Constant Velocity (CV) joints are critical drivetrain components that transfer power from the transmission to the wheels while allowing for suspension movement and steering.

These mechanical marvels operate under extreme conditions, handling high torque loads, constant rotation, variable angles, and exposure to road debris, water, and contaminants.

Despite these challenges, CV joint design and quality vary significantly across manufacturers and vehicle applications, resulting in substantial differences in durability and service life.

This comprehensive analysis examines both ends of the CV joint durability spectrum. We’ll explore five exceptional CV joint applications renowned for their longevity and ability to withstand abuse, alongside five notoriously problematic designs known for premature failure before reaching the 75,000-mile mark.

Understanding these differences is valuable for vehicle owners, mechanics, and automotive enthusiasts alike, helping to inform purchasing decisions, maintenance schedules, and repair expectations.

Whether you’re navigating off-road terrain, daily commuting, or simply trying to maximize your vehicle’s drivetrain longevity, knowledge of CV joint performance characteristics can save you from unexpected breakdowns and costly repairs.

Five 5 CV Joints That Take Abuse

These engineering marvels feature precision-manufactured CV joints with overbuilt components and exceptional sealing technology that routinely survive 200,000+ miles of punishing conditions.

Their high-grade materials, optimized designs, and superior boot protection create drive axle assemblies that shrug off extreme articulation, pothole impacts, and harsh environmental exposure.

From snowy, salt-covered northern roads to muddy off-road trails, these exceptional CV joints maintain smooth power delivery without developing the telltale clicking or vibration that signals impending failure.

Owners report completing entire vehicle lifespans without ever replacing these remarkably durable components—an impressive achievement that eliminates a traditionally common maintenance expense.

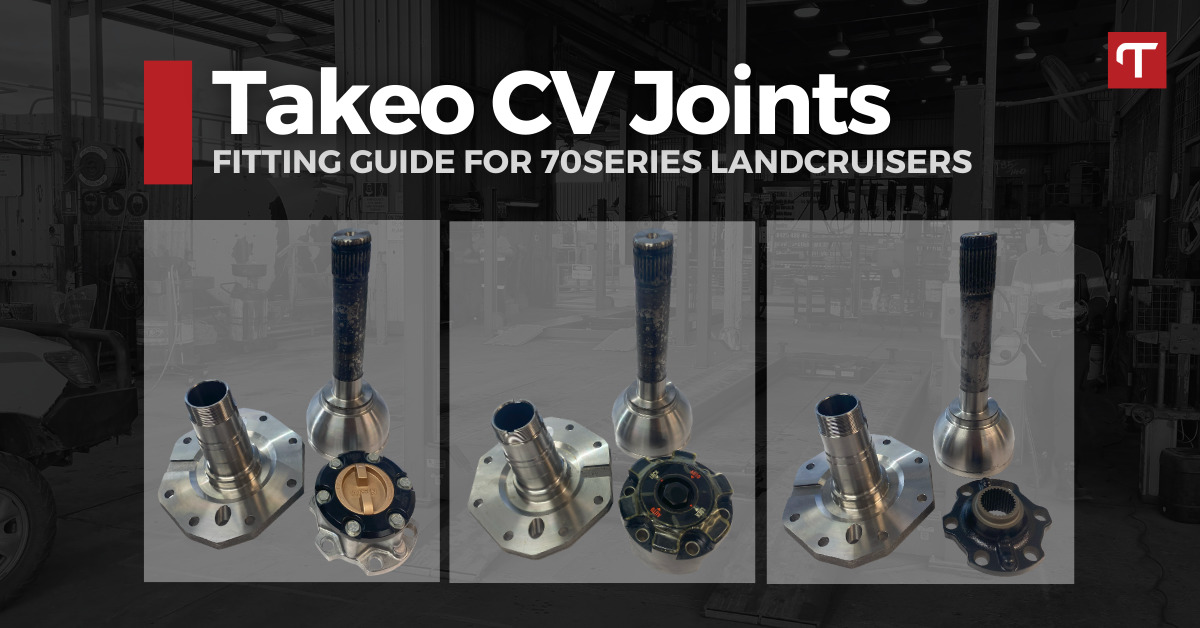

1. Toyota Land Cruiser 70 Series CV Joints

The Toyota Land Cruiser 70 Series has earned legendary status among off-road enthusiasts not just for its rugged frame and reliable powertrain, but specifically for its exceptionally durable CV joints.

Engineered for extreme durability in some of the world’s harshest environments, these CV joints represent the gold standard in driveline component longevity.

What makes Land Cruiser CV joints particularly robust is their oversized design with larger ball bearings and thicker cage construction than typical passenger vehicle applications.

Toyota engineers prioritized durability over noise, vibration, and harshness (NVH) characteristics, resulting in components that may lack refinement but deliver unmatched reliability.

The joints utilize high-grade chromoly steel alloys that resist deformation under load, while the bearing races are precision-ground and heat-treated to extraordinary hardness specifications.

The birfield joints (the outer CV joints) in particular are designed with a steeper angle capacity than most competitors, allowing for extreme articulation without increasing internal friction or accelerating wear.

This is complemented by robust dust boots manufactured from silicone-based compounds rather than standard neoprene, providing superior resistance to temperature extremes, ozone deterioration, and physical punctures.

Land Cruiser owners regularly report original CV joints lasting well beyond 200,000 miles even in demanding conditions including deep water crossings, desert heat, and technical rock crawling.

The key to their longevity lies not just in the components themselves but in Toyota’s integrated approach to driveline design the entire axle assembly works harmoniously to distribute stress, preventing any single component from bearing excessive load.

Perhaps most impressively, these CV joints maintain their integrity despite frequent operation at extreme angles. While most CV joints experience accelerated wear when constantly operated beyond 20 degrees of articulation, the Land Cruiser units maintain proper internal geometry and lubrication even at the suspension’s full droop.

This engineering achievement explains why these joints continue to deliver reliable performance on vehicles that see decades of service in remote locations where component failure could be life-threatening.

2. Honda Civic/Accord (1990s-2000s Era) CV Joints

Honda’s reputation for engineering excellence is particularly evident in the CV joints fitted to Civic and Accord models from the 1990s through the early 2000s.

These components exemplify how thoughtful design and precision manufacturing can create extraordinary durability even in relatively lightweight, cost-conscious applications.

Honda’s approach focused on precision rather than brute strength. The CV joints in these vehicles feature exceptionally tight manufacturing tolerances, with ball bearings and races ground to specifications that minimize play while optimizing smooth operation.

The metallurgy involves proprietary heat-treating processes that create an ideal balance of hardness and ductility, allowing the components to withstand both shock loads and constant stress without developing surface fatigue or spalling.

A key innovation in these Honda CV joints is their optimized internal geometry. The ball tracks are designed with subtle mathematical curves that distribute load more evenly throughout the operating range, preventing stress concentrations that typically lead to premature failure.

This is complemented by Honda’s highly refined lubrication formula, a specialized grease with molybdenum disulfide additives that maintains its viscosity characteristics across extreme temperature ranges while providing superior boundary lubrication during high-load, low-speed operation.

The boot design also contributes significantly to longevity. Honda engineers developed a multi-ridged, accordion-style boot with optimized wall thickness at critical flex points.

This prevents the cracking and splitting that typically initiates CV joint failure by allowing contaminant intrusion. The boot material combines excellent tear resistance with superior elasticity, maintaining a perfect seal even after decades of service.

What makes these joints particularly remarkable is their ability to withstand abuse despite being designed for relatively modest torque applications.

Owners who have modified these vehicles with forced induction, increasing power output by 50% or more, often report that the original CV joints continue to function flawlessly.

This overengineering has resulted in components that regularly achieve 250,000+ miles without replacement in normal service, with documented cases exceeding 300,000 miles on original joints when basic maintenance protocols are followed.

The legacy of these components is evident in Honda’s continuing reputation for drivetrain reliability, though many enthusiasts maintain that these particular generations represented the peak of the manufacturer’s CV joint design, combining simplicity with extraordinary durability in a way that later models with more complex geometry haven’t quite matched.

3. Volvo 240/740/940 Series Rear-Wheel Drive CV Joints

Volvo’s rear-wheel drive 200, 700, and 900 series vehicles from the 1980s and 1990s feature CV joints that epitomize the Swedish manufacturer’s philosophy of overengineered durability and safety-focused design.

These components have achieved near-legendary status among Volvo enthusiasts for their ability to withstand decades of operation in harsh Nordic conditions.

The Volvo approach to CV joint design emphasized robustness through simplified engineering. Rather than pursuing complex internal geometries, Volvo utilized larger-than-necessary components with thicker walls and more substantial bearing elements.

This conservative design philosophy resulted in joints that carry substantial safety margins beyond their rated load capacities. The inner tripod joints are particularly noteworthy for their massive bearing rollers and thick-walled housing that resist deformation even under extreme torque loads during rapid acceleration or when navigating icy conditions.

Material selection played a crucial role in their longevity. Volvo specified high-nickel content alloy steel for critical components, providing exceptional fatigue resistance and dimensional stability even after millions of load cycles.

The heat treatment process employed multiple stages of controlled heating and quenching to optimize the microstructure throughout the component rather than just at the surface, as was common in less durable designs.

The boot design represented another area where Volvo’s pragmatic engineering excelled. Rather than prioritizing aesthetics or manufacturing economy, the boots feature thick, high-durometer rubber compounds with reinforced flexing sections.

These boots were designed specifically for the Scandinavian climate, where they would encounter extreme temperature variations, road salt, and gravel impacts.

The clamping systems used to secure these boots employ stainless steel bands with mechanical locking mechanisms that maintain consistent tension throughout thermal cycles, preventing the gradual loosening that often leads to boot failure in other designs.

Perhaps most impressive is the performance of these CV joints in vehicles that have become prized for their longevity. It’s not uncommon to find 30+ year old Volvo 240s with original CV joints still functioning perfectly after 400,000+ miles of service.

The design’s durability is so renowned that when failures do occur, they’re often traced to external factors like damaged boots or improper service rather than inherent component failure.

This exceptional engineering explains why these particular Volvo models have developed cult followings in regions with extreme weather and poor road conditions.

The CV joints contribute significantly to these vehicles’ reputation for being “tanks” that can be passed down through generations of drivers while maintaining their functionality and safety, embodying Volvo’s commitment to creating vehicles that prioritize longevity over planned obsolescence.

4. Mercedes-Benz W124 E-Class CV Joints

The W124 platform Mercedes-Benz E-Class, produced from 1984 to 1997, represents one of the high points of German automotive engineering, with its CV joints frequently cited as among the most durable ever produced for passenger vehicles.

These components exemplify Mercedes-Benz’s approach to engineering during what many consider its golden era of quality and longevity. The W124’s CV joints benefit from Mercedes’ comprehensive approach to driveline engineering, where components are designed as an integrated system rather than individual parts.

This holistic design philosophy resulted in CV joints precisely matched to the vehicle’s weight distribution, suspension geometry, and power delivery characteristics.

The engineering team utilized extensive finite element analysis (relatively advanced for its era) to identify and eliminate potential stress risers or weak points in the design.

Material quality sets these components apart from lesser alternatives. Mercedes specified chromium-molybdenum steel alloys with precisely controlled carbon content, providing an optimal blend of surface hardness for wear resistance while maintaining core toughness to absorb impact loads.

The manufacturing process included multiple quality control checkpoints, with bearing race surfaces ground to tolerances measured in microns rather than the more typical thousandths of an inch used in mass-market applications.

A significant factor in their longevity is the lubrication system. Mercedes developed a proprietary high-temperature grease formulation specifically for these CV joints that maintains consistent viscosity across extreme temperature ranges.

This lubricant includes anti-wear additives that bond molecularly to metal surfaces, providing protection even during boundary lubrication conditions.

The grease is contained within exceptionally well-designed boots featuring reinforced flex points and sophisticated sealing lips that prevent both grease escape and contaminant intrusion.

What truly distinguishes the W124 CV joints is their performance under less-than-ideal conditions. These components maintain their integrity even when subjected to decades of operation, with many examples still functioning flawlessly after 30+ years and mileages exceeding 500,000.

Mercedes over-specified these joints for normal driving conditions, providing substantial reserve capacity that proves valuable when the vehicle encounters potholes, curb strikes, or aggressive driving maneuvers.

The W124 platform became particularly popular in taxi service across Europe and the Middle East precisely because of such durable components. Taxi operators reported extraordinary service intervals for CV joints, with many vehicles accumulating over 1,000,000 kilometers without requiring joint replacement.

This real-world validation of the design’s durability in the most demanding commercial applications confirms the engineering excellence invested in these seemingly humble but critical drivetrain components.

Mercedes’ approach to CV joint design during this period emphasized long-term reliability over manufacturing economy, a philosophy that unfortunately became less prominent in later models as cost-cutting measures were implemented.

This makes the W124 CV joints particularly sought after by enthusiasts looking to maintain these vehicles for decades of continued service.

Also Read:

5. Jeep XJ Cherokee Dana 30 Front Axle CV Joints

The Jeep Cherokee XJ (1984-2001) equipped with the Dana 30 front axle utilizes CV joints that have earned exceptional reputation for durability in severe off-road applications.

These components represent a fascinating case study in how relatively simple engineering executed with precision can result in extraordinary reliability even when subjected to extreme abuse.

The Dana 30 CV joints, particularly in their later iterations, benefit from Chrysler’s extensive real-world testing in off-road environments. Engineers recognized that theoretical models couldn’t fully account for the complex combination of forces encountered during technical trail driving, leading them to develop components based on empirical data gathered from actual off-road use.

This approach resulted in CV joints designed specifically to handle the shock loads, extreme angles, and contamination risks inherent to off-road driving.

What separates these CV joints from less durable competitors is their fundamental architecture. The outer birfield joints utilize a “cross-groove” design with deeper-than-standard races that allow the bearing balls to maintain proper contact even at extreme articulation angles.

This prevents the momentary loss of proper ball tracking that leads to accelerated wear in lesser designs. The inner tripod joints feature oversized rollers with barrel-shaped profiles that distribute load more effectively across the contact surface, reducing the contact pressure that typically initiates surface fatigue.

Material selection prioritized durability over manufacturing economy. The CV joints employ case-hardened alloy steel with exceptional core toughness, allowing them to absorb impact loads without permanent deformation.

The case hardening creates a wear-resistant outer layer while maintaining a ductile core that prevents catastrophic fractures when subjected to extreme torque spikes during challenging off-road maneuvers like rock crawling or extraction from mud.

Perhaps most impressive is how these components perform in environments specifically designed to test drivetrain durability. Jeep XJ Cherokees are frequently used in competitive rock crawling events where drivetrain components are subjected to forces far beyond their design parameters.

Even in these extreme applications, the Dana 30 CV joints demonstrate remarkable resilience, often outlasting other components that might be expected to fail first.

The CV boot design also contributes significantly to longevity. Rather than using standard rubber boots, later XJ models employed thermoplastic boots with superior resistance to punctures from trail debris and better heat dissipation characteristics.

These boots maintain their flexibility even after years of exposure to UV radiation, ozone, and temperature extremes that would degrade conventional materials.

Numerous documented cases exist of XJ Cherokees with 250,000+ miles on original CV joints despite years of recreational off-road use. This exceptional durability helps explain why the XJ platform remains highly sought after by off-road enthusiasts two decades after production ended, with many owners specifically citing drivetrain durability as a primary reason for their continued loyalty to these vehicles.

Five CV Joints That Split Before 75K Miles

These notoriously fragile drive axle assemblies feature substandard CV boots that crack and tear prematurely, exposing critical components to contamination that rapidly accelerates wear and failure.

Their inadequate design tolerances and questionable material choices create vulnerability to even minor impacts, with many owners reporting boot failures after encountering nothing more severe than typical city potholes.

What begins as a small tear quickly progresses to grease expulsion, contamination ingress, and the distinctive clicking during turns that signals expensive repairs are imminent often before the vehicle reaches middle age.

The frustrating frequency of replacement transforms what should be a long-lasting drivetrain component into a recurring maintenance headache, with repair forums filled with owners reporting multiple replacements within normal ownership periods.

1. Dodge Caliber/Jeep Compass/Patriot CVT Transmission CV Joints

The trio of compact vehicles built on Chrysler’s PM/MK platform the Dodge Caliber, Jeep Compass, and Jeep Patriot (2007-2017) equipped with Continuously Variable Transmissions (CVT) became notorious for their problematic CV joints.

These components represent one of the most widespread cases of systematic premature failure in modern automotive design, with owners routinely reporting complete joint failure before reaching 75,000 miles.

The fundamental issue with these CV joints stems from a problematic integration of components not optimally designed to work together. The JATCO-sourced CVT transmission paired with these vehicles has inherent characteristics that create challenging conditions for CV joints, including unusual vibration patterns and torque delivery that differs significantly from conventional automatic transmissions.

The CV joints specified for these vehicles lacked the robust engineering needed to accommodate these unique operational characteristics. Manufacturing quality control appears to have been a significant factor in their poor durability.

Numerous teardown analyses by independent mechanics have revealed inconsistent heat treatment, resulting in bearing races with inadequate hardness and premature surface fatigue.

The bearing cages often show signs of deformation under normal loads, allowing the bearing balls to develop improper tracking patterns that accelerate wear exponentially once they begin.

The boot design represents another critical weakness. Made from a relatively thin neoprene compound, these boots frequently develop cracks at flex points after just 30,000-50,000 miles of normal service.

Once the protective boot fails, contaminant intrusion quickly damages the precision surfaces within the joint. The clamping system used to secure these boots relies on thin-gauge stamped steel bands that lose tension over time, creating pathways for water and debris entry even before the boot material itself fails.

Environmental factors exacerbate these inherent weaknesses. Owners in regions with harsh winters and road salt usage often report complete CV joint failure within 40,000 miles, while those in milder climates might stretch to 60,000-70,000 miles before replacement becomes necessary.

This geographic variation highlights the marginal design that functions adequately only under ideal conditions. The economic impact on owners has been substantial.

The repair typically costs $600-800 per side when performed at independent shops, creating a significant unexpected expense for owners of vehicles marketed as economical transportation.

The frequency of failure is so common that online owner forums contain thousands of threads dedicated to this specific issue, with many owners reporting multiple replacements even with relatively low overall mileage.

Perhaps most telling is Chrysler’s response to the issue. Rather than implementing a comprehensive redesign, the manufacturer opted for incremental improvements to the boot material and clamping system in later production years.

While this reduced the failure rate marginally, it never fully addressed the underlying design inadequacies. The problem was ultimately “solved” only when the entire platform was discontinued, leaving thousands of owners with vehicles requiring ongoing drivetrain maintenance far exceeding industry norms.

2. Early Hyundai Elantra/Kia Forte (2010-2013) CV Joints

The shared platform underpinning the 2010-2013 Hyundai Elantra and Kia Forte represents a case study in how cost-cutting measures can compromise component durability, particularly in their notoriously fragile CV joints.

These vehicles, built during Hyundai-Kia’s aggressive expansion period in the North American market, suffered from CV joint issues that regularly manifested before the 75,000-mile mark, leading to widespread owner dissatisfaction.

The fundamental issue with these CV joints lies in their borderline undersized design relative to the vehicle’s weight and torque characteristics. Engineering analysis suggests the joints were designed with minimal safety margin, functioning adequately under ideal conditions but lacking the reserve capacity to handle real-world variables like potholes, aggressive driving, or manufacturing variations.

This minimal-specification approach left little room for error in either production or operation. Material composition played a significant role in their premature failure.

The steel alloy used for the bearing races lacked optimal carbon content and heat treatment, resulting in surface hardness that deteriorated more rapidly than industry standards would predict.

Microscopic examination of failed units reveals characteristic spalling (flaking of the metal surface) beginning as early as 40,000 miles far sooner than should occur in properly engineered components.

A particular weak point in these CVs is the inner joint design. Rather than utilizing a more robust tripod-style joint that distributes load across larger contact patches, Hyundai-Kia opted for a ball-type inner joint similar to the outer joint.

While this design choice likely reduced manufacturing costs, it resulted in higher point loading and accelerated wear patterns. The first symptom owners typically notice is a subtle vibration during acceleration that progressively worsens until the characteristic “clicking” during turns signals imminent failure.

The boot design compounds these inherent weaknesses. The rubber compound used lacks optimal elastomers for long-term durability, becoming brittle after exposure to ozone and UV radiation.

The boots frequently develop micro-cracks along their accordion folds around 50,000 miles, allowing water and contaminants to enter while permitting lubricant to escape.

This contamination accelerates what would already be a problematic wear situation due to the marginal internal design. Dealer service records and class action lawsuits reveal the statistical pattern of failure.

Approximately 35% of these vehicles require CV joint replacement before 75,000 miles, with the percentage climbing dramatically in regions with severe winters or poor road conditions.

The issue became so widespread that aftermarket parts manufacturers quickly developed upgraded replacement units with improved materials and slightly more robust internal geometry.

Hyundai-Kia eventually addressed these issues in later model years through incremental redesigns, including improved metallurgy, revised heat treatment protocols, and more durable boot compounds.

However, these improvements came too late for owners of the affected model years, many of whom experienced the financial burden of premature replacement well before reaching mileage where such major repairs would typically be expected.

3. Nissan Altima/Maxima with VQ35DE V6 (2002-2006) CV Joints

The fourth-generation Nissan Altima and sixth-generation Maxima equipped with the VQ35DE V6 engine became infamous among mechanics and owners for their problematic CV joint assemblies.

These vehicles, produced from 2002 to 2006, represent a peculiar case where high-performance engines were paired with inadequately specified drivetrain components, resulting in systematic CV joint failures typically occurring between 55,000 and 70,000 miles.

The core issue with these CV joints stems from a fundamental mismatch between the VQ35DE engine’s capabilities and the CV joint design specifications.

The 3.5-liter V6 produces substantial torque (246-265 lb-ft depending on specific application) with a particularly aggressive torque curve that delivers maximum output at relatively low RPM.

This characteristic creates shock loading on drivetrain components during rapid acceleration, particularly from a stop. The CV joints specified for these vehicles appear to have been designed with insufficient torque capacity margin, functioning adequately under gentle driving but rapidly deteriorating when subjected to the engine’s full capabilities.

Manufacturing inconsistencies exacerbated the inherent design limitations. Quality control documentation obtained through consumer protection litigation revealed significant batch-to-batch variation in critical dimensions and heat treatment parameters.

Some production runs exhibited hardness variations exceeding 15% across bearing surfaces that should maintain consistent properties. This inconsistency meant that some vehicles exhibited problems as early as 30,000 miles while others might reach 80,000 miles before failure creating a confusing pattern that initially obscured the systematic nature of the issue.

A unique aspect of these failures involves the interaction between the CV joints and Nissan’s engine mount design. The VQ35DE uses a sophisticated mount system intended to reduce NVH (Noise, Vibration, Harshness) by allowing controlled engine movement.

However, this movement can create momentary misalignment in the drivetrain during aggressive acceleration or deceleration. The CV joints, already operating near their design limits, experience additional stress from these transient misalignments, accelerating their deterioration.

The failure mode is particularly troublesome because it often manifests suddenly. Owners typically report minimal warning signs perhaps slight vibration during acceleration before experiencing a catastrophic joint failure that leaves the vehicle inoperable and potentially causes collateral damage to surrounding components.

This pattern contrasts with many CV joint failures in other vehicles that provide progressive symptoms allowing for scheduled replacement. Repair costs present another significant issue for owners.

The CV axle assemblies for these vehicles are integrated units that must be replaced as complete assemblies rather than allowing for individual joint replacement.

This design choice increases the average repair cost to $800-1200 per side, including labor, substantially higher than typical CV joint replacements in competing vehicles from the same era.

Nissan’s response to the widespread failures evolved. Initially, the company treated cases as isolated incidents, but as pattern failures became evident, an internal technical service bulletin advised dealers of revised replacement parts with upgraded materials and slightly modified internal geometry.

However, no recall was ever issued, leaving owners to bear the financial burden of these premature failures a particular point of contention among owners of affected vehicles who often experienced problems shortly after warranty expiration.

4. Ford Focus DCT Power Shift Transmission CV Joints (2012-2018)

The third-generation Ford Focus equipped with the problematic DPS6 “PowerShift” dual-clutch transmission presents a notable case of CV joint issues directly linked to transmission design flaws.

This platform, sold from 2012 to 2018, became notorious for multiple mechanical problems, with premature CV joint failure representing one of several systematic issues that led to widespread owner dissatisfaction and eventual legal action against Ford Motor Company.

What makes these CV joint failures particularly interesting from an engineering perspective is that they stem predominantly from secondary effects rather than inherent joint design flaws.

The PowerShift transmission’s well-documented clutch shudder and engagement issues create irregular torque delivery that subjects the CV joints to thousands of micro-shock loads during normal driving.

These repeated shock loads, while individually small, have a cumulative effect that accelerates wear patterns within the joint bearings and races. The specific failure mechanism typically begins with the inner CV joint (tripod design), where the bearing rollers develop flat spots and the races show premature wear patterns consistent with irregular loading rather than normal rotational wear.

Metallurgical analysis of failed components reveals evidence of work hardening and material fatigue that shouldn’t occur until much higher mileages under normal operating conditions.

Once this initial damage occurs, geometric precision within the joint degrades rapidly, leading to complete failure typically between 60,000 and 75,000 miles.

Environmental factors significantly impact failure rates on these vehicles. Owners in regions with frequent stop-and-go traffic report substantially earlier failures often around 45,000-50,000 miles due to the increased frequency of transmission engagement issues that stress the CV joints.

This pattern highlights how the transmission’s characteristics create especially problematic conditions for drivetrain components during certain driving scenarios.

The boot design compounds these inherent problems. The OEM boots utilize a material compound that becomes increasingly brittle when repeatedly subjected to the heat cycling generated by the problematic transmission.

This leads to premature cracking and splits, typically occurring at the inner convoluted section nearest the transmission. Once the protective boot fails, contaminant intrusion accelerates the already problematic wear situation within the joint.

While aftermarket solutions eventually emerged offering marginally improved durability, no third-party CV joint design can fully overcome the fundamental issue of irregular loading from the transmission.

This reality forces many owners into a cycle of repeated replacements unless they also address the underlying transmission issues an expensive proposition often costing several thousand dollars.

Ford’s response to these failures was complicated by the company’s need to manage the larger transmission issues affecting these vehicles. Technical service bulletins eventually acknowledged the higher-than-expected CV joint failure rates, recommending revised parts with slightly more robust internal components.

However, these improvements provided only incremental benefits without addressing the root cause stemming from the transmission’s operational characteristics.

The company ultimately settled multiple class-action lawsuits related to PowerShift transmission problems, though these settlements focused primarily on transmission repairs rather than associated CV joint failures.

5. Chevrolet Equinox/GMC Terrain 2.4L Models (2010-2015) CV Joints

The first-generation Chevrolet Equinox and GMC Terrain crossovers equipped with the 2.4L Ecotec engine became notorious among owners and mechanics for their systematically fragile CV joints.

These components regularly failed before reaching 75,000 miles, creating substantial unexpected repair costs for owners of vehicles marketed as reliable family transportation.

The primary engineering flaw in these CV joints stems from an apparent mismatch between the joint design and the specific vibration characteristics of the 2.4L engine.

This four-cylinder powerplant, while efficient, produces distinct vibration patterns particularly at specific RPM ranges that create resonance issues in the drivetrain components.

The CV joints appear to have been designed using standard specifications without adequate consideration for these vehicle-specific vibration profiles. The result is accelerated wear patterns that don’t typically appear in similar designs used in other GM applications.

A compounding factor involves the specific alloy and heat treatment process used for these components. Metallurgical analysis of failed units reveals inconsistent case hardening depth, with some areas showing inadequate surface hardness to resist the operational stresses.

This manufacturing variability creates weakness zones where wear accelerates rapidly once surface deterioration begins. Failed joints typically show characteristic pitting and surface spalling concentrated in specific regions rather than distributed evenly across bearing surfaces a telltale sign of resonance-induced stress concentration.

The failure pattern follows a remarkably consistent progression across thousands of documented cases. Owners typically first notice a subtle vibration during steady acceleration between 35-45 mph. This initial symptom often appears around 40,000-50,000 miles.

As deterioration progresses, the characteristic clicking during tight turns emerges, followed by increasingly pronounced vibration during straight-line acceleration.

Complete failure typically occurs between 60,000-75,000 miles, though vehicles in regions with harsh winters and road salt exposure often experience failures as early as 45,000 miles.

The boot design contributes significantly to the durability issues. The OEM boots feature relatively thin material at critical flex points, and the specific rubber compound becomes increasingly brittle with exposure to ozone and temperature cycling.

Boot failures typically begin with small cracks that are difficult to detect during casual inspection, allowing contaminant intrusion while still appearing superficially intact. Once contaminants enter the joint, the already problematic wear situation accelerates dramatically.

General Motors’ response to these systematic failures evolved. Initial dealer guidance treated failures as isolated incidents, but as pattern failure became undeniable, technical service bulletins recommended revised replacement parts.

However, teardown analysis of these “improved” components shows only minor changes to the boot material and clamping system rather than fundamental redesigns of the joint internals.

Many owners report similar longevity issues even with dealer-installed replacement parts. Aftermarket parts manufacturers recognized the opportunity presented by these systematic failures, with several companies developing significantly redesigned replacement CV axle assemblies.

The most successful aftermarket alternatives feature revised internal geometry specifically engineered to dampen the resonance issues inherent to this platform, along with improved metallurgy and more robust boot designs.

This aftermarket innovation highlights how properly engineered components can overcome inherent platform challenges when sufficient development resources are allocated.

Also Read: 7 SUVs That Allow Full-Height Box Loading With Ample Cargo Space