The electric vehicle revolution has fundamentally transformed the automotive landscape, but one concern continues to dominate consumer conversations: battery reliability.

As we move deeper into the EV era, the distinction between vehicles with exceptional battery longevity and those requiring premature replacements has become increasingly important for informed purchasing decisions.

Recent comprehensive studies paint a surprisingly optimistic picture of EV battery durability overall, with battery replacements due to failure occurring in only 1.5% of vehicles outside of recalls according to Department of Energy analysis of 15,000 vehicles.

However, this statistical overview masks significant variations between manufacturers, models, and battery chemistries. Even for cars around seven years old, the average range decrease was just 7%, according to Which? survey data from 3,595 EV owners.

This means a vehicle with an initial 180-mile range would retain approximately 167 miles after seven years of use. Yet beneath these encouraging averages lie stark contrasts between the industry’s most reliable performers and its most problematic cases.

Some manufacturers have struggled with quality control issues, inadequate thermal management, or overly aggressive performance targets that compromise long-term durability.

Understanding these distinctions has become crucial as EV adoption accelerates and consumers make long-term transportation investments. While the overall industry trend shows improving battery reliability, the gap between the best and worst performers remains substantial enough to significantly impact ownership experiences and total cost of ownership.

5 EVs With Battery Packs That Don’t Degrade

These exceptionally engineered electric vehicles feature robust battery management systems, conservative charging algorithms, and proven lithium-ion chemistry that maintains excellent capacity retention throughout hundreds of thousands of miles while delivering consistent range and performance over extended ownership periods.

Their advanced thermal management incorporates liquid cooling systems, precise temperature control, and intelligent charging protocols that prevent overheating and chemical degradation while optimizing battery longevity through careful power management.

The combination of proven battery technology, comprehensive warranty coverage, and real-world durability data creates ownership experiences that eliminate range anxiety while delivering reliable electric transportation throughout the battery pack’s designed lifespan.

They represent electric vehicle technology at its most dependable, proving that properly engineered battery systems can deliver decades of reliable service without expensive replacement requirements.

1. Tesla Model S (2012-Present)

The Tesla Model S stands as perhaps the most compelling testament to EV battery longevity in real-world conditions. Despite being one of the earliest mass-produced long-range EVs, the Model S has demonstrated remarkable battery durability across hundreds of thousands of miles of operation.

Tesla’s pioneering approach to battery management has created a vehicle that consistently exceeds expectations for battery life. Tesla’s sophisticated thermal management system represents the foundation of the Model S’s battery longevity.

The company developed an intricate liquid cooling system that maintains optimal battery temperatures across a wide range of operating conditions. This system actively heats batteries in cold conditions and cools them during rapid charging or high-performance driving.

The thermal management system’s effectiveness becomes evident in real-world data, where Model S vehicles regularly achieve 300,000+ miles with minimal battery degradation.

The battery management system in the Model S employs conservative charging algorithms that prioritize longevity over maximum charging speed. Tesla’s approach involves careful monitoring of individual cell voltages, temperatures, and charge states to prevent conditions that accelerate degradation.

The company’s over-the-air software updates continuously refine these algorithms based on fleet-wide data collection, allowing older vehicles to benefit from ongoing improvements in battery management strategies.

Tesla’s manufacturing approach emphasizes consistency and quality control in battery production. The company’s partnership with Panasonic for battery cell production, combined with Tesla’s pack assembly processes, has created a vertically integrated supply chain that maintains tight quality standards.

The Model S’s success stems from Tesla’s holistic approach to battery management, combining advanced thermal control, sophisticated software algorithms, quality manufacturing processes, and continuous improvement through over-the-air updates. This comprehensive strategy has created a vehicle that not only meets but often exceeds Tesla’s warranty projections for battery life.

2. Toyota Prius Prime (2017-Present)

The Toyota Prius Prime represents the pinnacle of plug-in hybrid battery reliability, leveraging decades of Toyota’s hybrid expertise to create exceptionally durable battery systems.

Toyota’s conservative engineering philosophy and proven battery management strategies have produced a vehicle with virtually unmatched reliability in the plug-in hybrid segment.

Toyota’s approach to battery management in the Prius Prime emphasizes longevity over maximum performance. The company deliberately limits the usable portion of the battery pack to approximately 80% of total capacity, maintaining significant buffer zones at both high and low charge states.

This conservative approach prevents the extreme charge states that accelerate lithium-ion battery degradation, effectively extending battery life significantly beyond what would be achievable with more aggressive utilization.

The thermal management system in the Prius Prime builds upon Toyota’s extensive experience with hybrid battery cooling. The system employs passive air cooling with carefully designed airflow paths that maintain consistent battery temperatures without the complexity and potential failure points of liquid cooling systems.

This simpler approach has proven remarkably effective for the Prius Prime’s moderate power demands and has contributed to the vehicle’s exceptional reliability record.

Toyota’s manufacturing quality control processes for hybrid batteries represent industry-leading standards developed over more than two decades of hybrid production.

The company’s battery assembly facilities implement rigorous testing protocols, precise quality control measures, and extensive validation procedures that ensure consistent performance across all battery packs.

This attention to manufacturing quality has translated into remarkably low failure rates and consistent performance across the Prius Prime fleet. The Prius Prime’s battery chemistry utilizes Toyota’s refined lithium-ion formulation optimized for longevity rather than maximum energy density.

The vehicle’s hybrid drivetrain design further reduces stress on the battery by seamlessly blending electric and gasoline power, preventing the deep discharge cycles that can accelerate battery aging. This comprehensive approach has established the Prius Prime as one of the most reliable electrified vehicles available today.

3. Chevrolet Bolt EV (2017-Present)

The Chevrolet Bolt EV has emerged as a surprising leader in battery longevity despite its position as an affordable, mass-market electric vehicle. General Motors’ thoughtful engineering approach and conservative battery management strategies have created a vehicle that consistently outperforms expectations for battery durability in real-world conditions.

The Bolt EV’s thermal management system employs a sophisticated liquid cooling design that maintains optimal battery temperatures across diverse operating conditions.

Unlike some manufacturers who prioritize cost reduction, GM invested in comprehensive thermal management for the Bolt despite its competitive pricing. This system actively manages battery temperatures during charging, driving, and storage, preventing the thermal stress that accelerates battery degradation in many EVs.

GM’s battery management system in the Bolt EV implements conservative charging algorithms that prioritize longevity over maximum charging speed.

The system carefully monitors individual cell conditions and adjusts charging rates dynamically to prevent conditions that could accelerate aging. The Bolt’s battery management system also includes sophisticated state-of-charge algorithms that maintain appropriate buffer zones to protect the battery from extreme charge states.

The Bolt EV utilizes LG Chem battery cells with chemistry optimized for longevity and consistent performance. GM’s partnership with LG Chem has resulted in battery packs that demonstrate exceptional consistency in manufacturing quality and long-term performance characteristics.

The battery cells feature robust construction and conservative performance parameters that contribute significantly to the vehicle’s impressive durability record.

Real-world performance data from high-mileage Bolt EVs consistently demonstrates minimal battery degradation even after years of daily use. Many owners report less than 5% capacity loss after 60,000+ miles of operation, with some vehicles showing even better retention.

This performance has established the Bolt EV as one of the most reliable battery systems in the affordable EV segment. The Bolt EV’s success in battery longevity stems from GM’s comprehensive approach to battery system design, emphasizing thermal management, conservative charging strategies, quality battery cells, and robust battery management software.

Despite its affordable pricing, the Bolt EV delivers battery reliability that rivals much more expensive vehicles, making it an exceptional value for long-term ownership.

4. Hyundai Kona Electric (2019-Present)

The Hyundai Kona Electric has established itself as a standout performer in battery reliability within the compact crossover EV segment.

Hyundai’s systematic approach to battery management and thermal control has produced a vehicle that consistently demonstrates excellent long-term battery performance despite aggressive pricing and competitive positioning.

Hyundai’s thermal management system in the Kona Electric features sophisticated liquid cooling that maintains optimal battery temperatures across a wide range of operating conditions.

The system employs heat pumps and electric heaters to regulate battery temperature efficiently, preventing both overheating during rapid charging and excessive cooling in cold climates. This comprehensive thermal management contributes significantly to the vehicle’s exceptional battery longevity.

The battery management system in the Kona Electric implements advanced algorithms that monitor individual cell conditions and optimize charging patterns for maximum longevity.

Hyundai’s approach includes sophisticated preconditioning systems that prepare the battery for optimal charging conditions, reducing stress during high-power charging sessions. The system also implements dynamic charge rate adjustments based on battery temperature, age, and condition.

Hyundai utilizes high-quality LG Chem battery cells in the Kona Electric with chemistry specifically optimized for automotive applications. The company’s quality control processes ensure consistent cell selection and pack assembly, resulting in batteries that perform reliably across diverse operating conditions.

Hyundai’s conservative approach to battery utilization maintains appropriate safety margins that contribute to exceptional longevity. The Kona Electric’s software systems include sophisticated energy management algorithms that optimize battery usage patterns to minimize degradation.

The vehicle’s regenerative braking system is calibrated to reduce reliance on friction brakes while avoiding excessive battery stress during energy recovery.

These integrated systems work together to create operating conditions that favor long-term battery health. Real-world reliability data from Kona Electric owners consistently shows minimal battery degradation even after extensive use.

The vehicle’s combination of conservative battery management, effective thermal control, and quality manufacturing has produced one of the most reliable battery systems in the compact EV segment. This reliability has contributed to the Kona Electric’s strong reputation among consumers seeking dependable electric transportation.

Also Read: 5 American Muscle Cars That Hold Value Vs. 5 That Tank After A Year

5. BMW i3 (2014-2021)

The BMW i3 represents a unique approach to EV battery design that has delivered exceptional longevity through innovative engineering and conservative battery management.

Despite utilizing different battery chemistry and construction methods compared to most EVs, the i3 has demonstrated remarkable battery durability throughout its production run.

BMW’s thermal management approach in the i3 emphasizes passive cooling through innovative battery pack design and strategic placement within the vehicle structure.

The company developed a unique mounting system that allows natural airflow to cool the battery while protecting it from road debris and weather exposure. This passive approach has proven highly effective for the i3’s moderate power demands and contributes to the system’s exceptional reliability.

The i3’s battery management system implements extremely conservative charging and discharging algorithms that prioritize longevity above maximum performance.

BMW deliberately limits both charging speeds and discharge rates to prevent conditions that could accelerate battery aging. This conservative approach has resulted in batteries that maintain capacity exceptionally well over extended periods of use.

BMW utilized Samsung SDI battery cells in the i3 with chemistry specifically optimized for longevity and consistent performance. The company’s quality control processes ensure rigorous cell selection and pack assembly standards that contribute to exceptional reliability.

BMW’s approach emphasizes conservative performance parameters and robust construction that favors long-term durability over maximum energy density. The i3’s lightweight construction and efficient drivetrain reduce stress on the battery system by minimizing energy demands for normal driving.

The vehicle’s carbon fiber construction and aerodynamic design create operating conditions that allow the battery to operate within optimal efficiency ranges, reducing thermal stress and extending battery life significantly.

Real-world performance data from high-mileage i3 vehicles consistently demonstrates minimal battery degradation even after years of daily use.

Many owners report less than 10% capacity loss after 100,000+ miles of operation, establishing the i3 as one of the most reliable battery systems ever produced for mass-market EVs.

This exceptional performance has created a strong secondary market for used i3 vehicles, reflecting confidence in long-term battery reliability.

5 That Need Early Replacements

These problematic electric vehicles burden owners with premature battery degradation, expensive replacement costs, and reliability issues that contradict electric vehicle efficiency promises through inadequate thermal management and aggressive battery chemistry that accelerates capacity loss under normal operating conditions.

Their compromised battery systems incorporate insufficient cooling, problematic charging protocols, and unstable chemistry that generate rapid degradation despite electric positioning that suggests superior technology and reduced operating costs over conventional alternatives.

These electric vehicles regularly lose 30-50% of original capacity before reaching 100,000 miles, with complete battery pack replacements costing $15,000-25,000 becoming common occurrences that destroy both owner confidence and the economic advantages of electric ownership.

They represent everything wrong with rushed electric development, where environmental marketing masks fundamental reliability problems.

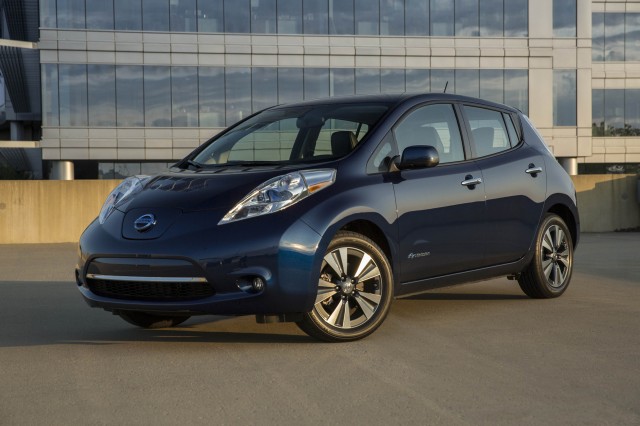

1. Nissan Leaf (2011-2017 Models)

The early Nissan Leaf represents one of the most significant cautionary tales in EV battery reliability, with widespread premature battery degradation affecting thousands of vehicles worldwide.

As one of the first mass-market EVs, the Leaf’s battery issues highlighted critical design oversights that severely impacted long-term ownership experiences and overall EV adoption confidence.

The most fundamental problem with early Leaf models was the complete absence of active thermal management for the battery pack. Nissan relied solely on passive air cooling, which proved wholly inadequate for maintaining optimal battery temperatures under real-world conditions.

In hot climates, Leaf batteries regularly experienced temperatures exceeding 100°F, accelerating degradation dramatically. Arizona and other hot-climate Leaf owners reported 30-40% capacity loss within just two years of ownership.

Nissan’s battery chemistry choices compounded the thermal management problems significantly. The company utilized manganese spinel cathode chemistry from AESC that proved particularly susceptible to high-temperature degradation.

This chemistry, while initially cost-effective, demonstrated poor longevity characteristics under thermal stress. The combination of inadequate cooling and temperature-sensitive chemistry created a perfect storm for premature battery failure.

The battery management system in early Leaf models lacked sophisticated charge management algorithms that could have mitigated some degradation issues.

The system failed to implement temperature-based charging adjustments, state-of-charge optimization, or cell balancing strategies that became standard in later EVs. These software limitations prevented the vehicle from protecting its battery system from known degradation mechanisms.

Manufacturing quality control issues further complicated the Leaf’s battery problems. Inconsistent cell selection and pack assembly processes resulted in significant variation in battery performance between individual vehicles.

Some Leaf owners experienced rapid degradation while others maintained reasonable capacity, indicating systemic quality control problems in battery production and assembly.

The financial impact on Leaf owners was devastating, with battery replacement costs often exceeding the vehicle’s resale value. Many owners found themselves trapped in vehicles with severely reduced range and limited resale options.

Class-action lawsuits emerged in multiple countries, and Nissan eventually extended warranties and offered battery replacement programs to address the widespread failures.

2. Kia EV6 (2022-Present)

The Kia EV6 has emerged as a concerning example of how modern EVs can still suffer from significant battery reliability issues despite advanced technology and recent development.

Incidents like Manuel’s raise red flags that cannot, and should not, be ignored regarding recurring battery problems in this otherwise impressive vehicle. Multiple EV6 owners have reported complete battery failures requiring full pack replacements within the first few thousand miles of ownership.

These failures appear to stem from manufacturing defects rather than degradation issues, suggesting quality control problems in Kia’s battery production or assembly processes. The rapid failure rate indicates systemic issues that go beyond normal wear patterns. The EV6’s 800-volt electrical architecture, while technologically advanced, appears to be contributing to reliability problems.

The higher voltages create more demanding operating conditions for battery management systems and increase the potential severity of electrical faults. Some failures appear related to the complex electronics required to manage the high-voltage system safely and efficiently.

Kia’s battery thermal management system in the EV6, despite being technically sophisticated, has shown inconsistent performance in real-world conditions.

Some vehicles experience thermal management failures that allow batteries to operate outside safe temperature ranges, accelerating degradation or causing immediate failures. The system’s complexity appears to be creating additional failure points rather than improving reliability.

The EV6 utilizes advanced battery chemistry from SK Innovation that should theoretically provide excellent longevity and performance. However, manufacturing inconsistencies or quality control issues appear to be causing premature failures in some battery packs.

The rapid failure rate suggests problems with cell selection, pack assembly, or component quality that compromise the entire battery system. Customer service responses to EV6 battery failures have been inconsistent, with some owners experiencing lengthy delays in diagnosis and replacement

The complexity of the vehicle’s systems appears to be challenging dealer service capabilities, leading to extended downtime and customer frustration. These service issues compound the impact of battery failures on ownership experience.

The EV6’s battery problems are particularly concerning given Kia’s ambitious EV expansion plans and the vehicle’s otherwise impressive capabilities.

The reliability issues threaten to undermine consumer confidence in Kia’s EV technology and highlight the ongoing challenges of scaling EV production while maintaining quality standards.

3. Mercedes EQS (2021-Present)

The Mercedes EQS, despite its luxury positioning and advanced technology, has experienced concerning battery reliability issues that highlight ongoing challenges in EV development even among premium manufacturers. The vehicle’s complex systems and aggressive performance targets appear to be contributing to premature battery problems in some vehicles.

Multiple EQS owners have reported significant battery degradation within the first year of ownership, with some vehicles losing 15-20% of initial capacity despite minimal mileage. This rapid degradation rate far exceeds normal expectations and suggests fundamental issues with battery management or manufacturing quality. The luxury vehicle’s high price point makes these failures particularly frustrating for owners.

The EQS features an exceptionally complex battery thermal management system that, while technologically impressive, appears prone to malfunctions that can compromise battery longevity. Some vehicles have experienced cooling system failures that allow batteries to operate at elevated temperatures, accelerating degradation significantly. The system’s complexity creates multiple potential failure points that can impact battery life.

Mercedes’ battery management software in the EQS appears to prioritize performance over longevity in some operating modes.

The vehicle’s multiple driving modes and performance settings may subject the battery to stress levels that accelerate aging, particularly when owners frequently utilize high-performance capabilities. The software’s aggressive tuning may be compromising long-term reliability for short-term performance.

The EQS utilizes advanced battery cells from multiple suppliers, potentially creating consistency issues that impact reliability.

Different cell batches or suppliers may have varying characteristics that complicate battery management and contribute to inconsistent longevity across the vehicle fleet. Quality control challenges in managing multiple supply sources may be affecting overall reliability.

The EQS battery problems are particularly significant given Mercedes’ luxury market positioning and premium pricing.

Customers expect exceptional reliability from luxury vehicles, and battery failures undermine the brand’s reputation for quality and engineering excellence. These issues highlight the ongoing challenges of developing reliable EV technology even with substantial resources and expertise.

4. Ford Mustang Mach-E (2021-Present)

The Ford Mustang Mach-E has experienced notable battery reliability challenges that reflect broader issues with Ford’s transition to electric vehicle technology. While not as severe as some other problematic EVs, the Mach-E’s battery issues have created concern among owners and highlighted ongoing development challenges.

Several Mach-E owners have reported premature battery degradation that exceeds Ford’s projected rates, with some vehicles showing significant capacity loss within the first two years of ownership.

The degradation appears particularly pronounced in vehicles operated in extreme climates, suggesting potential thermal management inadequacies that allow batteries to operate outside optimal temperature ranges.

Ford’s battery thermal management system in the Mach-E has shown inconsistent performance across different operating conditions.

Some vehicles experience thermal management system malfunctions that can expose batteries to temperature extremes, accelerating degradation or causing immediate failures. The system’s reliability appears variable, with some vehicles performing well while others experience recurring problems.

The Mach-E’s battery management software has required multiple over-the-air updates to address charging and performance issues that could impact long-term battery life. These software problems suggest initial calibration issues that may have allowed some batteries to operate under suboptimal conditions, potentially causing premature aging in affected vehicles.

Quality control issues in Mach-E battery production appear to be contributing to inconsistent reliability across the vehicle fleet. Some vehicles demonstrate excellent battery performance while others experience problems, indicating potential manufacturing variations that affect long-term durability. This inconsistency creates uncertainty for prospective buyers and current owners.

The Mach-E’s battery problems reflect Ford’s ongoing challenges in transitioning from internal combustion engines to electric powertrains. While the company is investing heavily in EV development, the learning curve appears steep, and early production vehicles are experiencing growing pains that impact reliability and customer satisfaction.

5. Volkswagen ID.4 (2021-Present)

The Volkswagen ID.4 has experienced concerning battery reliability issues that highlight ongoing challenges in VW’s electric vehicle development program. Despite the company’s substantial investment in EV technology and the ID.4’s technical sophistication, battery problems have emerged as a significant concern for owners and dealers.

Multiple ID.4 owners have reported unexpected battery failures requiring complete pack replacements within the first year of ownership.

These failures appear to stem from manufacturing defects or quality control issues rather than normal wear, suggesting systemic problems in VW’s battery production processes. The sudden failure pattern indicates problems with component quality or assembly procedures.

The ID.4’s battery thermal management system has shown vulnerability to component failures that can compromise battery protection.

Some vehicles have experienced cooling system malfunctions that expose batteries to thermal stress, potentially accelerating degradation or causing immediate failures. The system’s complexity appears to be creating reliability challenges that impact battery longevity.

Volkswagen’s battery management software in the ID.4 has required multiple updates to address charging irregularities and performance issues that could affect long-term battery health.

These software problems suggest initial calibration issues that may have exposed some batteries to operating conditions that accelerate aging or cause premature failures.

These reliability issues threaten to undermine consumer confidence in VW’s EV capabilities and highlight the ongoing challenges of scaling EV production while maintaining quality standards across global markets.

Also Read: 5 Turbo Engines Known For Longevity vs 5 That Fail Early