Fuel injectors represent the critical final step in delivering fuel to an engine’s combustion chamber, making their performance essential to vehicle operation, fuel economy, and emissions control.

Despite advancements in fuel technology and the widespread availability of premium gasoline with enhanced detergent packages, not all fuel injectors perform equally in real-world conditions.

Some demonstrate remarkable resilience against deposits and contaminants, maintaining consistent spray patterns and optimal atomization for years, while others develop problematic deposits relatively quickly, even when fed a strict diet of top-tier fuels.

This disparity stems from fundamental differences in design philosophy, manufacturing precision, materials science, and operational principles.

Understanding which injectors tend to stay clean versus those prone to clogging provides valuable insight for automotive engineers, mechanics, and vehicle owners seeking to maximize performance and minimize maintenance costs.

The following analysis explores five fuel injector types known for exceptional resistance to deposit formation, contrasted with five that have demonstrated tendencies toward clogging despite premium fuel usage, examining the underlying factors that contribute to these divergent performance characteristics and their implications for modern internal combustion engines.

Fuel Injectors That Stay Clean

These engineering masterpieces feature precision-manufactured injectors with advanced spray patterns and self-cleaning capabilities that maintain optimal performance through thousands of operating hours.

Their intelligent design includes optimal thermal management and protective coatings that resist carbon buildup and deposit formation even when subjected to varying fuel quality.

From direct injection systems that traditionally struggle with fouling to conventional port injectors, these exceptional components maintain consistent spray patterns and precise fuel delivery year after year.

Owners report maintaining factory-perfect performance and fuel economy well beyond 150,000 miles without requiring the expensive cleaning services or replacement procedures that plague lesser vehicles.

1. Bosch EV14 Series Direct Injection

The Bosch EV14 series represents the gold standard in deposit-resistant fuel injector technology, incorporating several key innovations that contribute to their exceptional cleanliness over time.

These high-precision components feature a specialized inward-opening, multi-hole design with laser-drilled orifices measuring just 80-120 microns in diameter.

What truly sets these injectors apart is their proprietary Diamond-Like Carbon (DLC) coating applied to critical internal components. This ultra-hard, low-friction surface treatment creates an exceptionally smooth finish at the microscopic level, significantly reducing the likelihood of fuel residue adhesion.

The EV14’s superior resistance to deposits stems partially from its advanced internal flow dynamics. Bosch engineers meticulously optimized the internal geometry to maintain laminar fuel flow throughout the injector body, minimizing turbulence that could create low-pressure zones where fuel components might separate and form deposits.

Additionally, the injector’s high-energy solenoid can generate opening pressures exceeding 200 bar, creating exceptional atomization that leaves minimal residual fuel on surfaces during the injection event.

Temperature management represents another crucial element of the EV14’s deposit resistance. The injector incorporates specialized heat-dissipation features that maintain more consistent operating temperatures, preventing the thermal cycling that often leads to coking and varnish formation.

This thermal stability helps prevent fuel from reaching the temperatures at which complex hydrocarbons begin to break down and form stubborn deposits.

Field testing demonstrates the EV14’s remarkable longevity, with many units maintaining over 95% of their original flow characteristics after 100,000 miles of operation. Even in challenging environments with variable fuel quality, these injectors typically require minimal cleaning maintenance.

Their effectiveness has made them the preferred choice for many German luxury vehicle manufacturers, where performance standards are particularly stringent and where they consistently demonstrate superior deposit resistance compared to conventional designs.

Automotive technicians frequently note that EV14-equipped vehicles rarely exhibit the common symptoms of injector fouling, such as rough idle, hesitation during acceleration, or increased emissions, even after extended service intervals.

This exceptional reliability translates directly to reduced maintenance costs and more consistent engine performance throughout the vehicle’s lifespan.

2. Denso High-Impedance Long-Nozzle Injectors

Denso’s High-Impedance Long-Nozzle injectors have earned a well-deserved reputation for exceptional cleanliness across extended service intervals, particularly in Toyota and Lexus applications where they’ve demonstrated remarkable longevity.

These injectors incorporate a distinctive design philosophy that prioritizes deposit prevention through precise manufacturing tolerances measured in microns.

The standout feature is their elongated, narrow-profile nozzle that positions the spray tip significantly deeper into the intake port or combustion chamber than conventional designs, reducing exposure to heat soak conditions that accelerate deposit formation.

The internal components undergo Denso’s proprietary “Micro-Precision” manufacturing process, which produces metal surfaces with extraordinarily low roughness values typically below 0.3μm Ra (average roughness).

This exceptional smoothness provides minimal surface irregularities where fuel contaminants could begin accumulating. Additionally, the injector incorporates specialized nickel-alloy components with inherent non-stick properties that further discourage deposit adhesion even when exposed to the harshest fuel contaminants.

Flow dynamics within these injectors benefit from Denso’s innovative “Dual-Stage” filtration system. Beyond the standard primary filter, these injectors incorporate a secondary micro-mesh filter with apertures smaller than 15 microns, effectively capturing particulates that might otherwise become nucleation sites for larger deposits.

The injector’s electrical characteristics also contribute to its cleanliness its high-impedance (12-16 Ω) design generates less heat during operation than low-impedance alternatives, reducing thermal stress on the fuel.

Field durability testing has demonstrated these injectors routinely maintain consistent flow rates and spray patterns beyond 120,000 miles in properly maintained vehicles.

Technicians performing injector flow testing on high-mileage examples frequently report deviation rates below 3% between cylinders, indicating exceptional consistency and cleanliness.

This performance stands in stark contrast to many competing designs showing 10-15% deviation after similar service periods.

Vehicle manufacturers utilizing these injectors report significantly reduced warranty claims related to fuel system cleaning procedures, and independent repair facilities note that vehicles equipped with Denso High-Impedance injectors rarely require injector service even when operating in regions with inconsistent fuel quality.

Their remarkable deposit resistance makes them particularly well-suited for vehicles that experience frequent short trips and incomplete warm-up cycles, conditions typically associated with accelerated injector fouling.

3. Continental Piezoelectric Direct Injectors

Continental’s Piezoelectric Direct Injectors represent a technological breakthrough in deposit-resistant fuel delivery systems, leveraging advanced materials science to overcome the limitations of conventional solenoid-based designs.

Unlike traditional injectors that rely on electromagnetic actuation, these units employ piezoelectric crystals that physically change dimensions when electrical current is applied, providing extraordinarily precise control over fuel delivery with response times measured in microseconds rather than milliseconds.

The deposit-resistant properties of these injectors stem primarily from their remarkable actuation speed, which enables them to snap open and closed with exceptional authority.

This rapid, decisive movement creates a self-cleaning “hydraulic hammer” effect that dislodges incipient deposits before they can accumulate and harden.

Additionally, the unique needle design incorporates a ball-end geometry that creates exceptional sealing properties and maintains consistent spray patterns throughout the injector’s service life.

Continental’s manufacturing process incorporates “Clean Room” assembly protocols typically reserved for semiconductor production, ensuring that injector components remain free from microscopic contaminants that could serve as nucleation sites for deposit formation.

The injector’s internal fuel passages undergo a proprietary electro-polishing treatment that creates an exceptionally smooth surface finish with roughness values below 0.2μm, significantly reducing areas where deposits might adhere.

The injector’s thermal management capabilities further enhance its deposit resistance. An innovative ceramic insulation layer shields critical components from combustion chamber heat, maintaining more consistent internal temperatures and reducing thermal stress that could lead to fuel breakdown and subsequent coking.

This thermal stability is particularly valuable in modern downsized turbocharged engines where combustion temperatures and pressures create especially challenging conditions for injector longevity.

Endurance testing has demonstrated these piezoelectric injectors maintain consistent spray patterns and flow rates beyond 150,000 miles, with minimal deviation from factory specifications.

Vehicle manufacturers utilizing these components report up to 70% reduction in fuel-system-related warranty claims compared to vehicles equipped with conventional solenoid injectors.

The exceptional precision and cleanliness of Continental’s piezoelectric injectors make them particularly well-suited for direct-injection applications, where they deliver consistent performance even when subjected to the rigors of high-pressure, high-temperature operation where deposit formation typically accelerates.

Independent laboratory analysis of high-mileage examples shows remarkably clean internal passages and spray orifices, with minimal evidence of the carbon accumulation that typically plagues direct injection systems.

This cleanliness translates directly to more consistent combustion, improved fuel economy, and reduced emissions throughout the vehicle’s service life.

4. Delphi Multec GDi Injectors with SABER Shield Technology

Delphi’s Multec GDi injectors with proprietary SABER Shield Technology represent a significant advancement in deposit-resistant fuel system design, specifically engineered to withstand the severe operating conditions encountered in modern direct-injection applications.

These injectors incorporate several innovative features that work synergistically to maintain cleanliness despite exposure to extreme temperatures and pressures that typically accelerate deposit formation in less robust designs.

The cornerstone of Delphi’s approach lies in their patented SABER (Surface Abrasion and Boundary Erosion Resistant) Shield coating, a multi-layer metallic-ceramic composite applied to critical internal components.

This specialized treatment creates an exceptionally hard (>1200 Vickers hardness) yet smooth surface with remarkable resistance to both mechanical wear and chemical attack from fuel contaminants.

Scanning electron microscopy reveals a nearly perfect surface at the microscopic level, providing minimal irregularities where deposits might begin forming.

Flow path design represents another crucial aspect of these injectors’ deposit resistance. Delphi engineers employed advanced computational fluid dynamics modeling to eliminate areas of fuel stagnation and recirculation within the injector body.

The resulting “Turbulent-Free Flow” architecture maintains consistent velocity throughout the injector, preventing the formation of low-pressure zones where fuel components might separate and create deposit precursors.

Additionally, the injector incorporates specialized anti-cavitation features that minimize the microscopic vapor bubbles that can collapse against surfaces and create damage that becomes nucleation sites for deposits.

Thermal management capabilities further enhance the Multec GDi’s cleanliness longevity. An innovative double-wall nozzle design incorporates a thermal isolation chamber that reduces heat transfer from the combustion chamber to the injector tip by approximately 40% compared to conventional designs.

This temperature reduction significantly decreases the likelihood of fuel decomposition and subsequent carbon formation on critical spray surfaces.

The injector’s electrical characteristics also contribute to deposit resistance, with precisely controlled “end-of-injection” tapering that virtually eliminates the dribbling often responsible for nozzle coking.

Field performance data indicates these injectors typically maintain consistent spray patterns and flow rates beyond 100,000 miles in properly maintained vehicles.

Automotive technicians report that even in high-mileage examples, flow testing shows remarkably consistent results across cylinders, typically varying less than 2-3% from specifications.

Vehicle manufacturers have reported up to 60% reduction in fuel-system-related warranty claims after transitioning to these Delphi injectors in their direct-injection platforms.

The exceptional deposit resistance of the Multec GDi injectors makes them particularly suitable for vehicles operated in environments with variable fuel quality or those that frequently experience short-trip driving patterns where deposit formation typically accelerates.

Their consistent performance characteristics translate directly to more stable combustion, reduced emissions, and sustained fuel economy throughout the vehicle’s service life.

Also Read: 5 Cars With Factory Batteries That Last 6+ years and 5 That Don’t Make 3

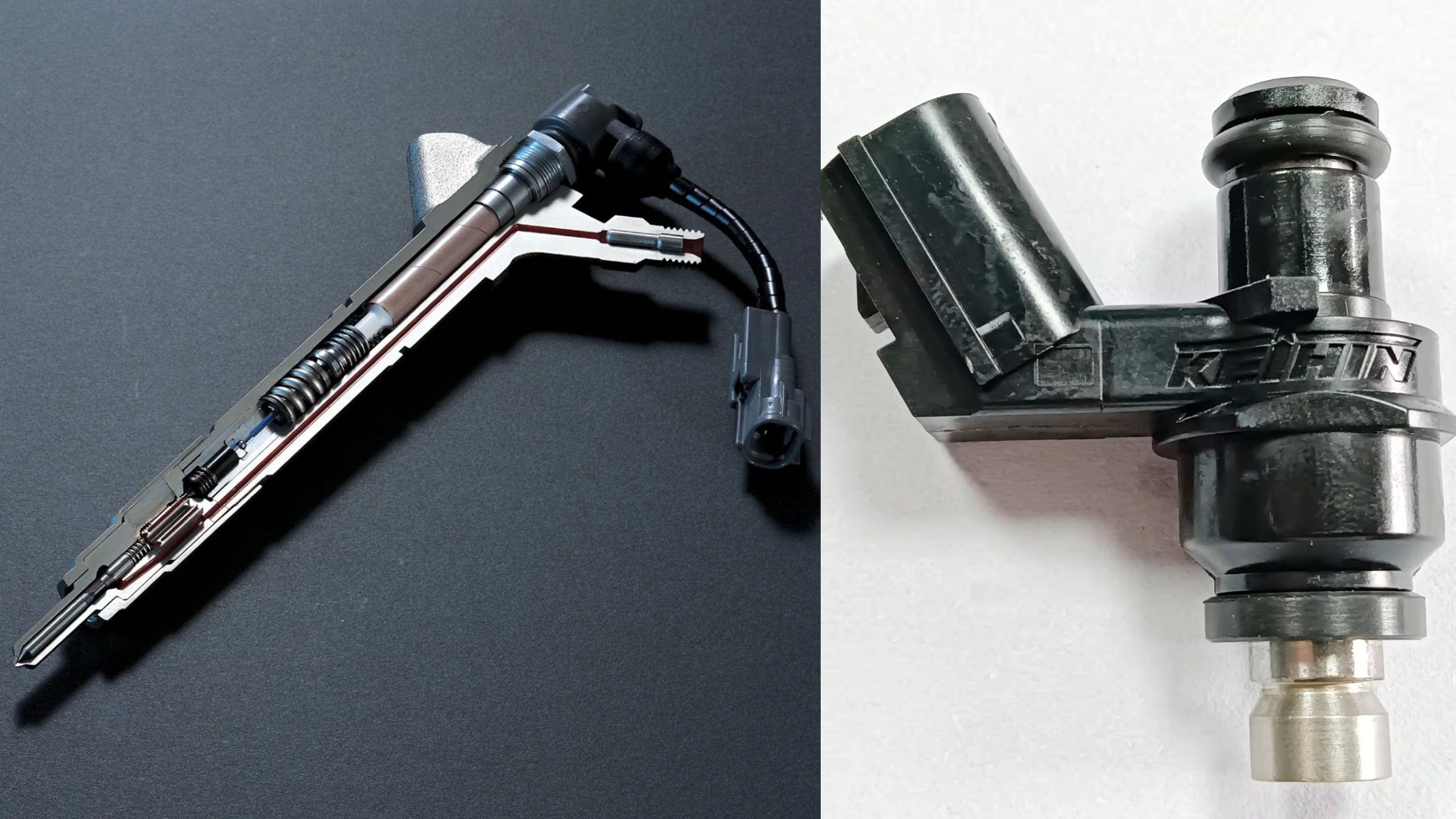

5. Keihin Fine Atomization (KFA) Multi-Port Injectors

Keihin’s Fine Atomization multi-port injectors represent Japanese engineering excellence in creating remarkably deposit-resistant fuel delivery systems.

Originally developed for Honda’s high-performance naturally aspirated engines, these injectors have earned a reputation for exceptional cleanliness longevity across extended service intervals.

Their resistance to clogging stems from several key design innovations that fundamentally change how fuel interacts with injector surfaces during the injection cycle.

At the heart of the KFA design lies Keihin’s proprietary “Micro-Stepped” atomization technology. Unlike conventional injectors that rely on simple pressure differentials for fuel atomization, these injectors incorporate a staged pressure-drop pathway with three distinct chambers.

This design creates exceptional fuel dispersion with droplet sizes averaging just 12-15 microns approximately 40% smaller than typical injectors. This superior atomization leaves minimal residual fuel on surfaces after each injection event, significantly reducing the foundation for deposit accumulation.

Material selection plays a crucial role in these injectors’ cleanliness and longevity. Critical components utilize Keihin’s specialized “K-alloy,” a proprietary stainless steel formulation with extremely low surface energy properties.

This composition fundamentally alters how hydrocarbon molecules interact with injector surfaces, creating a naturally repellent effect that discourages adhesion of potential deposit-forming compounds.

Internal passages undergo an electro-chemical polishing process that achieves surface roughness values below 0.25μm, eliminating microscopic crevices where deposits typically begin forming.

The injector’s mechanical operation further enhances its deposit resistance. Keihin engineers incorporated a “Dual-Spring” return mechanism that ensures exceptionally crisp closing characteristics with virtually zero post-injection dripping a common culprit in nozzle tip deposits.

Additionally, the needle valve incorporates a specialized tip geometry that creates a self-cleaning wiping action during each actuation cycle, physically removing any incipient deposits before they can accumulate and harden.

Field testing demonstrates these injectors maintain consistent flow patterns and spray geometry beyond 150,000 miles in properly maintained vehicles. Independent testing laboratories have documented flow rate consistency typically within 1-2% of factory specifications even in high-mileage examples.

Vehicle manufacturers utilizing these components report significantly reduced injector-related warranty claims compared to platforms using conventional injector designs.

The Keihin Fine Atomization injectors demonstrate particular resistance to ethanol-related deposits, making them especially suitable for markets with high biofuel content in gasoline.

Their exceptional cleanliness characteristics provide consistent performance across varying fuel qualities and operating conditions, maintaining optimal air-fuel ratios and emissions compliance throughout the vehicle’s service life.

This reliability has made them a preferred choice among numerous Japanese and Korean manufacturers prioritizing long-term durability and consistent performance.

Fuel Injectors That Clog (Even with Premium Gasoline)

These problematic fuel systems feature injectors prone to rapid carbon accumulation and clogging despite owners’ best efforts with premium fuel and quality additives.

Their flawed design places vulnerable components in unfavorable thermal environments, creating perfect conditions for deposit formation that gradually reduces flow rates and disrupts spray patterns.

Owners report experiencing classic symptoms of injector fouling—rough idle, hesitation, and decreasing fuel economy well before 60,000 miles, despite religious maintenance and high-quality fuel choices.

What begins as minor performance issues progresses to serious drivability problems requiring expensive professional cleaning services or complete injector replacement turning what should be lifetime components into recurring expenses.

1. First-Generation Direct Injection Systems (2007-2012)

The first-generation direct injection systems that emerged between 2007 and 2012 represent a cautionary tale in fuel injector design, demonstrating how technological ambition sometimes outpaces engineering solutions to long-term durability challenges.

Despite their innovative approach to fuel delivery, these early direct injection systems developed a well-documented propensity for carbon fouling and performance degradation, even when operated exclusively on premium fuels with enhanced detergent packages.

The fundamental vulnerability of these systems stems from their pioneering inward-opening pintle design, which places the injector tip directly within the combustion chamber.

This location exposes the delicate spray orifices typically measuring just 65-90 microns in diameter to extreme thermal cycling, with temperatures fluctuating from ambient to over 1800°F during normal operation.

These temperature extremes cause accelerated breakdown of fuel components that come into contact with the injector tip, creating a stubborn carbon buildup that progressively restricts fuel flow and distorts spray patterns.

Material limitations further exacerbated the clogging tendency. Most first-generation systems utilized conventional stainless steel components without specialized coatings or treatments that could resist carbon adhesion.

Scanning electron microscopy of fouled examples reveals microscopic surface irregularities where carbon deposits initially nucleate before expanding to form flow-restricting accumulations.

Additionally, these early systems typically operated at relatively modest pressures (around 1,200-1,800 psi) compared to later generations, providing insufficient mechanical force to prevent deposit formation or dislodge incipient deposits through hydrodynamic action.

The control strategies employed in these pioneering systems unintentionally contributed to their fouling tendency. Many utilized a simplified pulse-width modulation approach that lacked the sophisticated end-of-injection tapering found in more modern systems.

This abrupt cutoff frequently resulted in post-injection dribbling small fuel droplets that emerge after the main injection event and lack sufficient velocity for proper atomization. These droplets often remain on the injector tip where they rapidly carbonize when exposed to combustion temperatures.

Vehicle service records indicate these first-generation systems frequently required injector cleaning or replacement between 35,000-60,000 miles, even in vehicles maintained meticulously with premium fuels.

Technicians regularly document flow rate reductions exceeding 20% and significantly distorted spray patterns upon examination of removed injectors.

The carbon accumulation typically concentrates around the outer circumference of the spray orifices, creating a characteristic “mushrooming” effect that progressively restricts flow area and disrupts the carefully engineered spray geometry.

Most manufacturers of these early direct injection systems eventually implemented modified maintenance schedules recommending preventative chemical cleaning treatments every 15,000-30,000 miles tacit acknowledgment of their inherent vulnerability to clogging.

This fouling tendency represents a significant limitation that later generations of direct injection technology have worked diligently to overcome through enhanced materials, refined control strategies, and more sophisticated injector designs better suited to the harsh operating environment of modern direct injection engines.

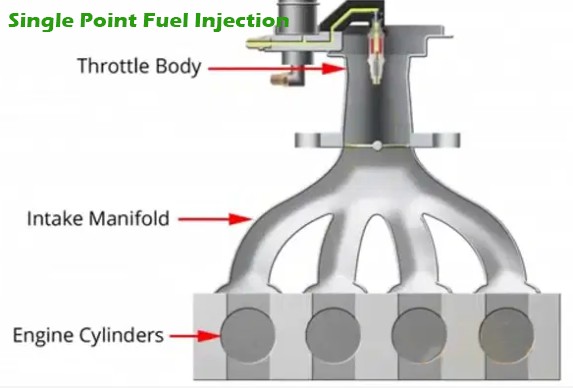

2. Single-Point Throttle Body Injection Units

Single-Point Throttle Body Injection (TBI) units, while representing an important evolutionary step beyond carburetors in automotive fuel delivery, contain inherent design limitations that render them particularly susceptible to deposit formation and clogging despite fuel quality.

These relatively primitive injection systems, which essentially function as electronically controlled carburetors, maintain significant popularity in budget-oriented vehicles, small engines, and marine applications due to their simplicity and low production cost. However, this simplicity directly contributes to their notorious deposit vulnerability.

The fundamental clogging vulnerability of TBI systems stems from their basic operational principle: delivering fuel at a single point above the throttle plate rather than at individual cylinders.

This design creates an exceptionally long wetted path from injection point to combustion chamber, providing extensive surface area for fuel separation and deposit formation.

Unlike port injection systems that benefit from intake valve temperature to help vaporize fuel, TBI systems inject into a relatively cool intake plenum where heavier hydrocarbons frequently condense before reaching the cylinders.

Material selection in typical TBI units further compounds their fouling tendency. Most utilize simple aluminum castings with relatively rough interior surfaces (typically 3-5μm Ra) that provide numerous microscopic crevices where deposits begin forming.

The injector nozzles themselves generally lack the specialized coatings found in premium fuel injectors, instead using basic stainless steel or even brass components that offer minimal resistance to deposit adhesion.

Magnified examination of fouled TBI injectors typically reveals a characteristic “stalagmite” pattern of deposits forming directly around the pintle seat and spray orifice.

Operating characteristics of TBI systems create additional challenges for deposit resistance. Most operate at extremely low pressures (typically 9-15 psi) compared to modern injection systems, providing insufficient mechanical force to dislodge incipient deposits through hydrodynamic action.

Their relatively large drop size (typically 150-250 microns versus 50-80 microns in modern injectors) creates inconsistent atomization that leaves significant fuel residue on surfaces.

Additionally, their simple on/off operation lacks the sophisticated pulse-width modulation capabilities that help modern injectors maintain cleanliness.

Service records indicate these injectors frequently require cleaning or replacement between 30,000-50,000 miles even in well-maintained vehicles using exclusively premium fuels.

Flow testing of removed injectors typically shows deviation exceeding 25% from specifications, with significantly degraded spray patterns showing pronounced asymmetry and reduced cone angles.

The deposits consist primarily of organic varnish compounds mixed with particulate contaminants, creating a stubborn composite material resistant to normal detergent action.

While premium fuels with enhanced detergent packages provide some protection against TBI clogging, they ultimately fight a losing battle against the system’s fundamental design limitations.

Vehicle manufacturers utilizing these systems typically recommend specialized cleaning treatments at regular service intervals tacit acknowledgment of their inherent vulnerability to deposit formation regardless of fuel quality. This persistent fouling tendency remains an inescapable compromise of the TBI’s simplified approach to fuel delivery.

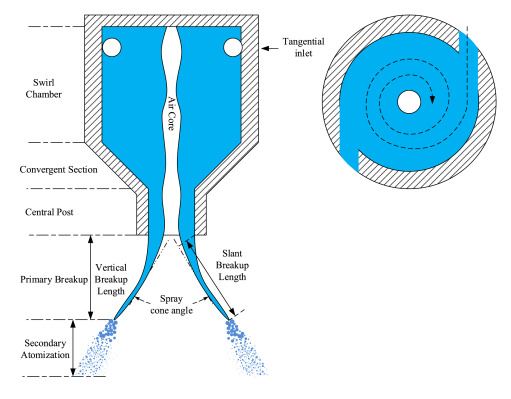

3. Low-Pressure Swirl Injectors with Wide Spray Patterns

Low-Pressure Swirl Injectors featuring wide spray patterns represent a specific subset of fuel delivery systems particularly prone to deposit formation and flow restriction despite premium fuel usage.

These injectors, commonly found in economy-oriented vehicles from the mid-1990s through early 2000s, were designed as a cost-effective compromise between basic throttle body injection and true multi-port systems.

However, their specific design characteristics create an unfortunate predisposition toward clogging that manifests even under ideal maintenance conditions.

The fundamental vulnerability stems from their distinctive internal geometry, which incorporates a spiral-shaped swirl chamber upstream of a relatively large single orifice.

This design creates a cone-shaped spray pattern through centrifugal force rather than through multiple precision-drilled holes. While cost-effective to manufacture, this approach creates several inherent weaknesses.

The swirl chamber contains numerous edges and corners where fuel velocity temporarily drops, creating localized areas where fuel components can separate and begin forming deposits.

Microscopic examination of fouled examples typically reveals initial deposit formation precisely at these transition points before progressing to the main spray orifice.

Material choices further compound the clogging tendency of these injectors. Most utilize basic 304-grade stainless steel without specialized coatings or surface treatments, providing relatively little protection against deposit adhesion.

The manufacturing process typically produces surface finish values around 1.0-1.5μm Ra, significantly rougher than premium injectors creating microscopic valleys where deposits can anchor themselves against detergent action.

Additionally, many incorporate plastic or polymer components in their internal assembly that can degrade over time, releasing compounds that contribute to deposit formation.

Operational characteristics create additional challenges for these injectors’ cleanliness longevity. Their relatively low operating pressure (typically 30-45 psi) provides insufficient “scrubbing” action to dislodge incipient deposits before they can accumulate and harden.

Their wide spray angle, often exceeding 70 degrees, creates significant wall-wetting in the intake port, leading to fuel puddles that evaporate slowly and leave residues.

Additionally, their relatively simple solenoid design often produces a “bounce” effect at closing, creating secondary injection events that leave poorly atomized fuel droplets prone to rapid evaporation and deposit formation.

Field service data indicates these injectors typically require cleaning or replacement between 40,000-70,000 miles, with flow testing frequently showing deviation exceeding 15% from specifications.

Technicians report characteristic “streaking” in the spray pattern as deposits progressively distort the carefully engineered swirl effect. The fouling typically manifests first as rough idle and cold-start hesitation before progressing to more severe performance issues as flow restriction increases.

Vehicle manufacturers utilizing these injectors often recommended shortened service intervals for fuel system cleaning typically every 30,000 miles tacit acknowledgment of their inherent vulnerability to clogging.

While premium fuels provide some protection by maintaining cleaner operation longer than standard fuels, they ultimately cannot overcome the fundamental design limitations that make these injectors particularly susceptible to deposit formation throughout their service life.

4. Pintle-Type Side-Feed Port Injectors

Pintle-Type Side-Feed Port Injectors represent a specific fuel injector architecture with a well-documented propensity for deposit accumulation and flow restriction despite premium fuel usage.

These injectors, which gained widespread adoption during the 1980s and early 1990s and remain common in certain applications today, utilize a distinctive side-entry fuel flow path that creates inherent vulnerabilities to clogging not present in more modern top-feed designs.

The fundamental weakness stems from their unique internal geometry, where fuel enters perpendicular to the main injector axis rather than aligned with it.

This creates an abrupt 90-degree transition in flow direction that generates turbulence and localized pressure drops where fuel components can separate and initiate deposit formation.

Fluid dynamics modeling reveals complex eddy currents forming in these transition zones, creating microscopic areas where fuel velocity temporarily approaches zero ideal conditions for precipitating dissolved contaminants.

These deposits typically begin forming at the entrance to the needle guide channel before progressively expanding to restrict the main flow path. Manufacturing limitations further exacerbate the clogging tendency of these injectors.

Most utilize relatively simple stamped components with manufacturing tolerances measuring in the hundreds of microns rather than the single-digit precision found in premium modern injectors.

This creates micro-gaps between assembled components where fuel can stagnate between injection events. The relatively modest production precision also results in surface finish values typically exceeding 1.5μm Ra, significantly rougher than contemporary injectors providing numerous microscopic anchor points where deposits readily adhere despite detergent action.

Operational characteristics create additional challenges for deposit resistance. The distinctive pintle-type needle valve, which uses a conical tip to seal against a circular orifice, naturally creates a ring-shaped spray pattern with inconsistent droplet distribution.

This uneven atomization leaves areas of the spray pattern with inadequately atomized fuel droplets prone to evaporation and subsequent deposit formation.

Additionally, the relatively simple spring-return mechanism often produces inconsistent closing characteristics that allow post-injection seepage a major contributor to nozzle-tip deposits.

Service records indicate these injectors typically require cleaning or replacement between 40,000-65,000 miles even in vehicles maintained exclusively with premium fuels.

Flow testing of removed injectors frequently reveals deviation exceeding 20% from specifications, with characteristic “ring pattern” distortion where deposits progressively close the circular gap between the pintle and orifice.

The clogging typically manifests first as difficult cold starting and deteriorating fuel economy before progressing to more noticeable driveability issues.

Vehicle manufacturers utilizing these injectors often implemented shorter-than-typical service intervals for fuel system maintenance, tacit acknowledgment of their inherent vulnerability to deposit formation.

While premium fuels with enhanced detergent packages provide some protection against the most aggressive deposit formation, they ultimately fight a losing battle against the fundamental design limitations that predispose these side-feed injectors to progressive flow restriction throughout their service life.

This persistent fouling tendency represents an intrinsic compromise of their simplified design approach and dated manufacturing techniques.

5. Low-Flow High-Resistance Port Injectors (LFHRs)

Low-Flow High-Resistance Port Injectors (LFHRs) represent a specific category of fuel delivery systems with a particularly problematic susceptibility to deposit formation and flow restriction, even when operated exclusively with premium fuels.

These specialized injectors, designed specifically for ultra-lean-burn and stratified-charge engines developed during the late 1990s and early 2000s, sought to achieve exceptional fuel atomization through extremely small orifices and high pressure differentials.

However, this approach created fundamental vulnerabilities to clogging that persist despite meticulous maintenance and premium fuel usage. The primary weakness stems from their defining characteristic: extraordinarily small spray orifices measuring just 60-80 microns in diameter, approximately half the size of conventional port injectors.

While these micro-apertures create exceptional fuel atomization beneficial for emissions control, they operate with minimal margin for deposit accumulation before flow restriction becomes problematic.

Mathematical modeling demonstrates that even microscopic deposits measuring just 15 microns thick can reduce flow area by over 30% in these injectors, compared to less than 10% impact in conventional designs with larger orifices.

This fundamental geometry creates an inherent vulnerability where even minimal deposit formation rapidly affects performance. Operational requirements further compound the fouling tendency.

These injectors typically operate at relatively modest pressures (45-60 psi) despite their small orifices, creating less mechanical “scrubbing” action than higher-pressure systems would provide.

Additionally, they were specifically designed for lean-burn applications requiring precise delivery of minimal fuel quantities, often operating at duty cycles below 15% under cruise conditions.

This limited flow duration provides insufficient self-cleaning effect compared to conventional injectors that benefit from longer injection events with more sustained flow velocity.

Material limitations of the era contributed additional vulnerabilities. Most LFHR injectors utilized conventional 304 or 316 stainless steel components without the specialized non-stick coatings found in modern premium injectors.

Scanning electron microscopy of fouled examples reveals microscopic surface irregularities ranging from 0.8-1.2μm Ra, significantly rougher than contemporary premium injectors providing numerous nucleation sites where deposits can initially adhere despite detergent action from premium fuels.

Service records indicate these injectors typically require cleaning or replacement between 30,000-50,000 miles, with flow testing frequently showing deviation exceeding 25% from specifications.

Technicians report characteristic “streaming” effects in spray patterns where previously uniform cone patterns degrade into distinct jets as deposits progressively distort flow through the micro-orifices.

The clogging typically manifests first as inconsistent idle quality and deteriorating emissions performance before progressing to more noticeable hesitation and power loss.

Vehicle manufacturers utilizing these specialized injectors often implemented compressed maintenance schedules recommending fuel system cleaning treatments every 15,000-25,000 miles tacit acknowledgment of their exceptional vulnerability to deposit formation.

While premium fuels provide some protection by extending the interval between cleanings, they ultimately cannot overcome the fundamental design limitations that make these micro-orifice injectors particularly susceptible to flow restriction throughout their service life.

Also Read: 5 Parking Sensors That Actually Help and 5 That Are Too Sensitive