The clutch serves as the critical intermediary between a vehicle’s engine and transmission, transferring power while allowing for gear changes and stopping without killing the engine.

In the automotive world, not all clutches are created equal some demonstrate remarkable durability and performance under pressure, while others falter prematurely, leaving drivers stranded and facing costly repairs.

This dichotomy between reliability and vulnerability often comes down to engineering choices, material quality, and design philosophy. For everyday drivers and enthusiasts alike, understanding which clutches stand the test of time versus those prone to early failure can save thousands in repairs and countless hours of frustration.

The following comprehensive analysis examines five clutch systems renowned for their exceptional durability and consistent performance alongside five notorious for their tendency to fail under otherwise normal driving conditions.

By examining the strengths and weaknesses of each, we aim to provide valuable insights for vehicle buyers, owners, and automotive professionals navigating the complex landscape of clutch technologies.

Whether you’re considering your next vehicle purchase or diagnosing a troublesome clutch, this guide offers critical information to make informed decisions.

5 Clutches That Hold Power

These engineering marvels feature overbuilt clutch assemblies with premium friction materials and robust pressure plates that effortlessly handle even aggressive driving without showing signs of wear.

Their advanced material science and precision manufacturing create engagement surfaces that maintain consistent bite point and pedal feel even after thousands of shifts and stop-and-go traffic cycles.

From occasional track day abuse to daily commuting duties, these exceptional clutches deliver smooth engagement and reliable power transfer well beyond 100,000 miles under normal driving conditions.

Owners report completing entire vehicle lifespans without clutch replacement an impressive achievement that eliminates a traditionally expected maintenance expense while maintaining like-new drivability throughout ownership.

1. Toyota Land Cruiser (70 Series) Heavy-Duty Clutch System

The Toyota Land Cruiser 70 Series clutch system represents perhaps the gold standard in clutch durability and power handling capability in mass-produced vehicles.

Engineered specifically for extreme environments and punishing use cases, this clutch system has earned a legendary reputation among off-road enthusiasts, mining companies, and military operations worldwide.

Its design incorporates an oversized pressure plate with exceptional clamping force, coupled with a heavy-duty clutch disc featuring riveted construction and specialized friction materials designed to withstand intense heat cycles without glazing or deformation.

What truly separates the Land Cruiser’s clutch from competitors is its dual-mass damper system that effectively absorbs torsional vibrations while preventing shock loading particularly crucial when crawling over obstacles or pulling heavy loads from a standstill.

This sophisticated vibration control mechanism prevents premature wear on the clutch components by minimizing stress on the friction surfaces during engagement and disengagement phases.

Even more impressive is the cooling design that integrates specialized venting channels in the clutch housing and bellhousing, allowing for efficient heat dissipation during prolonged heavy-duty operation.

The system incorporates hardened chromoly components throughout the clutch fork, pivot ball, and release bearing assembly, areas that often become failure points in lesser systems.

This attention to peripheral components demonstrates Toyota’s comprehensive understanding that clutch longevity depends not just on the disc and pressure plate, but on the entire operating system functioning cohesively.

Field reports consistently demonstrate Land Cruiser clutches exceeding 200,000 miles in severe service applications from Australian Outback mining operations to Saharan expeditions where ambient temperatures and operational demands would destroy conventional clutch systems in a fraction of that timeframe.

Perhaps most telling is that the clutch design has remained fundamentally unchanged for decades, with only incremental improvements to material science and manufacturing tolerances. This evolutionary rather than revolutionary approach speaks to the exceptional engineering of the original design.

When Toyota engineers developed a clutch system that could reliably transfer power from their diesel powerplants while withstanding the rigors of true all-terrain operation, they created a benchmark that few manufacturers have managed to approach, let alone surpass, even with modern technological advantages.

2. Porsche PDK Dual-Clutch Transmission

Porsche’s Doppelkupplung (PDK) dual-clutch transmission system represents the pinnacle of clutch engineering in performance applications, demonstrating remarkable durability despite handling extreme power levels and the demanding requirements of both track use and daily driving.

Unlike conventional manual transmissions with single clutch arrangements, the PDK utilizes two separate wet multi-plate clutch assemblies housed in an oil bath, each controlling alternate gears (one for odd-numbered gears, another for even-numbered).

This ingenious arrangement not only enables the lightning-fast gear changes Porsche is renowned for but distributes wear across multiple clutch plates, dramatically extending service life.

The sophisticated hydraulic actuation system in the PDK operates with millisecond precision, continuously adjusting clutch pressure and engagement characteristics based on driving conditions, vehicle speed, and throttle input.

This adaptive capability prevents the clutch plates from experiencing excessive slippage during engagement, a primary cause of premature wear in conventional systems.

More impressively, Porsche engineers developed specialized friction materials for the clutch plates that maintain consistent performance characteristics even after thousands of heat cycles, resisting the degradation that plagues lesser systems when subjected to repeated high-performance driving.

Perhaps most remarkable about the PDK’s durability is how it maintains this reliability despite the immense thermal loads generated in performance driving scenarios.

The transmission’s dedicated oil cooling circuit integrates with the vehicle’s thermal management system, rapidly drawing heat away from the clutch plates even during extended track sessions.

This advanced cooling architecture allows the clutch assemblies to operate within their optimal temperature window regardless of how aggressively the vehicle is driven, preventing the heat-related degradation that typically accelerates wear in performance applications.

Porsche’s commitment to overengineering extends to the entire driveline, with reinforced clutch baskets and hardened gear sets designed to withstand torque spikes far exceeding the engine’s rated output.

This built-in headroom accommodates not only the factory power levels but provides additional capacity for modified vehicles explaining why even substantially upgraded Porsches with aftermarket power enhancements often maintain reliable clutch performance.

The PDK’s reputation for durability is further validated by its widespread adoption in Porsche’s racing programs, where the same fundamental clutch technology handles the extreme demands of endurance racing without compromise.

What ultimately distinguishes the PDK clutch system is how it combines seemingly contradictory characteristics providing both incredible performance and exceptional longevity in a package that operates flawlessly through hundreds of thousands of engagements while requiring minimal maintenance beyond scheduled fluid changes.

3. Cummins Diesel Heavy-Duty Clutch System

The clutch systems engineered for Cummins diesel applications represent a masterclass in heavy-duty power transfer design, particularly in commercial applications where reliability directly impacts business operations and profitability.

These clutch assemblies have earned their reputation through decades of consistent performance in the most demanding applications from long-haul trucking operations accumulating millions of miles to construction equipment subjected to constant load cycles under extreme conditions.

What distinguishes the Cummins-specific clutch systems is their fundamentally different design philosophy compared to passenger vehicle applications, prioritizing longevity and consistent performance over lighter weight or smoother engagement.

At the core of these systems is a ceramic-metallic composite friction material developed specifically to handle the massive torque output of Cummins diesel engines, which can exceed 1,000 lb-ft in heavy-duty applications.

Unlike organic compounds used in lighter applications, this specialized material maintains consistent friction characteristics through extreme temperature ranges without deteriorating or glazing.

The pressure plate design incorporates multiple spring arrays rather than a single diaphragm, providing more even clamping pressure across the entire friction surface while simultaneously allowing for fine-tuned progressive engagement characteristics that prevent shock loading of driveline components.

Perhaps most impressive is the thermal management capability engineered into these clutch systems. The flywheel assemblies feature extensive mass and specialized venting designed to function as heat sinks, rapidly dissipating the tremendous thermal energy generated during clutch engagement when moving heavy loads from a standstill.

This thermal stability prevents the warping and material degradation that typically leads to premature clutch failure in less robust systems, particularly under the high-load conditions common in commercial diesel applications.

The release system in Cummins applications deserves special attention, as it represents another area where commercial-grade engineering outshines passenger vehicle designs.

Rather than using plastic composites or lightweight alloys in the release fork and bearing assemblies, Cummins-specific clutch systems utilize precision-machined steel components with hardened contact surfaces and pressurized lubrication points.

This attention to the peripheral components often the first to fail in lesser systems ensures the entire clutch operation remains smooth and consistent throughout its service life, even after hundreds of thousands of miles.

Field data consistently demonstrates these clutch systems exceeding 250,000 miles in normal service before requiring replacement, with many fleet operators reporting significantly longer intervals depending on application.

This exceptional longevity represents not just a testament to the robust engineering but translates directly into reduced downtime and maintenance costs critical factors that have helped establish Cummins powertrains as the preferred choice in applications where reliability cannot be compromised.

4. Honda S2000 OEM Clutch

The Honda S2000’s factory clutch system stands as one of the most remarkably overengineered components in modern sports car design, demonstrating exceptional durability despite the high-revving nature of the vehicle’s powerplant and the enthusiastic driving style the car encourages.

What makes this clutch system particularly noteworthy is how it defies conventional wisdom despite its relatively lightweight construction and the engine’s propensity for operating at high RPMs (with redlines reaching 9,000 RPM in AP1 models), the S2000 clutch consistently delivers service life far exceeding comparable sports cars, often lasting well beyond 150,000 miles even with spirited driving.

The secret behind this exceptional durability lies in Honda’s sophisticated engineering approach to the entire clutch assembly. The pressure plate utilizes a proprietary diaphragm spring design that maintains consistent clamping force across its entire operating range while minimizing the pedal effort required for actuation.

This balance between sufficient clamping pressure and comfortable operation prevents the excessive slippage that typically accelerates wear in performance applications.

The clutch disc itself features precision-balanced construction with specialized friction materials that resist glazing even when subjected to the heat generated during aggressive driving scenarios.

Perhaps most crucial to the S2000 clutch’s longevity is its hydraulic actuation system, which represents a masterclass in fluid dynamics engineering.

The system maintains consistent pressure and displacement throughout its travel, eliminating the vague engagement point that often leads drivers to inadvertently slip clutches in other vehicles.

This precision in the actuation system means even novice drivers typically engage the clutch cleanly, preventing the partially-slipped engagement that rapidly degrades clutch surfaces in less refined systems.

The S2000’s clutch also benefits from exceptional thermal management characteristics, with the bell housing design promoting efficient airflow around the clutch assembly during operation.

This passive cooling system prevents heat saturation during aggressive driving sessions, a common cause of premature clutch failure in many performance vehicles.

Additionally, Honda engineers incorporated a dual-mass flywheel that effectively dampens torsional vibrations from the high-revving engine, preventing the micro-slippage that can occur when engine harmonics create momentary variations in power delivery.

What truly distinguishes the S2000 clutch from competitors is how it maintains this exceptional durability while still delivering the crisp, direct engagement feel demanded by enthusiast drivers.

Unlike some overbuilt clutch systems that sacrifice feedback for durability, Honda achieved both objectives simultaneously, creating a clutch system that communicates precisely through the pedal while withstanding the demands of performance driving for remarkable service intervals.

Also Read: 5 Car Seats That Remain Firm For Years And 5 That Sag After 10K

5. ZF Sachs Performance Clutch Systems

ZF Sachs performance clutch systems represent the intersection of German engineering precision and motorsport-derived technology, resulting in clutch assemblies that deliver exceptional power handling capability without sacrificing longevity.

As the OEM supplier for numerous high-performance European manufacturers including BMW M division, Porsche, and AMG Mercedes models, Sachs has developed clutch systems that routinely outperform aftermarket alternatives despite handling power levels that would rapidly destroy conventional clutch assemblies.

What distinguishes these systems is their sophisticated engineering approach that optimizes every component within the clutch assembly rather than simply increasing clamping pressure the blunt-force approach employed by many aftermarket manufacturers.

The foundation of Sachs’ exceptional durability comes from their proprietary friction materials, developed through extensive research in both automotive and motorsport applications.

These specialized compounds maintain consistent friction characteristics across a broad temperature range, resisting the fade and glazing that typically occurs in lesser materials when subjected to repeated heat cycles.

Perhaps more impressively, Sachs engineers have developed progressive engagement characteristics that allow for smooth operation in daily driving scenarios while still providing the instantaneous power transfer needed during performance driving, eliminating the compromise between driveability and durability found in most performance clutches.

Sachs’ pressure plate designs incorporate advanced metallurgy with precisely calculated finger spring geometries that distribute clamping force evenly across the entire friction surface.

This uniform pressure distribution prevents the localized hotspots that typically accelerate wear in conventional designs. Furthermore, Sachs utilizes proprietary heat-treating processes for critical components, resulting in pressure plates and flywheels that maintain dimensional stability even after hundreds of heat cycles preventing the warping that commonly leads to juddering and premature failure in lesser systems.

The engineering excellence extends to the peripheral components, with Sachs developing specialized release bearings that incorporate low-friction ceramic materials and self-centering designs.

These seemingly minor components often become the failure point in performance applications, but Sachs’ holistic approach ensures the entire system maintains its integrity throughout its service life.

Even the clutch disc dampening mechanisms receive exceptional attention, with multi-stage torsional dampers that effectively filter driveline vibrations without compromising power transfer capability.

What ultimately sets Sachs’ performance clutches apart is their remarkable longevity in real-world applications. While many performance-oriented clutch systems show significant degradation after 30,000-50,000 miles, properly matched Sachs components routinely deliver 100,000+ mile service intervals even in vehicles modified beyond factory power specifications.

This reliability under pressure explains why many European performance tuning companies specify Sachs components exclusively despite the availability of less expensive alternatives the initial investment consistently proves economical when measured against the extended service life these systems provide.

5 Clutches That Burn Out Under Normal Use

These notoriously fragile clutch systems feature undersized components and questionable friction materials that deteriorate rapidly even under careful driving by experienced manual transmission operators.

Their inadequate thermal capacity and poor material choices create assemblies that begin slipping prematurely, often showing telltale symptoms of excessive wear before reaching 30,000 miles of normal use.

Owners report developing babying habits like avoiding hills and careful launches just to extend clutch life, compensations that shouldn’t be necessary with properly engineered components.

What should be a long-lasting drivetrain component instead becomes a recurring expense, with many frustrated owners facing their second or even third clutch replacement during normal ownership periods.

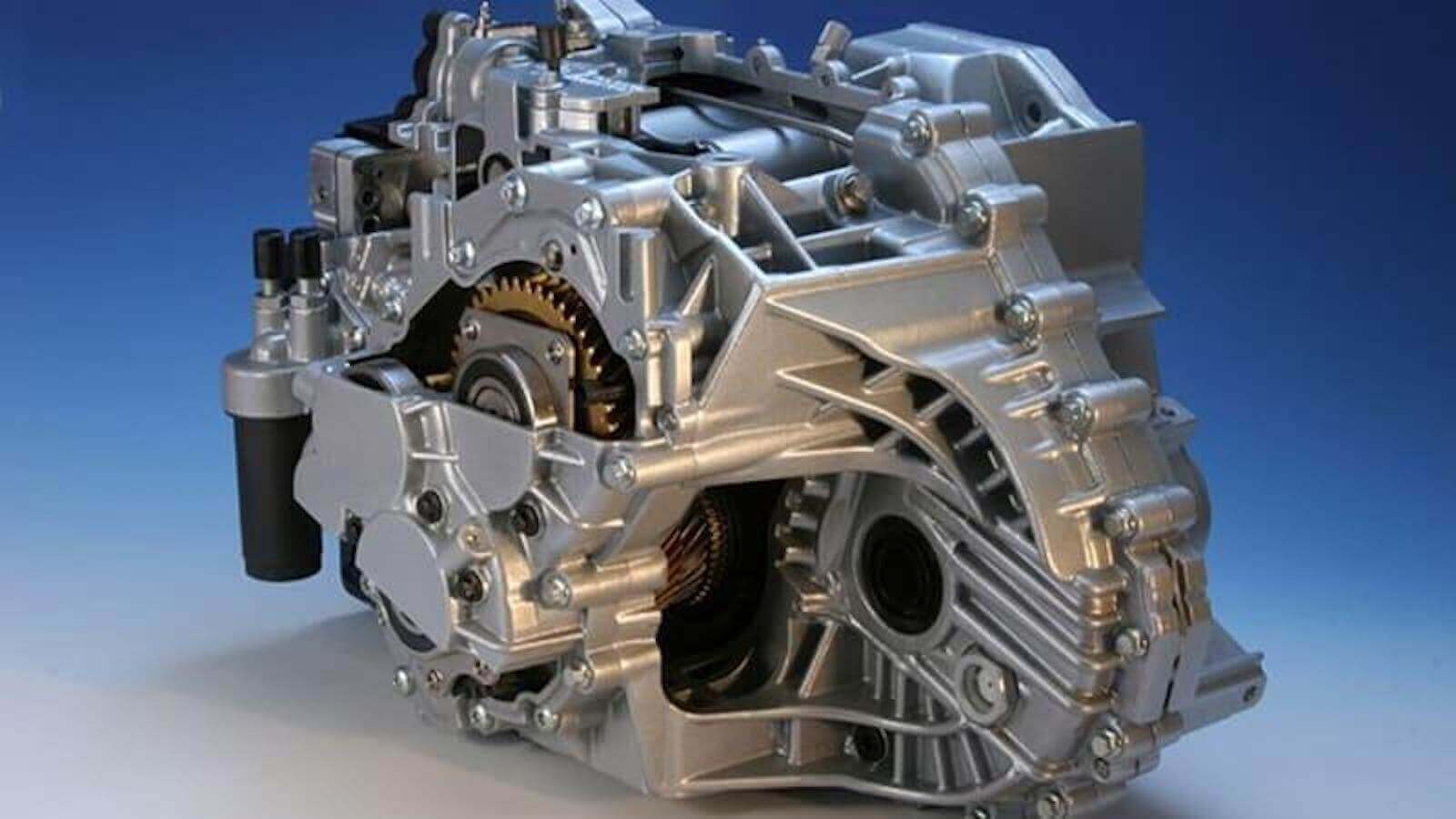

1. Ford Focus DCT PowerShift Transmission

The Ford PowerShift dual-clutch transmission, particularly as implemented in the Focus compact car lineup between 2012-2016, represents one of the most problematic clutch systems in modern automotive design.

What makes this case particularly egregious is that the failures occurred under entirely normal driving conditions, often with vehicles showing fewer than 30,000 miles.

Unlike performance vehicles where aggressive driving might explain premature clutch wear, the PowerShift failures affected ordinary commuters using their vehicles exactly as intended, leading to multiple class-action lawsuits and a severely damaged reputation for Ford’s small car program.

At the core of PowerShift’s problems was its fundamentally flawed dry-clutch design. While most dual-clutch transmissions in the industry utilized wet clutches bathed in cooling fluid (like the aforementioned Porsche PDK), Ford opted for a dry-clutch configuration to improve fuel efficiency and reduce manufacturing costs.

This design choice proved catastrophic, as the clutch plates quickly overheated during normal operation, particularly in stop-and-go traffic conditions.

The heat accumulation caused premature wear of the friction material, leading to the characteristic shuddering, slipping, and eventually complete failure that owners experienced.

The transmission control module (TCM) software exacerbated these problems by failing to properly manage clutch engagement, often resulting in delayed response followed by abrupt power delivery.

This jerky engagement placed additional stress on the already compromised clutch plates, creating a vicious cycle of accelerating deterioration. Ford issued multiple software updates attempting to address these concerns, but these proved insufficient to overcome the fundamental hardware limitations of the system.

The clutch actuation system itself utilized components that degraded rapidly under normal use, with internal seals failing and allowing contamination of the hydraulic fluid that controlled clutch operation.

Perhaps most telling about the PowerShift’s deficiencies was Ford’s internal communications, later revealed through legal proceedings, which showed engineers recognized the inherent design flaws early in development but were overruled by management decisions prioritizing cost reduction over reliability.

The company’s service bulletins continuously evolved, eventually requiring complete replacement of multiple core components rather than simple adjustments or software updates, tacitly acknowledging the fundamental design inadequacies of the original system.

The human impact of these failures extended beyond mere inconvenience, with many owners reporting dangerous situations including unexpected power loss during highway merges and intersection crossings when the transmission suddenly disengaged due to clutch failure.

Despite eventually extending warranty coverage and offering buyback programs under legal pressure, the PowerShift debacle remains a cautionary tale of how prioritizing short-term cost savings over engineering fundamentals can result in catastrophic long-term consequences for both consumers and manufacturers alike.

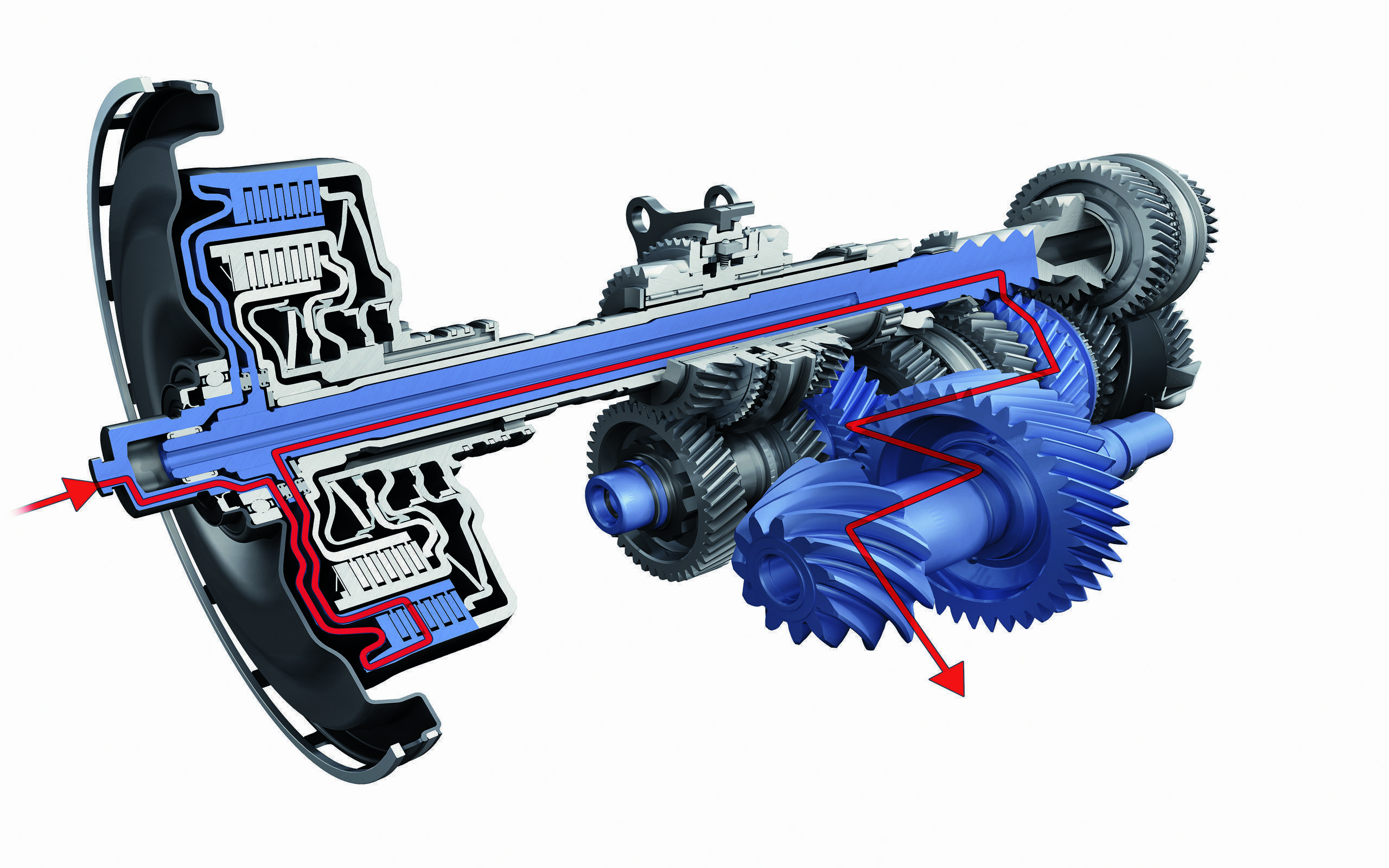

2. Nissan CVT with Auxiliary Gearbox Clutch System

Nissan’s Continuously Variable Transmission (CVT) with auxiliary gearbox clutch system, widely implemented across their product line from 2007 through 2017, has earned a notorious reputation for premature failure under entirely normal driving conditions.

While conventional CVTs eliminate traditional clutch components by using a steel belt and variable pulleys, Nissan’s implementation incorporated a starting clutch for launching the vehicle from a stop this component becoming the system’s Achilles’ heel.

The failures proved so widespread that extended warranty programs and class-action settlements became necessary, though these remedies came too late for many owners who experienced catastrophic transmission failures often shortly after warranty expiration.

What makes Nissan’s clutch failures particularly problematic is their unpredictability and the complete loss of functionality when they occur. Unlike conventional clutches that provide warning signs through progressively worsening performance, the Nissan system often failed suddenly and completely, leaving drivers stranded without warning.

The root cause traces to several engineering deficiencies, beginning with inadequate cooling provisions for the clutch assembly. The transmission fluid cooling system proved undersized for normal operating conditions, allowing fluid temperatures to exceed design parameters during everyday driving scenarios like moderate hills or warm weather operation.

The clutch plate materials themselves exhibited poor thermal stability, degrading rapidly when subjected to the elevated temperatures that the inadequate cooling system permitted.

This degradation created a cascade effect where material from the deteriorating clutch contaminated the transmission fluid, which then circulated through precision valve bodies and control solenoids, causing secondary failures throughout the system.

The transmission control programming exacerbated these issues by failing to properly modulate clutch engagement, particularly during partial-throttle acceleration, creating excessive slippage that generated additional heat in an already thermally compromised system.

Perhaps most damning about Nissan’s approach was their slow response to clearly documented failure patterns. Internal service documentation revealed engineering awareness of the clutch system vulnerabilities years before substantive design changes were implemented, with countless owners subjected to expensive repairs during this period.

When redesigns finally occurred, they primarily addressed symptom management rather than the fundamental thermal management issues at the heart of the failures.

The financial impact on owners proved substantial, with replacement costs often exceeding $4,000, a particularly harsh blow considering that many failures occurred between 60,000-90,000 miles, well short of the expected service life for modern transmissions.

The long-term damage extended beyond immediate repair costs, with resale values for affected Nissan models plummeting as the transmission’s reputation spread throughout the automotive community.

Even vehicles with functioning transmissions suffered significant depreciation due to market awareness of the impending failure risk, effectively punishing owners twice first through repair costs, then through accelerated depreciation when selling or trading affected vehicles.

3. Mini Cooper S (R56 Generation) Clutch Assembly

The Mini Cooper S models produced during the R56 generation (2007-2013) featured a clutch system that gained infamy for its premature failure rates, often requiring replacement before 40,000 miles under entirely normal driving conditions.

What makes this case particularly notable is that the failures occurred despite the vehicle’s relatively modest power output and lightweight construction factors that should theoretically reduce clutch stress compared to higher-performance applications.

The root causes trace to a combination of compromised engineering decisions and material quality issues that created a perfect storm of reliability problems for owners.

At the center of the Mini’s clutch woes was a fundamentally undersized clutch assembly relative to the engine’s torque characteristics, particularly in the turbocharged S models.

While the physical dimensions might have proven adequate with premium materials, Mini/BMW opted for lower-grade friction materials that degraded rapidly under normal thermal cycling.

The clutch disc faced especially accelerated wear at the engagement surfaces, with the friction material separating from the backing plate in many documented cases a failure mode that should never occur within normal service intervals and indicates fundamental material deficiencies.

The fly-by-wire clutch actuation system further complicated matters, utilizing a complex electro-hydraulic arrangement that often failed to provide consistent engagement points.

This inconsistency led even experienced drivers to occasionally slip the clutch unintentionally, accelerating wear rates beyond what would occur with a more direct mechanical linkage.

The system’s reliance on plastic components within the hydraulic circuit proved particularly problematic, with these components degrading over time and introducing air into the system, further compromising engagement precision.

Perhaps most frustrating for owners was how the Mini’s urban-oriented design exacerbated clutch wear through packaging decisions. The tight engine bay configuration restricted airflow around the bellhousing, creating a heat-soak effect that prevented efficient cooling between engagement cycles.

This thermal retention meant the clutch operated at elevated temperatures even during moderate driving, accelerating the deterioration of the already compromised friction materials.

The transverse engine layout also placed the transmission at a mechanical disadvantage, requiring a more complex linkage system with additional pivot points each introducing potential wear points and alignment issues that could affect clutch operation.

The financial impact on owners proved substantial, with replacement costs typically ranging between $1,500-2,500, depending on labor rates and whether peripheral components had been affected by the clutch failure.

Even more telling was BMW/Mini’s response rather than addressing the fundamental design deficiencies, later production runs simply utilized slightly upgraded materials while maintaining the same basic design architecture, resulting in marginally improved but still subpar service life compared to industry standards.

This minimal approach to remediation speaks volumes about the corporate prioritization of manufacturing cost control over engineering robust solutions to documented failure points.

4. Dodge Journey/Chrysler 200 (2011-2016) Dual Clutch Automatic

The dual-clutch automatic transmission deployed in various FCA (Fiat Chrysler Automobiles) products, particularly the Dodge Journey and Chrysler 200 models produced between 2011-2016, stands as a case study in how engineering compromises coupled with inadequate development can result in catastrophic reliability issues.

Unlike some problematic transmissions that at least provided acceptable performance when functioning properly, the FCA dual-clutch system managed to combine the worst aspects of both automatic and manual transmissions the complexity and expense of the former with the potential failure modes of the latter, while delivering neither the convenience nor the engagement that should have justified these compromises.

The transmission utilized a dry dual-clutch arrangement sourced from Fiat’s European operations but inadequately adapted for the larger, heavier American vehicles and their different usage patterns.

The clutch packs were fundamentally undersized for the torque outputs of the engines they were paired with, particularly the V6 options that generated substantially more heat during engagement than the clutch system could effectively dissipate.

This thermal management deficiency created a cascade of failures, with clutch material degrading rapidly under normal driving conditions, particularly during common American driving scenarios like prolonged idling in traffic or modest inclines at stoplights.

The electronic control unit governing clutch engagement proved equally problematic, with programming that never properly adapted to individual driving styles or compensated for clutch wear over time.

This resulted in increasingly erratic engagement characteristics as the system aged vehicles would hesitate unpredictably from stops, then lurch forward suddenly as the clutch finally engaged, creating not just driveability issues but genuine safety concerns in traffic situations.

The control software received multiple updates throughout production, but these represented attempts to manage symptoms rather than addressing the fundamental hardware limitations at the core of the problems.

What particularly distinguished the FCA dual-clutch failures from some competitors was how quickly they manifested many owners reported significant driveability issues with as little as 20,000 miles, with complete failures commonly occurring before 60,000 miles.

The repair costs proved especially burdensome, typically ranging between $3,000-4,000, depending on whether peripheral components had been damaged during the failure progression.

These costs represented a substantial percentage of the vehicles’ depreciated value at the time failures typically occurred, leaving many owners underwater on their financing and effectively trapped with unreliable vehicles.

The reputational damage eventually forced FCA to largely abandon the technology, reverting to conventional automatic transmissions in subsequent model years a tacit acknowledgment of the design’s fundamental unsuitability for its intended application.

However, this product planning correction came too late for existing owners, many of whom experienced multiple replacement transmissions exhibiting identical failure patterns, demonstrating that the issues stemmed from inherent design flaws rather than isolated manufacturing defects that could be remedied through quality control improvements.

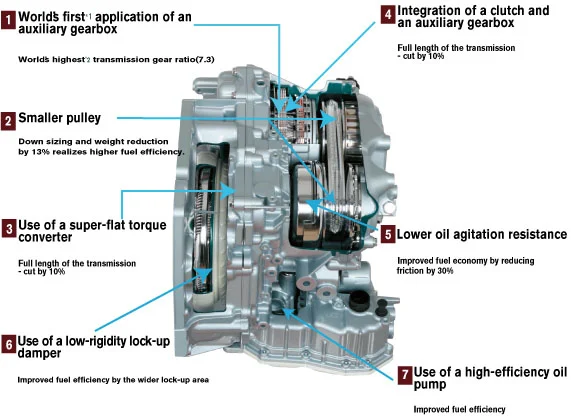

5. Volkswagen 1.4 TSI DSG Clutch Pack (2009-2013)

The Volkswagen 1.4 TSI engine paired with the DSG (Direct Shift Gearbox) transmission created a particularly problematic combination that resulted in premature clutch failure across multiple VW Group brands, including Volkswagen, Audi, SEAT, and Škoda.

What distinguishes this particular clutch system’s failures is how they manifested despite Volkswagen’s generally solid reputation for transmission engineering and previous success with DSG technology in other applications.

The 1.4 TSI DSG combination exposed the limitations of Volkswagen’s clutch design when subjected to specific operating conditions, particularly the high-heat, low-speed environments common in urban driving.

The core issues stemmed from multiple engineering miscalculations, beginning with thermal management inadequacies specific to the 1.4 TSI application.

Unlike larger displacement engines that operated at lower relative stress levels, the small-displacement turbocharged engine demanded frequent downshifts and higher RPM operation in everyday driving scenarios, placing additional thermal load on the clutch packs.

The cooling circuit for the transmission proved inadequate for these conditions, with the mechatronic control unit often limiting oil flow to the clutch packs in misguided attempts to improve efficiency, inadvertently accelerating clutch degradation through insufficient cooling during critical engagement phases.

Material selection decisions further compounded these problems, with Volkswagen utilizing friction materials that exhibited accelerated wear characteristics when repeatedly subjected to the elevated temperatures that became common in these applications.

The clutch friction material would develop uneven wear patterns, creating juddering during engagement that further accelerated deterioration through inconsistent pressure distribution across the clutch surfaces.

Once this degradation began, it progressed rapidly, with many owners reporting complete failure within 5,000-10,000 miles after initial symptoms appeared a particularly short runway for addressing developing problems.

The mechatronic control unit governing clutch operation introduced additional complications, with software that failed to properly adapt to developing wear patterns or compensate for the changing friction characteristics as the clutch materials degraded.

The transmission would attempt to maintain factory-specified shift timing and firmness even as the mechanical components became increasingly incapable of executing these commands properly, creating a mismatch between software expectations and hardware capabilities that further accelerated system deterioration.

When Volkswagen finally acknowledged these issues, their initial response focused primarily on software updates rather than addressing the fundamental hardware limitations, providing only temporary improvements before the underlying mechanical problems reasserted themselves.

Repair costs proved particularly burdensome for owners, with complete DSG overhauls typically ranging between €2,500-3,500 (approximately $3,000-4,000) depending on market and whether secondary damage had occurred during failure progression.

These substantial costs, often incurred between 50,000-80,000 kilometers (approximately 30,000-50,000 miles), represented a significant percentage of the vehicles’ depreciated value at the time of failure, creating financial hardships for owners who reasonably expected much longer service intervals from a modern transmission.

The widespread nature of these failures eventually prompted Volkswagen to implement extended warranty coverage in some markets, though many owners had already incurred substantial repair costs before these programs were established.

Also Read: 5 Car Key Systems That Rarely Fail And 5 That Leave You Stranded