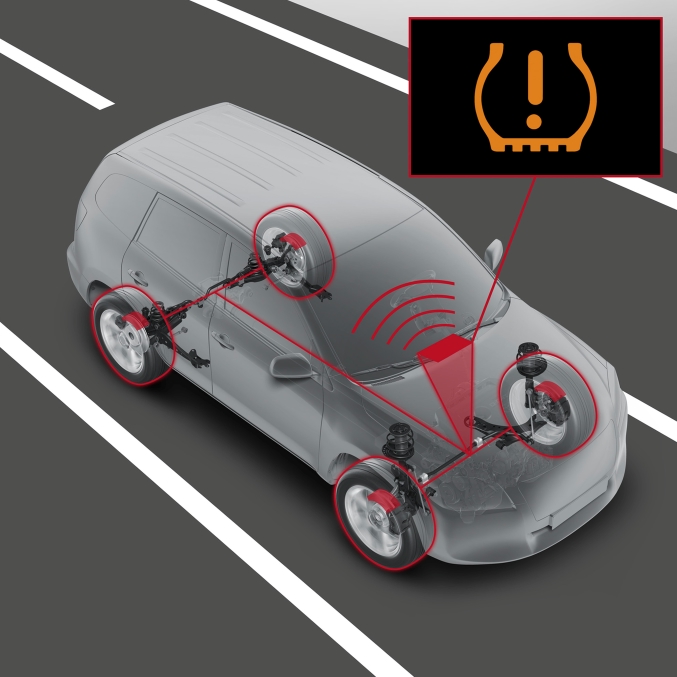

Tire Pressure Monitoring Systems (TPMS) have become a critical safety feature in modern vehicles, mandated by federal law since 2008 for all passenger vehicles in the United States.

These systems continuously monitor tire pressure and alert drivers when inflation levels drop below safe thresholds, preventing potential blowouts, improving fuel efficiency, and enhancing overall vehicle safety. However, not all TPMS implementations are created equal.

The automotive industry has witnessed a stark divide between TPMS systems that operate flawlessly for years and those that seem to require constant attention, resets, and sensor replacements.

This disparity often stems from fundamental differences in sensor technology, system architecture, manufacturing quality, and integration with vehicle electronics.

Direct TPMS systems, which use individual sensors mounted inside each wheel, generally offer superior accuracy but can be more prone to sensor failures and battery depletion.

Indirect systems, which monitor wheel speed through the ABS system, avoid sensor-related issues but may lack precision in certain driving conditions.

Understanding which TPMS setups demonstrate exceptional reliability versus those plagued by recurring problems can save vehicle owners significant time, money, and frustration.

The following analysis examines ten distinct TPMS configurations, highlighting five systems renowned for their dependability and five notorious for their maintenance demands, providing insights into what makes the difference between automotive excellence and endless aggravation.

5 TPMS Setups That Don’t Fail

These exceptionally reliable tire pressure monitoring systems feature robust sensors with long-lasting batteries and intelligent communication protocols that maintain accurate readings for years without intervention.

Their advanced sensor designs resist the moisture intrusion and impact damage that typically destroy lesser TPMS units, while maintaining consistent radio frequency transmission through various driving conditions.

From extreme temperature swings to tire rotation services, these dependable systems continue providing accurate pressure data without developing the false alerts or communication failures that plague problematic competitors.

Owners report years of trouble-free TPMS operation with these superior systems an often-overlooked reliability feature that provides genuine safety benefits without the maintenance headaches associated with failing sensor technology.

1. Toyota/Lexus Direct TPMS (2015-Present)

Toyota’s TPMS implementation stands as a benchmark for reliability in the automotive industry, earning praise from technicians and vehicle owners alike for its exceptional longevity and minimal maintenance requirements.

The system utilizes high-quality Denso sensors that are engineered to withstand extreme temperature fluctuations, road salt exposure, and the constant vibration inherent in wheel-mounted applications.

These sensors feature robust housing construction with superior sealing that prevents moisture ingress, a common failure point in lesser systems.

The Toyota TPMS architecture employs a sophisticated communication protocol that minimizes power consumption while maintaining accurate pressure readings.

The sensors operate on a 315 MHz frequency in North America and utilize advanced signal processing to reduce interference from external sources.

Battery life typically exceeds eight years, significantly longer than industry averages, due to optimized sleep modes and efficient transmission scheduling.

The system only transmits data when significant pressure changes occur or during regular health checks, preserving battery life while ensuring responsive monitoring.

Integration with Toyota’s vehicle control modules is seamless, featuring redundant error-checking protocols that prevent false alarms and ensure system stability.

The TPMS receiver module communicates directly with the instrument cluster and vehicle’s central computer, providing real-time pressure data without the lag or inaccuracy common in other systems.

Toyota’s commitment to backwards compatibility means that replacement sensors often work across multiple model years, reducing parts complexity and cost.

The learning procedure for new sensors is straightforward and can often be completed without specialized tools, simply by following a specific sequence of actions with the vehicle’s existing controls.

This user-friendly approach reduces dependency on dealership service visits and associated costs. Additionally, Toyota’s TPMS rarely requires relearning after routine tire rotations, as the system automatically adapts to new wheel positions through intelligent position detection algorithms.

Quality control in Toyota’s manufacturing process ensures consistent sensor performance across its entire vehicle lineup. The company’s vertical integration allows for tight control over component quality, from the pressure sensing elements to the radio frequency components.

This attention to detail results in remarkably low failure rates and consistent performance characteristics that maintain accuracy throughout the sensor’s operational life.

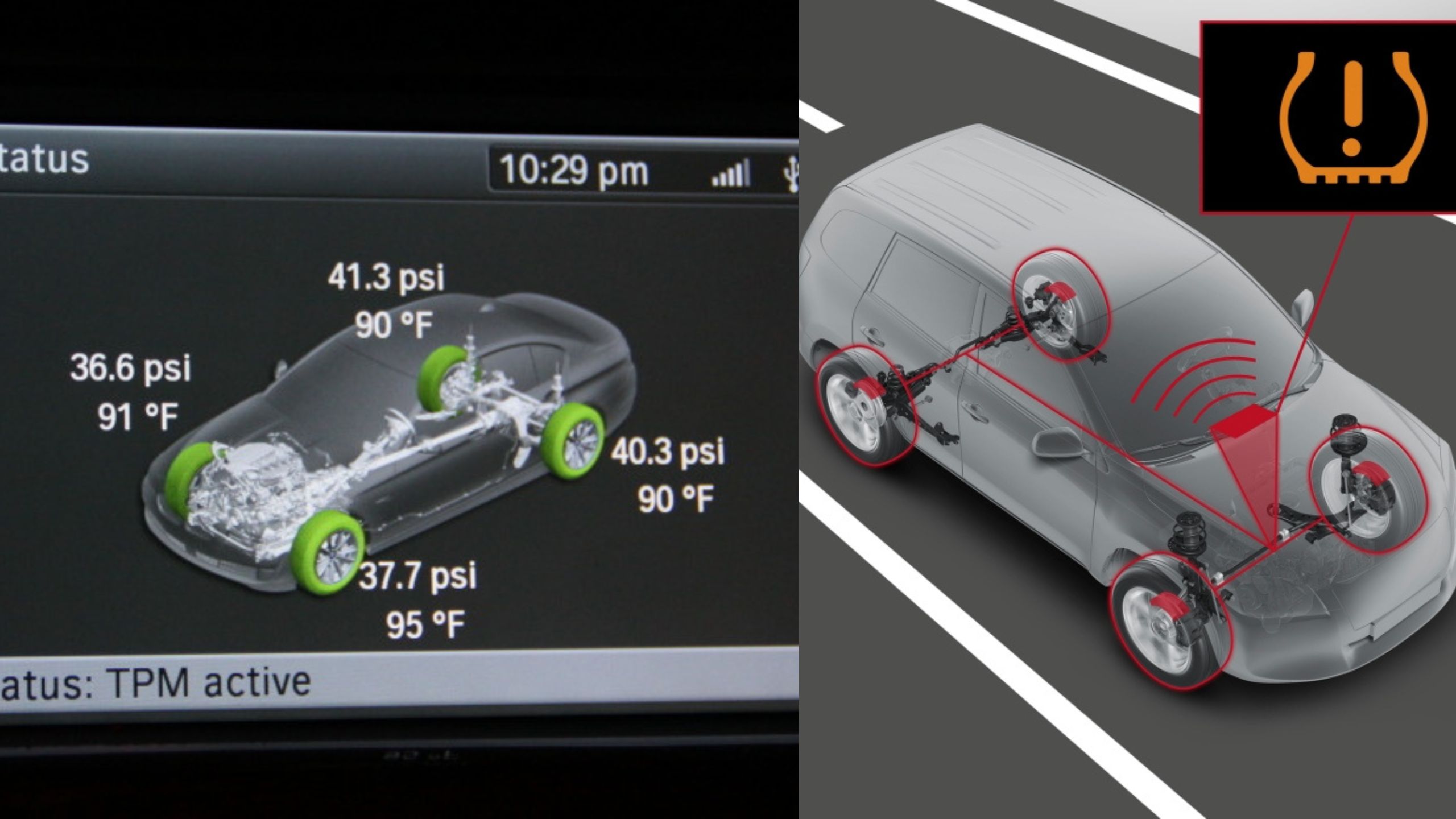

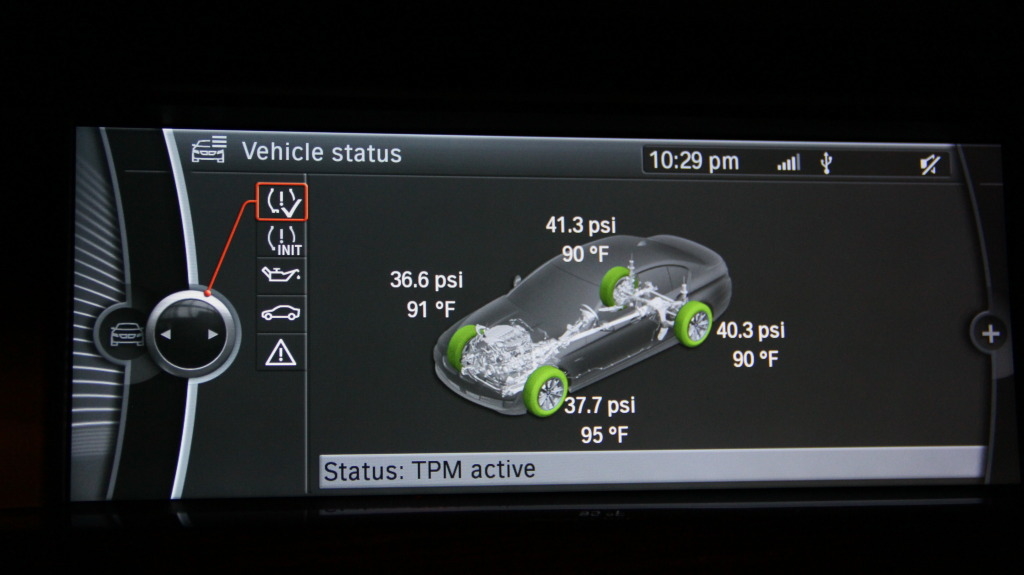

2. BMW iDrive Integrated TPMS (2016-Present)

BMW’s latest TPMS integration represents a sophisticated approach to tire monitoring that leverages the company’s advanced vehicle networking capabilities.

The system combines traditional pressure sensors with BMW’s intelligent vehicle communication network, creating a robust monitoring solution that rarely experiences the communication failures common in simpler implementations.

The integration with BMW’s iDrive system provides unprecedented user interface capabilities and diagnostic information. The sensors themselves are manufactured to BMW’s exacting specifications, featuring enhanced durability testing that includes exposure to temperature extremes from -40°F to 185°F, extensive vibration testing, and accelerated aging protocols.

This rigorous testing ensures that sensors maintain calibration accuracy and communication reliability throughout their service life. The sensors utilize a proprietary 433 MHz communication protocol that provides superior range and interference resistance compared to standard implementations.

BMW’s TPMS architecture incorporates multiple redundancy layers that prevent system failures from propagating into user-visible problems. The central control module continuously monitors sensor health and can adapt to individual sensor performance variations, maintaining system accuracy even as components age.

Advanced diagnostic capabilities allow the system to predict sensor failures before they occur, enabling proactive maintenance rather than reactive repairs.

The learning and calibration procedures are highly automated, typically requiring no user intervention beyond initial setup. The system automatically recognizes new sensors and begins monitoring within minutes of installation.

Tire rotation procedures are similarly streamlined, with the system automatically detecting new wheel positions and updating its internal mapping accordingly. This automation reduces the potential for human error during service procedures.

Integration with BMW’s comprehensive vehicle diagnostics means that TPMS issues can be identified and resolved using the same tools and procedures used for other vehicle systems.

This consistency reduces training requirements for technicians and ensures that problems can be diagnosed accurately and efficiently. The system’s ability to store detailed historical data also aids in identifying patterns or environmental factors that might affect tire pressure, providing valuable information for both maintenance planning and driving habit analysis.

BMW’s commitment to long-term software support means that system firmware updates can address emerging issues or add new capabilities throughout the vehicle’s operational life. This ongoing development ensures that the TPMS remains current with evolving automotive technologies and regulatory requirements.

3. Honda Sensing Suite TPMS (2018-Present)

Honda’s integration of TPMS within its comprehensive Honda Sensing safety suite demonstrates the company’s systematic approach to vehicle safety systems.

This integration creates synergies between tire monitoring and other safety features, resulting in enhanced overall reliability and performance. The system benefits from Honda’s extensive experience in sensor technology and its commitment to long-term reliability in safety-critical applications.

The TPMS sensors used in Honda Sensing-equipped vehicles feature advanced power management capabilities that significantly extend battery life. The sensors utilize adaptive transmission algorithms that adjust communication frequency based on driving conditions and detected pressure changes.

During highway driving, the sensors operate in a low-power monitoring mode, while city driving or detected pressure variations trigger more frequent status updates.

This intelligent power management typically results in sensor battery life exceeding ten years under normal driving conditions. Honda’s TPMS implementation includes sophisticated temperature compensation algorithms that maintain pressure reading accuracy across a wide range of operating conditions.

The system accounts for altitude changes, ambient temperature variations, and tire warming effects to provide consistently accurate pressure readings.

This attention to environmental factors reduces false alarms and ensures that genuine pressure issues are detected promptly and accurately. The mechanical design of Honda’s TPMS sensors emphasizes durability and serviceability.

The sensors feature corrosion-resistant materials and robust mounting systems that maintain secure attachment to wheel rims throughout the tire’s service life.

The valve stem integration is designed to minimize stress concentration points that could lead to air leaks or sensor damage during tire service operations.

Honda’s approach to system diagnostics provides clear, actionable information to both vehicle owners and service technicians. The system can differentiate between various types of TPMS issues, from low tire pressure to sensor malfunctions, and provides specific guidance for resolution.

The diagnostic capabilities extend to identifying which specific tire requires attention, eliminating guesswork and reducing service time. The learning procedure for new sensors is streamlined and can often be completed using the vehicle’s existing controls without requiring specialized diagnostic equipment.

Honda’s documentation and training materials ensure that both dealership technicians and independent service providers can properly service the system. The company’s parts distribution network ensures that replacement sensors are readily available and competitively priced.

4. Mercedes-Benz ASSYST Plus TPMS (2017-Present)

Mercedes-Benz’s ASSYST Plus integrated TPMS represents the pinnacle of German engineering applied to tire monitoring technology. The system is built to the same exacting standards as other Mercedes safety systems, with redundant design elements and premium components throughout.

This approach results in exceptional reliability and longevity that matches the brand’s reputation for engineering excellence. The sensors utilized in the ASSYST Plus system feature advanced materials science, including specialized polymer seals and corrosion-resistant alloys that maintain performance in harsh environments.

Each sensor undergoes extensive quality testing including pressure cycling, temperature extremes, and vibration exposure that far exceeds typical automotive standards. The manufacturing tolerances are held to aerospace-grade specifications, ensuring consistent performance across the entire production run.

Communication between sensors and the vehicle’s control systems utilizes Mercedes’ proprietary CAN bus architecture, providing rapid data transmission with extensive error checking. The system can detect and correct communication errors in real-time, maintaining accurate monitoring even in electrically noisy environments.

The integration with Mercedes’ comprehensive vehicle monitoring systems allows for correlation between tire pressure data and other vehicle parameters, enhancing diagnostic accuracy.

The ASSYST Plus system includes predictive maintenance capabilities that analyze tire pressure trends over time to identify potential issues before they become problems.

The system can detect gradual pressure losses that might indicate small punctures or valve problems, alerting drivers to seek service before complete tire failure occurs. This proactive approach significantly reduces the likelihood of roadside tire failures and associated safety risks.

User interface design reflects Mercedes’ attention to detail, with clear, intuitive displays that provide comprehensive tire status information without overwhelming the driver.

The system can display individual tire pressures, temperatures, and historical data through the vehicle’s infotainment system. Customizable alert thresholds allow drivers to set monitoring parameters appropriate for their specific driving conditions and preferences.

The learning and calibration procedures are fully automated, requiring no user intervention under normal circumstances. The system automatically recognizes new sensors and integrates them into the monitoring network within minutes.

Service procedures are supported by comprehensive diagnostic tools that provide detailed system status information and guided troubleshooting procedures for service technicians.

5. Subaru EyeSight Compatible TPMS (2019-Present)

Subaru’s TPMS implementation, designed for compatibility with their EyeSight driver assistance suite, demonstrates the company’s commitment to practical, reliable engineering solutions.

The system prioritizes consistent operation over complex features, resulting in a monitoring solution that provides dependable service with minimal maintenance requirements.

This approach aligns with Subaru’s brand philosophy of building vehicles that perform reliably in challenging conditions. The sensor design emphasizes robustness and environmental resistance, reflecting Subaru’s focus on all-weather capability.

Each sensor is sealed to IP67 standards, protecting against water immersion and dust infiltration that might be encountered during off-road driving or severe weather conditions.

The sensors utilize industrial-grade components throughout, including military-specification capacitors and resistors that maintain stable operation across temperature extremes.

Subaru’s TPMS operates on a proven 315 MHz platform with enhanced signal processing capabilities that reduce interference from external sources.

The system includes adaptive gain control that automatically adjusts sensitivity based on operating conditions, maintaining reliable communication even in challenging radio frequency environments.

Battery management algorithms optimize power consumption while ensuring responsive monitoring, typically achieving sensor battery life of eight to ten years.

The integration with Subaru’s vehicle electrical systems is designed for long-term stability and ease of service. The system utilizes standard automotive communication protocols that are well-understood by service technicians, reducing diagnostic complexity and service time.

The TPMS control module is positioned for easy access during routine maintenance, and diagnostic connections are marked and documented. Subaru’s approach to sensor learning and calibration emphasizes simplicity and reliability.

The system can automatically detect and configure new sensors without requiring specialized programming tools or complex procedures. Tire rotation procedures are similarly straightforward, with the system automatically adapting to new wheel positions through built-in position detection algorithms.

This user-friendly approach reduces service costs and ensures that the system remains functional even when serviced by technicians with varying levels of TPMS experience.

The company’s parts distribution and service support network ensures that replacement sensors and service information are readily available throughout Subaru’s dealer network and to independent service providers.

Training materials and technical documentation are comprehensive and regularly updated to reflect field experience and emerging best practices.

5 TPMS Systems That Always Need Resets

These problematic tire pressure monitoring systems constantly lose sensor communication and trigger false warning lights, transforming a valuable safety feature into a persistent source of dashboard anxiety.

Their fragile sensors and questionable programming create perfect conditions for frequent malfunctions, often requiring expensive dealership resets or complete sensor replacement well before batteries should expire.

Owners report the frustrating cycle of warning lights appearing after routine tire services, with many resorting to expensive TPMS relearn procedures multiple times per year just to maintain basic system functionality.

What should be a reliable safety monitoring system instead becomes a recurring maintenance expense, with many frustrated drivers eventually ignoring TPMS warnings entirely after experiencing too many false alarms from these unreliable implementations.

1. Chrysler/Dodge/Jeep TPMS (2012-2018)

The TPMS systems installed in Chrysler, Dodge, and Jeep vehicles from 2012 to 2018 represent some of the most problematic tire monitoring implementations in modern automotive history.

These systems are notorious for frequent sensor failures, communication issues, and an almost pathological need for constant relearning procedures that frustrate both vehicle owners and service technicians alike.

The root causes of these problems stem from fundamental design flaws, poor component quality, and inadequate system integration. The sensors themselves suffer from premature battery failure, often requiring replacement after just three to four years of service instead of the typical eight to ten years expected from quality TPMS implementations.

The battery chemistry used in these sensors appears particularly susceptible to temperature extremes and vibration-induced degradation. Many owners report sensor failures occurring in clusters, suggesting systematic quality control issues during manufacturing rather than random component failures.

Communication between sensors and the vehicle’s control systems is unreliable, with frequent dropouts and false alarms plaguing these vehicles throughout their service lives.

The system utilizes a 315 MHz communication protocol, but the implementation lacks the sophisticated error correction and interference rejection found in more reliable systems.

Radio frequency interference from other vehicle systems, external sources, or even adjacent vehicles can disrupt communication, leading to persistent warning lights and system malfunctions.

The learning procedure for new sensors is notoriously complex and unreliable, often requiring multiple attempts and specialized diagnostic equipment to complete successfully.

Even when the procedure appears to complete correctly, many vehicles lose sensor recognition after a few weeks or months, requiring repeated relearning sessions.

The system seems particularly sensitive to battery voltage fluctuations, vehicle electrical loads, and even atmospheric conditions during the learning process.

Integration with the vehicle’s other electronic systems creates additional complications, as TPMS malfunctions can sometimes interfere with other vehicle functions or be caused by unrelated electrical problems.

The system’s diagnostic capabilities are limited, often providing vague error codes that don’t identify the source of problems. This diagnostic ambiguity leads to increased troubleshooting time and often results in unnecessary parts replacement as technicians attempt to resolve persistent issues through component substitution.

The mechanical design of the sensors and their mounting hardware also contributes to reliability problems. The sensors are prone to corrosion around the valve stems, leading to air leaks and sensor damage.

The mounting systems can loosen over time, causing sensors to shift position within the wheel and affecting their ability to communicate with the vehicle’s receivers. These mechanical issues often require complete wheel dismounting to properly diagnose and repair.

2. General Motors TPMS (2014-2019)

General Motors’ TPMS implementation during the 2014-2019 model years represents a period of significant reliability challenges that affected millions of vehicles across the Chevrolet, GMC, Buick, and Cadillac brands.

These systems are characterized by frequent sensor communication failures, premature battery depletion, and a notorious sensitivity to routine maintenance procedures that often triggers system malfunctions requiring extensive reset procedures.

The core problem with GM’s TPMS during this period stems from the sensors’ inability to maintain stable communication with the vehicle’s control modules.

The sensors utilize a frequency-hopping communication protocol that was intended to improve interference resistance but instead created compatibility issues with the vehicle’s receiving hardware.

Many vehicles experience intermittent sensor communication, where sensors appear to work normally for days or weeks before suddenly dropping offline without warning.

Battery life in GM TPMS sensors from this era is notably shorter than industry standards, with many sensors requiring replacement after four to five years instead of the expected eight to ten years.

The premature battery failure appears to be related to inefficient power management algorithms that keep sensors active longer than necessary. Additionally, the sensors seem particularly sensitive to temperature extremes, with many failures occurring after exposure to very hot or cold conditions.

The relearning procedure for GM TPMS systems is exceptionally complex and often unreliable, requiring specific sequences of actions that must be performed in precise order with exact timing.

The procedure often fails to complete successfully on the first attempt, and many technicians report needing to perform the relearning process multiple times before achieving success.

Even when the procedure appears successful, many vehicles lose sensor recognition within a few weeks, necessitating repeated relearning sessions.

GM’s diagnostic capabilities for TPMS troubleshooting are inadequate, often providing generic error codes that don’t pinpoint specific problems. The diagnostic tools available to technicians frequently show conflicting information or fail to communicate with TPMS components entirely.

This diagnostic ambiguity leads to time-consuming troubleshooting processes and often results in unnecessary parts replacement as technicians attempt to resolve problems through trial and error.

The integration between TPMS and other vehicle systems creates additional complications, particularly with GM’s OnStar and infotainment systems.

TPMS malfunctions can sometimes interfere with these systems, and conversely, problems with other vehicle electronics can affect TPMS operation.

This interconnectedness makes it difficult to isolate TPMS problems and often requires comprehensive system diagnostics to identify root causes.

Quality control issues during sensor manufacturing have resulted in sensors with inconsistent performance characteristics. Some sensors may read accurately while others from the same production batch provide readings that drift over time or suddenly become wildly inaccurate.

This inconsistency makes it difficult for service technicians to predict which sensors will fail and when, leading to reactive rather than proactive maintenance approaches.

3. Ford TPMS with SYNC Integration (2015-2020)

Ford’s attempt to integrate TPMS functionality with their SYNC infotainment system during the 2015-2020 model years created a cascade of reliability problems that affected multiple vehicle systems simultaneously.

While the integration was intended to provide enhanced user interface capabilities and improved diagnostics, the reality has been a system plagued by communication failures, software glitches, and an almost constant need for resets and reprogramming.

The fundamental problem lies in Ford’s decision to route TPMS communications through the SYNC system rather than utilizing a dedicated TPMS control module.

This architecture creates multiple points of failure, as problems with the infotainment system can disable tire monitoring, and TPMS issues can interfere with other SYNC functions.

The system is particularly susceptible to software corruption, which can occur during routine software updates or as a result of electrical system problems.

Sensor communication reliability is severely compromised by the complex signal routing required by the SYNC integration. The sensors must communicate with a receiver module, which then transmits data to the SYNC system, which finally displays information to the driver.

Each step in this communication chain introduces potential failure points and signal degradation. Radio frequency interference that might not affect simpler TPMS systems can completely disable Ford’s integrated system.

The software components of Ford’s TPMS integration are notorious for corruption and malfunction. Software updates to the SYNC system often disrupt TPMS functionality, requiring complete system initialization.

The software seems particularly sensitive to interruptions during the update process, power fluctuations, or conflicts with other vehicle software systems. Many owners report that their TPMS system stops working entirely after SYNC software updates.

Diagnostic procedures for Ford’s integrated TPMS are exceptionally complex, often requiring specialized equipment and software that many independent service providers don’t possess.

The diagnostic process involves checking multiple systems simultaneously, including TPMS sensors, communication modules, SYNC software, and various vehicle networking components.

This complexity significantly increases diagnostic time and cost, making even simple sensor replacements expensive and time-consuming. The learning procedure for new sensors is dependent on the SYNC system functioning correctly, which is often not the case.

The procedure frequently fails to complete due to software glitches, communication errors, or interference from other vehicle systems. Many technicians report needing to perform multiple system resets and software reinitializations before sensor learning procedures can be completed successfully.

Ford’s integration architecture also creates problems during routine maintenance procedures. Simple tire rotations can trigger system malfunctions that require extensive reset procedures.

The system often loses sensor position information and requires complete relearning even when sensors haven’t been physically disturbed. This sensitivity to routine maintenance makes ownership of these vehicles particularly frustrating and expensive.

4. Nissan TPMS with CVT Integration (2016-2021)

Nissan’s decision to integrate TPMS functionality with their Continuously Variable Transmission (CVT) control systems during the 2016-2021 model years created an unusually problematic monitoring system that suffers from frequent malfunctions, communication failures, and an extraordinary sensitivity to vehicle electrical system variations.

This integration was intended to provide enhanced fuel economy monitoring and vehicle optimization, but instead resulted in a system that requires constant attention and frequent resets.

The integration between TPMS and CVT control systems creates unexpected failure modes where transmission problems can disable tire monitoring and tire pressure issues can affect transmission operation.

The systems share communication pathways and control modules, creating interdependencies that complicate troubleshooting and repair procedures. Many owners report that transmission software updates or repairs often require complete TPMS system reinitialization.

Sensor reliability in Nissan’s integrated system is compromised by aggressive power management algorithms designed to optimize overall vehicle efficiency.

The sensors are frequently placed in deep sleep modes to preserve battery life and reduce electrical system loads, but these power management routines often prevent sensors from responding promptly to pressure changes or communication requests.

The result is a system that appears to work intermittently, with sensors that suddenly stop responding for hours or days before resuming normal operation.

The communication protocol used in Nissan’s system is particularly susceptible to interference from the CVT control systems and other vehicle electronics.

The high-frequency switching characteristics of CVT operation create electrical noise that can disrupt TPMS communication, leading to frequent false alarms and system malfunctions.

The problem is most pronounced during highway driving when CVT systems are most active, ironically when tire monitoring is most critical. Diagnostic capabilities for Nissan’s integrated TPMS are severely limited, with the system often unable to distinguish between sensor failures, communication problems, and integration issues.

The diagnostic tools available to service technicians frequently provide conflicting information or fail to identify the actual source of problems. This diagnostic ambiguity leads to expensive trial-and-error repair approaches and often results in unnecessary component replacement.

The learning procedure for new sensors is exceptionally complex and unreliable, requiring coordination between TPMS and CVT control systems that often fails to complete successfully.

The procedure is sensitive to engine operating conditions, transmission state, and even driving history stored in the CVT control module. Many technicians report needing to clear transmission adaptation data and perform complete system resets before sensor learning procedures can be completed.

Quality control issues in sensor manufacturing have resulted in sensors with highly variable performance characteristics. Some sensors provide accurate readings while others from the same production batch drift significantly over time or provide readings that don’t correlate with actual tire pressures.

This inconsistency makes it difficult to determine when sensor replacement is necessary and often leads to premature replacement of sensors that are functioning correctly.

5. Volkswagen/Audi TPMS with MQB Platform (2015-2022)

The TPMS implementation on Volkswagen and Audi vehicles built on the MQB (Modular Transverse Matrix) platform from 2015 to 2022 represents one of the most frustrating examples of over-engineering leading to chronic reliability problems.

While the system incorporates advanced features and sophisticated integration with other vehicle systems, the complexity has resulted in a monitoring solution that requires frequent attention, constant resets, and expensive maintenance procedures that often exceed the cost of the tires being monitored.

The fundamental issue with the MQB platform TPMS lies in its integration with the vehicle’s comprehensive electronic architecture, which includes connections to the infotainment system, driver assistance features, and even climate control systems.

This extensive integration creates numerous failure points where problems in seemingly unrelated systems can disable tire monitoring. Software updates to any connected system can disrupt TPMS functionality, requiring complete system reinitialization.

Sensor communication reliability is severely compromised by the system’s use of an proprietary communication protocol that attempts to provide enhanced security and interference resistance.

While theoretically superior to standard TPMS communication methods, the implementation is highly sensitive to radio frequency interference, electrical system variations, and even atmospheric conditions.

The sensors frequently lose communication with the vehicle’s control modules, triggering persistent warning lights and system malfunctions. The complexity of the MQB TPMS extends to its diagnostic capabilities, which require specialized Volkswagen/Audi diagnostic equipment and software that costs thousands of dollars and is typically only available at dealership service centers.

Independent service providers often cannot properly diagnose or repair these systems, forcing owners to seek expensive dealership service for even simple sensor replacements. The diagnostic procedures themselves are time-consuming and often inconclusive.

Battery life in MQB platform TPMS sensors is notably shorter than industry standards, with many sensors failing after just four to five years of service.

The premature battery failure appears to be related to the system’s frequent communication requirements and aggressive monitoring algorithms that keep sensors active longer than necessary.

The sensors also seem particularly susceptible to damage from wheel cleaning chemicals and road salt exposure. The learning procedure for new sensors is extraordinarily complex, requiring precise sequences of actions that must be performed with specific diagnostic equipment in exactly the right order.

The procedure often fails due to software version incompatibilities, communication errors, or interference from other vehicle systems. Many dealership technicians report needing multiple attempts to complete sensor learning procedures, significantly increasing service time and cost.

Manufacturing quality control issues have resulted in sensors with inconsistent performance characteristics and premature failure rates. Some sensors may function normally for years while others from the same production batch fail within months of installation.

This inconsistency makes it difficult to predict maintenance requirements and often leads to unexpected system failures that leave drivers without tire pressure monitoring when it’s most needed.

The integration complexity also affects routine maintenance procedures, with simple tire rotations often triggering system malfunctions that require expensive reset procedures.

The system frequently loses calibration data and requires complete relearning even when sensors haven’t been physically disturbed. This sensitivity to routine maintenance makes ownership of MQB platform vehicles particularly expensive and frustrating for those who rely on independent service providers.

Also Read: 5 Serpentine Belts That Last Forever And 5 That Constantly Squeal