The valve cover gasket is a seemingly simple component that plays a critical role in your engine’s health and longevity. Situated between the valve cover and cylinder head, this thin seal prevents oil from escaping the upper portion of the engine where the valvetrain operates.

When functioning properly, these gaskets remain virtually unnoticed, quietly performing their duty for tens of thousands of miles. When they fail, however, the consequences range from unsightly oil leaks to potential engine damage if left unaddressed.

The market offers a vast array of valve cover gaskets made from different materials including cork, rubber, silicone, and multi-layer designs. Their performance varies dramatically based on material quality, design precision, installation technique, and compatibility with specific engine configurations.

Understanding which gaskets typically excel and which tend to fail prematurely can save vehicle owners significant time and expense on unnecessary repairs.

This comprehensive analysis examines five valve cover gaskets renowned for their exceptional reliability and five notorious for premature failure.

For each, we’ll explore the underlying factors contributing to their performance, including material composition, design features, common installation challenges, and the specific vehicle applications where these gaskets are typically found.

Whether you’re a professional mechanic, automotive enthusiast, or simply a vehicle owner seeking to make informed maintenance decisions, this information provides valuable insights into maximizing engine reliability through proper gasket selection.

Five Valve Cover Gaskets Known for Exceptional Reliability

These exceptionally engineered engines feature premium gasket materials and intelligent cover designs that maintain perfect seals through thousands of heat cycles and vibration exposure.

Their precision-machined mating surfaces and optimal bolt patterns create consistent clamping force across the entire sealing area, preventing the corner leaks that plague less thoughtfully designed systems.

From extreme temperature variations to decade-long service intervals, these remarkable gaskets maintain their elasticity and sealing properties well beyond 150,000 miles without weeping or seepage.

Owners report completing entire vehicle lifespans without experiencing the telltale oil stains on driveways or the burning smell of seepage hitting hot exhaust components an impressive achievement in gasket longevity.

1. Toyota 2JZ Series Engine Gaskets

Toyota’s legendary 2JZ engine family, famous for powering vehicles like the Supra and various Lexus models, comes equipped with one of the most reliable valve cover gaskets in automotive history.

The OEM gasket for these inline-six engines features a multi-layer construction with a specialized rubber compound designed to maintain flexibility while resisting oil degradation over extended periods.

What makes these gaskets particularly impressive is their ability to maintain integrity despite the high temperatures generated by these performance-oriented engines.

The gasket’s slightly raised sealing points create optimal compression when the valve cover is torqued to specification, ensuring a perfect seal that often lasts well beyond 100,000 miles without issue.

Toyota engineers designed these gaskets with precise tolerances matched specifically to the 2JZ’s aluminum cylinder head and valve cover. The material composition includes heat-stabilized polymers that resist hardening and embrittlement, common failure modes for lesser quality gaskets.

Additionally, the gasket’s cross-section features strategic thickness variations that accommodate the subtle surface irregularities inherent in the mating components.

Mechanics frequently report removing original 2JZ valve cover gaskets during major service intervals only to find them still in remarkably good condition.

This reliability extends across various operating conditions, from the humid heat of tropical environments to the bitter cold of northern winters. The gasket’s exceptional chemical resistance to oil additives further contributes to its longevity, as modern synthetic oils can often degrade lower-quality gasket materials.

While premium aftermarket options exist, many Toyota specialists maintain that the OEM gasket remains the gold standard for these engines, demonstrating how thoughtful engineering and quality materials can create a simple component that outlasts many more complex engine parts.

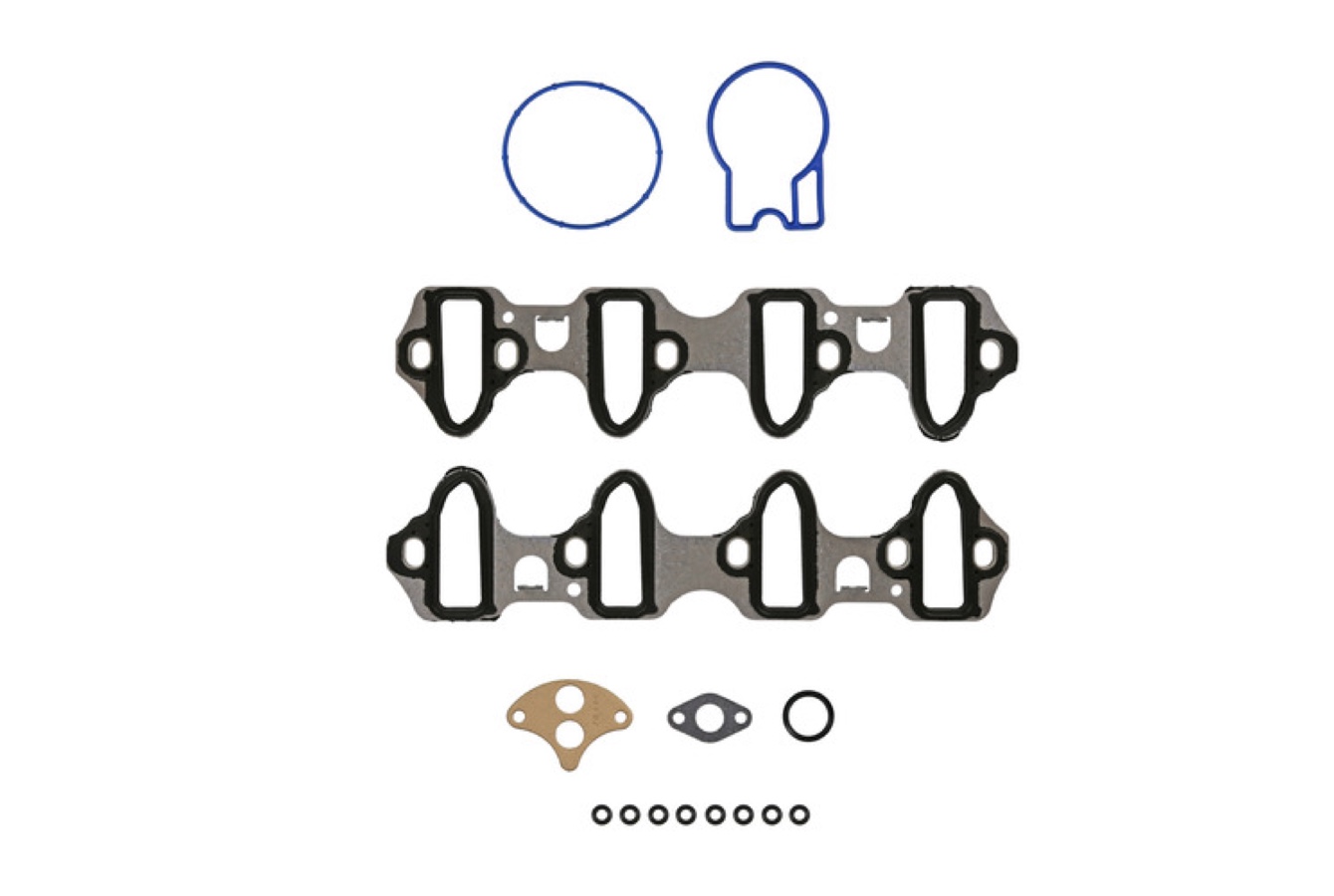

2. Fel-Pro Permadryplus Gaskets for GM LS Engines

The General Motors LS engine family has become one of the most popular powerplants for both production vehicles and custom builds, and the Fel-Pro PermaDryPlus valve cover gaskets have emerged as a go-to solution for reliable sealing in these applications.

These gaskets utilize an advanced molded silicone rubber compound with carrier reinforcement that addresses the unique challenges presented by the LS architecture.

The genius behind the PermaDryPlus design lies in its precision-engineered sealing beads that maintain optimal contact pressure across the entire mating surface.

This becomes particularly important with the LS engine’s aluminum components, which expand and contract at different rates during thermal cycling.

The gasket’s molded rubber construction includes specially formulated additives that resist drying and cracking even when subjected to the extreme temperature variations experienced in performance applications.

Installation quality significantly impacts gasket performance, but the PermaDryPlus design includes self-centering features and integrated alignment tabs that help ensure proper positioning during assembly.

The material’s slight compressibility accommodates minor surface imperfections on the valve cover and cylinder head without compromising seal integrity.

Long-term evaluations by both professional mechanics and DIY enthusiasts consistently show these gaskets maintaining their sealing properties beyond 75,000 miles under normal operating conditions.

Even in modified LS engines with increased oil temperatures and pressure, the PermaDryPlus gaskets typically outperform competitor offerings by significant margins.

Perhaps most impressively, these gaskets have demonstrated remarkable resistance to the chemical effects of modern synthetic oils and additives, which can cause premature deterioration in standard rubber compositions.

The specialized polymer blend maintains its elasticity and sealing properties even after prolonged exposure to these potentially harsh chemicals, contributing significantly to their exceptional service life.

3. Honda K-Series OEM Valve Cover Gaskets

Honda’s reputation for engineering excellence extends to their gasket design, particularly evident in the K-series engines found in vehicles like the Civic Si, Accord, and CR-V.

The OEM valve cover gaskets for these engines exemplify Honda’s attention to detail and commitment to reliability through a sophisticated multi-layer design with precisely calibrated compression characteristics.

The K-series valve cover gasket utilizes a specialized synthetic rubber compound that maintains optimal elasticity across a wide temperature range.

What sets these gaskets apart is their remarkable dimensional stability, which resists the shrinking and warping that plague inferior products. Honda engineers developed this gasket specifically to accommodate the K-series’ aluminum cylinder head and composite valve cover, components that expand and contract at different rates during thermal cycling.

A defining feature of these gaskets is their integrated metal reinforcement in high-stress areas, particularly around mounting bolt holes where crushing forces are concentrated.

This strategic reinforcement prevents over-compression while ensuring adequate sealing pressure is maintained across the entire gasket surface. The gasket’s cross-section includes precisely engineered sealing ribs that create multiple barriers against oil seepage.

Professional mechanics frequently report K-series valve cover gaskets remaining fully functional well beyond 80,000 miles under normal operating conditions.

This exceptional longevity stems partly from Honda’s precision manufacturing processes, which maintain tight tolerances that eliminate the small imperfections that often lead to premature gasket failure.

Another contributing factor to these gaskets’ reliability is their compatibility with Honda’s specific torque sequence and specifications. When installed according to factory guidelines, the gasket compresses uniformly, eliminating the localized stress concentrations that often initiate leakage paths.

This harmony between component design and installation methodology demonstrates Honda’s systems-level approach to engineering reliability into even the simplest components.

4. BMW N52 Valve Cover Gasket with Integrated Grommets

BMW’s naturally aspirated N52 inline-six engine, used extensively in its lineup from 2004 to 2011, features one of the most innovative and reliable valve cover sealing systems in the luxury segment.

What distinguishes this gasket is its integrated design, which incorporates both the main perimeter seal and individual spark plug tube seals (grommets) into a single, precisely engineered component.

The N52 valve cover gasket utilizes a high-grade silicone rubber compound specifically formulated to withstand BMW’s extended oil change intervals and the thermal stresses associated with performance driving.

The material composition includes specialized stabilizers that resist the hardening and embrittlement that typically occur as gaskets age, maintaining crucial elasticity throughout its service life.

BMW engineers designed this gasket with variable thickness sections that create optimal compression across different mating surface areas. Particularly impressive is the transition area between the main perimeter seal and the spark plug tube seals, where stress concentrations often lead to failure in conventional designs.

The integrated approach eliminates these potential weak points by ensuring continuous material flow and uniform compression characteristics. Installation precision is critical with any gasket, but BMW’s design includes self-aligning features that help ensure proper positioning.

The gasket’s cross-section features subtle ridges that engage with corresponding grooves in the aluminum valve cover, preventing misalignment during assembly.

This attention to installation ergonomics significantly reduces the likelihood of technician error leading to premature failure. When installed according to BMW’s torque specifications and sequence, these gaskets typically deliver 60,000 to 70,000 miles of reliable service even under demanding driving conditions.

The gasket’s exceptional dimensional stability prevents the microscopic movement between mating surfaces that often leads to accelerated wear and eventual leakage. This engineering thoroughness exemplifies BMW’s commitment to quality in even the most humble engine components.

Also Read: 5 Clutches That Hold Power And 5 That Burn Out Under Normal Use

5. Subaru EJ Series Cork-Rubber Composite Gaskets

While modern gasket technology has largely moved toward synthetic materials, Subaru’s approach to sealing its iconic boxer engines demonstrates that sometimes traditional methods, when properly executed, can deliver exceptional reliability.

The EJ series engines found in models like the Impreza, Forester, and Outback utilize a specialized cork-rubber composite valve cover gasket that has proven remarkably dependable across multiple generations.

The genius of Subaru’s design lies in its material composition: a precisely calibrated blend of natural cork particles suspended in a heat-resistant rubber matrix.

This hybrid approach leverages cork’s natural compressibility and conformability with rubber’s elasticity and oil resistance. The resulting gasket maintains excellent sealing properties while accommodating the unique thermal expansion characteristics of Subaru’s horizontally opposed engine layout.

What makes these gaskets particularly effective is their ability to conform to the slight surface irregularities inherent in the EJ’s aluminum cylinder heads and valve covers.

The composition allows for just enough compression to create an effective seal without the excessive deformation that leads to premature failure in pure cork designs.

Additionally, the rubber component provides crucial resistance to the deteriorating effects of motor oil and its additives. The gasket’s cross-section features subtle thickness variations that ensure optimal compression across different areas of the mating surface.

This precision engineering addresses the specific pressure distribution needs of the boxer engine’s distinctive head design. Particularly noteworthy is the gasket’s performance in the high-stress areas around the spark plug tubes, where many conventional designs frequently fail.

Professional Subaru technicians consistently report these gaskets delivering reliable service for 60,000 to 80,000 miles under normal operating conditions.

Even in the challenging environment of turbocharged applications like the WRX and STI models, where increased heat and pressure accelerate gasket degradation, the cork-rubber composite demonstrates impressive durability when properly installed and maintained.

Five Valve Cover Gaskets Prone to Premature Failure

These problematic engines develop embarrassing oil leaks from their valve covers well before 50,000 miles, often beginning as minor seepage that progressively worsens into visible drips and concerning puddles.

Their poorly designed cover geometries, inadequate bolt spacing, and substandard gasket materials create perfect conditions for premature failure, particularly at corners and near spark plug tubes.

Owners quickly become familiar with the distinctive smell of burning oil as seepage contacts hot exhaust components, along with the frustration of repeatedly cleaning engine compartments and driveways.

What should be a simple, long-lasting seal instead becomes a recurring maintenance headache, with many engines requiring multiple gasket replacements during normal ownership periods often with increasingly difficult access that drives up labor costs.

1. Mercedes-Benz M272/M273 V6/V8 Engine Gaskets

The Mercedes-Benz M272 V6 and M273 V8 engines, used extensively across the Mercedes lineup from 2004 to 2015, feature valve cover gaskets notorious among mechanics and owners for their premature failure.

These engines power everything from the E-Class and S-Class to the ML and GL SUVs, making their gasket issues particularly widespread in the luxury vehicle market.

The fundamental problem lies in Mercedes’ material selection a silicone rubber compound that initially performs adequately but deteriorates rapidly when exposed to the high temperatures generated by these performance-oriented engines.

The gasket material undergoes accelerated hardening, losing the crucial elasticity needed to maintain a proper seal between the aluminum cylinder head and plastic valve cover.

Complicating matters is the gasket’s demanding operating environment. The M272/M273 engines feature variable valve timing and direct injection technologies that generate substantial heat in the cylinder head area.

This thermal stress, combined with the plastic valve cover’s different expansion rate compared to the aluminum head, creates a particularly challenging scenario for maintaining a consistent seal.

The gasket design itself contributes to the problem. The relatively thin cross-section leaves little margin for material degradation before leakage occurs.

Additionally, the gasket must navigate complex contours around spark plug tubes and mounting points, creating numerous potential failure locations. The hardening process typically begins at these high-stress areas before progressing around the perimeter.

Most alarmingly, these gaskets commonly begin showing signs of leakage as early as 35,000 miles far short of what owners expect from a premium vehicle.

The leakage typically manifests first as oil seepage at the rear of the engine, often dripping onto exhaust components and creating both a fire hazard and a distinctive burning oil smell.

As deterioration progresses, visible oil trails appear on the engine’s sides, requiring costly repair that involves significant labor to access the deeply recessed valve covers.

2. Ford 4.6L and 5.4L Triton V8 Valve Cover Gaskets

Ford’s Triton V8 engines, particularly the 4.6L and 5.4L variants used extensively in F-Series trucks, Expeditions, and Navigators throughout the 2000s, come equipped with valve cover gaskets that have become synonymous with premature failure.

These gaskets exemplify how design limitations and material shortcomings can combine to create a persistent reliability issue. The original equipment gaskets utilize a molded rubber design that fundamentally lacks durability in the specific operating environment of these engines.

The material composition deteriorates rapidly when subjected to the substantial heat cycling these trucks experience, especially during towing or heavy-duty applications. The rubber progressively hardens and shrinks, creating minute gaps between the valve cover and cylinder head that allow oil to escape.

A critical design flaw involves the gasket’s sealing strategy around the spark plug tubes. The Triton’s deep-set spark plugs require extended tubes that pass through the valve cover, creating additional sealing interfaces.

The original gaskets feature relatively thin sections in these critical areas, providing minimal material to maintain sealing pressure as the gasket ages. This thin cross-section leaves little margin for the inevitable compression set and hardening that occurs over time.

Installation challenges further exacerbate the issue. The valve covers on these engines feature numerous mounting points that must be torqued to precise specifications in a specific sequence.

Even minor deviations during installation can create uneven gasket compression, accelerating deterioration in over-stressed areas. Additionally, the plastic valve covers commonly used on these engines tend to warp slightly over time, further compromising the gasket’s ability to maintain a consistent seal.

The failure typically manifests initially as oil seepage around the rear portions of the valve covers, often dripping down onto the exhaust manifolds and creating a distinctive burning smell.

As the condition worsens, visible oil trails appear on the engine, and in severe cases, significant oil consumption can occur. Most concerning for owners, these failures commonly begin occurring between 50,000 and 70,000 miles, well short of the expected service life for major engine components.

3. GM 3.6L “High Feature” V6 Valve Cover Gaskets

General Motors’ widely deployed 3.6L “High Feature” V6 engine serves as the powerplant for numerous vehicles across the Cadillac, Chevrolet, Buick, and GMC lineups.

While generally regarded as a decent performer, this engine’s valve cover gasket system has become infamous among mechanics for its consistent tendency toward premature failure, causing significant owner frustration across multiple vehicle platforms.

The fundamental issue stems from GM’s decision to use a relatively thin molded rubber gasket design that lacks sufficient material mass to maintain resilience throughout normal service intervals.

The gasket material initially performs adequately but undergoes accelerated degradation when subjected to the engine’s operating temperatures, particularly in the high-stress areas adjacent to exhaust components.

The rubber compound progressively hardens and shrinks, losing the elasticity needed to accommodate the subtle movements between the valve cover and cylinder head during thermal cycling.

Compounding this material shortcoming is a design architecture that places extraordinary demands on the gasket. The 3.6L engine features a complex cylinder head design with numerous bolt holes and contours that the gasket must navigate.

Particularly problematic are the areas around the integrated coil pack mounting points, where the gasket must maintain sealing integrity despite the additional stress concentrations created by these components.

The plastic valve covers themselves contribute significantly to the problem. Unlike metal covers that maintain dimensional stability, these plastic components experience subtle warping over time as they’re repeatedly heated and cooled.

This gradual deformation creates uneven pressure distribution across the gasket surface, accelerating deterioration in areas where compression is compromised.

Most frustratingly for owners, these gaskets typically begin showing signs of failure between 40,000 and 60,000 miles far sooner than expected for a modern engine.

The leakage pattern is distinctive, usually beginning at the rear corners of the valve covers before progressively worsening around the perimeter. Oil typically drips onto the exhaust manifold, creating not just unsightly leaks but also smoke and odors that often lead owners to fear more serious engine problems.

4. Chrysler/Dodge 3.5L V6 Valve Cover Gaskets

The 3.5L V6 engine, widely used across Chrysler and Dodge vehicles from the late 1990s through the 2000s, features valve cover gaskets that have become notorious among mechanics and owners for their consistent tendency toward premature failure.

Found in popular models like the Chrysler 300, Dodge Charger, and various minivans, these gaskets exemplify how suboptimal material selection and design decisions can create persistent reliability issues.

The original equipment gaskets utilized a relatively thin rubber compound that fundamentally lacked the durability required for long-term performance.

This material undergoes accelerated degradation when exposed to the engine’s normal operating temperatures and the chemical effects of modern motor oils.

The deterioration process typically begins with hardening and shrinking, causing the gasket to lose its ability to conform to the minor surface irregularities in the mating components.

A significant design limitation involves the gasket’s cross-sectional profile, which lacks the robust sealing beads and variable thickness sections found in more modern designs.

This simplified profile provides insufficient material in high-stress areas, particularly around bolt holes where compression forces are concentrated.

As the gasket hardens, these areas become the initial failure points from which oil leakage progressively spreads. Installation challenges further contribute to the problem. The valve cover mounting system requires precise torque application across multiple fasteners.

Even minor deviations from specifications can create uneven gasket compression, accelerating deterioration in overstressed areas. Additionally, the aluminum cylinder heads used in these engines are relatively susceptible to minor warping over time, creating subtle but problematic changes in the sealing surface geometry.

Perhaps most frustrating for owners is the typically early onset of these failures. The gaskets commonly begin showing signs of leakage between 40,000 and 60,000 miles well before most owners would expect to replace such components.

The failure pattern usually begins with slight seepage at the corners of the valve covers before progressing to more noticeable drips that typically land on exhaust components, creating distinctive burning oil odors and potential fire hazards in severe cases.

5. BMW N54/N55 Turbocharged Inline-6 Valve Cover Gaskets

BMW’s highly regarded N54 and N55 turbocharged inline-six engines, used extensively in vehicles like the 335i, 535i, and X5 from 2006 through the mid-2010s, come equipped with valve cover gaskets that have become infamous for their premature deterioration.

These engines, while praised for their performance capabilities, exemplify how even premier manufacturers can struggle with seemingly basic sealing challenges.

The fundamental issue lies in BMW’s material selection a silicone-based compound that initially performs adequately but rapidly deteriorates under the extreme thermal conditions generated by these turbocharged engines.

The high operating temperatures, particularly during aggressive driving or in hot climates, accelerate the gasket material’s aging process, causing it to harden and shrink progressively.

This loss of elasticity compromises the gasket’s ability to maintain consistent contact pressure against the aluminum cylinder head and plastic valve cover.

The gasket’s demanding operating environment significantly contributes to its early failure. The N54/N55 engines combine direct injection with turbocharging, technologies that generate substantial heat in the cylinder head area.

This thermal stress, coupled with the significant pressure pulsations created during boost conditions, subjects the gasket to mechanical and thermal cycling far beyond what most conventional engines experience.

Design limitations further exacerbate the problem. The gasket must navigate a complex sealing path around numerous obstacles, including integrated ignition coil mounting points and PCV system connections.

These intricate contours create multiple potential failure locations where initial oil seepage typically begins. Additionally, the plastic valve cover itself tends to undergo subtle warping over time, further compromising the gasket’s ability to maintain a consistent seal.

Most concerningly, these gaskets routinely begin failing between 40,000 and 60,000 miles exceptionally early for a premium vehicle. The leakage pattern typically begins at the rear of the engine near the firewall, making detection challenging until the problem has progressed significantly.

As the condition worsens, oil can drip onto hot exhaust components, creating not just unsightly leaks but also distinctive burning smells and potential fire hazards. The repair process requires substantial labor, as numerous components must be removed to access the deeply recessed valve cover.

Also Read: 5 Gearboxes That Feel New At 150K And 5 That Grind After 50K