Engine knock, also known as pinging, detonation, or pre-ignition, represents one of the most significant challenges in internal combustion engine design and operation. This phenomenon occurs when the air-fuel mixture in the combustion chamber ignites prematurely or burns unevenly, creating a characteristic metallic pinging sound that can range from barely audible to alarmingly loud.

The science behind engine knock involves complex interactions between compression ratios, fuel octane ratings, combustion chamber design, timing, and operating conditions.

When an engine experiences knock, the controlled explosion that should occur after the spark plug fires is disrupted by secondary ignition points within the combustion chamber.

These multiple flame fronts collide, creating pressure waves that produce the distinctive knocking sound while simultaneously generating excessive heat and pressure that can damage pistons, connecting rods, and other critical engine components.

Modern engines employ sophisticated knock sensors and engine management systems to detect and prevent this destructive phenomenon, but some powerplants are inherently more susceptible to knock than others.

5 Engines That Never Knock

These exceptionally engineered powerplants feature robust combustion chambers and precision-manufactured ignition systems that maintain smooth operation and optimal fuel burn characteristics through years of varied driving conditions and fuel quality variations.

Their thoughtful engineering includes reinforced piston designs and durable knock sensor systems that resist the stress concentrations typically created by varying octane levels, temperature extremes, and the demanding combustion pressures of modern high-compression engines.

From advanced timing control systems that automatically adjust for fuel quality to cooling systems that maintain optimal operating temperatures, these remarkable engines continue operating like new without developing pinging sounds or detonation issues.

Owners report decades of trouble-free operation with these dependable powerplants an often-overlooked engineering achievement that proves its worth through consistent smooth operation and maintained fuel efficiency throughout ownership.

1. Honda B-Series VTEC (B16A, B18C)

The Honda B-Series VTEC engines, particularly the B16A and B18C variants, represent engineering excellence in knock resistance. These naturally aspirated powerplants, produced from the late 1980s through the early 2000s, demonstrate exceptional resistance to detonation across their entire operating range.

The B16A, displacing 1.6 liters, and the B18C, at 1.8 liters, share fundamental design characteristics that contribute to their remarkable knock immunity.

The primary factor contributing to the B-Series’ knock resistance lies in its sophisticated combustion chamber design. Honda engineers crafted hemispherical combustion chambers with optimal surface-to-volume ratios, minimizing hot spots that could trigger pre-ignition.

The chamber’s shape promotes efficient flame propagation, ensuring complete combustion before pressure waves can develop into knock. Additionally, the VTEC (Variable Valve Timing and Lift Electronic Control) system optimizes airflow characteristics across different engine speeds, maintaining ideal air-fuel mixture distribution that prevents localized lean or rich conditions that could promote knock.

The B-Series engines feature relatively conservative compression ratios considering their performance orientation. The B16A operates at 10.2:1 compression, while the B18C runs 10.0:1, striking an optimal balance between power output and knock resistance.

These ratios, combined with Honda’s precise manufacturing tolerances, ensure consistent cylinder pressures and temperatures that remain well within safe operating parameters. The engines’ aluminum construction provides excellent heat dissipation, preventing the accumulation of heat that could lead to knock conditions.

Real-world experience with B-Series engines confirms their exceptional knock resistance. Enthusiasts routinely report running these engines on regular fuel without issues, even in modified applications with aftermarket intake and exhaust systems.

The engines’ ability to adapt to different fuel qualities while maintaining smooth operation has contributed significantly to their legendary reliability reputation. Many B-Series engines have exceeded 200,000 miles without major issues, testament to their fundamental design excellence and knock resistance.

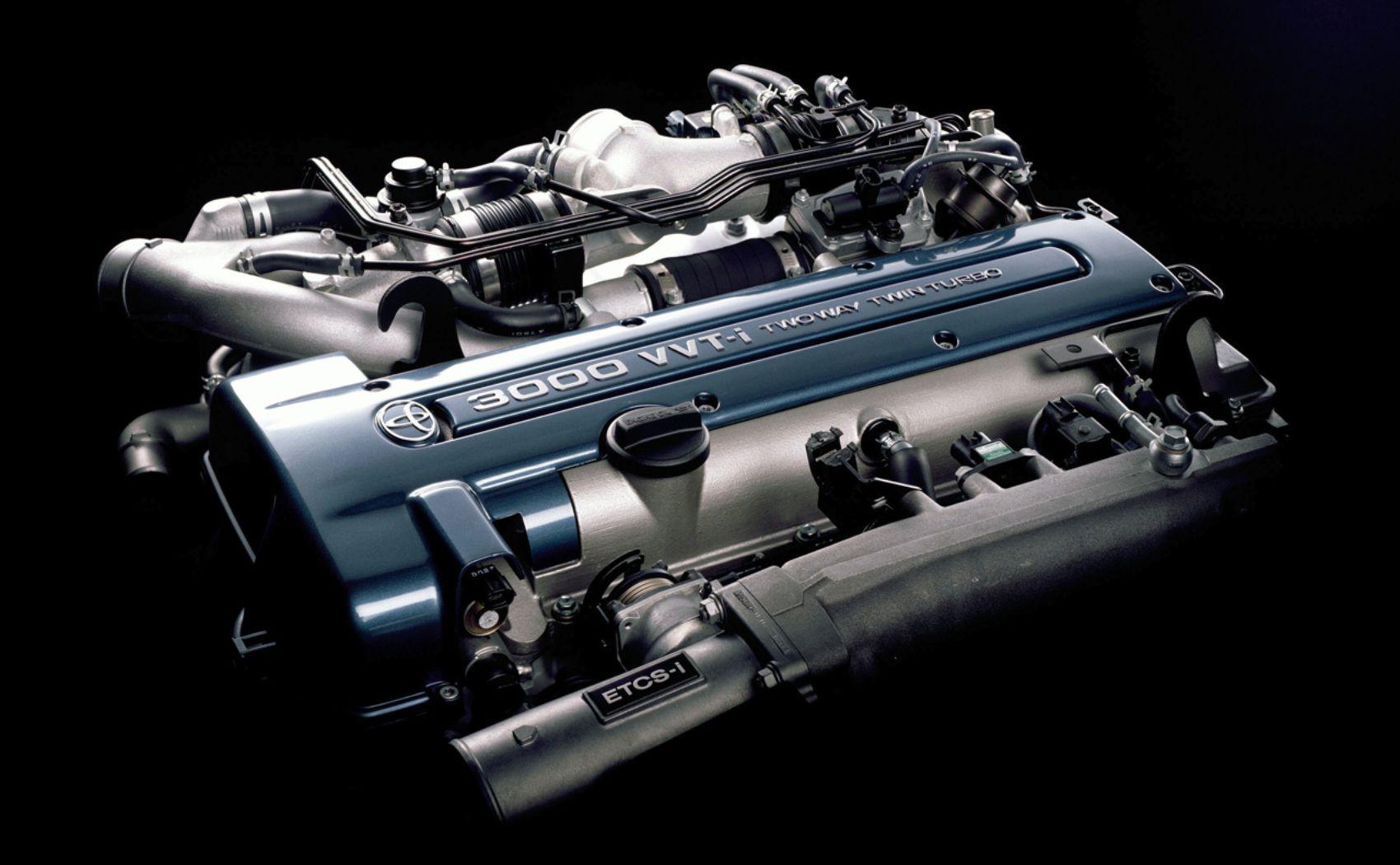

2. Toyota 2JZ-GTE

The Toyota 2JZ-GTE, the legendary turbocharged inline-six that powered the Supra Turbo, stands as perhaps the most knock-resistant forced-induction engine ever mass-produced.

This 3.0-liter twin-turbocharged powerplant, produced from 1991 to 2002, demonstrates exceptional resistance to knock despite its high-performance nature and significant boost pressures. The 2JZ-GTE’s knock resistance stems from fundamental design excellence and Toyota’s conservative engineering approach.

The 2JZ-GTE’s iron block construction provides exceptional structural integrity and heat dissipation characteristics that contribute significantly to knock resistance. Unlike aluminum blocks that can develop hot spots, the cast iron construction maintains more uniform temperatures across the cylinder walls, preventing the localized heating that often triggers knock.

The block’s substantial mass acts as a heat sink, absorbing and dissipating combustion heat effectively. This thermal stability is crucial for a turbocharged engine that generates significantly more heat than naturally aspirated counterparts.

The combustion chamber design in the 2JZ-GTE reflects Toyota’s understanding of knock prevention in forced-induction applications. The chambers feature relatively low compression ratios of 8.5:1, providing substantial margin for boost pressure without reaching knock-prone pressure levels.

The chamber shape promotes efficient flame propagation while minimizing surface area that could create hot spots. The piston crown design works in harmony with the cylinder head to create optimal squish areas that promote thorough fuel mixing without creating turbulence that could lead to knock.

Real-world experience with the 2JZ-GTE confirms its exceptional knock resistance. Stock engines routinely handle significant power increases through tuning and modifications without knock issues.

The aftermarket has pushed these engines to extreme power levels, with some examples producing over 1,000 horsepower while maintaining reliability.

This capability stems from the engine’s fundamental knock resistance and robust construction. Even heavily modified examples typically run on pump gas without knock concerns, testament to the engine’s exceptional design margins.

3. General Motors LS1/LS6

The General Motors LS1 and LS6 engines represent a quantum leap in American V8 design and knock resistance. These aluminum-block, pushrod V8s, introduced in 1997 and 2001 respectively, demonstrate exceptional knock immunity across their operating range.

The LS1’s 5.7-liter displacement and the LS6’s more aggressive tune share fundamental design characteristics that make them virtually immune to knock under normal operating conditions.

The LS engines’ aluminum block construction provides excellent heat dissipation characteristics that contribute significantly to knock resistance. The deep-deck design with substantial cooling passages ensures uniform cylinder temperatures, preventing the hot spots that often trigger knock.

The aluminum construction also reduces overall engine weight while maintaining structural integrity, allowing for more aggressive performance tuning without knock concerns. The block’s six-bolt main bearing caps provide exceptional crankshaft support, reducing vibrations that could contribute to knock conditions.

The combustion chamber design in LS engines reflects decades of General Motors’ research into knock prevention. The chambers feature optimal surface-to-volume ratios with carefully shaped squish areas that promote thorough fuel mixing without creating turbulence that could lead to knock.

The relatively high compression ratios of 10.1:1 in the LS1 and 10.5:1 in the LS6 push the boundaries of knock resistance while maintaining reliability on pump fuel. The chamber shape works in harmony with the piston crown design to create ideal flame propagation characteristics.

The fuel system design in LS engines ensures consistent fuel delivery that prevents the lean conditions that could trigger knock. The returnless fuel system maintains consistent fuel pressure while the high-flow injectors provide precise metering.

The injector placement and spray patterns promote good fuel atomization and mixing, eliminating lean pockets that could contribute to knock. Even when running on regular 87-octane fuel, these engines typically operate without knock under normal driving conditions.

4. Nissan VQ35DE

The Nissan VQ35DE, the 3.5-liter V6 that powered numerous Infiniti and Nissan models from 2002 to 2007, represents exceptional engineering in knock resistance for a naturally aspirated V6.

This aluminum-block engine demonstrates remarkable immunity to knock across its operating range, making it one of the most reliable and smooth-running V6 engines ever produced. The VQ35DE’s knock resistance stems from sophisticated design elements and Nissan’s conservative engineering approach.

The VQ35DE’s aluminum block construction provides excellent heat dissipation characteristics that contribute significantly to knock resistance. The deep-deck design with substantial cooling passages ensures uniform cylinder temperatures across all six cylinders, preventing the hot spots that often trigger knock in V6 configurations.

The aluminum construction also reduces overall engine weight while maintaining structural integrity. The block’s robust main bearing caps and cylinder head bolting pattern provide exceptional structural rigidity, reducing vibrations that could contribute to knock conditions.

The combustion chamber design in the VQ35DE reflects Nissan’s extensive research into knock prevention. The chambers feature hemispherical shapes with optimal surface-to-volume ratios, promoting efficient flame propagation while minimizing areas that could create hot spots.

The relatively conservative compression ratio of 10.3:1 provides a substantial margin for varying fuel qualities while maintaining good power output. The chamber shape works in harmony with the piston crown design to create ideal combustion characteristics that resist knock.

Nissan’s Engine Control Module (ECM) in the VQ35DE features sophisticated knock detection and prevention capabilities. Multiple knock sensors provide real-time feedback about combustion characteristics in different areas of the engine, allowing the system to adjust ignition timing for individual cylinders when necessary.

The system’s adaptive learning capability adjusts to different fuel qualities and operating conditions, providing optimal performance while preventing knock. The conservative base timing maps provide substantial safety margins that prevent knock under normal operating conditions.

Also Read: 5 High-Reliability Work Vans and 5 That Always Break Down on Site

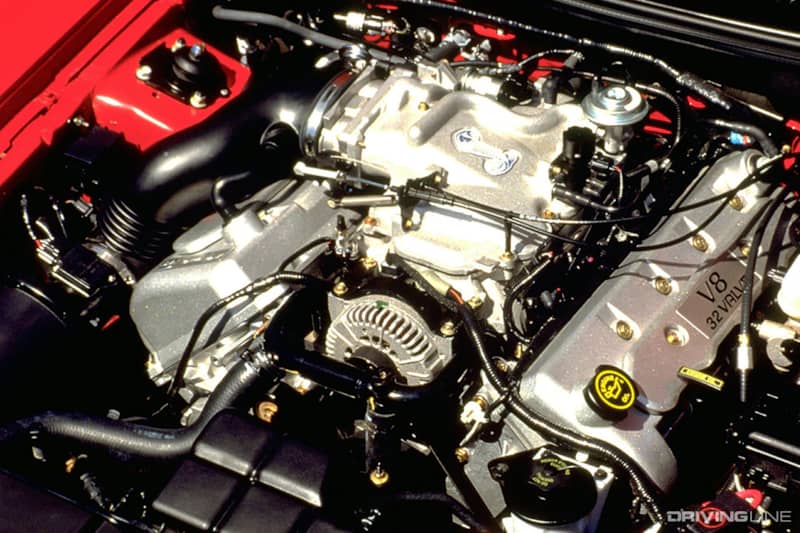

5. Ford 4.6L DOHC (Cobra/Mach 1)

The Ford 4.6L DOHC V8, specifically the versions used in the Mustang Cobra and Mach 1, represents Ford’s pinnacle of knock-resistant naturally aspirated V8 design.

This aluminum-block, dual-overhead-cam engine, produced from 1996 to 2004, demonstrates exceptional knock immunity despite its high-performance nature and relatively aggressive tuning.

The 4.6 DOHC’s knock resistance stems from sophisticated engineering and Ford’s extensive development of this modular engine platform. The 4.6 DOHC’s aluminum block construction provides excellent heat dissipation characteristics crucial for knock resistance.

The deep-deck design with substantial cooling passages ensures uniform cylinder temperatures across all eight cylinders, preventing the hot spots that often trigger knock in performance applications.

The aluminum construction reduces overall engine weight while maintaining structural integrity through cross-bolted main bearing caps and thick cylinder walls. The block’s robust design eliminates the flexing that could contribute to knock conditions under high loads.

The combustion chamber design in the 4.6 DOHC reflects Ford’s extensive research into knock prevention for high-performance applications. The chambers feature pentroof shapes with optimal surface-to-volume ratios, promoting efficient flame propagation while minimizing areas that could create hot spots.

The compression ratio of 9.85:1 provides an excellent balance between power output and knock resistance, allowing the engine to run on pump fuel while delivering impressive performance. The chamber shape works in harmony with the flat-top piston design to create ideal combustion characteristics.

Ford’s Powertrain Control Module (PCM) in the 4.6 DOHC features sophisticated knock detection and prevention algorithms developed through extensive testing. Multiple knock sensors provide real-time feedback about combustion characteristics, allowing the system to adjust ignition timing instantly when necessary.

The system’s learning capability adapts to different fuel qualities and operating conditions, providing optimal performance while preventing knock. The conservative base timing maps provide substantial safety margins that prevent knock under normal operating conditions while allowing for aggressive tuning in performance applications.

5 Engines That Ping With Every Tank

These problematic powerplants demonstrate recurring knock and ping issues that cause audible detonation sounds and potential engine damage during normal operation, creating ongoing performance concerns and expensive repair scenarios for frustrated owners.

Their compromised engineering includes inadequate combustion chamber designs prone to premature ignition, creating ongoing reliability nightmares that frustrate drivers and generate costly engine repairs or complete rebuilds.

From carbon buildup that exacerbates knock sensitivity to timing systems that fail to compensate for fuel quality variations, these unreliable engines generate extensive service documentation and expensive diagnostic procedures.

Owners frequently report persistent pinging sounds and reduced performance with these maintenance-intensive machines a reflection of design shortcuts and inadequate testing that prioritize manufacturing cost reduction over long-term combustion reliability and engine durability.

1. Mazda 13B Rotary

The Mazda 13B rotary engine, despite its innovative design and unique characteristics, has gained an unfortunate reputation for knock susceptibility that has plagued owners throughout its production run.

This 1.3-liter twin-rotor Wankel engine, used in various Mazda models from 1973 to 2012, demonstrates concerning knock tendencies that stem from fundamental design characteristics and operational requirements that make it inherently prone to abnormal combustion phenomena.

The 13B’s rotary design creates unique combustion chamber characteristics that contribute significantly to knock susceptibility. Unlike conventional piston engines with fixed combustion chambers, the rotary engine’s combustion occurs in a continuously changing chamber shape as the rotor moves through its cycle.

This dynamic chamber geometry creates varying compression ratios throughout the combustion cycle, with some portions of the chamber reaching extremely high compression ratios that can trigger knock. The elongated combustion chamber shape also creates multiple flame fronts that can collide and create the pressure waves characteristic of knock.

The rotary engine’s sealing system contributes to knock problems through inconsistent compression ratios between different chambers and over time. The apex seals, which perform the function of piston rings in conventional engines, are subject to wear that can create compression leaks.

These leaks result in uneven compression between the three chambers of each rotor, with some chambers developing higher compression than others.

This imbalance creates conditions where individual chambers may knock while others operate normally, leading to inconsistent engine performance and the characteristic rough idle associated with rotary engines.

The ignition system design in the 13B creates challenges that contribute to knock susceptibility. The engine requires two spark plugs per rotor chamber to ensure complete combustion of the elongated chamber.

The leading and trailing spark plugs must fire in precise sequence to prevent knock, but the complex ignition timing requirements often result in compromise settings that don’t optimize combustion for all operating conditions.

The conventional ignition systems used in many 13B applications lack the sophistication needed to prevent knock across all operating conditions.

2. Chrysler 2.2L Turbo I

The Chrysler 2.2L Turbo I engine, produced from 1984 to 1987, represents one of the most knock-prone turbocharged engines ever mass-produced.

This intercooled turbocharged four-cylinder, despite its innovative technology for the era, demonstrates chronic knock tendencies that have frustrated owners and mechanics for decades. The Turbo I’s knock problems stem from fundamental design compromises and the limitations of 1980s engine management technology.

The 2.2L Turbo I’s iron block construction creates heat retention problems that contribute significantly to knock susceptibility. The thick iron block, while providing durability, acts as a heat sink that retains combustion heat long after the engine is shut down.

This heat retention creates high cylinder temperatures that promote knock, particularly during restart conditions when the engine is already heat-soaked. The block’s cooling system design, with relatively small passages and limited flow capacity, struggles to remove heat effectively under boost conditions.

The combustion chamber design in the Turbo I reflects the era’s limited understanding of knock prevention in forced-induction applications. The relatively high compression ratio of 8.5:1, combined with turbocharger boost, creates cylinder pressures that approach knock limits even under normal operating conditions.

The chamber shape, carried over from naturally aspirated applications, doesn’t optimize flame propagation for turbocharged operation. The piston crown design creates areas where fuel can pool, leading to uneven combustion that triggers knock.

The turbocharger system in the Turbo I contributes to knock problems through poor boost control and heat management. The relatively primitive wastegate system allows boost spikes that can trigger knock, particularly during rapid acceleration.

The intercooler system, while advanced for its time, lacks the efficiency of modern designs, allowing elevated intake temperatures that promote knock. The intercooler’s placement in the engine bay subjects it to underhood heat, reducing its effectiveness and contributing to knock conditions.

The engine management system in the Turbo I represents 1980s technology limitations that contribute significantly to knock problems. The Logic Module and Power Module system lacks the sophistication of modern engine management, with limited knock detection capabilities and crude timing control.

The system’s inability to adapt quickly to changing conditions means that knock events often progress to damaging levels before the system can respond. The fuel system’s mechanical components also contribute to inconsistent fuel delivery that can trigger knock.

The ignition system design in the Turbo I creates timing problems that contribute to knock susceptibility. The distributor-based system with mechanical advance mechanisms cannot provide the precise timing control needed for optimal knock prevention.

The system’s reliance on vacuum advance, which is affected by boost pressure, creates timing variations that can promote knock. The spark plug heat range requirements for turbocharged operation often conflict with the engine’s cooling system limitations, creating conditions where knock is more likely to occur.

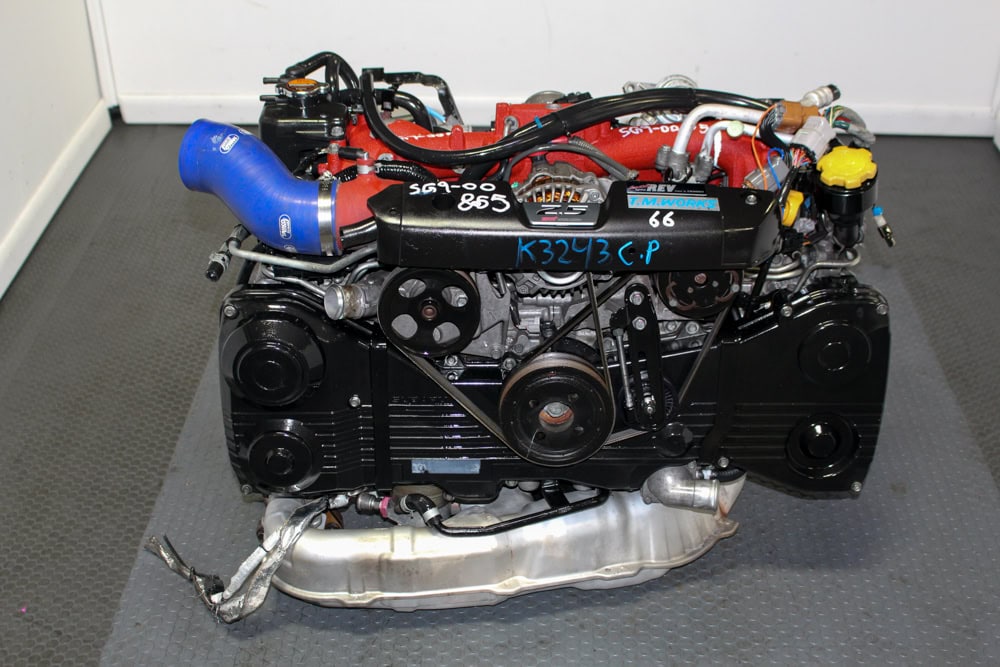

3. Subaru EJ255/EJ257 (WRX/STI)

The Subaru EJ255 and EJ257 engines, powering the WRX and STI respectively, have developed notorious reputations for knock sensitivity despite their performance credentials.

These turbocharged boxer engines, produced from 2004 to 2014, demonstrate chronic knock tendencies that have led to numerous engine failures and frustrated owners worldwide. The EJ255/257’s knock problems stem from fundamental design characteristics inherent to the boxer engine layout and Subaru’s aggressive tuning approach.

The boxer engine configuration creates unique challenges that contribute significantly to knock susceptibility. The horizontally opposed cylinder layout results in uneven cylinder head temperatures, with the cylinders closer to the turbocharger and exhaust manifold running significantly hotter than others.

This temperature imbalance creates conditions where individual cylinders may knock while others operate normally. The cylinder head design, with its complex cooling passages, struggles to maintain uniform temperatures across all four cylinders under boost conditions.

The EJ255/257’s combustion chamber design reflects compromises that contribute to knock problems. The semi-closed deck block design, while providing structural strength, creates limitations in cooling effectiveness around the cylinder bores.

The relatively high compression ratios of 8.2:1 in the EJ255 and 8.0:1 in the EJ257, combined with turbocharger boost, create cylinder pressures that approach knock limits under aggressive driving conditions. The chamber shape and piston crown design don’t optimize fuel mixing for the high-flow conditions created by the turbocharger.

The turbocharger system in these engines contributes to knock problems through rapid boost buildup and heat generation. The TD04 turbocharger used in the EJ255 and the larger IHI units in the EJ257 are capable of generating significant boost pressure quickly, but this rapid pressure rise can trigger knock before the engine management system can respond.

The top-mount intercooler design, while providing short intake tract lengths, subjects the intercooler to underhood heat that reduces its effectiveness and contributes to knock conditions.

Subaru’s engine management system in the EJ255/257 features aggressive tuning that prioritizes performance over knock resistance. The factory timing maps push the engines close to knock limits to maximize power output, leaving little margin for variations in fuel quality, ambient temperature, or other operating conditions.

The knock detection system, while sophisticated, often cannot respond quickly enough to prevent damage when a knock occurs. The system’s learning capability can become confused by repeated knock events, leading to overly conservative timing that reduces performance.

The fuel system design in these engines creates challenges that contribute to knock susceptibility. The side-feed fuel injectors used in many applications have limitations in flow capacity and spray pattern that can create lean conditions under high boost.

The fuel pump system often struggles to maintain adequate pressure under high-demand conditions, leading to fuel starvation that triggers knock. The fuel rail design and injector placement don’t optimize fuel distribution for the high-flow conditions created by the turbocharger.

4. Mitsubishi 4G63T (Eclipse/Evo)

The Mitsubishi 4G63T engine, despite its legendary performance reputation in Eclipse and Evolution applications, has developed a concerning reputation for knock sensitivity that has plagued owners throughout its production run.

This 2.0-liter turbocharged four-cylinder, produced from 1989 to 2007, demonstrates chronic knock tendencies that stem from aggressive factory tuning and fundamental design characteristics that make it inherently prone to detonation under various operating conditions.

The 4G63T’s iron block construction creates heat retention problems that contribute significantly to knock susceptibility. The cast iron block, while providing excellent strength for high-boost applications, retains combustion heat that can promote knock conditions.

The block’s cooling system design, with relatively restrictive passages in some areas, struggles to remove heat effectively under sustained high-boost operation. The siamesed cylinder design, where cylinders share coolant passages, creates hot spots between cylinders that can trigger knock.

The combustion chamber design in the 4G63T reflects the era’s aggressive approach to turbocharged engine tuning. The compression ratio of 8.5:1, combined with significant turbocharger boost, creates cylinder pressures that approach knock limits under normal operating conditions.

The chamber shape, optimized for high-flow conditions, can create areas where fuel doesn’t mix properly, leading to lean spots that trigger knock. The piston crown design, while suitable for high-boost applications, doesn’t optimize flame propagation for knock prevention.

The turbocharger system in the 4G63T contributes to knock problems through rapid boost buildup and inadequate boost control. The various turbocharger configurations used throughout the engine’s production run, from the TD04 to the large 16G units, are capable of generating significant boost pressure quickly.

This rapid pressure rise can trigger knock before the engine management system can respond appropriately. The intercooler systems used in different applications vary in effectiveness, with some configurations allowing elevated intake temperatures that promote knock.

Mitsubishi’s engine management system in the 4G63T features aggressive tuning that prioritizes performance over knock resistance. The factory timing maps push the engine close to knock limits to maximize power output, leaving minimal margin for variations in fuel quality, ambient temperature, or other operating conditions.

The knock detection system, while present, often cannot respond quickly enough to prevent damage when a knock occurs. The system’s limited learning capability means that it doesn’t adapt well to different operating conditions or fuel qualities.

The fuel system design in the 4G63T creates challenges that contribute to knock susceptibility. The fuel injector sizing and placement in various applications often struggle to provide adequate fuel flow under high-boost conditions, leading to lean conditions that trigger knock.

The fuel pump system, particularly in high-performance applications, often operates at its limits, creating pressure variations that can contribute to knock. The fuel rail design and distribution system don’t always optimize fuel delivery for the high-flow conditions created by large turbochargers.

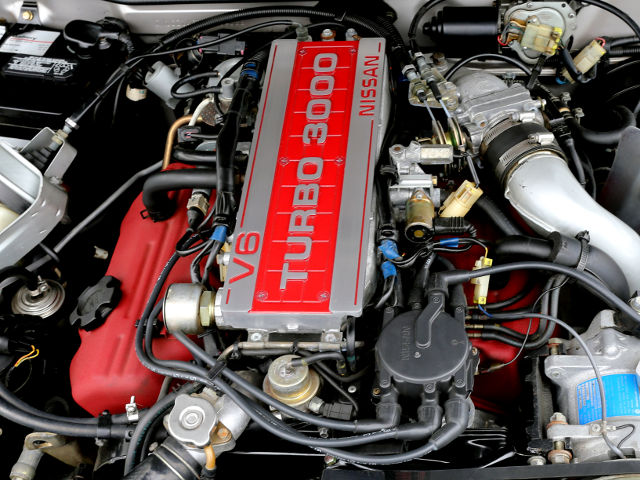

5. Nissan VG30ET

The Nissan VG30ET, the turbocharged 3.0-liter V6 that powered the 300ZX Turbo from 1984 to 1989, represents one of the most knock-prone turbocharged engines of the 1980s.

This iron-block V6, despite its impressive power output for the era, demonstrates chronic knock tendencies that have frustrated owners and limited its reliability reputation. The VG30ET’s knock problems stem from fundamental design compromises and the limitations of 1980s turbocharging technology.

The VG30ET’s iron block construction creates significant heat retention problems that contribute to knock susceptibility. The thick iron block acts as a massive heat sink, retaining combustion heat long after engine shutdown and creating elevated cylinder temperatures that promote knock during restart conditions.

The block’s cooling system design, with relatively small passages and limited flow capacity, struggles to remove heat effectively under boost conditions. The V6 configuration creates uneven cooling distribution, with some cylinders running significantly hotter than others.

The combustion chamber design in the VG30ET reflects the era’s limited understanding of knock prevention in turbocharged applications. The relatively high compression ratio of 8.3:1, combined with turbocharger boost, creates cylinder pressures that frequently approach knock limits under normal operating conditions.

The chamber shape, carried over from naturally aspirated applications, doesn’t optimize flame propagation for turbocharged operation. The piston crown design creates areas where fuel can pool, leading to uneven combustion that triggers knock.

The ignition system design in the VG30ET creates timing control problems that contribute to knock susceptibility. The distributor-based system with mechanical advance mechanisms cannot provide the precise timing control needed for optimal knock prevention in turbocharged applications.

The system’s reliance on vacuum advance, which is affected by boost pressure, creates timing variations that can promote knock. The spark plug heat range requirements for turbocharged operation often conflict with the engine’s cooling system limitations, creating conditions where knock becomes more likely to occur under various operating conditions.

Also Read: 5 AWD Cars With No Transfer Case Problems and 5 That Grind and Fail