The serpentine belt, that single continuous loop of rubber and reinforcement that drives multiple engine accessories, represents one of automotive engineering’s most elegant solutions.

Yet within this seemingly simple component lies a world of dramatic performance differences that can make or break your driving experience.

Some belts are engineered marvels that soldier on for hundreds of thousands of miles with barely a whisper, while others seem destined to announce their presence with ear-piercing squeals from the moment they’re installed.

Understanding the divide between these two categories isn’t just about brand recognition or price points it’s about fundamental differences in materials science, manufacturing precision, and engineering philosophy.

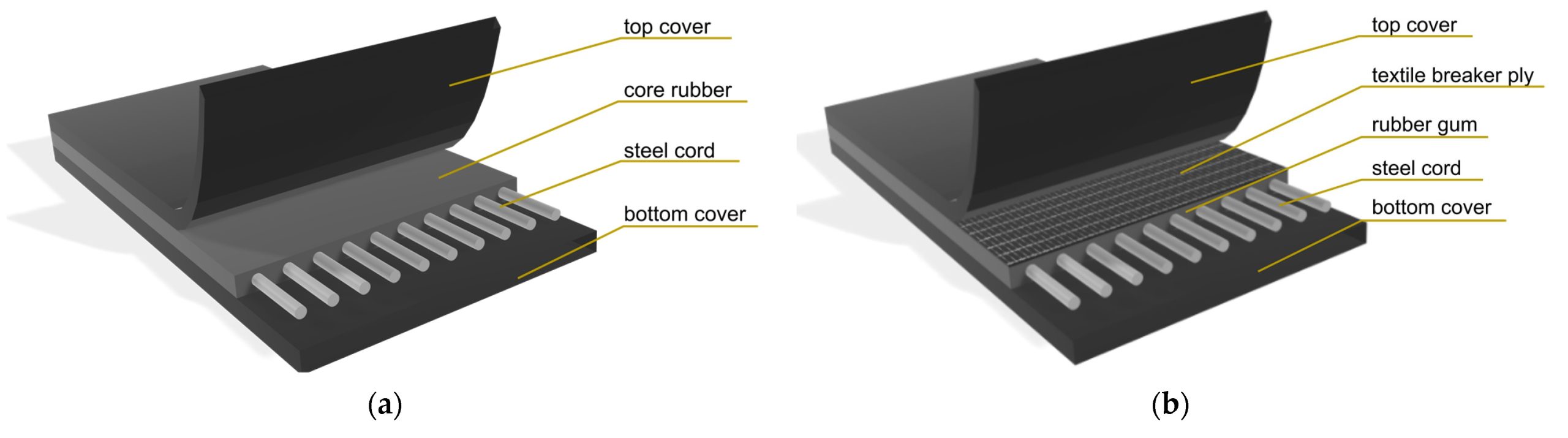

The best serpentine belts combine advanced EPDM rubber compounds with precisely engineered tensile members and specialized rib profiles that maintain their grip and flexibility across extreme temperature ranges and demanding operating conditions.

They feature noise-dampening technologies and wear-resistant formulations that keep them running smoothly long after lesser belts would have failed.

Conversely, the problematic belts often cut corners in material quality, manufacturing tolerances, or design optimization. They may use inferior rubber compounds that harden prematurely, inadequate reinforcement that allows stretching and slippage, or rib designs that create harmonic vibrations.

The result is not just annoying noise, but accelerated wear of both the belt and the pulleys it contacts, leading to cascading maintenance issues that far exceed the initial cost savings of choosing a cheaper option.

The Forever Champions: Serpentine Belts Built to Last

These exceptionally engineered accessory drive systems feature premium belt materials and perfectly aligned pulley systems that maintain proper tension and quiet operation through hundreds of thousands of miles.

Their advanced rubber compounds and reinforcement fibers resist the stretching, cracking, and fraying that typically develops in lesser belts, maintaining consistent power delivery to all engine accessories.

From extreme temperature variations to years of constant flexing around multiple pulleys, these remarkable belts continue operating silently without developing the telltale squealing or visible wear that signals replacement time.

Owners report completing entire vehicle lifespans on original equipment serpentine belts an impressive achievement that eliminates a traditionally expected maintenance expense while ensuring reliable accessory operation throughout ownership.

1. Gates Micro-V Belt

Gates has established themselves as the gold standard in serpentine belt technology, and their Micro-V line represents the pinnacle of their engineering expertise.

These belts incorporate a proprietary EPDM rubber compound that maintains its flexibility and strength across temperature extremes from -40°F to 275°F, making them virtually immune to the cracking and hardening that plague lesser belts.

The secret lies in their advanced polymer chemistry, which includes specialized plasticizers and stabilizers that prevent thermal degradation and ozone damage.

The tensile member construction uses high-strength polyester cords that are precisely wound and embedded within the rubber matrix. This isn’t just about strength the cord placement and tension are engineered to minimize stretch while maintaining the belt’s ability to conform to pulleys of varying sizes.

The result is consistent tension throughout the belt’s service life, preventing the slippage that causes both noise and accelerated wear. What truly sets the Micro-V apart is its rib design and manufacturing precision.

The ribs are molded using computer-controlled processes that ensure consistent geometry and surface finish. The rib profile is optimized for maximum contact area with V-groove pulleys while incorporating subtle features that break up harmonics and reduce noise generation.

The rubber compound includes noise-dampening fillers that absorb vibrations rather than transmitting them through the engine bay. Installation and maintenance characteristics of Gates Micro-V belts reflect their quality engineering.

They require minimal break-in period and maintain consistent performance from installation through replacement. The belt’s resistance to stretching means tensioner adjustments are rarely needed, and the high-quality materials ensure even wear patterns that prevent premature failure of associated components like tensioner pulleys and idler wheels.

Professional mechanics consistently report service intervals of 100,000 miles or more with Gates Micro-V belts, often exceeding manufacturer recommendations.

The belts maintain their grip and quiet operation throughout their service life, rarely requiring attention beyond routine inspections. When replacement is finally necessary, it’s typically due to normal wear rather than catastrophic failure, allowing for planned maintenance rather than roadside emergencies.

2. Continental ContiTech Elite

Continental’s ContiTech Elite serpentine belts represent German engineering precision applied to automotive belt technology. These belts feature Continental’s advanced HNBR (Hydrogenated Nitrile Butadiene Rubber) compound, which offers superior resistance to heat, oil, and chemical degradation compared to standard rubber formulations.

This material choice isn’t just about longevity it’s about maintaining consistent performance characteristics throughout the belt’s extended service life.

The Elite’s construction incorporates Continental’s proprietary fiber-reinforced tensile member technology. Rather than using simple polyester cords, these belts feature a complex weave of high-modulus synthetic fibers that are precisely oriented to handle both tensile loads and the complex stresses created by multiple pulley contact points.

The fiber orientation is optimized through computer modeling to minimize stress concentrations while maximizing power transmission efficiency.

Manufacturing quality sets the ContiTech Elite apart from commodity belts. Continental’s production facilities use advanced automation and quality control systems that monitor belt dimensions, compound consistency, and surface finish to tolerances measured in hundredths of millimeters.

This precision translates to belts that run true on their pulleys without the wobbling or tracking issues that create noise and uneven wear. The Elite’s rib design incorporates Continental’s noise reduction technology, featuring subtle variations in rib spacing and profile that disrupt the formation of standing waves and harmonic resonances.

The ribs themselves are molded with a surface texture that optimizes grip while minimizing the stick-slip behavior that causes squealing. Special attention is paid to the transition zones where ribs contact and leave pulleys, areas where many belts generate noise due to abrupt loading changes.

Field performance of ContiTech Elite belts consistently exceeds expectations, with many installations surpassing 150,000 miles without replacement.

The belts maintain their original dimensions and flexibility throughout their service life, showing minimal signs of wear even under severe operating conditions.

Professional fleet operators frequently specify Continental belts for their high-mileage vehicles, where reliability and longevity directly impact operational costs.

3. Dayco Poly Rib Gold Label

Dayco’s Poly Rib Gold Label represents the company’s premium offering in the serpentine belt market, incorporating decades of OEM experience and aftermarket refinement.

These belts feature Dayco’s advanced EPDM formulation enhanced with proprietary additives that provide exceptional resistance to cracking, hardening, and chemical attack.

The rubber compound is specifically formulated to maintain its elastic properties across the extreme temperature cycles encountered in modern engine compartments.

The tensile member construction uses Dayco’s high-strength cord technology, featuring precisely wound polyester fibers that are treated with special adhesion promoters to ensure permanent bonding with the rubber matrix.

The cord tension and placement are optimized through extensive testing to provide maximum power transmission capability while minimizing belt stretch over time. This attention to tensile member design results in belts that maintain consistent operation throughout their service life.

Manufacturing excellence defines the Gold Label line, with Dayco’s facilities employing advanced process controls that monitor every aspect of belt production.

The molding process uses precision tooling that creates consistent rib geometry and surface finish, while automated inspection systems verify dimensional accuracy and detect any defects before packaging.

This quality focus ensures that every belt meets Dayco’s stringent performance standards. The Gold Label’s rib design incorporates noise-reduction features developed through extensive NVH (Noise, Vibration, Harshness) testing.

The rib profile and spacing are optimized to minimize contact pressure variations while maintaining positive drive characteristics. Special attention is paid to the rib sidewall geometry, which is designed to provide smooth engagement and disengagement with pulley grooves without generating the vibrations that cause squealing.

Dayco’s reputation for longevity is well-earned, with Gold Label belts routinely achieving service lives of 100,000+ miles in demanding applications.

The belts resist the environmental factors that degrade lesser products, maintaining their flexibility and grip even after years of exposure to heat, oil, and chemical contaminants.

Professional mechanics appreciate the Gold Label’s consistent performance and predictable wear characteristics, which allow for planned replacement rather than emergency repairs.

4. ACDelco Professional Series

ACDelco’s Professional Series serpentine belts leverage General Motors’ extensive OEM experience and engineering resources to deliver exceptional aftermarket performance.

These belts are manufactured to OEM specifications using the same materials and processes employed for original equipment applications, ensuring compatibility and performance that matches or exceeds factory standards.

The Professional Series represents ACDelco’s commitment to providing professional-grade components for serious automotive applications. The belt construction features an advanced EPDM compound that incorporates GM’s latest polymer technology developments.

This formulation provides exceptional resistance to thermal degradation, ozone attack, and chemical contamination while maintaining the flexibility and strength characteristics essential for reliable operation.

The rubber compound includes specialized additives that enhance wear resistance and provide natural lubrication properties that reduce friction and heat generation.

Tensile member technology in the Professional Series uses high-strength polyester cords that are precisely engineered to GM’s specifications. The cord material, twist rate, and embedding process are all optimized to provide maximum strength while maintaining the flexibility needed for small pulley applications.

The result is a belt that can handle high loads without stretching while remaining capable of conforming to the complex pulley arrangements found in modern engines.

Manufacturing quality reflects ACDelco’s position as a tier-one automotive supplier, with production facilities that meet stringent OEM requirements for quality and consistency.

The belts are manufactured using precision molding processes that ensure accurate rib geometry and consistent material properties. Quality control systems monitor every aspect of production, from raw material verification to final inspection, ensuring that each belt meets professional standards.

The Professional Series’ rib design incorporates features developed specifically for quiet operation and long service life. The rib profile is optimized for maximum contact area while minimizing stress concentrations that can lead to premature wear.

Special attention is paid to the rib root design, which is engineered to prevent crack initiation and propagation. The overall rib geometry is designed to provide positive engagement with pulleys while minimizing noise generation.

Field performance of ACDelco Professional Series belts consistently meets or exceeds OEM expectations, with service lives routinely reaching 100,000+ miles in normal applications.

The belts maintain their original performance characteristics throughout their service life, showing minimal dimensional changes or property degradation. Professional installers appreciate the consistent quality and reliable performance that allows them to offer extended warranties with confidence.

Also Read: 5 Windshield Washer Systems That Always Work And 5 That Clog Instantly

5. Bando Rib Ace Precision Engineered

Bando’s Rib Ace Precision Engineered serpentine belts represent Japanese manufacturing excellence applied to automotive belt technology. These belts incorporate Bando’s advanced synthetic rubber compounds and precision manufacturing processes to deliver exceptional performance and longevity.

The Precision Engineered designation reflects Bando’s commitment to tight manufacturing tolerances and consistent quality that meets the demands of modern high-performance engines.

The rubber compound features Bando’s proprietary HNBR formulation enhanced with specialized additives that provide superior resistance to heat, chemicals, and environmental degradation.

This advanced material maintains its properties across extreme temperature ranges while providing the flexibility and strength characteristics needed for reliable power transmission.

The compound includes natural lubrication properties that reduce friction and wear while minimizing noise generation. Tensile member construction uses Bando’s high-modulus aramid fiber technology, providing an exceptional strength-to-weight ratio and minimal stretch characteristics.

The aramid fibers are precisely oriented and embedded within the rubber matrix using advanced adhesion systems that ensure permanent bonding throughout the belt’s service life. This construction provides superior power transmission capability while maintaining the flexibility needed for complex drive systems.

Manufacturing precision sets Bando belts apart from commodity products, with production facilities that employ advanced automation and quality control systems.

The molding process uses precision tooling that creates consistent rib geometry and surface finish to tolerances measured in microns. Computer-controlled systems monitor every aspect of production, ensuring that each belt meets Bando’s exacting standards for dimensional accuracy and material properties.

The Rib Ace’s rib design incorporates Bando’s noise-reduction technology, featuring optimized rib profiles and spacing that minimize vibration and noise generation.

The rib sidewalls are engineered with specific angles and surface textures that provide smooth engagement with pulleys while preventing the stick-slip behavior that causes squealing.

Special attention is paid to the rib root design, which incorporates stress-relief features that prevent crack initiation. Bando’s reputation for quality is reflected in the Rib Ace’s exceptional service life, with belts routinely achieving 120,000+ miles in demanding applications.

The belts maintain their original dimensions and properties throughout their service life, showing minimal signs of wear even under severe operating conditions. Professional mechanics value the consistent performance and predictable service intervals that allow for efficient maintenance scheduling.

The Squealing Nightmares: Belts That Never Stay Quiet

These problematic drive systems develop embarrassing squealing noises within months of installation, often beginning with subtle chirping during cold starts before progressing to constant noise that advertises mechanical issues.

Their inadequate belt materials and questionable pulley alignment create perfect conditions for premature glazing and slippage, particularly when accessories like air conditioning place additional loads on the system.

Owners report the mortifying experience of noisy startups in quiet parking areas and the anxiety of wondering whether squealing indicates impending belt failure that could strand them roadside.

What should be a long-lasting engine component instead becomes a recurring replacement expense, with many frustrated owners reporting multiple belt changes within normal service intervals, often accompanied by expensive tensioner and pulley replacements.

1. Generic Auto Parts Store Belts

The automotive aftermarket is flooded with generic serpentine belts sold under various store brands and unknown manufacturers, representing the bottom tier of belt technology and quality.

These belts typically originate from low-cost manufacturing facilities that prioritize price over performance, resulting in products that may appear acceptable initially but quickly reveal their shortcomings through persistent noise, premature wear, and unreliable operation.

The rubber compound used in generic belts is typically a basic EPDM formulation without the specialized additives and processing aids that characterize premium products.

These compounds lack the thermal stability, ozone resistance, and flexibility retention properties needed for long-term automotive service. The rubber often contains excessive amounts of low-cost fillers that reduce material costs but compromise performance characteristics.

As a result, the belt material begins to harden and crack within months of installation, leading to loss of grip and the characteristic squealing that announces the belt’s deterioration.

Tensile member construction in generic belts reflects their cost-cutting origins, typically using basic polyester cords without the precise orientation and quality control found in premium products.

The cord material may be of inconsistent quality, with variations in strength and stretch characteristics that create uneven loading and premature failure.

The bonding between the cord and rubber matrix is often inadequate, leading to separation and belt failure as the tensile members lose their ability to maintain proper belt tension.

Manufacturing quality issues plague generic belts from the moment of production. Molding processes often use worn or imprecise tooling that creates dimensional variations and surface imperfections.

The rib geometry may be inconsistent or poorly formed, leading to inadequate contact with pulleys and resulting in slippage and noise. Quality control is typically minimal, with little or no inspection to verify dimensional accuracy or material properties before packaging and distribution.

The rib design of generic belts often represents outdated technology or poor copying of successful designs without understanding the underlying engineering principles.

The rib profile may be incorrect for the intended application, creating contact pressure variations that lead to squealing and uneven wear. The rib spacing and geometry may not be optimized for noise reduction, resulting in belts that generate harmonic vibrations and resonances that are transmitted throughout the engine bay.

Installation and service characteristics of generic belts reveal their inadequacies immediately. These belts often require frequent adjustments as they stretch and lose tension, leading to slippage and noise that worsens over time.

The squealing typically begins within days or weeks of installation and progressively worsens as the belt materials degrade. Professional mechanics report service lives of 20,000-40,000 miles at best, with many belts failing prematurely due to cracking, stretching, or complete separation.

The false economy of choosing a generic belt becomes apparent when the cost of frequent replacements and associated labor exceeds the price of a quality belt that would have lasted the entire period without issue.

2. Cheap Import Belts from Unknown Manufacturers

The global marketplace has created opportunities for extremely low-cost serpentine belts manufactured in facilities with minimal quality standards or engineering expertise. These products often carry generic part numbers or unknown brand names and are sold primarily based on price rather than performance specifications. While they may appear to offer significant cost savings, their actual performance reveals the true cost of compromising on quality.

Material quality represents the fundamental weakness of cheap import belts, with manufacturers using whatever rubber compounds and reinforcement materials are available at the lowest cost.

The rubber formulations often lack the sophisticated polymer chemistry needed for automotive applications, using basic compounds that may be suitable for static applications but fail under the dynamic stresses of serpentine belt service.

The materials may contain contaminants or recycled content that compromise their mechanical properties and durability. The tensile member construction typically uses whatever cord material is readily available, often without regard for the specific requirements of automotive belt applications.

The cords may be of inconsistent quality or inappropriate specification, leading to belts that stretch excessively or fail under normal loads. The bonding process between the cord and rubber may use inadequate adhesion systems that allow separation under stress, resulting in catastrophic belt failure.

Manufacturing processes in low-cost facilities often lack the precision and quality control needed for consistent belt production. Molding equipment may be outdated or poorly maintained, creating dimensional variations and surface defects that affect performance.

The curing process may be inadequately controlled, resulting in rubber properties that vary from belt to belt or even within individual belts. Quality inspection may be minimal or nonexistent, allowing defective products to reach the market.

Design deficiencies are common in cheap import belts, often reflecting a lack of engineering expertise or understanding of automotive requirements.

The rib geometry may be copied from successful designs without understanding the underlying principles, resulting in profiles that create noise and premature wear.

The overall belt design may not be optimized for the intended application, leading to performance issues that become apparent only after installation.

Service experience with cheap import belts is consistently poor, with squealing often beginning immediately after installation and worsening rapidly.

The belts may exhibit excessive stretch, requiring frequent tensioner adjustments and leading to cascade failures of associated components. Service life is typically 15,000-30,000 miles at best, with many belts failing catastrophically without warning.

The total cost of ownership, including frequent replacements, labor, and potential damage to other components, far exceeds the initial savings from choosing a low-cost option.

3. Rebuilt/Remanufactured Belt Attempts

The concept of remanufacturing serpentine belts represents a misguided attempt to extend the life of worn components through surface treatments or partial rebuilding.

While remanufacturing works well for many automotive components, serpentine belts present unique challenges that make successful remanufacturing extremely difficult and often counterproductive.

The rubber compounds and reinforcement materials undergo irreversible changes during service that cannot be effectively reversed through rebuilding processes.

The remanufacturing process typically involves cleaning worn belts and applying surface treatments intended to restore grip and flexibility. However, the fundamental material degradation that occurs during normal service cannot be reversed through surface treatments alone.

The rubber compound undergoes cross-linking and plasticizer migration that changes its basic properties, while the tensile members may have experienced stress-induced damage that compromises their strength and dimensional stability.

Surface treatments used in belt remanufacturing often create more problems than they solve, introducing contaminants or coatings that may initially improve grip but quickly deteriorate under operating conditions.

These treatments may temporarily mask the belt’s deteriorated condition but fail to address the underlying material degradation. The result is often a belt that appears to be improved but quickly returns to its original problematic condition or develops new issues related to the treatment process.

Quality control in remanufacturing operations is typically inadequate for serpentine belt applications, lacking the sophisticated testing and inspection procedures needed to verify belt performance characteristics.

The complex stress patterns and dynamic loading conditions of serpentine belt service require testing methods that are beyond the capabilities of most remanufacturing facilities.

Without proper quality verification, remanufactured belts may appear acceptable but fail under normal operating conditions. The fundamental problem with belt remanufacturing is that serpentine belts are consumable components designed for single-use service life.

The materials and construction are optimized for specific performance characteristics that change irreversibly during use. Attempting to restore these characteristics through remanufacturing processes is like trying to restore the spring rate of a used coil spring the fundamental material properties have changed in ways that cannot be effectively reversed.

Service experience with remanufactured belts is consistently problematic, with squealing and performance issues typically appearing immediately after installation.

The belts may exhibit unpredictable behavior, sometimes appearing to work initially but failing suddenly as the temporary effects of surface treatments disappear.

Professional mechanics avoid remanufactured belts due to reliability concerns and the potential for callback problems that damage their reputation with customers.

4. Mismatched Application/Universal Belts

One of the most common sources of serpentine belt problems stems from using belts that are not specifically designed for the intended application.

Universal or “close enough” belts may have similar overall dimensions but lack the specific engineering characteristics needed for particular engine configurations.

These mismatched applications often result in chronic noise problems and premature wear that could be avoided through proper belt selection. Length variations represent a critical issue with mismatched belts, as serpentine drive systems are designed with specific belt lengths that provide proper tensioner positioning and component alignment.

A belt that is slightly too long may not allow the tensioner to maintain adequate pressure, leading to slippage and squealing. Conversely, a belt that is too short may over-stress the tensioner and associated components while creating excessive tension that accelerates wear.

Rib geometry compatibility is often overlooked when selecting universal belts, despite its critical importance for proper operation. Different engine applications may require specific rib profiles, spacing, or depths to accommodate the pulley designs used in particular systems.

A belt with incorrect rib geometry may not seat properly in pulley grooves, creating contact pressure variations that lead to noise and uneven wear patterns.

Width specifications are another critical factor often ignored in universal belt applications. The belt width must be precisely matched to the pulley groove dimensions to ensure proper load distribution and prevent edge loading or inadequate contact.

Universal belts may have width variations that create improper loading conditions, leading to premature wear and noise generation. Load capacity mismatches occur when universal belts are used in applications requiring different power transmission capabilities.

High-performance engines or applications with power steering, air conditioning, and other accessories may require belts with specific tensile strength and power transmission characteristics. Using a belt designed for lighter duty applications can result in slippage, overheating, and premature failure.

Tensioner compatibility issues arise when universal belts are used with automatic tensioning systems designed for specific belt characteristics. The tensioner spring rate and travel are calibrated for particular belt stretch and load characteristics.

Using an incompatible belt may prevent the tensioner from maintaining proper pressure, leading to chronic squealing and accelerated wear of both the belt and tensioner components.

Service problems with mismatched belts are predictable and persistent, typically manifesting as squealing that cannot be resolved through tensioner adjustments or other remedial measures.

The fundamental incompatibility between the belt and application creates operating conditions that generate noise and accelerate wear regardless of installation quality or maintenance practices.

5. Old Stock/Degraded New Belts

Even quality belts can become problematic when they have been stored improperly or for extended periods before installation. Rubber compounds are susceptible to degradation from exposure to heat, light, ozone, and time, even when the belt has never been installed on an engine.

Old stock belts may appear new but have already undergone material changes that compromise their performance and service life. Heat exposure during storage can cause irreversible changes in rubber compounds, leading to hardening and loss of flexibility that affects the belt’s ability to conform to pulleys and maintain proper contact.

Warehouse storage conditions often include temperature extremes that accelerate these degradation processes, particularly in facilities without climate control.

Belts stored near heat sources or in direct sunlight may experience severe degradation that becomes apparent only after installation. Ozone exposure is particularly damaging to rubber compounds, causing surface cracking and internal degradation that weakens the material structure.

Belts stored in areas with electrical equipment, welding operations, or other ozone sources may experience significant degradation even when protected from light and heat. The damage may not be visible externally but affects the belt’s performance characteristics and service life.

Light exposure, particularly ultraviolet radiation, can cause polymer degradation that affects both surface and internal properties of rubber compounds.

Belts stored under fluorescent lighting or near windows may experience UV damage that compromises their material properties. The degradation may manifest as surface chalking or discoloration but extends into the material structure, affecting flexibility and strength.

Age-related degradation occurs even under ideal storage conditions, as rubber compounds naturally undergo chemical changes over time. Plasticizers migrate, cross-linking continues, and polymer chains may break down through oxidation and other chemical processes.

Belts that have been stored for several years may have significantly different properties than when they were manufactured, regardless of storage conditions.

Package integrity issues can accelerate degradation by allowing exposure to environmental factors that should be excluded. Damaged packaging may allow moisture, light, or chemical contaminants to reach the belt during storage, causing localized degradation that affects performance.

Belts should be stored in original packaging in climate-controlled environments to minimize degradation. Installation problems with old stock belts often become apparent immediately, with squealing and performance issues that suggest a defective product when the actual problem is storage-related degradation.

The belt may have lost its flexibility and grip characteristics, making it impossible to achieve proper operation regardless of installation quality. Professional mechanics learn to check manufacturing dates and storage conditions when encountering immediate problems with apparently new belts.

Also Read: 5 Cabin Air Filters Placed For Easy Access And 5 That Require Disassembly