Turbocharged engines represent one of the most significant engineering achievements in automotive history, transforming how we extract power from internal combustion engines.

By forcing compressed air into the combustion chamber, turbochargers enable smaller displacement engines to produce power equivalent to much larger naturally aspirated units while theoretically improving fuel efficiency.

This technology has become increasingly prevalent across all automotive segments, from economy cars to high-performance supercars, as manufacturers strive to meet stringent emissions regulations without sacrificing performance.

However, the promise of turbocharged engines comes with inherent complexities that can dramatically impact their longevity. The addition of a turbocharger introduces numerous moving parts operating under extreme conditions, turbine wheels spinning at speeds exceeding 200,000 RPM, temperatures reaching over 1,000°C, and oil systems working under tremendous pressure.

These harsh operating environments create multiple failure points that don’t exist in naturally aspirated engines. Heat management becomes critical, as does oil quality and change intervals, intercooler efficiency, and boost control systems.

Understanding these differences is crucial for consumers, enthusiasts, and industry professionals alike. The following comprehensive analysis examines ten turbocharged engines that represent the extremes of this reliability spectrum.

We’ll explore five engines renowned for their exceptional longevity and dependability, followed by five that have gained notoriety for premature failures. Each engine’s story reveals important lessons about design philosophy, manufacturing quality, materials science, and the critical importance of proper maintenance protocols in turbocharged applications.

5 Turbo Engines Known For Longevity

These exceptionally engineered powerplants feature robust internal components and conservative tuning parameters that deliver reliable forced induction performance through hundreds of thousands of miles of demanding service.

Their thoughtful design includes oversized oil cooling systems and precision-manufactured turbocharger assemblies that resist the thermal stress and mechanical wear typically associated with high-boost applications and aggressive driving cycles.

From extreme operating temperatures that challenge bearing materials to the constant pressure cycling of daily commuting, these remarkable engines continue producing strong power without developing the oil consumption or turbocharger failure issues found in less durable designs.

Owners report decades of trouble-free operation with these dependable powertrains, a testament to conservative engineering that proves its worth through consistent performance and maintained reliability throughout extended ownership periods.

1. Toyota 2JZ-GTE

The Toyota 2JZ-GTE stands as perhaps the most legendary turbocharged engine ever produced, earning its reputation through an extraordinary combination of robust engineering, premium materials, and conservative tuning from the factory.

Introduced in 1991 and powering iconic vehicles like the Toyota Supra Turbo, this 3.0-liter inline-six engine has become synonymous with reliability and tunability in the performance community.

The foundation of the 2JZ-GTE’s legendary durability lies in its iron block construction, which provides exceptional strength and heat dissipation compared to aluminum alternatives.

Toyota’s engineers employed a closed-deck design with siamesed cylinders, creating a structure capable of handling enormous amounts of boost pressure and power multiplication.

The crankshaft was forged rather than cast, featuring large bearing surfaces and conservative stress concentrations that virtually eliminate the risk of catastrophic bottom-end failure.

The cylinder head design showcases Toyota’s commitment to longevity over maximum power output. The sequential twin-turbo system, while complex, was engineered with reliability as the primary objective.

The smaller primary turbocharger provides immediate throttle response and eliminates turbo lag at low RPMs, while the larger secondary turbo seamlessly engages for high-RPM power delivery. This system reduces stress on both turbochargers compared to a single large unit and provides remarkable durability when properly maintained.

Heat management, often the Achilles’ heel of turbocharged engines, was masterfully addressed in the 2JZ-GTE. The engine features substantial oil cooling capacity, robust water cooling circuits, and strategic placement of heat-sensitive components.

The turbochargers receive dedicated oil feed and return lines, along with proper heat shielding, while the intercooler system ensures consistent charge air temperatures under all operating conditions.

What truly sets the 2JZ-GTE apart is its ability to handle significant power increases without internal modifications. Stock engines routinely support 500-600 horsepower with appropriate tuning and supporting changes, while the bottom end can often handle 800+ horsepower before requiring internal upgrades.

This over-engineering philosophy means that stock power levels place minimal stress on engine components, resulting in exceptional longevity. Well-maintained examples routinely exceed 300,000 miles while maintaining full performance capability, and many continue operating reliably with minimal maintenance requirements well into their third decade of service.

2. Volvo B230FT (Redblock Turbo)

The Volvo B230FT, affectionately known as the “Redblock Turbo” in enthusiast circles, represents Swedish engineering at its finest and stands as one of the most reliable turbocharged engines ever mass-produced.

The 2.3-liter inline-four engine powered various Volvo models from the late 1970s through the early 1990s, including the iconic 240 Turbo and 740 Turbo wagons, which became synonymous with longevity and safety.

Volvo’s approach to turbocharging prioritized reliability and daily usability over maximum power output. The B230FT produces modest power figures by modern standards, but this conservative tuning philosophy directly contributed to its exceptional longevity.

The engine features a robust iron block construction with generous cylinder wall thickness and a heavily reinforced bottom end designed to handle the additional stresses of forced induction without compromise.

The turbocharger system employed by Volvo was elegantly simple and remarkably reliable. Rather than pursuing complex multi-turbo configurations or variable geometry systems, Volvo selected proven single-turbo layouts with conservative boost levels and comprehensive heat management.

The Garrett or Mitsubishi turbochargers used were sized appropriately for the engine’s displacement and power goals, operating well within their efficiency ranges and maintaining excellent durability characteristics.

Oil system design represents another area where the B230FT excels. Volvo engineered dedicated turbocharger oil feed and scavenge systems with proper filtration and cooling capacity.

These engines regularly achieve 400,000+ miles with basic maintenance, and examples approaching 500,000 miles are not uncommon in Volvo enthusiast communities.

The combination of conservative engineering, quality manufacturing, and robust materials created an engine that could withstand decades of daily driving while maintaining consistent performance and reliability. Even today, well-maintained B230FT engines continue operating in daily driver applications, a testament to their exceptional engineering and construction quality.

3. Audi 1.8T (20V)

The Audi 1.8T 20-valve engine represents a masterpiece of German engineering that successfully bridged the gap between performance, efficiency, and long-term reliability.

Introduced in the mid-1990s and continuing production through the mid-2000s, this turbocharged inline-four engine powered numerous Audi and Volkswagen models, earning a devoted following among enthusiasts for its combination of tunability and dependability.

The foundation of the 1.8T’s success lies in its sophisticated aluminum block construction combined with a five-valve-per-cylinder head design. This configuration provides exceptional breathing characteristics and heat dissipation while maintaining relatively light weight compared to iron block alternatives.

The engine’s bore and stroke dimensions were carefully optimized for turbocharged applications, providing excellent torque characteristics while maintaining high-RPM capability.

Audi’s approach to turbocharging emphasized refinement and daily usability. The KKK K03 turbocharger was perfectly matched to the engine’s displacement and power characteristics, providing excellent throttle response while operating conservatively within its efficiency range.

The turbocharger’s water-cooled center section and dedicated oil cooling circuits ensured consistent operating temperatures and exceptional longevity under normal driving conditions.

The engine management system represents another area where the 1.8T excels. Bosch Motronic engine management provides sophisticated knock control, fuel delivery, and boost management that protects engine components while optimizing performance.

The system’s ability to adapt to varying fuel quality and environmental conditions contributes significantly to the engine’s reliability across diverse operating environments and maintenance schedules.

What sets the 1.8T apart from many turbocharged competitors is its remarkable tolerance for performance modifications without sacrificing reliability.

The engine’s most common issues are typically related to auxiliary systems rather than core engine components, and most problems can be addressed through preventive maintenance and quality replacement parts.

The combination of German engineering excellence, proven turbocharger technology, and robust construction created an engine that continues to serve enthusiasts and daily drivers alike more than two decades after its introduction.

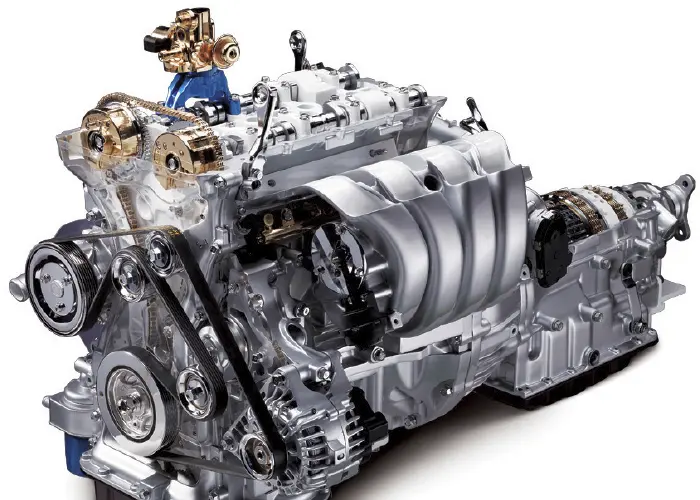

4. Subaru EJ205/EJ207

The Subaru EJ205 and EJ207 turbocharged boxer engines represent the pinnacle of Subaru’s flat-four engine development, combining the unique characteristics of horizontally opposed cylinder configuration with proven turbocharging technology.

These 2.0-liter engines powered various Subaru performance models, including the WRX and STI, earning reputations for exceptional durability when properly maintained and operated within reasonable parameters.

The boxer engine configuration provides inherent advantages for turbocharged applications, particularly in terms of center of gravity and packaging efficiency.

The top-mount intercooler configuration, while sometimes criticized for heat soak issues, provides excellent packaging efficiency and simplified plumbing that reduces potential failure points.

The EJ205/EJ207’s engine management system represents sophisticated Japanese engineering at its finest. The ECU provides precise control over fuel delivery, ignition timing, and boost pressure while incorporating advanced safety features that protect engine components from abuse or adverse conditions.

The knock detection system is particularly sophisticated, allowing the engine to operate safely on varying fuel octane ratings while maintaining optimal performance when premium fuel is available.

Internal engine construction emphasizes durability and consistent performance over maximum power output. The semi-closed deck block design provides excellent cylinder bore stability while maintaining adequate cooling capacity.

Well-maintained examples routinely exceed 200,000 miles while maintaining strong performance, and many continue serving in daily driver applications well beyond 250,000 miles.

The combination of proven Japanese engineering, robust construction, and enthusiast community support has created engines that continue to provide excellent service decades after production.

Also Read: 5 Takata Airbag-equipped Models That Remain Safe Vs. 5 Still At Risk

5. BMW N54

The BMW N54 twin-turbocharged inline-six engine represents a remarkable achievement in German automotive engineering, successfully combining high performance with surprising long-term reliability when properly maintained.

Introduced in 2007 as BMW’s first production twin-turbo engine, the N54 powered various BMW models, including the 335i and 135i, quickly earning recognition for its exceptional power delivery and tunability.

The N54’s aluminum block construction provides excellent weight characteristics while maintaining structural integrity under high boost conditions. BMW’s engineers employed an open-deck design with robust cylinder liners and substantial cooling capacity to manage the additional heat generated by twin-turbocharger operation.

The crankshaft and connecting rod assemblies were specifically designed for forced induction applications, featuring forged construction and conservative stress concentrations.

The twin-turbocharger configuration represents the N54’s most distinctive feature and primary contributor to its performance characteristics. Rather than using a single large turbocharger, BMW employed two smaller BorgWarner turbochargers that provide immediate throttle response and eliminate virtually all turbo lag.

This configuration also provides redundancy; should one turbocharger fail, the engine can continue operating on the remaining unit, though with reduced performance.

High-pressure fuel injection technology sets the N54 apart from many contemporary turbocharged engines. The direct injection system operates at pressures exceeding 2,000 PSI, providing precise fuel metering and excellent charge cooling characteristics.

This technology enables the engine to operate at high compression ratios while maintaining knock resistance, contributing to both performance and efficiency characteristics. Engine management sophistication reaches new levels with the N54’s DME (Digital Motor Electronics) system.

High-pressure fuel pump upgrades, regular carbon cleaning, and attention to turbocharger oil feed systems have largely eliminated the early reliability concerns. Well-maintained examples are now routinely achieving 200,000+ miles while maintaining excellent performance, and the engine’s exceptional tunability has created a devoted enthusiast following.

The combination of sophisticated German engineering, premium materials, and lessons learned from early production experience has created an engine that exemplifies modern turbocharged reliability when properly cared for.

5 That Fail Early

These problematic powerplants suffer from inadequate cooling systems and aggressive tuning strategies that create premature failure patterns well before reaching typical engine longevity expectations.

Their flawed engineering includes undersized oil pumps and cost-reduced turbocharger components that cannot withstand the thermal cycling and mechanical stress of normal forced induction operation.

Despite impressive power figures and marketing claims, these engines develop catastrophic problems, including turbocharger shaft failure, carbon buildup, and timing chain stretch, that require expensive repairs or complete replacement.

Owners experience costly breakdowns as these unreliable powerplants transform from exciting performance assets into financial burdens, a frustrating reality that demonstrates the importance of proven engineering over peak power numbers in forced induction applications.

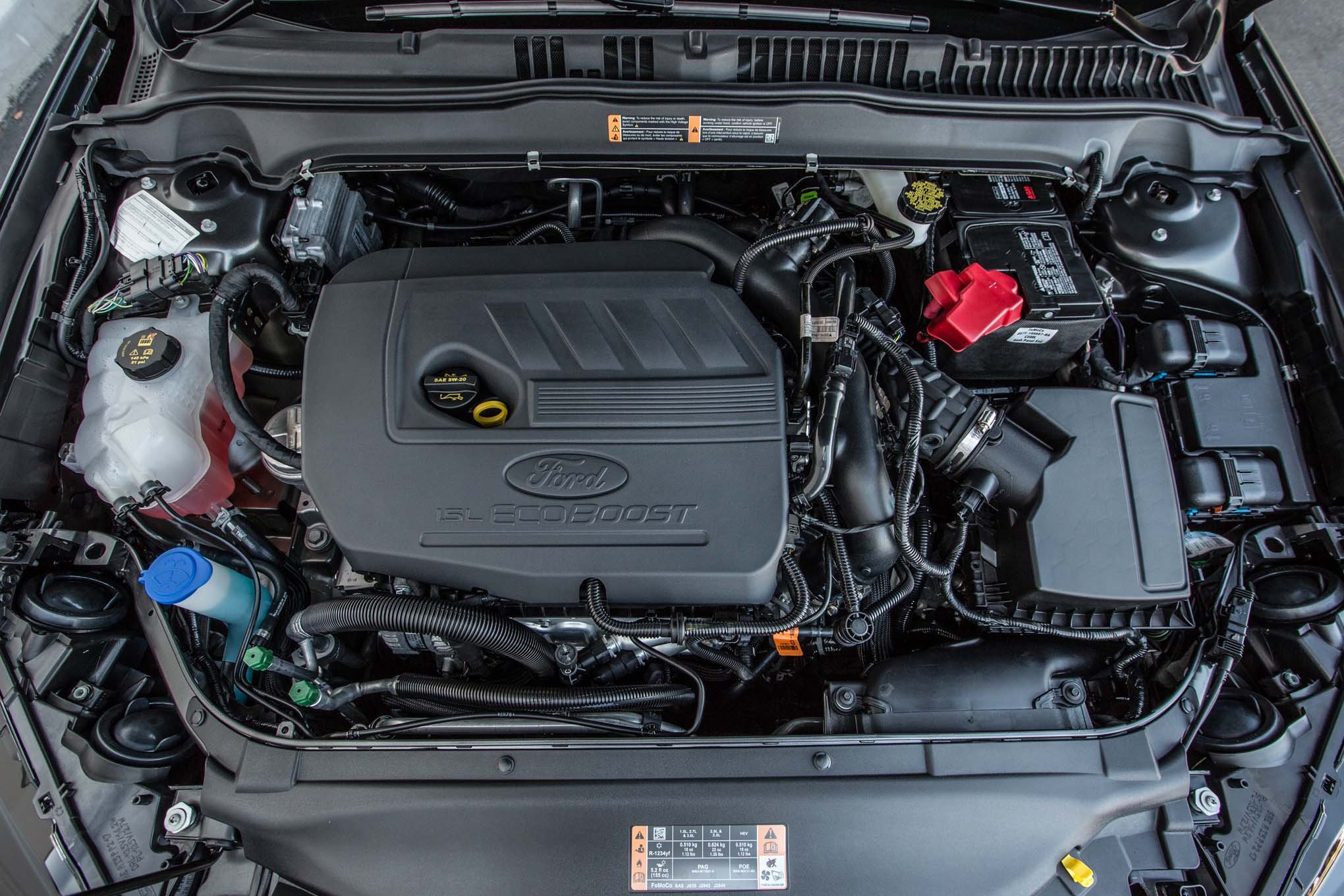

1. Ford EcoBoost 1.6L

The Ford EcoBoost 1.6-liter turbocharged engine represents one of the automotive industry’s most disappointing examples of forced induction technology, demonstrating how aggressive downsizing and cost-cutting measures can compromise long-term reliability.

Introduced as part of Ford’s global engine strategy, this direct-injection turbocharged four-cylinder was designed to replace larger naturally aspirated engines while improving fuel economy and reducing emissions.

Ford’s engineering approach prioritized maximum power output from minimal displacement, resulting in an engine that operates under extreme stress levels throughout its rev range. The 1.6L EcoBoost produces power levels typically associated with engines 50-100% larger, creating internal pressures and thermal loads that challenge every component’s durability limits.

The aluminum block construction, while weight-efficient, lacks the thermal mass and structural rigidity needed for sustained high-stress operation.

The turbocharger system represents a fundamental weak point in the 1.6L EcoBoost design. Ford selected relatively small turbochargers to minimize turbo lag and improve throttle response, but these units operate at the extreme edge of their efficiency maps under normal driving conditions.

The turbochargers frequently experience premature bearing failure, compressor wheel damage, and wastegate actuator problems, often requiring replacement before 60,000 miles under normal driving conditions.

Cooling system inadequacies compound the engine’s thermal management challenges. The compact engine bay packaging and aggressive power-to-displacement ratio create extreme heat loads that overwhelm the cooling system’s capacity during sustained operation.

Coolant temperatures often exceed design parameters, leading to head gasket failures, cylinder head warping, and premature water pump failure. The intercooler system, while adequate for brief acceleration events, struggles to maintain consistent charge temperatures during sustained operation.

Perhaps most concerning is the engine’s poor tolerance for deferred maintenance or operating condition variations. Minor delays in oil change intervals, use of incorrect oil specifications, or operation in extreme temperatures can trigger cascading failures that destroy multiple engine systems simultaneously.

The combination of aggressive engineering parameters, cost-optimized construction, and minimal safety margins has created an engine with one of the industry’s worst reliability records, with many examples requiring major repairs or complete replacement before reaching 80,000 miles despite following manufacturer maintenance schedules.

2. Hyundai Theta II 2.0T

The Hyundai Theta II 2.0-liter turbocharged engine stands as one of the most problematic forced induction powerplants of the modern era, generating numerous recalls, class-action lawsuits, and warranty extensions due to fundamental design and manufacturing defects.

Despite Hyundai’s reputation for reliability and extensive warranties, the Theta II 2.0T has experienced catastrophic failure rates that have damaged consumer confidence and cost the manufacturer hundreds of millions in warranty claims and legal settlements.

The engine’s most notorious problem involves catastrophic bearing failure leading to complete engine seizure, often occurring without warning and typically before 100,000 miles. Investigation revealed that manufacturing debris left in the crankcase during assembly acts as an abrasive compound, accelerating bearing wear and eventually causing connecting rod bearing failure.

This debris, consisting of metal particles from machining operations, was not properly removed during the manufacturing process, creating a ticking time bomb within each engine.

Oil system design flaws compound the bearing failure issues. The Theta II’s oil pump and circulation system struggle to maintain adequate pressure and flow under high-load conditions, particularly when combined with the restricted oil passages that result from manufacturing debris accumulation.

The oil pan design incorporates inadequate baffling for turbocharged applications, allowing oil starvation during aggressive driving or sustained high-load operation.

The direct injection system, while providing efficiency benefits, creates additional reliability concerns. Carbon buildup on intake valves occurs rapidly due to the lack of port fuel injection cleaning action, requiring expensive cleaning services every 30,000-40,000 miles to maintain proper engine operation.

The high-pressure fuel pump system has also proven problematic, with premature failures causing fuel starvation and potential engine damage. Turbocharger reliability issues plague many Theta II 2.0T examples, with oil contamination from the engine’s internal problems frequently destroying turbocharger bearings and seals.

Most damaging to the Theta II’s reputation is its unpredictable failure pattern. Unlike engines with specific weak points that fail gradually with warning symptoms, the Theta II can experience sudden catastrophic failure during normal operation, leaving drivers stranded and facing complete engine replacement costs.

This unpredictability, combined with Hyundai’s initially poor response to warranty claims, has created one of the automotive industry’s most notorious reliability disasters of the past decade.

3. BMW N63

The BMW N63 twin-turbocharged V8 represents one of the most ambitious yet fundamentally flawed engine designs in recent automotive history, demonstrating how excessive complexity and questionable design decisions can create a maintenance nightmare despite premium engineering and construction.

Introduced in 2008 as BMW’s flagship V8 engine, the N63 incorporated numerous innovative technologies that, while impressive on paper, created multiple reliability issues that have plagued owners throughout the engine’s production run.

The N63’s most controversial design element involves its “hot-vee” turbocharger configuration, where both turbochargers are mounted within the engine’s valley between the cylinder banks.

While this arrangement provides compact packaging and improved throttle response, it creates extreme thermal conditions that overwhelm component durability limits.

The turbochargers operate in a heat-soaked environment that accelerates bearing wear, causes frequent wastegate actuator failures, and leads to oil coking within the turbocharger center sections.

Valve stem seal failure represents the N63’s most widespread and expensive problem, affecting the majority of engines between 60,000 and 120,000 miles.

The extreme heat generated by the hot-vee design causes premature deterioration of valve stem seals, leading to excessive oil consumption that can exceed one quart per 1,000 miles.

Repairing this issue requires complete engine disassembly and costs exceeding $8,000 at BMW dealerships, as the turbochargers must be removed to access the cylinder heads.

The timing chain system presents another area of concern, with premature stretching and tensioner failure occurring frequently in N63 engines. The combination of high combustion pressures, aggressive valve timing strategies, and thermal cycling causes timing chain elongation that can lead to catastrophic valve train damage if not addressed promptly.

The combination of poor design decisions, excessive complexity, and inadequate component durability has created an engine that exemplifies everything wrong with modern automotive engineering’s pursuit of performance and efficiency at the expense of reliability and serviceability.

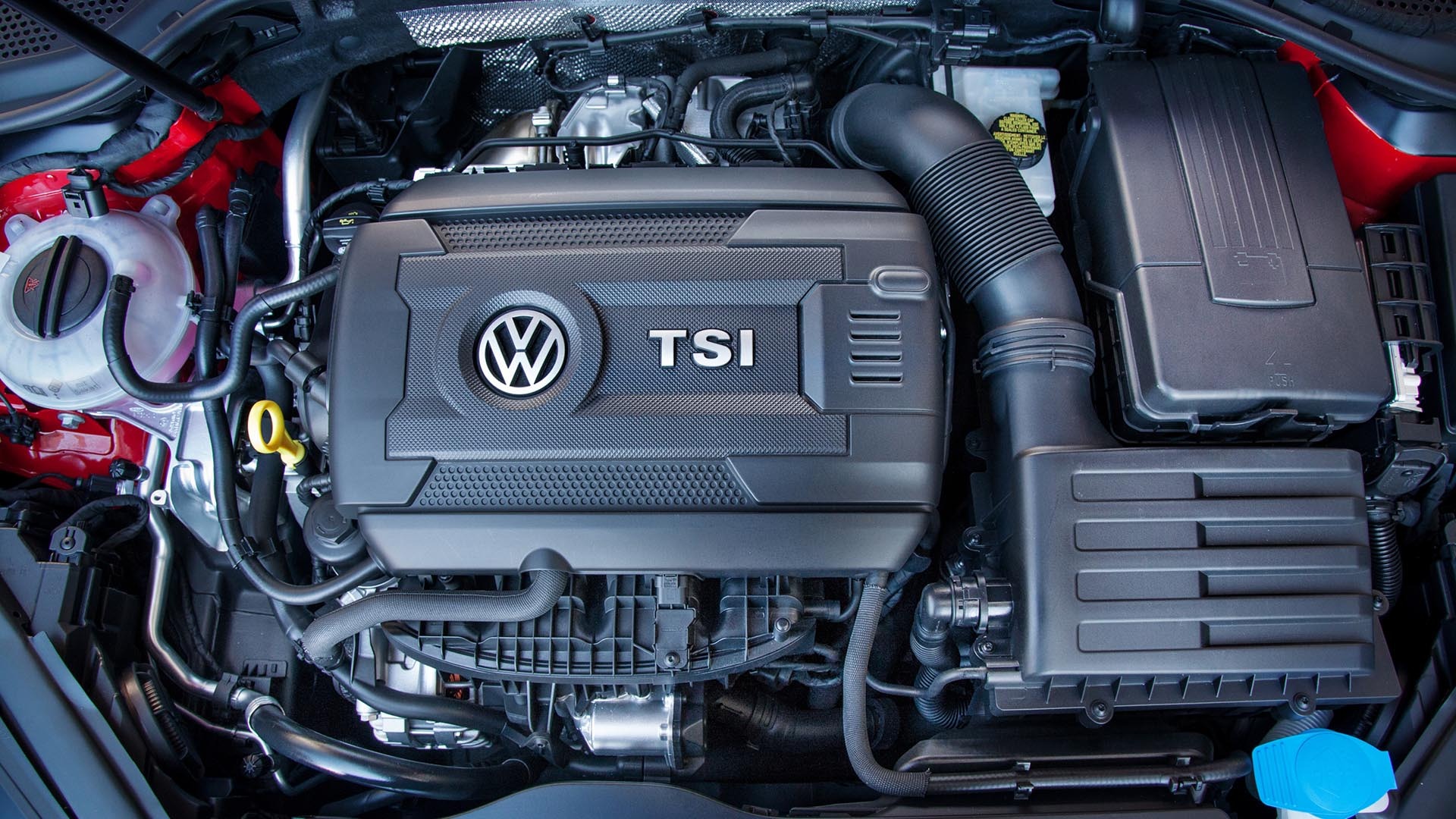

4. Volkswagen EA888 Gen 1 & 2

The early generations of Volkswagen’s EA888 turbocharged engine family represent a significant engineering misstep for a manufacturer renowned for precision and reliability, demonstrating how design flaws and manufacturing shortcuts can compromise even well-intentioned engineering efforts.

The EA888 Gen 1 and Gen 2 engines, produced from 2008 through 2012, powered numerous Volkswagen and Audi models but developed notorious reputations for premature failures and expensive repairs that damaged brand reliability perceptions.

The most catastrophic issue affecting these engines involves timing chain tensioner failure, typically occurring between 40,000 and 80,000 miles without warning.

The plastic timing chain tensioner, designed to reduce manufacturing costs and engine noise, proves inadequate for the high loads and temperature cycling experienced in turbocharged applications. When the tensioner fails, the timing chain jumps multiple teeth or breaks entirely, causing catastrophic valve-to-piston contact that destroys the engine beyond economical repair.

Carbon buildup on intake valves represents another endemic problem affecting virtually all EA888 Gen 1 and Gen 2 engines. The direct injection system, combined with positive crankcase ventilation routing and high combustion chamber temperatures, creates rapid carbon accumulation that restricts airflow and causes rough operation, misfiring, and reduced performance.

The cleaning process requires specialized equipment and significant labor, with costs typically exceeding $800 every 40,000-60,000 miles. Water pump failure occurs with alarming frequency in these engines, often before 60,000 miles and sometimes with catastrophic consequences.

The plastic impeller water pump design proves inadequate for the thermal cycling and pressure variations experienced in turbocharged applications. When the pump fails, overheating can occur rapidly, potentially causing head gasket failure, cylinder head warping, and complete engine destruction if not immediately addressed.

The combination of multiple simultaneous failure modes, expensive repair costs, and poor component accessibility has created engines that are often considered total losses when major problems occur.

Many examples are scrapped or receive engine replacements before reaching 100,000 miles, and the engines’ reputation has severely damaged Volkswagen’s reliability perception in markets where these powerplants were widely used.

5. Mitsubishi 4B11T

The Mitsubishi 4B11T turbocharged engine marks a disappointing end to Mitsubishi’s storied legacy of performance engines, illustrating how cost-cutting measures and compromised engineering can undermine even proven racing technology.

Developed as the successor to the legendary 4G63T engine that powered the Evolution series, the 4B11T was intended to provide improved efficiency and emissions compliance while maintaining the performance characteristics that made Mitsubishi synonymous with turbocharged excellence.

The engine’s most fundamental flaw involves its aluminum block construction, which prioritizes weight reduction over durability. Unlike the legendary iron-block 4G63T that could handle enormous power levels and abuse, the 4B11T’s aluminum block lacks the thermal mass and structural rigidity necessary for sustained high-performance operation.

The open-deck design, while lighter and more cost-effective to manufacture, provides inadequate cylinder bore support under boost, leading to head gasket failures and cylinder distortion.

Timing chain system problems plague the 4B11T throughout its service life, with premature stretching and tensioner failure occurring frequently before 80,000 miles.

The lightweight timing chain system, designed to reduce rotating mass and improve fuel efficiency, proves inadequate for the high loads and rapid acceleration/deceleration cycles experienced in turbocharged applications. When the timing chain stretches or jumps teeth, expensive valve train damage often results.

The MIVEC (Mitsubishi Innovative Valve timing Electronic Control) system adds complexity that proves problematic in real-world applications. The variable valve timing mechanism experiences frequent solenoid failures, oil passage restrictions, and control system malfunctions that cause rough operation, reduced performance, and expensive diagnostic challenges.

These problems are exacerbated by the system’s sensitivity to oil quality and change intervals. Oil consumption issues affect many 4B11T engines due to piston ring design compromises and excessive blow-by.

The engine often consumes oil at rates exceeding acceptable limits, requiring frequent monitoring and top-offs to prevent damage. This oil consumption also leads to carbon buildup problems that compound performance and reliability issues throughout the engine’s service life.

The combination of compromised engineering, cost-cutting construction, and poor reliability has made the 4B11T one of the most disappointing performance engine developments of the past decade, effectively ending Mitsubishi’s reputation for building bulletproof turbocharged powerplants that could withstand both daily driving and track abuse.

Also Read: 5 American Muscle Cars That Hold Value Vs. 5 That Tank After A Year