The exhaust system is one of the most critical components of your vehicle, responsible for directing harmful emissions away from the passenger compartment, reducing engine noise, and in many cases, enhancing performance.

However, not all exhaust systems are created equal. The harsh conditions they endure extreme temperature fluctuations, constant exposure to moisture, corrosive chemicals from the road, and physical impacts make them particularly susceptible to deterioration.

For vehicle owners, understanding which exhaust setups offer superior longevity and which might require premature replacement can save significant time, money, and frustration.

In this comprehensive guide, we’ll explore five exhaust system configurations known for their exceptional resistance to rust and deterioration, standing the test of time even in challenging environments.

We’ll also examine five common exhaust setups notorious for their premature failure, often leaving drivers stranded or facing costly repairs much sooner than expected.

Whether you’re a daily commuter concerned about maintenance costs, an off-road enthusiast needing durability in extreme conditions, or a performance car owner looking for reliability alongside horsepower gains, this information will help you make informed decisions about your vehicle’s exhaust system.

Let’s take a look at the world of exhaust durability and discover what separates the long-lasting performers from the early failures.

Durable Exhaust Setups That Resist Rust

These engineering marvels feature premium stainless steel construction and intelligent design choices that maintain structural integrity and appearance through years of exposure to moisture and road salt.

Their seamless manufacturing techniques and advanced metallurgy create exhaust systems that resist the perforation and flaking that typically transform lesser systems into crumbling rust sculptures.

From snow belt states to coastal environments, these exceptional exhausts maintain their original appearance and performance without developing the telltale rusty stains on driveways or increasing noise from deteriorating connections.

Owners report completing entire vehicle lifespans with factory original exhaust components an impressive achievement that eliminates a traditionally expected replacement expense while maintaining proper backpressure and sound characteristics.

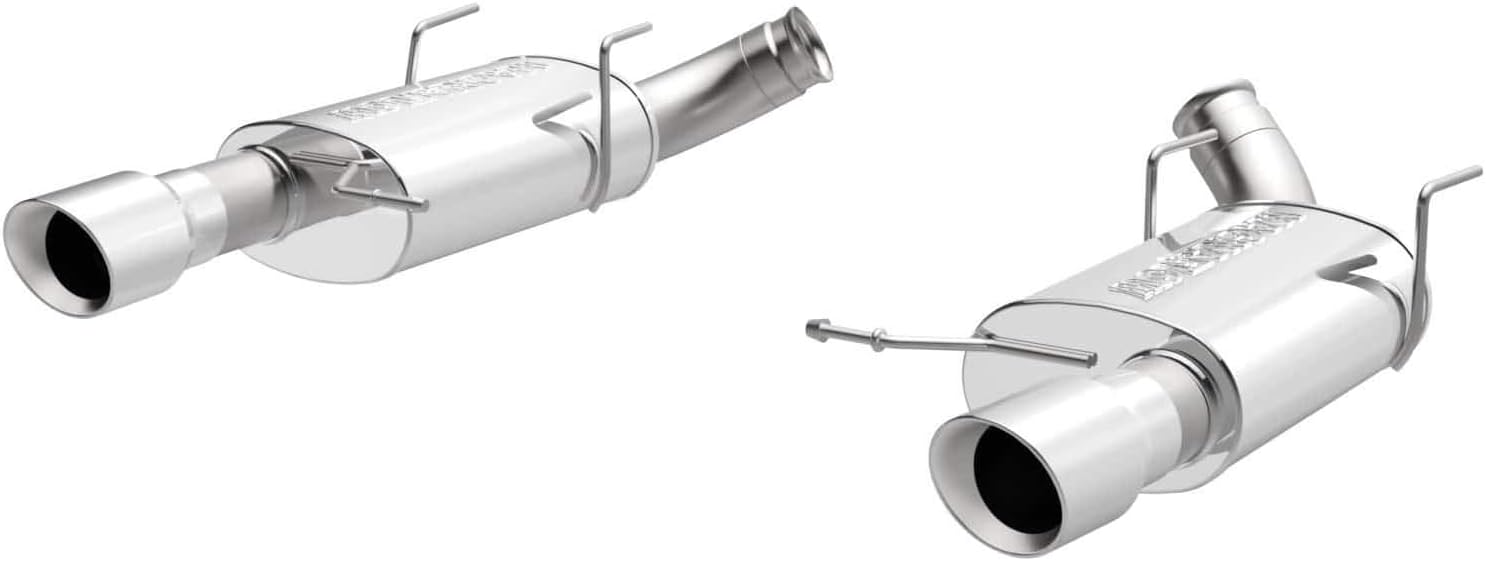

1. Stainless Steel Performance Systems

Stainless steel exhaust systems represent the gold standard for durability and corrosion resistance in the automotive world. These systems typically utilize 304 or 316 grade stainless steel, with the latter offering superior resistance to salt and road chemicals.

The secret behind their impressive longevity lies in the chromium content of stainless steel typically 10.5% or higher which forms a passive chromium oxide layer on the surface that self-heals when damaged, providing continuous protection against corrosion.

High-quality stainless steel exhaust systems, such as those manufactured by companies like Borla, Magnaflow, and Corsa, often feature mandrel-bent tubing that maintains consistent diameter throughout curves, enhancing both flow characteristics and structural integrity.

These systems typically use precision TIG welding at junction points, creating strong, clean welds that resist failure even under significant thermal stress and vibration.

Even after a decade of use in harsh winter climates where road salt is common, these systems often show minimal deterioration beyond a slight dulling of their original luster.

The durability advantages extend beyond mere rust resistance. Stainless steel exhaust components maintain their structural integrity at higher temperatures than mild steel alternatives, reducing the likelihood of warping during extreme heat cycles.

This temperature stability prevents the formation of stress cracks that often initiate corrosion in lesser systems. Additionally, premium stainless exhaust systems frequently incorporate floating ball connections or slip joints with graphite gaskets, allowing for thermal expansion without placing stress on fixed connection points.

While the initial investment in a stainless steel exhaust system may be two to three times that of a standard replacement system, the total cost of ownership proves economical for vehicles kept beyond five years.

Many stainless systems are backed by lifetime limited warranties against manufacturing defects and perforation due to corrosion, reflecting manufacturers’ confidence in their longevity.

For performance enthusiasts, these systems offer the added benefit of maintaining optimal flow characteristics throughout their extended service life, without the gradual internal corrosion that can affect performance in lesser systems.

The primary drawback to stainless steel systems is their premium price point, but for those seeking the ultimate in exhaust longevity, particularly in coastal regions or areas with harsh winters, they represent the most dependable solution available.

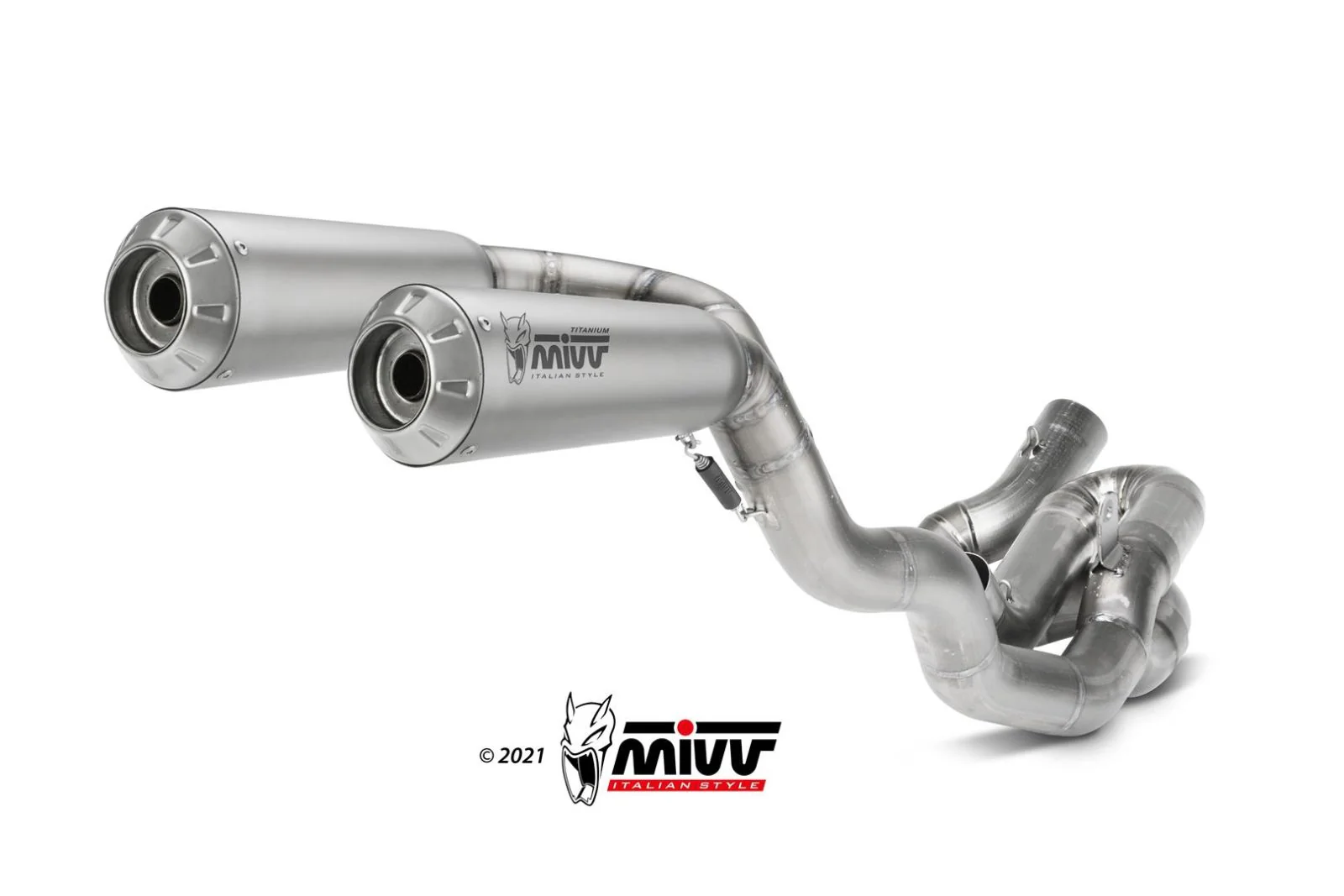

2. Titanium Exhaust Systems

Titanium exhaust systems represent the pinnacle of lightweight durability in the exhaust world, offering virtually complete immunity to rust and corrosion while weighing approximately 40% less than comparable stainless steel systems.

This remarkable material creates exhaust components that can endure decades of service with minimal signs of degradation, even in the harshest environments.

The corrosion resistance of titanium stems from its ability to instantly form a stable, protective oxide layer when exposed to oxygen, creating a shield that prevents further oxidation regardless of environmental conditions.

Primarily found in high-performance and exotic applications due to their premium cost, titanium exhaust systems from manufacturers like Akrapovič, GReddy, and Inconel combine unmatched durability with significant weight reduction.

This weight savings proves particularly beneficial for performance applications, where reducing unsprung mass and overall vehicle weight translates to measurable improvements in acceleration, handling, and braking.

Additionally, titanium possesses exceptional heat management characteristics, maintaining its structural integrity at temperatures that would compromise other materials.

The fabrication process for titanium exhaust systems requires specialized equipment and expertise, as the material demands precise temperature control during welding to prevent contamination that could compromise its integrity.

Modern titanium systems typically utilize Grade 2 commercially pure titanium or Grade 9 titanium alloy (Ti-3Al-2.5V), with the latter offering enhanced strength characteristics.

Many premium titanium systems feature ceramic coating on internal surfaces to optimize heat retention and flow characteristics, while external surfaces develop a distinctive blue-purple patina when subjected to high temperatures a hallmark signature prized by enthusiasts.

Beyond their corrosion resistance, titanium exhaust systems excel in damping vibration, contributing to reduced drone and a more refined exhaust note.

Their resistance to thermal fatigue means they maintain their physical properties through countless heat cycles without developing stress fractures common in lesser materials.

For vehicles operated in coastal environments with salt air exposure or regions with aggressive winter road treatments, titanium systems can outlast multiple sets of conventional exhaust components and often survive the usable lifespan of the vehicle itself.

Though the initial investment in a titanium exhaust system can be substantial often three to four times the cost of comparable stainless steel alternatives their extreme longevity, performance benefits, and unique aesthetic characteristics make them the ultimate choice for those seeking both durability and distinction in their exhaust system.

3. Ceramic-Coated Exhaust Systems

Ceramic-coated exhaust systems represent a technological marvel in the battle against corrosion and premature exhaust failure. These systems utilize a base material typically stainless steel or aluminized steel that receives a specialized ceramic coating applied through thermal spraying techniques.

This ceramic layer, often comprised of zirconia, alumina, or proprietary ceramic composites, creates a virtually impenetrable barrier against moisture, salt, road chemicals, and other corrosive elements that typically attack exhaust components from the outside in.

The ceramic coating process involves meticulously cleaning and preparing the metal surface before applying the ceramic material at temperatures exceeding 1,800°F.

This creates a molecular bond between the coating and the underlying metal that can withstand extreme temperature fluctuations without cracking or separating.

Premium ceramic coatings from companies like Cerakote, Jet-Hot, and Swain Tech Coatings can withstand continuous operating temperatures up to 2,000°F while providing a thermal barrier that keeps more heat inside the exhaust system improving flow characteristics while reducing underbody temperatures.

Beyond their exceptional corrosion resistance, ceramic-coated exhaust systems offer significant performance and longevity advantages. By maintaining higher exhaust gas temperatures, these systems promote more complete scavenging of exhaust gases, potentially improving horsepower and torque output.

The thermal insulation properties also reduce heat soak to nearby components, extending the life of heat-sensitive parts in the engine bay. When applied to both interior and exterior surfaces, ceramic coatings provide dual-protection against both internal corrosion from condensation during cold starts and external corrosion from environmental exposure.

Many ceramic-coated exhaust systems maintain their protective properties and appearance for 8-10 years under normal use conditions, far outlasting conventional painted or bare metal alternatives.

The coating’s resistance to chipping and abrasion means it continues protecting even after minor impacts from road debris. For off-road applications or vehicles with minimal ground clearance, this resilience proves particularly valuable.

Some ceramic coatings also offer aesthetic advantages, available in a range of colors and finishes from subtle matte black to eye-catching metallic hues that maintain their appearance despite the extreme conditions.

While ceramic coating adds approximately 15-25% to the cost of an exhaust system, the extended service life and potential performance benefits make it a cost-effective investment for those planning long-term vehicle ownership.

For ultimate protection, combining a ceramic coating with a high-quality stainless steel base material creates an exhaust system that can potentially outlast the vehicle itself.

4. Aluminized Steel Systems with Thermal Barriers

Aluminized steel exhaust systems represent an excellent middle-ground solution combining reasonable durability with affordability. These systems utilize steel that has undergone a hot-dip process, coating it with an aluminum-silicon alloy that provides significant corrosion protection at a fraction of the cost of stainless steel or titanium alternatives.

The aluminum coating creates a sacrificial barrier that corrodes preferentially to the underlying steel, substantially extending system life even in challenging environments.

What elevates premium aluminized steel systems to an exceptional durability status is the integration of thermal barrier technologies. Advanced systems employ multi-layer construction with air gaps or heat-reflective materials between the inner and outer pipes, creating a thermal barrier that serves multiple protective functions.

This design keeps exhaust gases hotter within the system, reducing condensation during cold operation a primary initiator of internal corrosion. Simultaneously, it prevents heat-induced degradation of the external aluminum coating, maintaining its protective properties longer than traditional single-wall designs.

Manufacturers like Walker, Dynomax, and Flowmaster produce enhanced aluminized systems with wall thicknesses up to 16-gauge (approximately 1.5mm), significantly thicker than economy-grade alternatives.

This additional material provides a corrosion allowance that extends functional life even after the protective coating begins to degrade.

Leading systems also incorporate specialized mounting hardware using dissimilar metals isolation techniques to prevent galvanic corrosion at attachment points a common failure mode in lesser exhaust systems.

Installation details significantly impact the longevity of aluminized systems. Professional installation with proper alignment eliminates stress points that could lead to premature cracking and subsequent corrosion.

High-quality aluminized systems typically employ advanced hanger designs with polyurethane insulators that absorb vibration while allowing proper thermal expansion, preventing the metal fatigue that often initiates corrosion sites.

Some premium systems also feature drain holes at strategic low points, allowing condensation to escape rather than pooling against internal surfaces.

With proper care including allowing full warm-up cycles to evaporate condensation and avoiding prolonged exposure to standing water quality aluminized systems with thermal barriers can provide 5-7 years of service in moderate climates and 3-5 years even in regions with harsh winters.

While this falls short of stainless steel or titanium longevity, it represents excellent value for vehicles with intermediate ownership horizons, offering 80% of the durability at roughly 40% of the cost of premium stainless alternatives.

Also Read: 5 Gearboxes That Feel New At 150K And 5 That Grind After 50K

5. Composite Exhaust Systems with Carbon Fiber Components

Composite exhaust systems represent the cutting edge of exhaust technology, combining traditional metals with advanced materials like carbon fiber, inconel, and ceramic matrix composites to create exceptionally durable yet lightweight components.

These hybrid systems strategically place materials where their specific properties provide maximum benefit: corrosion-resistant metals for high-temperature exhaust manifolds and catalytic converters, with composite materials for mufflers, resonators, and in some cases, exhaust tips and intermediate piping.

Carbon fiber reinforced silicon carbide (C/SiC) and other ceramic matrix composites represent a revolutionary advancement in exhaust technology. These materials offer virtually complete immunity to corrosion while providing strength-to-weight ratios that exceed even titanium.

Originally developed for aerospace and Formula 1 applications, these composites are now finding their way into premium aftermarket exhaust systems from manufacturers like Akrapovič, FI Exhaust, and Fabspeed.

The inherent properties of these materials thermal stability, corrosion resistance, and vibration damping make them ideal for exhaust applications where conventional materials struggle.

The manufacturing process for composite exhaust components involves precision layering of carbon fiber or other reinforcement materials within a ceramic or metal matrix, often utilizing autoclave curing under precisely controlled pressure and temperature conditions.

This creates components with tailored performance characteristics that simply cannot be achieved with homogeneous metal construction. Many systems utilize selective reinforcement, with additional material layers in high-stress areas while maintaining minimal wall thickness elsewhere to optimize both durability and weight.

Beyond corrosion resistance, composite exhaust systems excel at thermal management. Their superior insulation properties maintain optimal exhaust gas temperature for improved performance while simultaneously reducing heat radiation to surrounding components.

This temperature stability minimizes thermal stress cycling, eliminating a primary cause of crack formation that leads to premature failure in conventional systems.

Some advanced composite systems incorporate active thermal management with heat-reflective layers that adapt their properties based on exhaust temperature, providing optimal performance across the entire operating range.

While the initial cost of composite exhaust systems can be significant often comparable to or exceeding titanium systems their potential for extreme longevity and performance benefits make them increasingly popular for high-end performance applications.

For vehicles operated in particularly harsh environments or those subjected to extreme performance demands, composite exhaust systems offer durability advantages that conventional materials simply cannot match, potentially maintaining like-new performance characteristics for well over a decade of regular use.

Problematic Exhaust Setups Prone to Early Failure

These problematic systems develop catastrophic rust issues within just a few years, often beginning with the distinctive hollow sound of broken hangers before progressing to complete sections separating during normal driving.

Their inadequate material choices and poor manufacturing techniques create perfect conditions for accelerated corrosion, particularly at weld joints and flex points where moisture can accumulate.

Owners in northern states report the distinctive horror of hearing their exhaust suddenly dragging on the pavement after hitting a minor bum,p sometimes with as little as three winters of salt exposure.

What should be a long-lasting emissions and sound control system instead becomes an embarrassing reliability liability, with many frustrated owners facing complete exhaust replacement well before their vehicles reach middle age.

1. Mild Steel Systems with Poor Coatings

Mild steel exhaust systems with inadequate protective coatings represent perhaps the most common source of premature exhaust failure across the automotive world.

These budget-oriented systems, often installed as low-cost replacements or featured on economy vehicles, utilize basic carbon steel with minimal corrosion protection typically just a thin layer of high-temperature paint or basic zinc phosphating.

This nominal protection begins deteriorating almost immediately upon installation, setting in motion a rapid degradation process that often results in system failure within 2-3 years, or even sooner in harsh environments.

The fundamental weakness stems from mild steel’s inherent vulnerability to oxidation when exposed to moisture, road chemicals, and the normal byproducts of combustion.

Without robust protection, the metal surface quickly develops pinhole corrosion sites, particularly at low points where condensation collects during cooling cycles.

This moisture combines with carbon and sulfur compounds from exhaust gases to form mild acids that accelerate the corrosion process from inside the system, even while external corrosion advances from exposure to splash water, salt, and road grime.

The thin wall construction typical of economy systems often using 18 or 20-gauge steel (0.9-1.1mm thick) provides minimal corrosion allowance, meaning even slight surface degradation quickly compromises structural integrity.

Poor manufacturing processes compound these material deficiencies. Many budget systems employ crush-bent tubing rather than mandrel bending, creating stress points and wall thinning at curves that become primary failure locations.

Welds on inexpensive systems often lack complete penetration or proper preparation, leaving microscopic gaps where moisture can penetrate between joined surfaces.

The mounting hardware typically uses basic rubber hangers that deteriorate from heat and environmental exposure, allowing excessive movement that stresses connections and accelerates fatigue failure.

The coating failures on these systems follow predictable patterns. Initial breakdown typically occurs near connections and welds where thermal stress is greatest, creating expanding zones of surface rust that eventually penetrate the material.

Mufflers and resonators, with their complex internal structures and condensation-trapping chambers, usually fail first either through internal baffle collapse or external shell perforation.

Once perforation occurs, exhaust leaks accelerate deterioration of surrounding components through increased heat concentration and changed flow dynamics.

Vehicle owners often first notice problems with these systems through increasing noise levels, followed by distinctive exhaust odors in the cabin, decreased fuel efficiency, and eventually visible exhaust leaks or dragging components.

While their low initial cost makes these systems appealing for budget-constrained repairs, their short service life ultimately results in higher long-term ownership costs through frequent replacement cycles a classic example of false economy in automotive maintenance.

2. Custom Welded Systems with Dissimilar Metals

Custom welded exhaust systems incorporating dissimilar metals represent a significant risk for premature failure despite often being created with performance enhancement intentions.

These systems, frequently assembled by well-meaning but metallurgically uninformed builders, create the perfect conditions for accelerated galvanic corrosion an electrochemical process that occurs when dissimilar metals come into electrical contact in the presence of an electrolyte.

In exhaust applications, condensation from exhaust gases provides the perfect electrolyte medium, while the different metals establish the necessary electrical potential difference.

The most problematic combinations involve joining metals with widely separated positions on the galvanic series. For example, pairing stainless steel components with galvanized hangers, connecting aluminum mufflers to steel pipes, or utilizing brass fittings with steel components creates significant galvanic potential.

In these scenarios, the less noble metal (lower on the galvanic series) becomes the sacrificial anode, corroding at an accelerated rate that can cause failure within months rather than years.

This effect is particularly pronounced in performance applications where systems regularly cycle between extreme temperatures, creating condensation during cool-down periods that activates the galvanic cell.

Beyond galvanic concerns, many custom systems suffer from improper welding techniques. When joining dissimilar metals, specialized welding procedures and compatible filler materials are essential to create metallurgically sound connections.

Amateur or inexperienced welders often lack the specialized equipment and knowledge required for these challenging joints.

Inadequate purging of oxygen during welding of stainless components, improper filler material selection, or incorrect heat input can create brittle intermetallic compounds or heat-affected zones with compromised corrosion resistance, even when the base metals themselves would otherwise be durable.

The physical properties of different metals further complicate custom systems. Materials expand and contract at different rates when heated, creating significant mechanical stress at connection points during normal operation.

For example, stainless steel expands approximately 50% more than carbon steel when heated, while aluminum expands nearly twice as much. Without proper expansion joints or flexible connections to accommodate these differences, connections can crack or break loose over time, especially in systems that experience significant temperature fluctuations.

Custom systems also frequently suffer from design flaws that accelerate deterioration. Improper routing that creates low spots where condensation collects, insufficient clearance from undercarriage components that creates damage from normal suspension travel, or inadequate support leading to vibration fatigue can all contribute to premature failure.

When these design deficiencies combine with metallurgical incompatibilities, even well-intentioned performance upgrades can result in systems that deteriorate far more quickly than the factory components they replaced.

3. Downpipe-Back Systems with Factory Front Sections

Partial exhaust upgrades that retain factory front sections while replacing rear components often create a perfect storm of conditions leading to premature failure.

These “downpipe-back” or “cat-back” systems represent a common compromise for enthusiasts seeking improved sound or modest performance gains without the expense or emissions compliance concerns of a complete system replacement.

However, this mixing of old and new components frequently results in accelerated deterioration of both the original and aftermarket sections through several specific mechanisms.

The fundamental issue stems from the inherent age and wear differential between components. Factory exhaust manifolds, catalytic converters, and front pipes on vehicles with moderate mileage have typically already undergone years of thermal cycling and initial corrosion.

When connected to new aftermarket components, these aged sections become the weak link in the system chain. The connection point between old and new components typically a flange joint or slip connector creates a stress concentration point where different thermal expansion rates, vibration patterns, and corrosion potentials meet.

Exhaust system flow dynamics further complicate these hybrid setups. New aftermarket sections typically feature larger diameter piping and less restrictive mufflers than factory components, creating a change in backpressure and flow velocity at the transition point.

This altered flow characteristic can create turbulence and exhaust gas temperature changes that concentrate heat at the connection point between systems.

The thermal stress at this junction accelerates metal fatigue and breaks down gaskets or sealants, eventually leading to leaks that further accelerate deterioration through concentrated heat exposure and increased oxygen availability for corrosion.

The electrical properties of aging exhaust systems also contribute to premature failure in hybrid setups. As factory components age, their electrical resistance often increases due to surface oxidation and deteriorating ground connections.

When connected to new components with different electrical resistance characteristics, small electrical currents can develop between sections, effectively creating a weak galvanic cell that accelerates corrosion at connection points.

This effect is particularly pronounced when the factory and aftermarket sections use different base metals or protective coatings. Installation challenges with hybrid systems frequently introduce additional failure points.

Achieving proper alignment between aging factory components that have settled or shifted over time and rigid new aftermarket sections often requires excessive force during assembly.

This can damage flanges, warp connecting points, or stress factory hangers beyond their remaining service capacity. Many installers resort to extending or modifying connecting points, introducing amateur welds or additional clamps that create new vulnerability points in the system.

For enthusiasts operating within budget constraints, a more durable approach involves saving for a complete system replacement rather than pursuing the false economy of sectional upgrades that often require complete replacement within 1-2 years due to these accelerated failure mechanisms.

4. Ultra-Lightweight “Race” Systems for Street Use

Ultra-lightweight “race” exhaust systems designed primarily for competition environments frequently suffer premature failure when pressed into daily street service.

These systems, optimized for absolute minimum weight and maximum flow rather than longevity, employ design compromises that make them poorly suited to the diverse conditions encountered in everyday driving.

While their performance on the track may be impressive, their durability on public roads often proves disappointing for owners expecting race-inspired sound without race-like maintenance intervals.

The most significant vulnerability of these systems stems from their minimal wall thickness. To achieve extreme weight reduction, many race-oriented systems utilize tubing as thin as 0.8mm (21-gauge) compared to the 1.5-2.0mm thickness common in quality street systems.

This minimal material provides almost no corrosion allowance even slight surface oxidation can quickly compromise structural integrity. The situation worsens with titanium race systems, which often use even thinner material (as little as 0.6mm) relying on the metal’s inherent strength rather than bulk for structural integrity.

While adequate for controlled race environments with regular inspection, this minimal thickness provides insufficient durability for street exposure to impacts, vibration, and corrosive elements.

Race systems typically eliminate or minimize components essential for street longevity. Flexible joints that accommodate engine movement and prevent stress cracking are often replaced with solid connections that transmit all movement stress to mounting points and welds.

Resonators and expansion chambers that prevent harmonic vibration in street systems are frequently eliminated to save weight, resulting in specific frequencies that can cause metal fatigue over time.

Proper heat shielding found in street systems is typically minimized or eliminated, exposing surrounding components and the vehicle underbody to excessive heat that accelerates aging of bushings, wiring, and other heat-sensitive components.

The materials and construction methods in race systems often prioritize high-temperature performance over corrosion resistance. Many utilize specialized heat-resistant alloys like Inconel or thin-wall stainless that excel in managing extreme temperatures but offer less protection against the wet-dry cycles encountered in street use.

Welding techniques optimized for weight reduction often use minimal material and smaller attachment points that create stress concentrations vulnerable to vibration fatigue.

Drainage considerations vital for street systems are frequently overlooked, creating collection points for moisture that accelerate internal corrosion.

The installation of race systems on street vehicles introduces additional complications. Many race-oriented systems assume the presence of other competition modifications like solid engine mounts, reinforced subframes, or modified suspension geometry.

When installed on otherwise stock vehicles, the different vibration characteristics and range of movement can stress these minimalist systems beyond their design parameters.

Ground clearance issues are also common, with race systems designed for smooth track surfaces suffering damage from everyday road hazards like speed bumps, driveway entrances, and road debris.

For enthusiasts seeking race-inspired sound and performance, street-oriented systems from reputable manufacturers offer a far more durable alternative to true competition-grade components, delivering 90% of the performance benefit with exponentially better longevity under real-world conditions.

5. Economy “Universal Fit” Replacement Systems

Economy “universal fit” replacement exhaust systems represent perhaps the most problematic category of exhaust components, frequently failing within months rather than years despite their appealing low initial cost.

These systems, typically sold through discount auto parts retailers or online marketplaces at prices 50-70% below vehicle-specific alternatives, attempt to serve multiple vehicle applications through a one-size-fits-most approach that compromises virtually every aspect of proper exhaust system design and function.

The fundamental structural weakness of universal systems stems from their adaptable nature. Rather than precisely matching vehicle-specific mounting points, pipe routings, and clearance requirements, they rely on adjustable hangers, extension pipes, and compression fittings to accommodate different vehicle configurations.

These adjustable components introduce numerous potential failure points, with each clamp, slip joint, and adapter representing a vulnerability to leaks, separation, and accelerated corrosion.

The typical universal system may contain 3-5 times more connection points than a vehicle-specific system, with each representing a point where exhaust gases can escape, moisture can penetrate, and structural integrity is compromised.

Material quality in universal systems is typically far below even basic OEM standards. Many utilize thin-wall mild steel with minimal corrosion protection—often just a layer of high-temperature paint rather than proper aluminization or stainless construction.

This base material, combined with the numerous cut ends created during custom fitting, leaves extensive exposed surfaces vulnerable to immediate corrosion onset.

The cutting process itself often introduces burrs and rough edges that concentrate stress and accelerate deterioration, while the typical use of compression clamps rather than welded joints allows moisture intrusion between overlapping surfaces a perfect environment for crevice corrosion that quickly compromises joint integrity.

Installation challenges further compromise these systems’ already limited durability potential. The fitting process typically requires cutting, bending, and otherwise modifying components to match the specific vehicle’s undercarriage configuration.

These field modifications, often performed with basic hand tools rather than specialized exhaust fabrication equipment, create stress points and material deformation that accelerate failure.

The need to adapt hangers to non-standard positions frequently results in inadequate support, allowing excessive vibration that stresses connections beyond their design capacity.

Poor fitment commonly results in components contacting the vehicle underbody during suspension travel or engine movement, creating wear points that quickly perforate thin-wall tubing.

Performance implications compound the durability issues. Universal mufflers and resonators rarely match the flow characteristics specified for particular engine displacements and configurations, potentially creating back-pressure issues that affect engine performance and efficiency.

The irregular interior surfaces created by compression fittings disrupt laminar flow, generating turbulence that increases noise, reduces efficiency, and concentrates heat at connection points.

This heat concentration accelerates the deterioration of clamps and gaskets, creating a progressive failure mode where initial minor leaks quickly expand as surrounding materials are subjected to concentrated exhaust heat.

For vehicle owners truly constrained by budget limitations, a quality used OEM system or remanufactured vehicle-specific replacement typically offers far greater durability than even a new universal system, making them the more economical choice despite potentially higher initial investment.

Also Read: 5 Kia Models That Surprise With Longevity And 5 That Fail Early