When purchasing a vehicle, one of the most critical factors to consider is engine longevity. The difference between an engine that purrs smoothly at 200,000 miles and one that develops concerning knocks before reaching 80,000 miles can mean the difference between years of reliable transportation and costly repairs or premature replacement.

Understanding which engines have earned reputations for exceptional durability and which ones are prone to early failure can save consumers thousands of dollars and countless headaches.

Engine reliability isn’t just about initial build quality it’s a complex interplay of design philosophy, materials engineering, manufacturing precision, and real-world testing.

Some manufacturers have perfected time-tested designs that prioritize longevity over cutting-edge features, while others have pushed boundaries with advanced technologies that sometimes compromise long-term reliability.

The engines that make it past the 200,000-mile mark typically share common characteristics: conservative tuning, robust internal components, effective cooling systems, and designs that have been refined over multiple generations.

Conversely, engines that develop problems before 80,000 miles often suffer from design flaws, inadequate testing, cost-cutting measures in critical components, or overly aggressive performance tuning that stresses internal parts beyond their long-term capabilities.

This comprehensive analysis examines ten engines that represent the extremes of automotive reliability, providing insights into what makes some powerplants legendary for their longevity while others become cautionary tales in automotive history.

5 Engines That Stay Smooth After 200K Miles

These exceptionally engineered powerplants demonstrate remarkable longevity through precision manufacturing tolerances and robust internal component design that maintains optimal performance well beyond typical engine lifespans.

Their advanced metallurgy includes hardened cylinder walls, precisely balanced rotating assemblies, and superior bearing surfaces that resist wear even under demanding operating conditions and extended service intervals.

From extreme temperature cycling to varying load conditions, these proven engines continue delivering smooth power delivery without developing the typical rattles, vibrations, or performance degradation associated with high-mileage powertrains.

Owners consistently report trouble-free operation extending past 300,000 miles with these dependable engines a testament to superior engineering that maintains refinement and reliability throughout their extended service life.

1. Toyota 2JZ-GTE (1991-2002)

The Toyota 2JZ-GTE stands as perhaps the most legendary engine in automotive history when it comes to combining performance with bulletproof reliability.

This 3.0-liter twin-turbocharged inline-six was the heart of the iconic Toyota Supra and has achieved mythical status among enthusiasts for its ability to handle massive power increases while maintaining exceptional longevity.

The engine’s reputation for running smoothly well beyond 200,000 miles isn’t just marketing hype it’s backed by decades of real-world evidence from owners who have pushed these engines to astronomical mileage figures.

The secret to the 2JZ-GTE’s incredible durability lies in its conservative design philosophy and overbuilt construction. Toyota engineers designed this engine with a closed-deck iron block that provides exceptional strength and rigidity.

The cylinders feature iron sleeves that resist wear even under extreme conditi ons, while the forged steel crankshaft and connecting rods were built to handle far more stress than the factory turbochargers could ever produce.

This overengineering approach meant that even in stock form, the engine possessed the structural integrity to support double or triple its factory power output.

The cooling system design is another crucial factor in the 2JZ-GTE’s longevity. Toyota implemented an efficient coolant flow pattern that prevents hot spots and ensures even temperature distribution throughout the engine block.

The oil cooling system is equally impressive, with an integrated oil cooler that maintains optimal lubrication temperatures even during spirited driving. These thermal management systems work together to prevent the kind of heat-related wear that destroys many high-performance engines.

Manufacturing quality control was exceptionally tight for the 2JZ-GTE production. Toyota’s assembly processes ensured consistent tolerances and proper break-in procedures that set these engines up for long-term success.

The fuel injection system, while not as advanced as modern direct injection setups, proved remarkably reliable and consistent over hundreds of thousands of miles.

The sequential twin-turbo system, though complex, was engineered with redundancy and fail-safes that prevented catastrophic failures. Perhaps most importantly, the 2JZ-GTE was designed during an era when Japanese manufacturers prioritized long-term reliability over short-term cost savings.

Every component, from the head gasket to the oil pump, was built to last. The result is an engine that not only survives high mileage but often runs better at 200,000 miles than many modern engines do at 50,000 miles.

Owners regularly report these engines running smoothly past 300,000 miles with nothing more than regular maintenance, making the 2JZ-GTE the gold standard for durable performance engines.

2. Honda B16A (1989-2000)

The Honda B16A represents the pinnacle of naturally aspirated four-cylinder engineering, proving that high-revving performance engines can achieve remarkable longevity when properly designed.

This 1.6-liter DOHC VTEC engine powered various Honda models including the Civic Si and Integra, earning a reputation for delivering spirited performance while maintaining reliability that extends well beyond 200,000 miles.

The B16A’s success stems from Honda’s meticulous attention to internal component design and their revolutionary VTEC variable valve timing system.

Honda’s approach to the B16A centered on achieving high specific output through advanced valve train technology rather than forced induction. The VTEC system allows the engine to operate with mild cam profiles at low RPM for smooth idle and good fuel economy, then switch to aggressive high-lift cams at higher RPM for maximum power output.

This dual-personality design means the engine doesn’t need to compromise low-speed drivability for high-RPM performance, reducing wear during daily driving while still providing exhilarating performance when demanded.

The internal components of the B16A were engineered with exceptional precision and quality materials. The forged crankshaft provides incredible strength and perfect balance, allowing the engine to rev safely to 8,400 RPM without the vibration issues that plague many high-revving engines.

The connecting rods are manufactured from high-strength steel and feature precise weight matching that contributes to the engine’s remarkable smoothness.

The pistons are lightweight yet durable, with carefully designed ring packages that maintain excellent compression and oil control even after hundreds of thousands of miles.

Honda’s legendary build quality shines through in every aspect of the B16A’s construction. The cylinder head casting is exceptionally rigid, preventing valve train geometry changes that could affect timing or cause premature wear.

The VTEC system itself is a masterpiece of mechanical engineering, with precise oil pressure control and robust actuator mechanisms that function flawlessly for decades.

The oil pump design ensures consistent pressure at all RPM ranges, while the cooling system efficiently manages heat even during extended high-RPM operation.

Real-world longevity data for the B16A is impressive, with many examples surpassing 250,000 miles while still maintaining factory compression ratios and smooth operation. The engine’s ability to maintain its high-revving character even at extreme mileages is particularly noteworthy, as most engines lose their willingness to rev as wear accumulates.

Regular oil changes with quality lubricants and respect for proper warm-up procedures are typically all that’s needed to achieve this exceptional longevity. The B16A proves that performance and reliability aren’t mutually exclusive when engineering excellence is the priority.

3. General Motors LS1 (1997-2004)

The General Motors LS1 5.7-liter V8 marked a revolutionary departure from traditional American V8 design, introducing advanced materials and engineering concepts that would redefine expectations for domestic engine reliability.

This all-aluminum pushrod V8 powered the C5 Corvette, fourth-generation Camaro Z28, and Pontiac Firebird Trans Am, establishing a reputation for smooth operation and exceptional durability that extends well beyond 200,000 miles.

The LS1’s success represents GM’s commitment to combining traditional V8 characteristics with modern engineering excellence. The LS1’s aluminum construction was groundbreaking for a mass-production American V8, providing significant weight savings while maintaining exceptional strength.

The cylinder block features an aluminum construction with iron cylinder liners, creating an optimal balance of thermal expansion characteristics and wear resistance.

This design allows for tighter tolerances than traditional iron blocks while providing superior heat dissipation that contributes to long-term durability. The aluminum heads feature excellent port designs that promote efficient airflow and even fuel distribution across all cylinders.

Internal component quality in the LS1 represents a significant advancement over previous GM V8 engines. The crankshaft is manufactured from high-strength nodular iron with precise counterweighting that ensures smooth operation throughout the RPM range.

The connecting rods are powdered metal units that provide excellent strength-to-weight ratios, while the hypereutectic pistons feature advanced ring packages that maintain excellent sealing properties over extended mileage.

The hydraulic roller lifters and lightweight rocker arms create a valve train that operates quietly and efficiently for hundreds of thousands of miles.

The LS1’s fuel injection system represents one of its most reliable subsystems, featuring sequential port injection with precise fuel delivery and excellent atomization characteristics.

The ignition system utilizes individual coil-on-plug units that provide consistent spark energy while eliminating the maintenance issues associated with traditional distributor systems.

The PCM (Powertrain Control Module) features sophisticated engine management strategies that optimize performance while protecting critical components from damage due to adverse operating conditions.

Thermal management in the LS1 is exemplary, with an efficient cooling system design that maintains optimal operating temperatures under all conditions.

The oil system features adequate capacity and excellent circulation patterns that ensure proper lubrication of all critical components. The drive belt system is simplified compared to previous designs, reducing the potential for accessory-related failures that could strand drivers or cause engine damage.

Real-world reliability data for the LS1 is outstanding, with many examples exceeding 200,000 miles while maintaining factory performance levels and smooth operation.

The engine’s ability to maintain consistent oil pressure, compression ratios, and performance characteristics at high mileages has made it a favorite among enthusiasts who demand both reliability and performance.

Regular maintenance consisting of quality oil changes, coolant system service, and occasional spark plug replacement typically keeps these engines running smoothly for decades.

4. Mercedes-Benz OM617 (1974-1991)

The Mercedes-Benz OM617 diesel engine stands as one of the most durable powerplants ever produced, with countless examples surpassing 400,000 miles while maintaining smooth, reliable operation.

This 3.0-liter five-cylinder diesel powered various Mercedes models including the 300D and 300TD, earning a legendary reputation for longevity that has made these vehicles highly sought after by those prioritizing reliability above all else.

The OM617’s exceptional durability stems from Mercedes-Benz’s uncompromising approach to engineering and their deep understanding of diesel engine requirements.

The foundation of the OM617’s incredible longevity lies in its robust construction and conservative design parameters. The cast iron block features exceptionally thick cylinder walls and massive main bearing webs that provide tremendous structural rigidity.

This overbuilt construction allows the engine to maintain precise tolerances even after hundreds of thousands of miles of operation. The forged steel crankshaft is perfectly balanced and supported by five main bearings, creating a rotating assembly that exhibits minimal wear even after extreme mileages.

Mercedes engineers designed the OM617 with diesel-specific requirements in mind, resulting in components that could withstand the high compression ratios and combustion pressures inherent to diesel operation.

The combustion chambers are designed to promote efficient fuel mixing and complete combustion, while the injection system delivers fuel with precise timing and quantity control. The indirect injection design, while less efficient than modern direct injection systems, provides gentler combustion characteristics that contribute to engine longevity.

The valve train design of the OM617 emphasizes durability over complexity, featuring a single overhead cam with mechanical valve adjustment. This simple yet effective design eliminates the potential failures associated with hydraulic systems while providing precise valve timing that remains consistent over hundreds of thousands of miles.

The valve springs and guides are manufactured to exacting standards, ensuring proper sealing and minimal wear even under the demanding conditions of diesel operation.

Lubrication system design in the OM617 is exemplary, with generous oil capacity and efficient circulation patterns that ensure all critical components receive adequate lubrication.

The oil pump is gear-driven and provides consistent pressure throughout the engine’s operating range. The oil filtration system is robust, with full-flow filtration that keeps lubricants clean and protective.

The cooling system design effectively manages the higher heat loads associated with diesel operation while maintaining optimal operating temperatures.

The OM617’s reputation for extreme longevity is supported by countless real-world examples of these engines operating smoothly past 300,000 miles with nothing more than routine maintenance.

Many owners report engines that start easily, run smoothly, and maintain excellent compression even at astronomical mileages. The engine’s ability to maintain its characteristic diesel clatter without developing concerning noises or vibrations is particularly impressive.

Regular oil changes, fuel system maintenance, and occasional valve adjustments are typically sufficient to keep these engines running indefinitely, making the OM617 the benchmark for diesel engine durability.

Also Read: 5 Cars That Have Clean Titles at 200K Miles and 5 That Hide Lemon History

5. Subaru EJ22 (1990-1996)

The Subaru EJ22 2.2-liter naturally aspirated boxer engine represents one of the most reliable powerplants in Subaru’s history, earning a sterling reputation for smooth operation and exceptional longevity that often extends well beyond 200,000 miles.

This horizontally opposed four-cylinder engine powered various Subaru models including the Legacy and Impreza, demonstrating that proper engineering and conservative tuning can create remarkably durable engines even in unconventional configurations.

The EJ22’s success proves that Subaru’s boxer engine design can achieve exceptional reliability when not stressed by forced induction. The EJ22’s unique horizontally opposed configuration provides inherent advantages for long-term durability.

The low center of gravity reduces stress on engine mounts and surrounding components, while the opposed piston design creates natural balance that minimizes vibration throughout the RPM range.

This smooth operation reduces wear on internal components and surrounding systems, contributing to the engine’s exceptional longevity. The aluminum block construction provides excellent heat dissipation while maintaining adequate strength for reliable operation.

Internal component quality in the EJ22 represents Subaru engineering at its finest. The forged steel crankshaft is perfectly balanced and supported by five main bearings, creating exceptional smoothness and durability.

The connecting rods are manufactured from high-strength steel with precise weight matching, while the pistons feature robust ring packages that maintain excellent compression and oil control over extended mileages. The hydraulic valve lifters provide consistent valve lash adjustment while operating quietly and reliably for hundreds of thousands of miles.

The EJ22’s fuel injection system is simple yet effective, featuring multi-port injection with reliable fuel delivery and consistent atomization characteristics.

The ignition system utilizes a traditional distributor design that, while not as advanced as modern systems, provides reliable spark delivery with minimal maintenance requirements.

The engine management system is straightforward and robust, providing adequate control without the complexity that can lead to long-term reliability issues.

One of the EJ22’s greatest strengths is its conservative tuning philosophy. Unlike later turbocharged variants that pushed the limits of the boxer design, the EJ22 operates well within its mechanical limits under all conditions.

The compression ratio is moderate, the valve timing is conservative, and the power output is achieved through efficient breathing rather than high stress levels. This approach ensures that all components operate with adequate safety margins, contributing to exceptional longevity.

Cooling system design in the EJ22 effectively manages heat loads while providing consistent operating temperatures. The horizontally opposed layout actually aids cooling by providing excellent airflow access to both cylinder banks.

The oil system features adequate capacity and good circulation patterns, though owners should be diligent about oil changes due to the boxer engine’s tendency to consume small amounts of oil over time.

Real-world reliability data for the EJ22 is impressive, with many examples exceeding 250,000 miles while maintaining smooth operation and factory performance levels.

The engine’s ability to maintain its characteristic boxer rumble without developing concerning noises is particularly noteworthy. Regular maintenance consisting of quality oil changes, coolant system service, and timing belt replacement at specified intervals typically ensures decades of reliable operation, making the EJ22 one of Subaru’s most successful engine designs.

5 Engines That Knock Before 80K Miles

These problematic powerplants suffer from inherent design flaws and manufacturing compromises that lead to premature internal component failure and devastating knock conditions well before reaching typical replacement intervals.

Their substandard construction includes inadequate bearing clearances, poor cylinder head design, and insufficient cooling systems that create destructive operating conditions under normal driving scenarios and maintenance schedules.

From carbon buildup caused by direct injection systems to timing chain stretch that affects valve timing, these engines develop characteristic knocking sounds that signal impending catastrophic failure.

Owners frequently report expensive engine rebuilds or complete replacements before 100,000 miles with these unreliable powerplants costly repairs that often exceed the vehicle’s remaining value and leave drivers stranded unexpectedly.

1. Cadillac HT4100 (1982-1988)

The Cadillac HT4100 engine stands as one of the most notorious reliability disasters in automotive history, with many examples developing catastrophic problems well before reaching 80,000 miles.

This 4.1-liter aluminum V8 was designed during GM’s desperate attempt to meet fuel economy standards while maintaining Cadillac’s luxury image, but the result was an engine that combined inadequate engineering with cost-cutting measures that virtually guaranteed premature failure.

The HT4100’s problems were so severe that they nearly destroyed Cadillac’s reputation and served as a cautionary tale about rushing unproven technology to market.

The fundamental problem with the HT4100 was its aluminum construction, which would have been fine if properly executed, but GM’s implementation was severely compromised by cost-cutting and inadequate development time.

The aluminum block featured iron cylinder liners, but the thermal expansion characteristics between these dissimilar materials were not properly accounted for.

As the engine heated up during operation, the differential expansion rates would cause the cylinder liners to shift, leading to blown head gaskets, coolant leaks, and eventually complete engine failure.

The head gasket design was particularly problematic, featuring inadequate sealing surfaces and materials that couldn’t withstand the thermal stresses created by the aluminum block and iron liner combination.

Head gasket failures typically occurred between 40,000 and 60,000 miles, often presenting as coolant loss, overheating, and white smoke from the exhaust.

Many owners experienced multiple head gasket failures, as the underlying design problems meant that repairs were only temporary solutions to fundamental engineering flaws.

Internal component quality in the HT4100 was compromised by GM’s cost-cutting initiatives during the early 1980s. The crankshaft was adequate for the engine’s modest power output but showed premature wear due to inadequate lubrication and cooling.

The pistons and rings were of marginal quality, often developing excessive blow-by and oil consumption before 50,000 miles. The valve train components were similarly problematic, with lifters that developed noise and inconsistent operation relatively early in the engine’s life.

The fuel injection system, while advanced for its time, was plagued by reliability issues that contributed to the engine’s poor reputation. The throttle body injection system often developed fuel delivery problems that caused rough idle, poor performance, and increased emissions.

The engine management system was primitive by modern standards and couldn’t adequately compensate for the various mechanical problems that developed as the engine aged.

Cooling system inadequacy was another critical flaw in the HT4100 design. The system was undersized for the engine’s heat rejection requirements, leading to chronic overheating problems that accelerated all other failure modes.

The water pump was prone to early failure, while the radiator design was inadequate for the thermal loads generated by the aluminum engine. These cooling system deficiencies created a cascade of problems that typically resulted in complete engine failure before 80,000 miles.

The HT4100’s reputation was so poor that it effectively ended GM’s early attempts at aluminum engine construction and forced Cadillac to completely redesign its approach to luxury car powertrains.

Many owners experienced multiple complete engine replacements under warranty, while others simply abandoned their vehicles rather than continue fighting the ongoing reliability issues.

The HT4100 serves as a perfect example of how inadequate development time and cost-cutting can create engines that are fundamentally unreliable regardless of maintenance or driving habits.

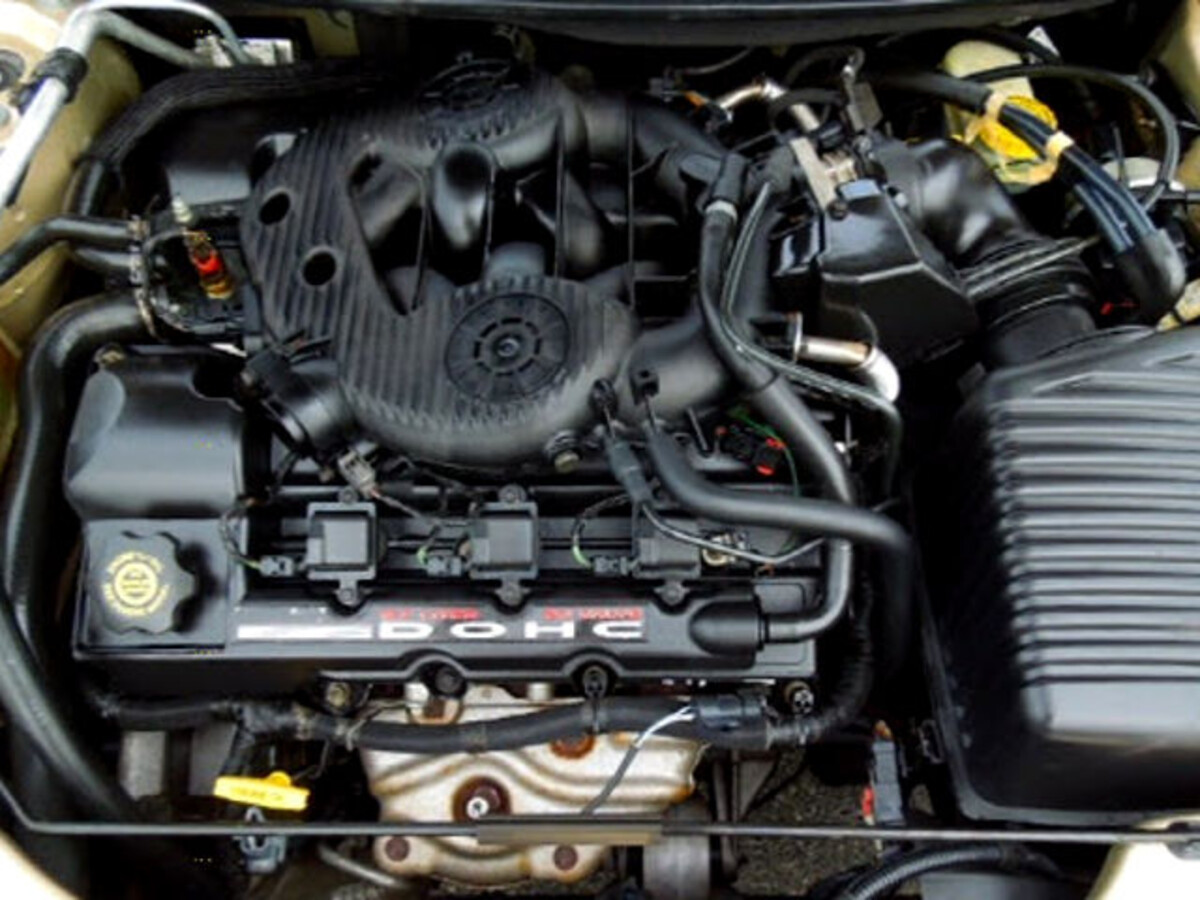

2. Chrysler 2.7L V6 (1998-2010)

The Chrysler 2.7-liter V6 engine earned an infamous reputation as one of the most problematic powerplants of the modern era, with many examples developing catastrophic oil sludge problems and complete engine failure before reaching 80,000 miles.

This engine powered various Chrysler, Dodge, and Plymouth models, including the Intrepid, Concorde, and Sebring, creating countless warranty claims and customer satisfaction issues that damaged the reputation of every vehicle it powered.

The 2.7L V6’s problems stemmed from fundamental design flaws that made it nearly impossible to achieve reliable long-term operation regardless of maintenance practices.

The most notorious problem with the 2.7L V6 was its tendency to develop severe oil sludge buildup that would completely clog oil passages and cause catastrophic engine failure. This sludging issue was caused by several design factors working in combination.

The engine’s cooling system design created hot spots that caused oil breakdown, while inadequate oil change intervals recommended by Chrysler accelerated the sludge formation process.

The oil passages were designed with insufficient capacity to handle the sludge buildup, creating a situation where even minor sludge accumulation could block critical lubrication routes.

The timing chain system in the 2.7L V6 was particularly problematic, featuring guides and tensioners that were inadequate for long-term durability.

As oil sludge accumulated in the timing chain area, the chain would stretch and the guides would wear, eventually leading to timing chain failure and catastrophic engine damage.

Many engines experienced timing chain problems between 60,000 and 80,000 miles, often without warning signs until complete failure occurred. The interference design meant that timing chain failure typically resulted in bent valves and complete engine destruction.

Water pump failure was another common problem with the 2.7L V6, typically occurring between 50,000 and 70,000 miles. The water pump design was inadequate for the engine’s cooling requirements, and failure often occurred without warning, leading to severe overheating and additional engine damage.

The location of the water pump made replacement expensive and time-consuming, often costing more than the vehicle was worth by the time failure occurred.

The oil pump design in the 2.7L V6 was marginal at best, providing barely adequate pressure when new and often failing to maintain proper pressure as wear accumulated.

The pump’s pickup screen was prone to clogging with oil sludge, further reducing oil pressure and accelerating engine wear. Many engines experienced oil pump failure before 80,000 miles, typically resulting in complete engine seizure and total loss.

Head gasket problems were also common with the 2.7L V6, often developing between 60,000 and 80,000 miles. The aluminum heads and iron block combination created thermal expansion issues similar to other problematic engines, while the cooling system inadequacies contributed to head gasket failure.

Blown head gaskets typically presented as coolant loss, overheating, and white smoke from the exhaust, but repair was often not economically viable due to the likelihood of additional problems.

The 2.7L V6’s reputation became so poor that it significantly impacted the resale values of all vehicles it powered. Many owners experienced complete engine failure before 80,000 miles despite following manufacturer’s maintenance recommendations.

The engine’s problems were so severe and widespread that class-action lawsuits were filed against Chrysler, and the company eventually discontinued the engine due to its terrible reputation.

The 2.7L V6 serves as a perfect example of how fundamental design flaws can create engines that are essentially unreliable regardless of maintenance or care.

3. Oldsmobile Diesel V8 5.7L (1978-1985)

The Oldsmobile 5.7-liter diesel V8 represents one of the most catastrophic engine failures in American automotive history, with most examples developing severe problems well before reaching 80,000 miles and many failing before 50,000 miles.

This engine was GM’s attempt to capitalize on diesel fuel’s price advantage during the late 1970s fuel crisis, but the execution was so fundamentally flawed that it nearly destroyed consumer confidence in diesel passenger cars for decades.

The Oldsmobile diesel’s problems stemmed from attempting to convert a gasoline engine design to diesel operation without adequate engineering changes.

The fundamental flaw in the Oldsmobile diesel was that it was essentially a converted gasoline engine rather than a purpose-built diesel powerplant.

GM took their existing 5.7-liter gasoline V8 and made minimal modifications to accommodate diesel combustion, including raising the compression ratio and installing a diesel injection system.

However, the basic engine block, crankshaft, and internal components were never designed for the dramatically higher combustion pressures and different operating characteristics of diesel fuel. This approach virtually guaranteed structural failures and premature wear.

Head gasket failure was the most common and devastating problem with the Oldsmobile diesel, typically occurring between 30,000 and 60,000 miles.

The head gasket design was completely inadequate for diesel combustion pressures, and the head bolt pattern and torque specifications were insufficient to maintain proper sealing.

Head gasket failure usually presents as coolant mixing with oil, severe overheating, and white smoke from the exhaust. Many engines experienced multiple head gasket failures, as the underlying design problems meant that repairs were only temporary fixes.

The injection pump system was another major source of problems, featuring mechanical fuel injection components that were poorly matched to the engine’s requirements.

The injection pumps were prone to premature failure, often before 50,000 miles, causing rough running, poor performance, and excessive smoke. Replacement injection pumps were extremely expensive and often failed just as quickly as the originals, creating an ongoing cycle of expensive repairs that exceeded the vehicles’ values.

Crankshaft and bearing problems were common due to the engine’s inadequate design for diesel operation. The crankshaft was not properly strengthened for diesel combustion pressures, while the bearing sizes and materials were marginal for the increased loads.

Many engines developed severe bearing knock before 60,000 miles, often progressing to complete crankshaft failure. The connecting rods were similarly inadequate, frequently bending or breaking under the stress of diesel combustion.

The cooling system design was woefully inadequate for diesel operation, leading to chronic overheating problems that accelerated all other failure modes. Diesel engines generate more heat than gasoline engines, but GM failed to adequately upgrade the cooling system capacity.

The water pump, radiator, and cooling passages were all undersized for the application, creating a situation where overheating was virtually inevitable under normal operating conditions.

Fuel system contamination was another persistent problem, as the diesel fuel injection system was sensitive to water and contaminants that were commonly found in diesel fuel of that era.

Water in the fuel system would cause injection pump failure and internal engine corrosion, while fuel contamination would clog injectors and cause poor performance. The fuel filtration system was inadequate for the contamination levels commonly encountered, leading to frequent fuel system problems.

The Oldsmobile diesel’s reputation became so poor that it effectively killed the market for diesel passenger cars in America for over two decades. Most owners experienced complete engine failure before 80,000 miles, often requiring complete engine replacement that cost more than the vehicle was worth.

The engine’s problems were so severe and widespread that they became the subject of congressional hearings and multiple lawsuits against GM. The Oldsmobile diesel serves as the ultimate cautionary tale about attempting to take shortcuts in engine design and the importance of proper development and testing before bringing products to market.

4. Audi 2.7T V6 (1999-2005)

The Audi 2.7-liter twin-turbocharged V6 engine, while capable of impressive performance, gained an unfortunate reputation for developing serious reliability problems before reaching 80,000 miles, particularly related to catastrophic turbocharger failures and carbon buildup issues.

This engine powered high-performance Audi models, including the S4 and A6, representing Audi’s attempt to combine luxury refinement with serious performance capabilities.

However, the aggressive tuning and complex systems required to achieve this performance came at the cost of long-term reliability, creating an engine that often required major repairs well before most owners expected.

The most notorious problem with the 2.7T was sudden and catastrophic turbocharger failure, typically occurring between 60,000 and 80,000 miles without warning.

The turbochargers were prone to bearing failure due to inadequate oil supply and cooling, often caused by clogged oil return lines or carbon buildup in the oil passages.

When a turbocharger failed, it typically sent metal debris throughout the engine oil system, contaminating the entire lubrication system and often necessitating complete engine replacement.

The twin-turbo design meant that when one turbocharger failed, the other usually followed shortly after due to contamination. Carbon buildup on the intake valves was another severe problem that affected virtually all 2.7T engines, typically becoming critical between 50,000 and 70,000 miles.

The direct injection system, while providing performance benefits, allowed carbon deposits to accumulate on the intake valves since fuel wasn’t washing over them as in port injection systems.

This carbon buildup would eventually cause rough idle, misfires, and reduced performance, requiring expensive walnut blasting or chemical cleaning procedures to remove. Many engines required this service multiple times throughout their lifespan.

The cooling system design in the 2.7T was complex and prone to multiple failure points that could cause catastrophic engine damage. The system featured multiple coolant pumps, complex routing, and numerous plastic components that were prone to failure.

Coolant pump failures were common before 80,000 miles, often causing severe overheating that could warp cylinder heads or damage other critical components. The cooling system’s complexity made diagnosis and repair expensive and time-consuming.

Oil sludge problems plagued many 2.7T engines, particularly those that didn’t receive frequent oil changes with high-quality synthetic lubricants. The turbochargers’ high operating temperatures and the engine’s complex oil routing created conditions that promoted oil breakdown and sludge formation.

Once sludge accumulated in critical oil passages, it would restrict flow to the turbochargers and other vital components, leading to catastrophic failures. Many engines required complete teardown and cleaning to address sludge problems.

The variable valve timing system in the 2.7T was another source of reliability concerns, featuring cam adjusters that were prone to failure due to oil contamination and wear.

am adjuster problems typically manifested as rough idle, poor performance, and diagnostic trouble codes, but repair required significant engine disassembly and expensive parts replacement.

The timing chain tensioners were also problematic, often failing before 80,000 miles and potentially causing timing chain jump and engine damage.

Fuel system problems were common due to the high-pressure requirements of the twin-turbo system and the sensitivity of the direct injection components.

Fuel pumps often failed before 80,000 miles, while the high-pressure fuel rail and injectors were prone to clogging and failure. These fuel system problems would cause misfires, poor performance, and potential engine damage if not addressed promptly.

The 2.7T’s reputation for expensive repairs before 80,000 miles made it one of the most feared used car purchases among enthusiasts. Many owners experienced repair bills that exceeded the vehicle’s value, often for problems that occurred well before the engine should have required major service.

While some examples achieved higher mileages with intensive maintenance, the majority required significant repairs or complete replacement before reaching what most consumers would consider acceptable mileage thresholds. The 2.7T serves as an example of how complex, highly tuned engines can sacrifice long-term reliability for short-term performance gains.

5. Ford 6.0L Power Stroke (2003-2007)

The Ford 6.0-liter Power Stroke diesel engine stands as one of the most problematic heavy-duty truck engines ever produced, with countless examples developing catastrophic failures well before reaching 80,000 miles despite being designed for commercial duty cycles that should have enabled much higher mileage capability.

This engine powered Ford Super Duty trucks during a critical period when diesel truck popularity was exploding, but its numerous design flaws and reliability problems created enormous warranty costs for Ford and frustration for customers who expected commercial-grade durability.

The 6.0L Power Stroke’s problems were so severe that they significantly damaged Ford’s reputation in the diesel truck market. The most notorious problem with the 6.0L Power Stroke was head gasket failure, which occurred with alarming frequency before 60,000 miles.

The head gasket design was inadequate for the combustion pressures and thermal stresses of diesel operation, while the head bolt pattern and torque specifications were insufficient to maintain proper sealing.

The problem was exacerbated by the engine’s tendency to overheat due to cooling system inadequacies. Head gasket failure typically presents as coolant loss, white smoke from the exhaust, and eventual complete engine failure if not addressed immediately.

The EGR (Exhaust Gas Recirculation) cooler was another major source of problems, failing catastrophically on most engines before 80,000 miles. The EGR cooler design was fundamentally flawed, featuring inadequate construction that couldn’t withstand the thermal cycles and corrosive exhaust gases it was exposed to.

When the EGR cooler failed, it would dump coolant directly into the cylinders, causing severe engine damage including bent connecting rods, cracked pistons, and destroyed cylinder heads.

This failure mode often occurred without warning and typically required complete engine replacement. Oil cooler problems plagued virtually every 6.0L Power Stroke, typically developing between 40,000 and 70,000 miles.

The oil cooler design was prone to internal leakage that would allow coolant to mix with engine oil, causing severe bearing damage and complete engine failure.

The oil cooler’s location made replacement expensive and time-consuming, while the damage caused by coolant contamination often necessitated complete engine rebuilding or replacement.

Turbocharger problems were common due to the engine’s inadequate oil supply system and the turbo’s exposure to excessive heat from the problematic EGR system.

The variable geometry turbocharger was prone to sticking vanes and bearing failure, typically occurring between 50,000 and 80,000 miles. Turbocharger failure often caused additional engine damage due to oil starvation or over-boost conditions, turning what should have been a component replacement into a major engine overhaul.

The high-pressure oil system that operated the fuel injectors was another persistent source of problems. The system featured numerous O-rings and seals that were prone to failure, causing rough running, poor performance, and eventually complete fuel system failure.

The high-pressure oil pump was also problematic, often failing before 80,000 miles and requiring expensive replacement. When the high-pressure oil system failed, it typically left the truck completely inoperable.

Fuel injection system problems were common due to the complexity of the hydraulically actuated electronic unit injectors (HEUI). The injectors themselves were prone to failure, often sticking open or closed and causing severe engine damage.

The fuel system’s sensitivity to contamination meant that even minor fuel quality issues could cause expensive injector failures. Many trucks required complete injector replacement before 80,000 miles, with costs often exceeding $4,000.

The cooling system design was fundamentally inadequate for the engine’s heat rejection requirements, leading to chronic overheating that accelerated all other failure modes.

The radiator, cooling fans, and water pump were all undersized for the application, while the complex coolant routing created numerous potential failure points. Cooling system failures typically triggered cascading problems that resulted in complete engine destruction.

The 6.0L Power Stroke’s reputation became so poor that it significantly impacted Ford’s position in the heavy-duty truck market. Many fleet operators abandoned Ford trucks entirely due to the engine’s reliability problems, while individual owners faced repair bills that often exceeded the vehicles’ values.

The engine’s problems were so severe and widespread that numerous aftermarket companies built entire businesses around fixing the fundamental design flaws.

Ford eventually replaced the 6.0L with a completely different engine design, effectively admitting that the problems were too severe to fix through conventional means.

The 6.0L Power Stroke serves as a cautionary tale about the importance of thorough testing and proper engineering in commercial vehicle applications where reliability is paramount.

Also Read: 5 Vehicles That Qualify for Insurance Discounts and 5 That Cost More Each Year