Transmissions are the unsung heroes of our vehicles, translating engine power into usable motion while operating under extreme conditions. The longevity of a gearbox speaks volumes about its engineering quality, manufacturing precision, and the materials used in its construction.

While many transmissions begin to exhibit symptoms of deterioration after 100,000 miles, there exists a fascinating divide certain models remain remarkably resilient well beyond 150,000 miles, while others begin to protest with concerning noises before reaching even the 50,000-mile mark.

This comprehensive examination explores ten notable transmissions across the automotive landscape, highlighting five that maintain their factory-fresh feel and performance characteristics well into six-figure mileage territory, alongside five notorious examples that develop grinding issues or other significant problems prematurely.

For enthusiasts, mechanics, and everyday drivers alike, understanding which transmissions demonstrate exceptional durability versus those prone to early deterioration provides valuable insight when purchasing, maintaining, or repairing vehicles.

Each transmission’s design philosophy, common failure points, and long-term reliability characteristics will be thoroughly analyzed to provide a complete picture of what separates the mechanical marathoners from the short-lived sprinters in the world of automotive transmissions.

5 Gearboxes That Feel New at 150,000 Miles

These engineering masterpieces feature precision-crafted manual transmissions with perfectly synchronized gear sets and robust shift mechanisms that maintain crisp, tactile engagement through hundreds of thousands of shifts.

Their exceptional metallurgy, optimized lubrication passages, and tight manufacturing tolerances create gearboxes that resist the synchro wear and bearing noise that typically develop in lesser transmissions.

From cold morning commutes to spirited backroad drives, these remarkable transmissions deliver the same positive gear engagement and satisfying mechanical feedback they provided when new.

Owners report enjoying the same precise shift feel and silent operation well into six-figure mileage, proving that properly engineered manual gearboxes can truly last the lifetime of a vehicle without degradation.

1. Toyota A750E/F Automatic Transmission

The Toyota A750E/F automatic transmission is a testament to Japanese engineering excellence and has earned its reputation as one of the most reliable transmissions ever produced.

Found in numerous Toyota trucks and SUVs including the Tundra, Land Cruiser, and 4Runner, this 5-speed automatic transmission was designed with durability as its primary focus rather than maximizing fuel economy or providing lightning-quick shifts.

What makes the A750E/F particularly impressive is its overbuilt nature. Toyota engineers incorporated several design features that contribute to its legendary longevity.

The transmission features exceptionally robust planetary gear sets constructed from high-grade hardened steel that resist wear even under extreme torque loads.

Its valve body is precisely machined to ensure consistent hydraulic pressure, minimizing the erratic shifting that can accelerate wear in lesser transmissions. The lockup torque converter is also notably resilient, avoiding the slippage issues that plague many competitors.

Cooling was a priority in the A750’s design. The transmission features an oversized fluid pan that increases fluid capacity, effectively improving heat dissipation.

This is complemented by an efficient transmission cooler system that maintains optimal operating temperatures even when towing heavy loads in challenging conditions. Since heat is the primary enemy of automatic transmissions, this superior cooling capacity substantially extends service life.

The transmission fluid itself receives special attention in this design. Toyota specifies its proprietary ATF WS (World Standard) fluid, which maintains its viscosity properties and lubricating capabilities far longer than conventional transmission fluids.

While Toyota officially claims the fluid is “lifetime” (a claim regarded skeptically by most mechanics), many owners who perform fluid changes at 60,000-100,000 mile intervals report transmissions that shift indistinguishably from new even at the 200,000-mile mark.

Perhaps most telling is that Toyota A750E/F transmissions rarely exhibit the intermediate failure symptoms common to aging transmissions. There’s typically no progressive deterioration with soft shifts becoming harder, or vice versa.

The transmission either works perfectly or, in very rare cases, experiences a complete failure (usually due to extreme neglect). This binary reliability profile is rare in the automotive world and speaks to the exceptional engineering tolerances built into every component.

Owner forums are filled with testimonials of A750E/F transmissions exceeding 300,000 miles with nothing more than regular fluid changes.

While most modern vehicles eventually succumb to electrical issues or body deterioration, it’s not uncommon for these transmissions to outlast the vehicles they’re installed in, often finding second lives when transplanted into project vehicles or rebuilds.

2. ZF 8HP Automatic Transmission

The ZF 8HP automatic transmission represents German precision engineering at its finest, having revolutionized the automatic transmission landscape since its introduction in 2009.

This 8-speed automatic has become ubiquitous across numerous manufacturers, including BMW, Audi, Jaguar, Land Rover, Chrysler, and Dodge, proving its adaptability across different vehicle platforms and power outputs.

What makes the ZF 8HP particularly remarkable is its ability to maintain like-new performance characteristics well beyond the 150,000-mile mark while handling everything from economy sedans to high-performance applications.

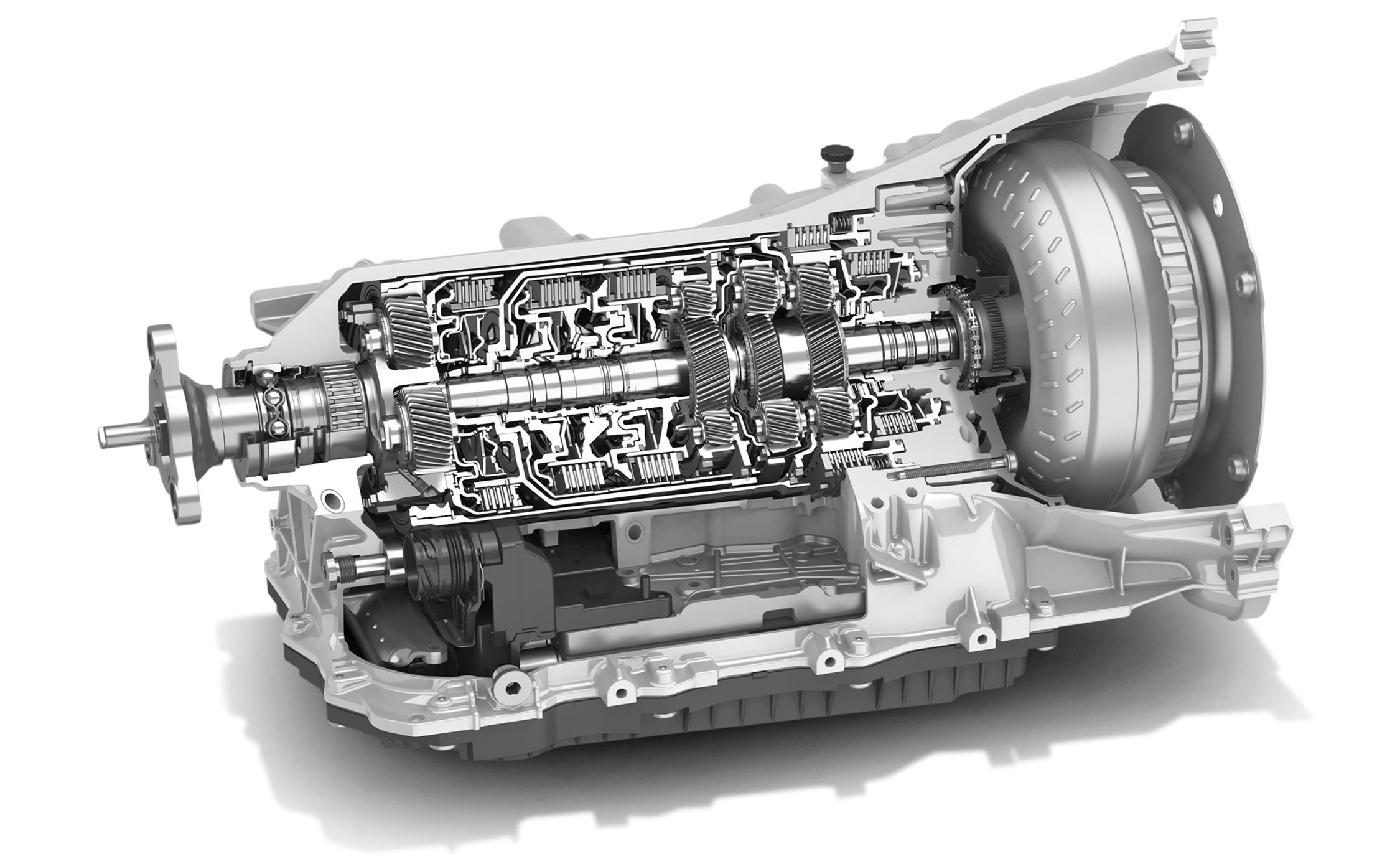

The ZF 8HP’s durability stems from its sophisticated yet fundamentally sound engineering philosophy. Unlike many modern transmissions that sacrifice longevity for weight savings, the 8HP utilizes robust planetary gear sets arranged in a compact package.

The transmission employs only five shift elements (multi-disc clutches and brakes) despite offering eight forward gears, minimizing potential failure points while maximizing efficiency.

This design reduces internal friction by up to 50% compared to earlier six-speed transmissions, generating less heat and prolonging component life.

Central to the 8HP’s longevity is its advanced thermal management system. The transmission features precise computer-controlled cooling that maintains optimal operating temperatures under varying conditions.

Unlike transmissions that either run too cool (causing inefficiency) or too hot (accelerating wear), the 8HP consistently operates within its ideal temperature range.

This is complemented by specially formulated transmission fluid that maintains its lubricating properties far longer than conventional fluids, with many units still performing flawlessly with the original factory fill at high mileages.

The 8HP’s electronic control unit deserves particular praise for its adaptability. Rather than employing fixed shift parameters that can’t account for wear over time, the 8HP continually learns and adapts to changing conditions and component wear.

If microscopic wear occurs on clutch materials or valve bodies over tens of thousands of miles, the transmission’s software compensates by adjusting hydraulic pressures and shift timing, maintaining the same shift quality experienced when new.

Most impressively, the ZF 8HP maintains its performance characteristics remarkably well across widely varying applications. Whether installed in a BMW 7-Series luxury sedan, a Ram 1500 pickup truck, or a high-performance Dodge Challenger Hellcat, the basic architecture proves astonishingly resilient.

The higher-torque variants (designated 8HP70 and 8HP90) feature strengthened components but retain the same fundamental design and reliability characteristics.

Mechanics and transmission specialists frequently express surprise at the internal condition of high-mileage 8HP transmissions when they’re opened for inspection.

Even at 150,000+ miles, clutch materials typically show minimal wear, planetary gear sets remain within factory tolerances, and valve bodies continue to operate with precision.

This transmission has redefined expectations for automatic transmission longevity in an era when many manufacturers seem content with units that become problematic shortly after warranty expiration.

3. Honda 6-Speed Manual Transmission

Honda’s six-speed manual transmission, particularly the versions found in performance-oriented vehicles like the S2000, Civic Si, and Type R models, exemplifies the company’s reputation for building bulletproof manual gearboxes.

These transmissions are engineered with such precision and durability that they regularly surpass 150,000 miles while maintaining the same crisp, mechanical feel that Honda enthusiasts cherish from day one.

The foundation of the Honda 6-speed’s remarkable longevity begins with its construction. Unlike manufacturers who cut costs with softer metals, Honda uses high-carbon steel alloys for critical components like gears and synchronizes.

These components undergo extensive heat treatment processes that create an exceptionally hard outer surface while maintaining a slightly more flexible core, allowing the parts to withstand enormous stresses without becoming brittle.

The result is a transmission that handles both daily commuting and occasional track use without developing the notchiness or grinding that plagues lesser manual transmissions as they age.

Synchronizer design represents another area where Honda’s engineering excellence shines. The double-cone or triple-cone synchronizers (depending on the specific transmission variant) provide effortless shifts when new, but more importantly, they maintain this same effort level even after hundreds of thousands of shifts.

The brass synchronizer rings are precisely matched to their corresponding gears with tight tolerance control during manufacturing, and the materials are selected specifically for their wear resistance characteristics.

This attention to detail means that even high-mileage Honda transmissions rarely develop the synchronizer wear that causes grinding or difficult engagement in other transmissions.

The shift mechanism itself deserves special mention. Honda’s renowned shift feel comes from a direct mechanical linkage rather than the cable systems many manufacturers employ to reduce noise and vibration. While slightly louder, this direct linkage eliminates the vague feeling that develops in cable systems as they stretch and wear.

The shift forks and selector mechanism are constructed from forged components rather than stamped or cast parts, providing greater durability under the constant back-and-forth motion of shifting.

Even the detent springs and balls that provide the positive “click” into each gear maintain their tension remarkably well over time. Honda’s lubrication strategy further enhances transmission longevity.

While many manufacturers have moved to “lifetime” transmission fluids (a questionable concept among mechanics), Honda specifically recommends periodic fluid changes using their formulated manual transmission fluid.

This fluid maintains its viscosity characteristics and anti-wear properties far longer than conventional gear oils, protecting the transmission even under extreme heat conditions that would break down lesser lubricants.

Perhaps most telling is that Honda manual transmissions rarely exhibit progressive deterioration. While transmissions from other manufacturers gradually develop notchy shifts, increased effort, or synchronizer grinding as they age, Honda transmissions tend to maintain consistent performance characteristics throughout their service life.

When problems do eventually occur, they typically manifest suddenly rather than through a gradual decline in shift quality a testament to the significant engineering margins built into every component.

4. Aisin AZ6 Six-Speed Manual Transmission

The Aisin AZ6 six-speed manual transmission represents Japanese manufacturing precision at its finest, demonstrating remarkable longevity across multiple vehicle applications.

Most famously utilized in the Toyota 86/Subaru BRZ platform and various Lexus models, this transmission maintains exceptional shift quality and mechanical integrity well beyond the 150,000-mile mark, often feeling virtually identical to new units even after years of service.

What sets the Aisin AZ6 apart is its foundational engineering philosophy of overbuilding critical components. The transmission case itself is cast from high-strength aluminum alloy with strategically reinforced mounting points that prevent the flexing that can misalign internal components in lesser transmissions.

Inside, the gear sets are manufactured from specially formulated chrome-molybdenum steel alloys that undergo sophisticated heat-treatment processes, creating gears with incredibly hard wearing surfaces while maintaining sufficient core ductility to resist cracking under shock loads.

This balance of hardness and toughness enables the AZ6 to withstand both the steady wear of daily driving and the occasional abuse of spirited performance driving.

The synchronizer assemblies in the AZ6 deserve particular attention for their contribution to the transmission’s longevity. Utilizing triple-cone synchronizers on the most frequently used gears (typically first and second) and dual-cone designs on the higher gears, the AZ6 provides exceptionally smooth engagement when new which remarkably doesn’t deteriorate with age.

The synchronizer rings themselves are manufactured from proprietary brass alloys with precisely engineered friction characteristics, allowing them to effectively match gear speeds during shifts without excessive wear. This design prevents the development of the grinding or difficult engagement that commonly affects aging manual transmissions.

Bearing selection further demonstrates Aisin’s commitment to durability. Rather than using the minimum sufficient bearings to reduce manufacturing costs, the AZ6 employs oversized needle and ball bearings at critical load points throughout the transmission.

These bearings maintain precise gear alignment even after hundreds of thousands of shifts and massive cumulative torque transfer. The input shaft bearings, which bear enormous loads during clutch engagement, are particularly robust, preventing the shaft wobble that creates progressive seal wear and eventual oil leakage in many competitive transmissions.

The shift mechanism employs a direct mechanical linkage rather than cables, providing the responsive, mechanical feel that enthusiasts prize while eliminating the vagueness that develops in cable systems as they age and stretch.

The shifter fork assembly uses hardened steel components with tight manufacturing tolerances, preventing the slop and imprecision that typically develops in lesser transmissions over time.

Even the detent mechanism that provides positive engagement into each gear position maintains its precise action well beyond 150,000 miles. Perhaps most impressively, the Aisin AZ6 achieves its remarkable longevity without requiring extraordinary maintenance.

While regular transmission fluid changes using the manufacturer-specified gear oil are recommended, the transmission doesn’t demand the frequent rebuilds or adjustment procedures that some performance-oriented manual transmissions require.

This combination of day-to-day usability with exceptional durability has made the AZ6 a favorite among enthusiasts who demand both performance and reliability, with numerous examples exceeding 200,000 miles while maintaining the precise, mechanical shift feel that makes manual transmissions so engaging to drive.

Also Read: 5 Car Key Systems That Rarely Fail And 5 That Leave You Stranded

5. Mercedes-Benz 722.9 (NAG2) 7-Speed Automatic Transmission

The Mercedes-Benz 722.9 transmission, also known as the New Automatic Gearbox 2 (NAG2), represents German engineering excellence in creating a transmission that maintains exceptional performance characteristics well beyond the 150,000-mile mark.

Introduced in 2003 and utilized across Mercedes’ lineup until the early 2010s, this 7-speed automatic transmission became renowned for its remarkable durability when properly maintained, often maintaining like-new shifting characteristics even as vehicles approached the 200,000-mile threshold.

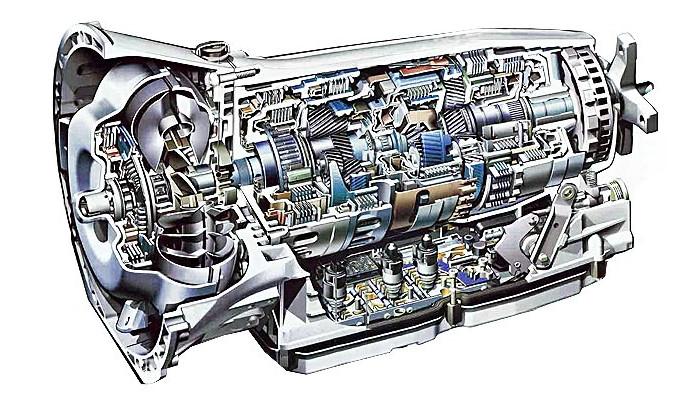

The 722.9’s extraordinary longevity begins with its fundamental mechanical design. Mercedes engineers opted for a planetary gear system with specially hardened components manufactured to extremely tight tolerances.

Unlike competitors who increasingly moved toward lighter materials to improve fuel economy, the 722.9 features robustly constructed planetary carriers and sun gears made from high-grade steel alloys that resist wear even under the substantial torque loads of Mercedes’ larger engines.

The clutch packs utilize innovative friction materials that maintain consistent engagement characteristics over hundreds of thousands of shift cycles, preventing the harsh or slipping shifts that typically develop in aging transmissions.

Perhaps the most significant contributor to the 722.9’s durability is its advanced hydraulic control system. The transmission employs a sophisticated electrohydraulic control unit with precisely calibrated solenoids that maintain accurate pressure regulation throughout the transmission’s life.

This precision prevents the erratic pressure spikes that accelerate wear in valve bodies and clutch packs of lesser transmissions. Even more impressively, the electronic control module continuously adapts shift parameters based on driving style and component wear, effectively compensating for the minimal wear that does occur over extensive mileage.

Mercedes’ approach to transmission cooling also plays a crucial role in the 722.9’s longevity. The transmission features an exceptionally efficient cooling system integrated with the vehicle’s radiator, maintaining optimal fluid temperatures even under heavy loads or extreme operating conditions.

Since excessive heat is the primary enemy of automatic transmission longevity, this superior thermal management prevents the fluid degradation and hardening of seals that typically lead to transmission deterioration.

The transmission also benefits from a larger-than-average fluid capacity, which provides additional thermal stability during operation. The 722.9’s reliability does come with one significant caveat it requires strict adherence to Mercedes’ maintenance schedule, particularly regarding transmission fluid changes.

While Mercedes initially claimed the transmission fluid was “lifetime” (a claim they later retracted), transmission specialists universally recommend fluid changes every 40,000-60,000 miles.

When this maintenance is performed, the 722.9 routinely delivers exceptional longevity. Technicians frequently report opening high-mileage 722.9 transmissions to find internal components that look nearly new, with minimal wear on clutch packs and planetary gear sets even after 150,000+ miles of service.

Most telling is the 722.9’s behavior at high mileage when properly maintained, it typically doesn’t develop the progressive symptoms common to aging transmissions.

There’s no gradual increase in shift harshness, no developing hesitation before engagement, and no erratic shifting between gears. Instead, the transmission maintains consistent, smooth operation throughout its extended service life.

This preservation of new-like performance characteristics, even as the odometer rolls well into six figures, cements the 722.9’s reputation as one of the most durable automatic transmissions ever produced by a European manufacturer.

5 Gearboxes That Grind After 50,000 Miles

These problematic transmissions quickly develop the telltale symptoms of synchromesh failure and bearing wear, transforming what began as crisp shifts into crunching, grinding experiences that worsen by the mile.

Their inadequate synchro materials and questionable tolerances create shift mechanisms that rapidly deteriorate under normal use, developing notchy engagement and resistance that makes daily driving increasingly frustrating.

Owners report needing to adopt compensatory driving techniques like double-clutching and rpm matching just to complete normal shifts—skills that shouldn’t be necessary in modern manual transmissions.

What should be a lasting drivetrain component instead becomes a source of constant anxiety, with many frustrated owners facing expensive rebuild decisions well before their vehicles reach middle age.

1. Nissan CVT (RE0F10A/JF011E)

The Nissan RE0F10A/JF011E Continuously Variable Transmission, commonly referred to simply as the “Nissan CVT,” has earned a notorious reputation as one of the least durable transmissions in modern automotive history.

Found in numerous Nissan vehicles including the Altima, Sentra, Versa, and Juke from the mid-2000s through the mid-2010s, this transmission frequently begins exhibiting serious operational problems before reaching the 50,000-mile mark, with catastrophic failures commonly occurring between 60,000 and 80,000 miles.

The fundamental weakness of Nissan’s CVT design lies in its steel push belt and pulley system. Unlike conventional automatic transmissions that use planetary gear sets, the Nissan CVT relies on a steel belt running between two variable-diameter pulleys to provide an infinite range of gear ratios.

While elegant in theory, this design places enormous strain on the belt and pulley surfaces, particularly during conditions involving rapid acceleration or operating at high loads.

The belt itself consists of hundreds of steel elements that must maintain perfect alignment while transmitting the engine’s torque.

As these components experience inevitable wear, the precisely machined surfaces begin to deteriorate, causing the characteristic “juddering” or “shuddering” sensation that owners typically report as the first symptom of impending failure.

Compounding the mechanical shortcomings is Nissan’s severely inadequate thermal management system for these transmissions.

CVTs generate significant heat during operation due to the constant friction between the belt and pulleys, yet the cooling capacity provided proves woefully insufficient, particularly in hot climates or during demanding driving conditions.

This inadequate cooling accelerates the breakdown of transmission fluid, which in turn hastens the wear of critical components. Nissan’s early insistence that these transmissions contained “lifetime fluid” (a claim they later retracted) only exacerbated the problem, as the deteriorating fluid lost its ability to properly lubricate and cool the system.

The transmission control module (TCM) that manages the CVT’s operation introduces another significant failure point. These electronic units frequently fail prematurely, creating erratic shifting behavior, loss of power, and in some cases, complete transmission lockup during operation.

Even more concerning, the TCM is programmed with shift logic that prioritizes fuel economy over durability, often allowing the transmission to operate at the very edge of its mechanical tolerance a practice that accelerates component wear.

When the inevitable mechanical issues begin to develop, the TCM lacks the adaptive capacity to compensate effectively, unlike more sophisticated transmission control systems.

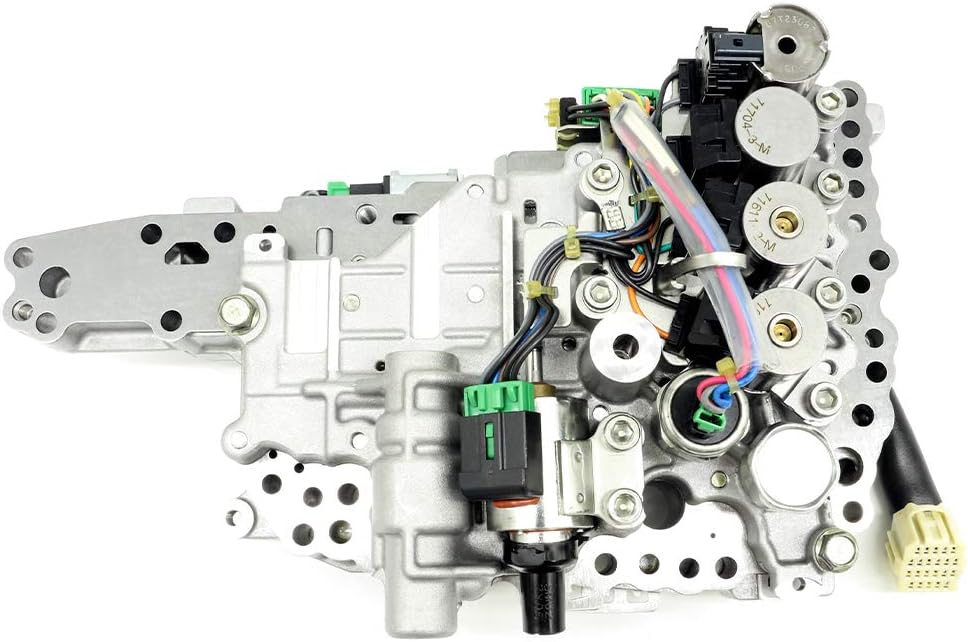

Perhaps most telling is the valve body assembly’s propensity for premature failure. This critical component regulates hydraulic pressure throughout the transmission, and its deterioration manifests as delayed engagement when shifting from park to drive, inconsistent acceleration response, and eventually, complete failure to engage gears properly.

The valve body’s solenoids and pressure sensors frequently develop electrical faults before 50,000 miles, creating erratic operation that places additional stress on the already compromised mechanical components.

Nissan’s response to these widespread failures has been equally problematic. Despite extending the warranty on some affected vehicles, many owners report receiving rebuilt transmissions that exhibit the same issues within 30,000 miles.

The company’s repeated use of similar designs across multiple vehicle generations, despite well-documented reliability problems, has severely damaged consumer confidence.

Professional mechanics and transmission specialists often advise clients to either budget for a replacement transmission when purchasing used Nissan vehicles with this CVT or to avoid these models entirely a damning assessment of a component that should reasonably be expected to last the lifetime of the vehicle with proper maintenance.

2. Ford PowerShift Dual-Clutch Transmission (DPS6)

The Ford PowerShift DPS6 dual-clutch transmission stands as one of the most problematic transmissions in modern automotive history, becoming the centerpiece of class-action lawsuits and damaging Ford’s reputation significantly.

Installed in Ford Focus and Fiesta models between 2011 and 2016, this dry-clutch dual-clutch automatic transmission was marketed as combining the efficiency of a manual with the convenience of an automatic.

However, in practice, it frequently began exhibiting serious operational problems well before reaching 50,000 miles, with some vehicles showing symptoms within months of purchase.

At the heart of the PowerShift’s problems lies its fundamental design philosophy. Unlike most dual-clutch transmissions that utilize wet clutches bathed in cooling and lubricating fluid, Ford opted for a dry-clutch design to maximize fuel efficiency.

This decision proved catastrophic for durability, as the dry clutches generate significant heat during operation without adequate means to dissipate it.

The clutch friction materials deteriorate prematurely under these conditions, leading to the transmission’s signature symptoms: shuddering during acceleration, hesitation when shifting from a stop, grinding noises, and the alarming tendency to slam into gear after momentary disengagement.

The transmission control module (TCM) compounds these mechanical issues with programming that never seemed fully developed for real-world conditions.

The module frequently fails to properly predict appropriate shift timing, resulting in the characteristic “shudder-bang-shudder” sequence as it hunts for the correct gear.

Even more concerning, the TCM and its associated wiring harness are vulnerable to heat and moisture intrusion, leading to electrical failures that can render the transmission inoperable.

When these electrical issues occur, drivers often experience complete loss of forward propulsion with little warning a particularly dangerous scenario in traffic.

The PowerShift’s internal seals and clutch actuators represent another significant failure point. These components frequently begin leaking or malfunctioning before 40,000 miles, causing erratic engagement and disengagement of the clutches.

As these issues progress, drivers experience increasingly unpredictable behavior: the transmission might engage normally one moment, then hesitate dangerously the next, making everyday maneuvers like merging onto highways or crossing busy intersections hazardous propositions.

Ford’s attempts to address these widespread problems through software updates and revised parts proved largely ineffective. Service bulletins issued to dealers included reprogramming the TCM, replacing clutch assemblies, and in some cases, completely rebuilding transmissions.

However, the fundamental design flaws meant that vehicles often returned with the same issues within months of repair. Many owners reported having their transmissions replaced multiple times under warranty, only to experience identical problems with each replacement unit.

The PowerShift saga ultimately culminated in a $77 million class-action settlement in 2020, with Ford acknowledging the widespread issues while avoiding explicit admission of design defects.

Professional mechanics and transmission specialists typically advise potential used car buyers to avoid these model years of Focus and Fiesta entirely, regardless of mileage or service history perhaps the most damning indictment possible of a transmission design.

For existing owners, the typical advice is equally grim: plan for complete transmission replacement with a traditional automatic conversion or trade the vehicle before reaching 60,000 miles when problems typically escalate from annoying to potentially dangerous.

3. GM 8L45/8L90 Eight-Speed Automatic Transmission

The GM 8L45 and 8L90 eight-speed automatic transmissions, introduced with considerable fanfare in 2015, have become notorious examples of modern transmissions that frequently develop significant problems well before reaching the 50,000-mile mark.

Found in numerous GM vehicles, including the Chevrolet Silverado, GMC Sierra, Cadillac CTS, and Chevrolet Camaro, these transmissions promised improved fuel economy and performance but instead delivered a host of durability concerns that have resulted in class-action lawsuits and widespread owner dissatisfaction.

The fundamental issues with these transmissions center around their hydraulic system design and control strategy. Unlike previous GM transmissions known for their bulletproof reliability, the 8L45/8L90 utilizes a complex hydraulic architecture with precisely machined valve bodies and solenoids that control gear selection and clutch engagement.

These components exhibit an alarming tendency to develop wear prematurely, leading to the transmission’s signature symptom: harsh, unpredictable shifts that owners commonly describe as “slamming” or “jerking” between gears.

This behavior typically begins subtly, then progressively worsens as mileage accumulates, becoming particularly pronounced during moderate acceleration or when the transmission attempts to downshift for passing maneuvers.

Perhaps more concerning is the transmission’s propensity for developing what technicians refer to as the “shudder” problem. This manifests as a sensation similar to driving over rumble strips, typically occurring between 25-80 mph when the torque converter clutch engages.

The issue stems from excessive friction in the torque converter causing stick-slip conditions rather than smooth engagement. GM has issued multiple service bulletins addressing this problem, including specialized fluid flush procedures using a specific transmission fluid. However, these remedies often provide only temporary relief, with symptoms frequently returning within 5,000-10,000 miles of treatment.

The transmission control module’s programming compounds these mechanical shortcomings. In an effort to maximize fuel economy to meet increasingly stringent CAFE standards, the transmission is programmed to upshift aggressively and resist downshifting unless absolutely necessary.

This strategy places additional strain on components already operating near their design limits, accelerating wear particularly in the clutch packs and bands that engage each gear.

As these components deteriorate, shift quality continues to degrade, creating a progressive decline in performance that owners find increasingly intolerable.

Internal fluid leaks present another common failure point in these transmissions. The complex network of hydraulic passages, controlled by precision-machined valve bodies, relies on perfect sealing to maintain consistent pressure.

As manufacturing tolerances inevitably vary and components experience wear, internal leakage develops, causing unpredictable pressure drops that manifest as hesitation during gear changes or momentary loss of drive engagement.

These symptoms typically become noticeable between 30,000-50,000 miles and progressively worsen until a complete rebuild or replacement becomes necessary.

GM’s response to these widespread issues has evolved over time. Initial dealer guidance focused on explaining to customers that the harsh shifting was “normal” or “adaptive behavior,” an assertion undermined by the progressive nature of the problems.

Later service bulletins acknowledged specific issues but offered solutions that provided only temporary improvement. Class-action lawsuits filed in multiple states have alleged that GM was aware of these defects yet continued to sell affected vehicles without adequate disclosure or permanent solutions.

For potential used vehicle purchasers, these transmissions have acquired a reputation that demands caution, with mechanics often recommending extensive pre-purchase testing specifically focused on shift quality and torque converter behavior, regardless of the vehicle’s mileage.

4. Chrysler 62TE Six-Speed Automatic Transmission

The Chrysler 62TE six-speed automatic transmission represents a cautionary tale in the automotive world, having developed a reputation for premature deterioration that frequently manifests before vehicles reach the 50,000-mile mark.

Widely deployed across Chrysler, Dodge, and Jeep product lines from the mid-2000s through the 2010s, particularly in minivans and crossovers with V6 engines, this transmission promised smooth operation and improved fuel economy but delivered a litany of reliability concerns that have plagued owners and damaged the resale values of affected vehicles.

The 62TE’s primary weakness lies in its solenoid pack and valve body assembly, components critical to proper hydraulic pressure regulation throughout the transmission.

These precision-machined parts begin to exhibit wear patterns prematurely, resulting in erratic pressure control that manifests as harsh, unpredictable shifts.

Typically beginning with occasional rough engagements that owners might initially dismiss, the problem progressively worsens until the transmission delivers jarring shifts that can be felt throughout the vehicle.

Particularly problematic is the transition from first to second gear and from second to third gear during moderate acceleration, where the transmission frequently hesitates momentarily before slamming into the next gear with excessive force.

Compounding these mechanical issues is the transmission’s inadequate cooling system, particularly in vehicles frequently used for towing or operated in hot climates. The transmission fluid rapidly degrades under these conditions, accelerating wear on friction surfaces throughout the unit.

Despite Chrysler’s initial claims that the transmission fluid was “lifetime” (a claim later quietly retracted), transmission specialists universally recognize that these units require fluid changes at intervals of 30,000 miles or less to mitigate damage a maintenance schedule that many owners remain unaware of until problems develop.

The transmission control module (TCM) introduces another significant failure point in the 62TE. This electronic brain coordinates shifting decisions based on numerous inputs including vehicle speed, throttle position, and engine load.

The units exhibit an alarming tendency to develop erratic behavior or complete failure before 60,000 miles, resulting in unpredictable shifting patterns, failure to engage certain gears, or in some cases, causing the transmission to default to “limp mode” with only second gear available.

When the TCM fails, vehicles often become undrivable, requiring costly replacement of both the electronic module and frequently the accompanying wiring harness.

Perhaps most concerning is the 62TE’s tendency to develop internal mechanical failures that progress rapidly once symptoms appear.

The planetary gear sets, particularly their bearings and thrust washers, show accelerated wear patterns that create increasingly pronounced grinding noises during operation.

This grinding typically begins subtly, occurring only during specific gear transitions, but progressively worsens until it becomes constant during operation. Once these noises develop, catastrophic failure typically follows within 5,000-10,000 miles unless major repairs are undertaken.

Chrysler’s approach to addressing these issues has been problematic for consumers. While the company has issued multiple technical service bulletins acknowledging specific concerns, the recommended repairs frequently provide only temporary relief.

Many owners report multiple transmission rebuilds or replacements within the first 100,000 miles of vehicle operation, with each repair lasting progressively shorter periods.

This experience has led to a cottage industry of aftermarket modification specialists who reinforce known weak points in the transmission during rebuilds tacit acknowledgment that the factory design contains fundamental shortcomings that require correction rather than simple replacement with identical parts.

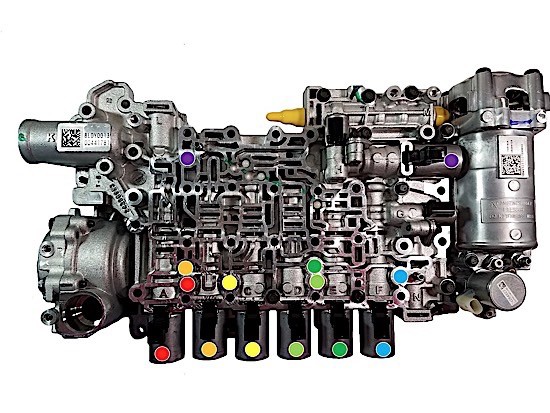

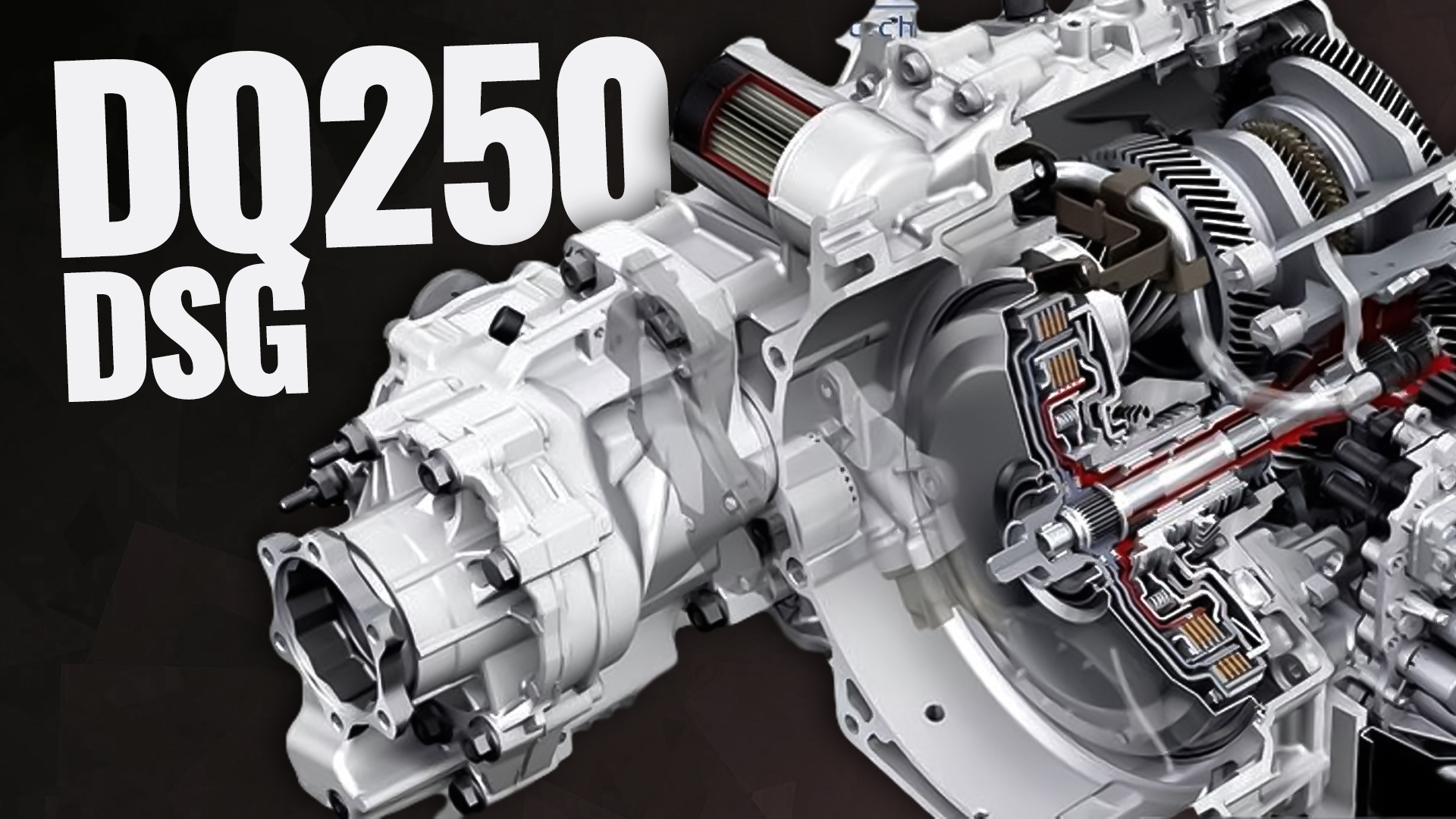

5. Volkswagen DSG (DQ250) Dual-Clutch Transmission

The Volkswagen DQ250 Direct-Shift Gearbox (DSG), while innovative in design and lightning-quick in operation when functioning properly, has earned a problematic reputation for developing significant issues before reaching the 50,000-mile mark.

Found in numerous Volkswagen and Audi vehicles from the mid-2000s through the 2010s, this dual-clutch automated manual transmission promised the efficiency of a manual with the convenience of an automatic.

However, in practice, many units begin exhibiting concerning symptoms remarkably early in their service life, creating frustration for owners and substantial repair bills once the warranty expires.

At the heart of the DSG’s reliability issues lies its mechatronic unit an integrated assembly combining the transmission control module (TCM) with the hydraulic control unit.

This complex component orchestrates the precise timing of clutch engagement and gear selection, requiring exceptionally tight tolerances and flawless electronic operation.

Unfortunately, the mechatronic units frequently develop both electrical and mechanical faults, typically manifesting first as hesitation during acceleration from a stop, followed by increasingly harsh or unpredictable shifts.

As the problems progress, drivers experience alarming symptoms including momentary losses of power during gear changes, complete failure to engage gears, or sudden activation of limp mode accompanied by transmission warning lights.

The dual-clutch assembly itself represents another significant failure point in the DSG. Unlike traditional automatic transmissions that use a torque converter to smooth power delivery, the DSG relies on wet clutches to transfer power.

These clutch packs operate in an oil bath and require precise hydraulic pressure control to engage smoothly. As the clutch friction materials inevitably wear and the hydraulic components develop minor internal leakage, shift quality deteriorates noticeably.

The deterioration typically begins with subtle jerking during low-speed maneuvering, particularly in parking situations or stop-and-go traffic precisely the conditions where smooth operation is most appreciated by drivers.

Perhaps most concerning is the transmission’s internal sealing system. The DSG relies on numerous rubber seals and plastic components that degrade when exposed to the heat cycles and chemical properties of the transmission fluid.

As these seals harden and lose elasticity, they allow internal fluid leakage that creates inconsistent hydraulic pressure. This manifests as increasingly erratic shifting behavior, with the transmission sometimes shifting perfectly and other times delivering harsh engagements or missing shifts entirely.

Once these sealing issues begin, they progressively worsen until a major overhaul becomes necessary. The DSG’s specialized transmission fluid compounds these reliability concerns.

Volkswagen specifies a particular formulation that must be changed at strict 40,000-mile intervals a requirement many owners remain unaware of until problems develop.

The fluid not only lubricates mechanical components but also serves as a hydraulic medium and cooling agent, making its condition critical to proper operation.

As the fluid inevitably degrades between services, it accelerates wear on precision components and deposits varnish on control valves, exacerbating the mechanical issues already developing within the transmission.

Volkswagen’s response to these widespread concerns evolved. After initially resisting acknowledgment of systemic issues, the company eventually extended warranties on mechatronic units in some markets and issued multiple technical service bulletins addressing specific symptoms.

However, these measures provided little comfort to owners experiencing problems beyond the extended warranty period, who often faced repair bills ranging from $3,000 to $6,000 for mechatronic replacement or complete transmission rebuilds.

Most concerning for potential used car buyers, these issues frequently recur even after repairs, suggesting fundamental design limitations rather than isolated component failures.

This pattern has led many European vehicle specialists to recommend preventative mechatronic replacement around 60,000 miles regardless of symptoms an expensive proposition that highlights the transmission’s questionable long-term durability.

Also Read: 5 Clutches That Hold Power And 5 That Burn Out Under Normal Use