Engine sludge formation represents one of the most significant challenges in automotive maintenance, directly impacting engine longevity, performance, and reliability.

This thick, tar-like substance forms when engine oil breaks down due to heat, oxidation, and contamination, creating deposits that can clog oil passages, damage components, and ultimately lead to catastrophic engine failure.

Understanding which engines are prone to sludge formation and which maintain cleaner internals is crucial for both mechanics and vehicle owners.

The propensity for sludge formation varies dramatically between different engine designs, manufacturers, and maintenance practices. Some engines demonstrate remarkable resistance to sludge buildup through superior engineering, better oil circulation systems, and advanced materials.

These engines often feature improved oil filtration, better cooling systems, and design elements that minimize hot spots where oil degradation typically occurs. Conversely, certain engines are notorious for rapid sludge accumulation due to design flaws, inadequate oil circulation, poor heat management, or manufacturing defects.

Factors contributing to sludge formation include infrequent oil changes, short-trip driving patterns, extreme temperatures, contaminated oil, and specific engine design characteristics.

The consequences of sludge buildup extend beyond mere maintenance inconvenience, potentially causing complete engine seizure, expensive repairs, and premature engine replacement.

This comprehensive analysis examines ten engines that exemplify the extremes of this spectrum, providing valuable insights for automotive enthusiasts, mechanics, and anyone seeking to understand the critical relationship between engine design and long-term reliability.

5 Engines That Stay Clean Inside

These exceptionally designed powerplants feature robust oil circulation systems and precision-manufactured components that maintain optimal internal cleanliness through years of operation without developing the sludge buildup that destroys lesser engines

Their thoughtful engineering includes efficient oil flow patterns and durable PCV systems that resist the contamination typically created by combustion byproducts, temperature cycling, and extended service intervals.

From crankcase ventilation designs that effectively remove moisture to oil passages that prevent stagnation zones, these remarkable engines continue operating like new without developing internal deposits.

Owners report decades of clean operation with these dependable powerplants, an often-overlooked quality feature that proves its worth through consistent performance and maintained longevity throughout ownership.

1. Honda K-Series Engine (2001-2011)

The Honda K-series engine family stands as a testament to exceptional engineering and long-term reliability, consistently earning praise for maintaining remarkably clean internals throughout extended service intervals.

This naturally aspirated four-cylinder engine, found in vehicles like the Civic Si, Accord, and CR-V, incorporates several design elements that actively prevent sludge formation and promote optimal oil circulation.

The K-series benefits from Honda’s meticulous attention to oil passage design, featuring large, strategically placed oil galleries that ensure consistent lubrication flow throughout the engine.

The oil pump delivers adequate pressure across all RPM ranges, preventing oil starvation that often leads to localized heating and subsequent sludge formation. Additionally, the engine’s aluminum construction provides superior heat dissipation compared to iron blocks, maintaining more consistent operating temperatures that reduce oil breakdown.

Honda’s variable valve timing system (VTEC) in the K-series contributes to cleaner operation by optimizing combustion efficiency, reducing blow-by gases that contaminate engine oil.

The precise engineering tolerances minimize internal friction, generating less heat and reducing the likelihood of oil degradation. The engine’s relatively simple design eliminates unnecessary complexity that could create oil circulation dead spots or maintenance challenges.

Real-world evidence supports the K-series’ reputation for cleanliness. Mechanics frequently report finding minimal sludge deposits even in high-mileage examples exceeding 200,000 miles, provided basic maintenance schedules are followed.

The engine’s forgiving nature means that even with extended oil change intervals, serious sludge problems rarely develop. This reliability has made the K-series a favorite among both daily drivers and performance enthusiasts who appreciate its combination of durability and responsiveness.

The K-series’s success stems from Honda’s philosophy of conservative engineering and extensive testing. Rather than pushing boundaries with complex technologies that might introduce reliability issues, Honda focused on perfecting fundamental engine design principles.

This approach resulted in an engine that not only stays clean but also delivers consistent performance throughout its operational life, making it a benchmark for automotive reliability.

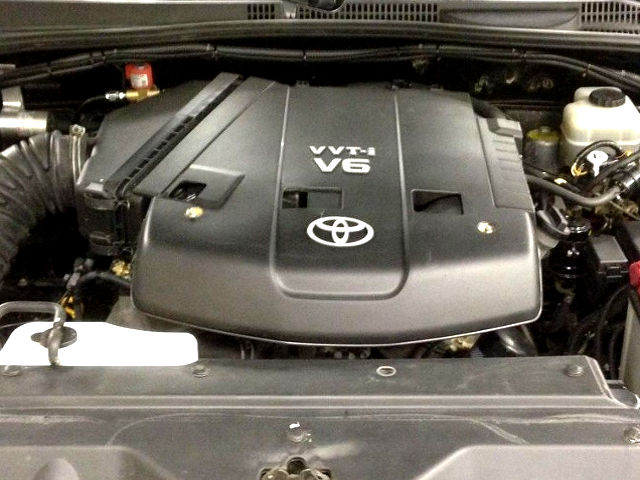

2. Toyota 1GR-FE V6 Engine (2003-2015)

Toyota’s 1GR-FE V6 engine represents a masterclass in engineering reliability and internal cleanliness, serving as the powerplant for vehicles including the 4Runner, Tacoma, and FJ Cruiser.

This 4.0-liter naturally aspirated V6 has earned widespread recognition for maintaining exceptionally clean internals even under demanding operating conditions, making it a preferred choice for off-road enthusiasts and commercial applications.

The 1GR-FE’s superior performance against sludge formation stems from its robust oil circulation system, which features a high-capacity oil pump and well-designed oil galleries that ensure consistent lubrication to all engine components.

Toyota engineers optimized the oil flow paths to eliminate stagnant areas where oil could accumulate and degrade. The engine’s aluminum block and heads provide excellent thermal conductivity, effectively dissipating heat that could otherwise cause oil breakdown and sludge formation.

One of the most significant advantages of the 1GR-FE is its dual variable valve timing system (VVT-i), which optimizes combustion efficiency across all operating conditions.

This technology reduces the production of combustion by-products that typically contaminate engine oil, extending oil life and preventing sludge accumulation.

The engine’s relatively conservative compression ratio and advanced knock control systems further contribute to cleaner operation by minimizing combustion irregularities. The 1GR-FE’s reputation for cleanliness extends beyond theoretical advantages to real-world performance.

Mechanics consistently report finding minimal sludge deposits in engines with over 300,000 miles of service, particularly impressive given that many of these vehicles operate in harsh conditions, including extreme temperatures, dusty environments, and frequent towing applications.

The engine’s ability to maintain cleanliness under stress demonstrates the effectiveness of Toyota’s engineering approach. Toyota’s commitment to quality control and extensive testing protocols ensures that each 1GR-FE engine meets strict cleanliness standards before leaving the factory.

The company’s emphasis on long-term reliability over short-term performance gains has resulted in an engine that not only resists sludge formation but also maintains consistent performance characteristics throughout its operational life, solidifying Toyota’s reputation for dependable powertrains.

3. General Motors LS Series V8 (1997-2017)

The General Motors LS series V8 engine family represents one of the most successful and clean-running powerplants in automotive history, demonstrating exceptional resistance to sludge formation while delivering impressive performance and reliability.

Found in vehicles ranging from the Chevrolet Corvette to the Cadillac Escalade, the LS series has consistently maintained clean internals even under extreme operating conditions.

The LS series’ resistance to sludge formation begins with its advanced aluminum construction, which provides superior heat dissipation compared to traditional iron blocks.

This thermal efficiency prevents the formation of hot spots where oil degradation typically occurs, maintaining more consistent operating temperatures throughout the engine. The deep-skirt block design enhances structural rigidity while creating optimal oil circulation patterns that prevent stagnation and promote continuous oil movement.

General Motors engineers designed the LS series with a sophisticated oil management system featuring a high-volume oil pump and strategically placed oil galleries that ensure adequate lubrication to all critical components.

The engine’s relatively flat oil pan design, combined with windage trays and oil control measures, prevents oil foaming and maintains consistent oil pressure across all operating conditions. This attention to oil management directly contributes to reduced sludge formation and extended engine life.

The LS series benefits from an advanced combustion chamber design that promotes complete fuel burning, reducing the production of combustion by-products that contaminate engine oil.

The engine’s efficient breathing characteristics, achieved through carefully designed intake and exhaust ports, minimize blow-by gases that typically accelerate oil degradation. Additionally, the LS series’ robust valve train design operates with minimal wear, reducing metal particles that could catalyze sludge formation.

Real-world evidence strongly supports the LS series’ reputation for cleanliness. Mechanics frequently encounter high-mileage LS engines with remarkably clean internals, even those subjected to performance modifications or demanding driving conditions.

The engine’s forgiving nature means that even with extended service intervals, serious sludge problems rarely develop, making it a favorite among both casual drivers and performance enthusiasts who appreciate its combination of power and reliability.

4. BMW N52 Inline-6 Engine (2004-2015)

The BMW N52 inline-6 engine stands as a remarkable achievement in automotive engineering, combining sophisticated technology with exceptional internal cleanliness to deliver a powerplant that maintains pristine conditions throughout its operational life.

This naturally aspirated 3.0-liter engine, found in vehicles including the 3 Series, 5 Series, and X3, demonstrates how advanced engineering can effectively prevent sludge formation while delivering impressive performance.

The N52’s resistance to sludge formation stems from its innovative magnesium-aluminum composite construction, which provides exceptional thermal conductivity and lightweight characteristics.

This advanced metallurgy enables superior heat dissipation, preventing the formation of hot spots where oil degradation typically occurs. The engine’s sophisticated cooling system, featuring electronically controlled thermostats and precise coolant flow management, maintains optimal operating temperatures that preserve oil integrity.

BMW’s Valvetronic technology in the N52 contributes significantly to internal cleanliness by optimizing combustion efficiency and reducing blow-by gases that contaminate engine oil.

This infinitely variable valve lift system eliminates the need for a traditional throttle body, reducing pumping losses and improving combustion quality. The result is cleaner operation with fewer combustion by-products that could contribute to sludge formation.

The N52 features an advanced oil circulation system with precisely calibrated oil galleries and a variable displacement oil pump that delivers optimal pressure across all operating conditions.

BMW engineers designed the oil flow paths to eliminate stagnant areas while ensuring adequate lubrication to all critical components. The engine’s sophisticated oil filtration system, combined with extended oil change intervals using high-quality synthetic oils, further contributes to maintaining clean internals.

Real-world experience confirms the N52’s exceptional cleanliness, with mechanics regularly reporting minimal sludge deposits even in high-mileage examples exceeding 200,000 miles.

The engine’s ability to maintain cleanliness while delivering smooth, responsive performance has made it a favorite among BMW enthusiasts who appreciate its combination of sophistication and reliability. This success demonstrates how advanced engineering and quality materials can effectively prevent sludge formation while maintaining long-term durability.

Also Read: 5 Million-Mile Engines You’ve Never Heard Of and 5 That Never Last Long

5. Mazda Skyactiv-G 2.0L Engine (2011-Present)

The Mazda Skyactiv-G 2.0L engine represents a revolutionary approach to internal combustion engine design, achieving remarkable internal cleanliness through innovative engineering solutions that optimize combustion efficiency and oil management.

This naturally aspirated four-cylinder engine, found in vehicles including the Mazda3, Mazda6, and CX-5, demonstrates how modern technology can effectively prevent sludge formation while delivering impressive fuel economy and performance.

The Skyactiv-G’s exceptional cleanliness stems from its ultra-high compression ratio of 13:1, which promotes complete combustion and reduces the production of harmful by-products that contaminate engine oil.

Mazda engineers achieved this high compression ratio through precise combustion chamber design, optimized fuel injection timing, and advanced knock control systems. The result is cleaner burning that minimizes oil contamination and extends oil life.

Mazda’s innovative approach to oil circulation in the Skyactiv-G includes strategically placed oil jets that provide targeted cooling to critical components, preventing hot spots where oil degradation typically occurs.

The engine’s aluminum construction provides excellent thermal conductivity, while the sophisticated cooling system maintains optimal operating temperatures. These design elements work together to preserve oil integrity and prevent sludge formation.

The Skyactiv-G features an advanced oil management system with a variable displacement oil pump that delivers optimal pressure while reducing parasitic losses.

The engine’s precisely designed oil galleries ensure consistent lubrication flow, while the efficient oil filtration system removes contaminants before they can contribute to sludge formation. Additionally, the engine’s low-friction design reduces wear particles that could catalyze oil degradation.

Real-world evidence supports the Skyactiv-G’s reputation for cleanliness, with early adopters reporting minimal sludge formation even after extended service intervals.

The engine’s efficient operation and clean combustion characteristics contribute to extended oil life, reducing maintenance costs while maintaining optimal performance.

This success demonstrates Mazda’s commitment to developing engines that combine environmental responsibility with long-term reliability and cleanliness.

5 Engines That Sludge Up Quickly

These problematic powerplants demonstrate recurring sludge formation that causes catastrophic lubrication failures and expensive engine damage during normal operation, creating costly ownership scenarios for unsuspecting drivers.

Their compromised engineering includes inadequate oil circulation designs prone to deposit formation, creating ongoing reliability nightmares that generate devastating repair bills.

From poor crankcase ventilation that allows moisture buildup to oil passages that create stagnation zones, these unreliable engines generate extensive sludge-related documentation and expensive cleaning procedures.

Owners frequently report complete engine failure with these deposit-prone machines, a reflection of design shortcuts that prioritize manufacturing cost reduction over internal cleanliness and lubrication system effectiveness.

1. Audi/Volkswagen 1.8T Engine (1996-2006)

The Audi/Volkswagen 1.8T engine, while revolutionary in its introduction of affordable turbocharged performance, unfortunately became notorious for rapid sludge formation that could lead to catastrophic engine failure.

This 1.8-liter turbocharged four-cylinder engine, found in vehicles including the Audi A4, Volkswagen Passat, and Jetta, demonstrated how design compromises and manufacturing issues could create conditions conducive to severe sludge accumulation.

The 1.8T’s propensity for sludge formation stems from several fundamental design characteristics that promote oil degradation. The engine’s turbocharger creates extreme heat conditions that rapidly break down engine oil, particularly in the oil return passages from the turbocharger housing.

These high-temperature conditions, combined with relatively narrow oil passages, create ideal environments for sludge formation. The turbocharger’s oil supply and return system, while functional, lacks the robust design necessary to handle the thermal stress without accelerating oil degradation.

Manufacturing tolerances in early 1.8T engines contributed significantly to sludge problems. The engine’s complex oil circulation system, featuring numerous small passages and galleries, proved vulnerable to blockage from even minor amounts of sludge.

When these passages became restricted, oil flow decreased, leading to localized heating and accelerated sludge formation in a destructive cycle. The engine’s aluminum construction, while lightweight, showed sensitivity to thermal cycling that could affect oil circulation patterns.

The 1.8T’s Variable Valve Timing system, while technologically advanced, introduced additional complexity that could exacerbate sludge problems.

The system’s oil-actuated components required clean, flowing oil to function properly, and any sludge accumulation could cause timing irregularities that further stressed the engine and accelerated oil degradation. Additionally, the engine’s relatively small oil capacity meant that contamination levels rose quickly, overwhelming the oil’s ability to suspend particles and prevent sludge formation.

Real-world experience with the 1.8T revealed the severity of its sludge problems, with many engines requiring major repairs or complete replacement due to sludge-related failures.

Mechanics frequently encountered engines with completely blocked oil passages, seized turbochargers, and damaged internal components directly attributable to sludge accumulation.

These problems often manifested relatively early in the engine’s life, sometimes before reaching 100,000 miles, making the 1.8T a cautionary tale about the importance of proper oil management in turbocharged applications.

2. Toyota 3.0L V6 3VZ-E Engine (1988-1995)

The Toyota 3VZ-E 3.0L V6 engine represents an unusual departure from Toyota’s typically reliable powertrains, demonstrating how even experienced manufacturers can produce engines prone to rapid sludge formation.

This naturally aspirated V6, found in vehicles including the Camry, Pickup (later Tacoma), and 4Runner, developed a reputation for sludge-related problems that contrasted sharply with Toyota’s usual reliability standards.

The 3VZ-E’s sludge problems stem primarily from its inadequate oil circulation system, which features oil galleries that proved insufficient for the engine’s thermal demands.

The engine’s iron block construction, while durable, retains heat more readily than aluminum alternatives, creating conditions that accelerate oil breakdown. The V6 configuration, combined with the engine’s relatively compact design, resulted in heat concentration areas where oil circulation was marginal, leading to localized sludge formation.

Manufacturing issues further compounded the 3VZ-E’s sludge problems. The engine’s oil pump, while adequate for basic lubrication, lacked the capacity to maintain optimal oil pressure under all operating conditions.

When combined with the engine’s tendency to run hot, particularly in truck applications with heavy loads or trailer towing, oil pressure drops could occur, reducing circulation and promoting sludge formation.

The engine’s oil filtration system, while functional, proved inadequate for managing the contaminants generated by the engine’s combustion characteristics.

The 3VZ-E’s combustion system contributed to its sludge problems through the production of excessive blow-by gases that contaminated engine oil.

The engine’s piston ring design and cylinder wall finish, while meeting specifications, allowed more combustion gases to enter the crankcase than optimal. These gases, combined with fuel vapors and combustion by-products, accelerated oil degradation and created conditions conducive to sludge formation.

Real-world experience with the 3VZ-E revealed consistent patterns of sludge-related problems, particularly in vehicles subjected to demanding operating conditions.

Mechanics frequently encountered engines with severely restricted oil passages, damaged bearing surfaces, and complete sludge blockages that required extensive rebuilding or replacement. These problems often manifested in vehicles with seemingly adequate maintenance, highlighting the engine’s inherent vulnerability to sludge formation regardless of owner care.

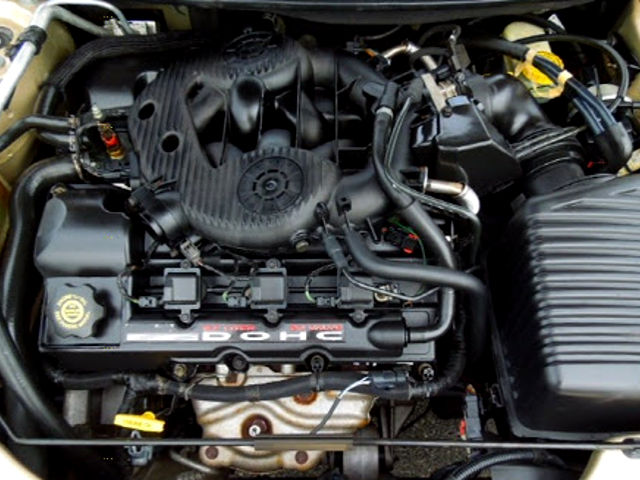

3. Chrysler 2.7L V6 Engine (1998-2010)

The Chrysler 2.7L V6 engine became infamous throughout the automotive industry for its propensity to develop severe sludge problems that often led to complete engine failure.

This aluminum V6, found in vehicles including the Dodge Intrepid, Chrysler Concorde, and Sebring, demonstrated how cost-cutting measures and design compromises could create conditions that rapidly promote sludge formation and engine destruction.

The 2.7L’s sludge problems stem from its fundamentally flawed oil circulation system, which features inadequately sized oil passages and galleries that restrict proper oil flow.

The engine’s aluminum construction, while reducing weight, proved sensitive to thermal cycling that could affect oil circulation patterns. The narrow oil passages, originally designed to reduce manufacturing costs, became easily blocked by even small amounts of sludge, creating a cascade effect where reduced oil flow led to increased heat generation and accelerated sludge formation.

Chrysler’s cost-cutting approach extended to the 2.7L’s oil pump design, which proved inadequate for maintaining proper oil pressure under all operating conditions.

The pump’s relatively small capacity meant that any restriction in oil flow could cause pressure drops that reduced circulation throughout the engine.

This problem was particularly acute in the upper cylinder head areas, where oil had to flow against gravity through already narrow passages. When sludge began forming, these areas became critically under-lubricated, leading to component damage and further oil degradation.

The 2.7L’s timing chain system, while eliminating the maintenance requirements of timing belts, introduced additional complexity that exacerbated sludge problems.

The chain tensioners and guides required clean, flowing oil to function properly, and any sludge accumulation could cause timing irregularities that stressed the engine and accelerated oil breakdown. The engine’s Variable Valve Timing system, when equipped, added further oil flow requirements that the inadequate circulation system struggled to meet.

Manufacturing quality control issues further compromised the 2.7L’s reliability. Inconsistent machining tolerances in oil passages, combined with assembly problems that could restrict oil flow, created engines that were particularly vulnerable to sludge formation.

The engine’s relatively small oil capacity meant that contamination levels rose quickly, overwhelming the oil’s ability to suspend particles and prevent sludge formation. These problems often manifested catastrophically, with complete engine seizure occurring with little warning.

4. Volkswagen 2.0L FSI Engine (2003-2008)

The Volkswagen 2.0L FSI (Fuel Stratified Injection) engine, although technologically advanced and offering impressive performance and fuel economy, unfortunately developed a reputation for rapid sludge formation, which could lead to expensive repairs and premature engine failure.

This naturally aspirated four-cylinder engine, found in vehicles such as the Golf, Jetta, and Audi A3, demonstrated how complex fuel injection systems can inadvertently create conditions conducive to oil contamination and sludge accumulation.

The FSI engine’s sludge problems stem primarily from its innovative direct injection system, which, while improving performance and emissions, introduced new challenges for oil management.

The high-pressure fuel injection system operates at pressures exceeding 2,000 PSI, creating conditions where fuel can leak past seals and contaminate engine oil.

This fuel contamination acts as a solvent that breaks down oil additives and promotes sludge formation. Additionally, the direct injection system’s operation can create carbon deposits that, when mixed with oil, accelerate sludge formation.

The FSI’s Variable Valve Timing system, while providing performance benefits, requires precise oil pressure and flow to function properly. The system’s complexity, combined with relatively narrow oil passages, creates multiple points where sludge can accumulate and restrict oil flow.

When these passages become blocked, the VVT system can malfunction, causing timing irregularities that increase combustion temperatures and accelerate oil degradation. This creates a destructive cycle where sludge formation begets more sludge formation.

Manufacturing and design issues further compromised the FSI’s oil management capabilities. The engine’s oil pump, while adequate for normal operation, proved sensitive to oil viscosity changes that could occur as sludge formed.

The oil pickup screen, designed to prevent large particles from entering the oil system, could become clogged with sludge, reducing oil flow and creating localized heating. The engine’s relatively complex oil circulation system, featuring numerous small passages and galleries, proved vulnerable to blockage from even minor amounts of sludge.

Real-world experience with the FSI revealed consistent patterns of sludge-related failures, often occurring relatively early in the engine’s life. Mechanics frequently encountered engines with severely restricted oil passages, damaged Variable Valve Timing components, and complete sludge blockages that required extensive repairs or engine replacement.

These problems often manifest in vehicles with regular maintenance, highlighting the engine’s inherent vulnerability to sludge formation regardless of owner care and attention.

5. Mitsubishi 3.8L V6 6G75 Engine (2006-2012)

The Mitsubishi 3.8L V6 6G75 engine, while offering adequate performance in vehicles like the Eclipse and Galant, unfortunately developed a reputation for rapid sludge formation that could lead to catastrophic engine failure.

This naturally aspirated V6 demonstrated how seemingly minor design compromises and manufacturing issues could create conditions that rapidly promote oil degradation and sludge accumulation.

The 6G75’s sludge problems stem from its inadequate oil circulation system, which features oil galleries and passages that proved insufficient for the engine’s thermal and lubrication demands.

The engine’s aluminum construction, while providing weight savings, showed sensitivity to thermal cycling that could affect oil flow patterns. The relatively narrow oil passages, designed to reduce manufacturing costs, became easily restricted by even small amounts of sludge, creating conditions where reduced oil flow led to increased heat generation and accelerated sludge formation.

Mitsubishi’s approach to oil pump design in the 6G75 proved problematic, with the pump showing inadequate capacity for maintaining proper oil pressure under all operating conditions.

The pump’s relatively small displacement meant that any restriction in oil flow could cause pressure drops that reduced circulation throughout the engine.

This problem was particularly acute in the upper cylinder head areas, where oil had to flow through already narrow passages against gravity. When sludge began forming, these areas became critically under-lubricated.

The 6G75’s Variable Valve Timing system, while providing performance benefits, introduced additional complexity that exacerbated sludge problems. The system’s oil-actuated components required clean, flowing oil to function properly, and any sludge accumulation could cause timing irregularities that stressed the engine and accelerated oil breakdown.

The engine’s relatively complex valve train, featuring multiple camshafts and timing components, created numerous areas where sludge could accumulate and restrict proper operation.

Manufacturing quality control issues further compromised the 6G75’s reliability. Inconsistent machining tolerances in oil passages, combined with assembly problems that could restrict oil flow, created engines that were particularly vulnerable to sludge formation.

The engine’s combustion characteristics, including blow-by rates and fuel contamination levels, proved higher than optimal, accelerating oil degradation and creating conditions conducive to sludge formation.

These problems often manifested catastrophically, with complete engine seizure occurring with minimal warning, making the 6G75 a cautionary example of how multiple minor issues can combine to create major reliability problems.

Also Read: 5 High-Mileage Cars You Can Still Buy Cheap and 5 That Cost a Fortune to Maintain