. The timing chain system, properly maintained, can last the life of the engine without replacement.

What truly separates the OM617 from other durable engines is its ability to recover from abuse.

Where other engines suffer permanent damage from overheating or lubrication failures, the OM617 often survives conditions that would destroy most power plants.

Mercedes taxi fleets around the world have documented examples exceeding one million kilometers in punishing service often outlasting multiple transmissions, suspension rebuilds, and interior refurbishments.

When the bodies of these vehicles finally succumb to corrosion or collision damage, the engines are frequently salvaged and reinstalled in new chassis, beginning their second or even third operational lives.

7. BMW M42/M44 (1.8-1.9L Inline-4)

The BMW M42 and its evolutionary successor, the M44, represent BMW’s first serious foray into mass-produced four-cylinder engines with modern overhead cam designs.

Powering the E30, E36, and E46 3-series compact models throughout the 1990s and early 2000s, these engines challenged the perception that BMW could only produce excellent six-cylinder powerplants.

What makes the M42/M44 family remarkable is their ability to maintain BMW’s signature smoothness and performance characteristics while delivering exceptional longevity that frequently sees them outlasting the vehicles they power.

The M42/M44’s durability begins with a uniquely hybrid construction: an aluminum block with cast iron cylinder liners, paired with an aluminum head featuring BMW’s sophisticated four-valve-per-cylinder design.

This construction provides excellent thermal stability while keeping weight manageable. Unlike many manufacturers who pushed for maximum specific output, BMW deliberately underrated these engines, with the 1.8-liter M42 producing a modest 138 horsepower and the 1.9-liter M44 making 138-142 horsepower depending on application.

This conservative tuning means the engines rarely operate near their design limits in normal driving.

What truly distinguishes the M42/M44 from its contemporaries is BMW’s attention to internal component quality.

The engines feature fully counterweighted forged crankshafts, stronger connecting rods than strictly necessary for their power output, and precisely balanced reciprocating assemblies.

The timing chain design, with its dual-chain system and robust tensioners, frequently exceeds 200,000 miles without replacement a significant achievement for an overhead cam engine of this era.

The cooling system design represents another engineering triumph, with precision-controlled coolant flow that maintains even cylinder head temperatures, preventing the warping and head gasket failures common to many aluminum-head engines.

While the cooling system components themselves (water pumps, thermostats, radiators) require regular maintenance, the engine’s internal components demonstrate remarkable resilience even when subjected to occasional overheating incidents.

These engines commonly reach 250,000-300,000 miles with only basic maintenance, often outliving the complex electrical systems, suspension components, and body integrity of their host vehicles.

In European taxi services, especially in German cities where emissions regulations favored these relatively clean four-cylinders, documented examples exceeding 400,000 miles are not uncommon.

Perhaps most tellingly, when E36 and early E46 BMWs reach end-of-life due to corrosion or collision damage, the engines are frequently salvaged for transplantation into project cars and track vehicles a testament to their ability to outlive the vehicles around them.

8. Volvo Redblock B230 (2.3L Inline-4)

Volvo’s B230 engine, commonly known as the “Redblock” due to its distinctive red-painted valve cover, stands as one of the most overbuilt four-cylinder engines ever mass-produced.

Powering the legendary 240, 740, 940, and 960 series from 1985 through 1998, this 2.3-liter inline-four created Volvo’s reputation for indestructible powerplants that routinely outlive their already durable chassis.

The B230’s extraordinary longevity stems from a design philosophy that prioritized robustness above all else, resulting in an engine that appears almost comically overengineered by modern standards.

The foundation of the B230’s durability is its massive cast iron block featuring extraordinarily thick cylinder walls and five main bearings.

The siamese cylinders provide exceptional rigidity, while the undersquare design (larger stroke than bore) reduces stress on cylinder walls.

Volvo’s engineers specified bearings and journals of dimensions more appropriate for a six-cylinder engine, creating a bottom end that rarely experiences failure even at extreme mileages.

The oil galleries and passages are deliberately oversized, ensuring adequate lubrication even with extended oil change intervals or partial blockage.

Particularly in naturally aspirated form (the B230F variant), these engines operate well below their mechanical limits in normal driving.

With modest horsepower outputs ranging from 114 to 138 depending on specific model and year, the B230 rarely experiences the internal stresses that lead to premature wear in more highly-tuned engines.

Even the turbocharged versions (B230FT) feature conservative boost levels from the factory, though these variants require more diligent maintenance to achieve maximum longevity.

The B230’s cooling system deserves special mention for its contribution to the engine’s lifespan.

With a cross-flow design, a thermostatically controlled oil cooler on many models, and oversized water passages, these engines maintain exceptional temperature stability even under extreme conditions.

This thermal control prevents the head warping and gasket failures common in many competitors, while the cast iron construction resists the fatigue that can occur with repeated heating and cooling cycles.

Documented examples of B230 engines exceeding 500,000 miles without internal repairs are relatively common, with some well-maintained specimens approaching the one-million-mile mark.

Volvo taxi operators in Sweden and other Nordic countries routinely recorded 700,000+ kilometers on original engines.

Most impressively, these engines often continue running smoothly long after the vehicles around them have succumbed to rust, electrical failures, or transmission issues cementing their reputation as powerplants that truly can outlast their chassis.

9. Isuzu 4XE1 (1.6-1.8L Inline-4)

While Isuzu may not enjoy the same brand recognition as Toyota or Honda in the passenger car segment, their 4XE1 series engines particularly the 1.6L 4XE1T and 1.8L 4XE1W variants deserve recognition as some of the most durable small-displacement engines ever manufactured.

Found primarily in the Isuzu Gemini, Stylus, and various rebadged variants (including the Geo Storm and early Chevrolet/Holden models through GM’s partnership), these engines established a global reputation for exceptional longevity that frequently saw them outlasting multiple transmissions and surviving body deterioration in humid climates.

The 4XE1’s extraordinary durability stems from Isuzu’s heavy-duty diesel engineering expertise applied to gasoline engine design.

The cast iron block features cylinder walls substantially thicker than most competitors, while the crankshaft rides on five main bearings with larger-than-necessary journals.

This overbuilt bottom end provides exceptional resistance to wear even under poor maintenance regimes.

The aluminum cylinder head features a cross-flow design that maintains even thermal distribution, preventing the warping that plagues many engines with aluminum heads.

Where many manufacturers of the era (the late 1980s through mid-1990s) were pushing toward higher specific outputs, Isuzu deliberately conserved the 4XE1’s state of tune.

The naturally aspirated variants produced a modest 95-115 horsepower depending on market and application, allowing the engine to operate well below its mechanical limits in normal driving conditions.

Even the turbocharged variants found in sporty models were conservatively tuned compared to contemporary performance engines.

Perhaps most remarkable is the 4XE1’s tolerance for neglect. These engines demonstrate exceptional resistance to damage from extended oil change intervals, poor quality fuels, and even occasional overheating incidents.

The cooling system design, with its precisely controlled flow paths and effective water jacket coverage, prevents hot spots that lead to premature failure in many competitors’ engines.

The timing belt system, while requiring regular maintenance, is non-interference in most applications preventing catastrophic damage even if the belt fails.

In markets where Isuzu had a substantial presence, particularly Southeast Asia and parts of South America, these engines routinely exceeded 300,000 miles in punishing conditions including extreme heat, humidity, poor road conditions, and variable fuel quality.

Commercial applications in light delivery vehicles and taxis demonstrated even more impressive durability, with documented examples exceeding 500,000 miles on original internal components.

It’s not uncommon to find these engines being salvaged from otherwise deteriorated vehicles for transplantation into project cars a testament to their ability to outlast virtually every other component of the vehicles they power.

10. Nissan A-Series (1.0-1.5L Inline-4)

The Nissan A-series engine family, particularly the A14 and A15 variants, represents one of the longest-running and most reliable small-displacement engine designs in automotive history.

Produced from 1966 through the early 1990s in various forms, these engines powered everything from the humble Sunny/Sentra to the Pulsar, Cherry, and numerous small commercial vehicles across global markets.

While lacking the performance pedigree of some Nissan engines, the A-series created its legacy through exceptional durability that routinely saw engines outliving multiple body shells, especially in markets with harsh environmental conditions.

The foundation of the A-series’ extraordinary longevity is its deliberately conservative engineering.

The cast iron block features extraordinarily thick cylinder walls and main bearing supports, while the seven-bearing crankshaft (unusual for engines of this size) provides exceptional rigidity and resistance to flexing under load.

The oversquare design (larger bore than stroke) reduces piston speeds and side loading on cylinder walls, minimizing wear on crucial components.

Perhaps most importantly, Nissan deliberately underrated these engines from a performance standpoint, with most variants producing between 60 and 85 horsepower allowing them to operate far below their mechanical limits in normal driving.

What truly distinguishes the A-series is its ability to withstand abuse and neglect. The simple overhead valve design, with its directly actuated valvetrain, eliminates the complexity and failure points of overhead cam systems.

The mechanical fuel delivery system (typically single or dual carburetors) offers straightforward repair when needed and exceptional resistance to poor fuel quality.

The cooling system, with its high-capacity design and effective water jacket coverage, prevents localized overheating that leads to warping and gasket failures in many engines.

Particularly in developing markets where these engines saw extensive use, the A-series demonstrated remarkable resilience in the face of extended service intervals, variable quality fuels, and punishing operating conditions.

Taxi and light commercial applications in countries like Mexico, India, and Southeast Asia regularly recorded mileages exceeding 500,000 kilometers on original internal components.

The engines frequently outlived multiple clutches, transmissions, suspension rebuilds, and body repairs.

Perhaps the most telling evidence of the A-series’ durability is its continued presence in developing markets long after production ceased.

In parts of Africa, South America, and Asia, these engines are still sought after for transplantation into newer vehicles when the original powerplants fail creating a secondary market for A-series equipped donor cars regardless of their condition.

This ability to quite literally outlast everything around them, often continuing to run reliably when the vehicle’s body has deteriorated beyond repair, cements the A-series’ place among the most durable small-displacement engines ever built.

Also Read: 11 V12-Powered Cars That Offer the Ultimate Driving Experience in a Changing Industry