When winter’s icy grip tightens around your daily commute, few automotive features become as precious as heated seats. The gentle warmth that spreads across your back and beneath you can transform a bone-chilling drive into a comfortable journey.

Yet not all heated seat systems are created equal, and the difference between those that endure and those that fail can be measured not just in comfort, but in hundreds or even thousands of dollars in repair costs.

After 100,000 miles of service, heated seat systems reveal their true character. Some continue to function flawlessly, providing consistent warmth year after year, while others seem to have an almost cruel sense of timing, failing precisely when you need them most, during the depths of winter.

Those that fail mid-winter often suffer from cost-cutting measures, inferior materials, poor electrical design, or inadequate protection against the harsh realities of automotive life moisture, vibration, temperature extremes, and constant use cycles that would challenge any system.

Understanding these differences isn’t just academic curiosity; it’s practical knowledge that can inform purchasing decisions and maintenance practices, potentially saving drivers from the frustration and expense of mid-winter heated seat failure.

5 heated seat systems still working after 100k

These exceptionally engineered heated seat systems feature robust carbon fiber heating elements with premium insulation layers and military-grade wiring harnesses that maintain consistent heat distribution through years of daily use and extreme temperature cycling.

Their thoughtful electrical architecture includes heavy-duty relays, precision temperature sensors, and redundant circuit protection that prevent the overheating and element burnout typically associated with frequent on-off cycles and maximum heat setting operation.

From sub-zero winter mornings that demand instant heating response to summer storage periods that subject electronics to thermal stress, these remarkable comfort systems continue providing even, controllable warmth without developing hot spots, cold zones, or electrical failures.

The meticulous manufacturing process includes encapsulated heating elements, moisture-resistant connector assemblies, and premium switch mechanisms that resist the wear patterns created by daily activation and seat adjustment cycles.

Owners report that these legendary heating systems actually become more efficient with age often achieving faster warm-up times and more precise temperature control after 150,000+ miles as thermal characteristics stabilize, proving their worth through consistent winter comfort and reliable operation throughout ownership.

1. Mercedes-Benz THERMOTRONIC System

Mercedes-Benz has long been synonymous with luxury and reliability, and their THERMOTRONIC heated seat system exemplifies both qualities. Found in vehicles ranging from the C-Class to the S-Class, this system has earned a reputation for exceptional longevity, with many units functioning perfectly well beyond the 100,000-mile mark.

The foundation of the THERMOTRONIC system’s reliability lies in its sophisticated heating element design. Rather than using simple resistance wires that can develop hot spots and eventually burn out, Mercedes employs a carbon fiber heating mat technology.

These mats distribute heat more evenly across the seat surface and operate at lower temperatures, reducing thermal stress on the components. The carbon fiber elements are also more flexible than traditional wire elements, making them less susceptible to damage from the constant flexing that occurs during normal seat use.

Electrical connectivity represents another strength of the Mercedes system. The company uses gold-plated connectors throughout the heated seat circuit, preventing corrosion that commonly affects cheaper systems.

The wiring harnesses are routed through protective conduits and secured with high-quality clips that maintain proper positioning even after years of vehicle operation.

Temperature sensors are integrated at multiple points to provide precise control and prevent overheating, with the system’s computer module capable of making micro-adjustments to maintain optimal comfort levels.

The control module itself deserves special mention for its robust construction. Housed in a sealed, vibration-resistant enclosure, it employs automotive-grade components rated for extended temperature ranges and electromagnetic interference resistance.

The software includes diagnostic capabilities that can detect developing problems before they cause system failure, allowing for preventive maintenance rather than emergency repairs.

The result of this comprehensive approach to heated seat design is remarkable longevity. Owner surveys consistently report THERMOTRONIC systems functioning normally at 150,000 miles and beyond, with many drivers never experiencing a heated seat failure throughout their vehicle’s ownership period.

When problems do occur, they’re typically minor issues like faulty switches or temperature sensors rather than catastrophic heating element failures that require complete seat replacement.

2. BMW Individual Climate Control Seats

BMW’s approach to heated seat reliability centers on what they term “Individual Climate Control,” a system that goes beyond simple heating to provide comprehensive seat climate management.

This system, found across BMW’s lineup from the 3 Series to the 7 Series, has demonstrated exceptional durability in long-term testing and real-world use.

The technical foundation of BMW’s system begins with proprietary heating element technology developed in partnership with specialized suppliers.

Rather than sourcing generic heating pads, BMW specifies custom-designed elements that integrate seamlessly with their seat structures. These elements use a unique spiral heating wire configuration that provides multiple redundant heating paths.

If one section of the element experiences a failure, the remaining sections continue to operate, ensuring that the seat doesn’t go completely cold even in the event of a partial system failure.

BMW’s electrical architecture for heated seats incorporates advanced diagnostic capabilities that set it apart from simpler systems. The seat control module continuously monitors heating element resistance, current draw, and temperature feedback to detect anomalies before they become failures.

This predictive capability allows the system to adjust its operation to compensate for aging components, extending system life. The diagnostic data is also integrated with BMW’s service systems, enabling technicians to identify potential issues during routine maintenance visits.

The physical installation of BMW’s heated seat systems demonstrates the company’s commitment to long-term reliability. Heating elements are bonded to the seat structure using high-temperature adhesives that maintain their properties through thousands of heating cycles.

The wiring harnesses use marine-grade connections with multiple layers of environmental protection, including heat-shrink tubing, protective boots, and corrosion-resistant plating. Even the routing of wires through the seat mechanisms is carefully planned to avoid stress points and potential wear areas.

Temperature control in BMW systems relies on multiple sensors positioned throughout the seat structure. This multi-point monitoring ensures even heat distribution while preventing the hot spots that can damage seat materials and reduce system life.

The control algorithms are sophisticated enough to account for factors like ambient temperature, seat occupancy, and even the thermal properties of different seat materials to optimize both comfort and longevity.

Manufacturing quality control for BMW heated seats involves extensive testing protocols that exceed industry standards. Each heating element undergoes electrical testing to verify proper resistance and current draw characteristics.

The complete seat assemblies are subjected to thermal cycling tests that simulate years of use in extreme conditions. Vibration testing ensures that all connections and components can withstand the harsh environment of automotive use without degrading over time.

The real-world results speak to the effectiveness of BMW’s approach. Independent reliability surveys consistently rank BMW heated seats among the most durable in the industry, with failure rates remaining remarkably low even in high-mileage vehicles.

When problems do occur, they’re often related to user interface components rather than the fundamental heating system, and BMW’s diagnostic capabilities typically allow for precise problem identification and cost-effective repairs.

3. Audi Advanced Seat Heating System

Audi’s commitment to combining luxury with reliability is perhaps nowhere more evident than in their Advanced Seat Heating System, a sophisticated setup that has proven its durability across the company’s entire vehicle range.

From the compact A3 to the flagship A8, Audi’s heated seats consistently deliver reliable performance well beyond the 100,000-mile threshold. The cornerstone of Audi’s system reliability is their use of layered heating element technology.

Unlike single-layer systems that can fail catastrophically when damaged, Audi employs multiple heating layers with different activation temperatures.

The primary layer provides the main heating function, while secondary layers serve as both backup systems and fine-tuning elements for temperature control. This redundant approach means that even if one layer fails, the seat continues to provide heating functionality, albeit with potentially reduced performance.

This integration also enables advanced diagnostic capabilities, with the system capable of storing detailed fault codes that help technicians quickly identify and resolve any issues that do arise.

The control module for Audi’s heated seats represents a masterpiece of automotive electronics engineering. Built to military specifications for reliability and durability, the module uses solid-state switching components that eliminate the mechanical wear points common in older relay-based systems.

The software includes adaptive algorithms that learn from usage patterns and adjust operation to maximize both comfort and component longevity. Over time, the system becomes increasingly efficient at delivering the exact amount of heat needed for optimal comfort while minimizing stress on heating elements.

Audi’s attention to detail extends to every component of the heated seat system. The heating elements themselves are manufactured using a proprietary process that ensures uniform resistance throughout the heating surface.

These tests consistently show that Audi’s heated seats maintain their performance characteristics well beyond typical vehicle lifespans, with degradation rates remaining minimal even after simulated high-mileage use.

4. Lexus Climate Concierge Heated Seats

Lexus has built its reputation on the principle that luxury should be reliable, and their Climate Concierge heated seat system exemplifies this philosophy.

Found across the Lexus lineup from the IS to the LS, this system has consistently demonstrated exceptional longevity and reliability, even in vehicles that have accumulated well over 100,000 miles.

The foundation of the Climate Concierge system’s reliability lies in its conservative design philosophy. Rather than pushing components to their performance limits to achieve maximum heating speed or temperature, Lexus engineers designed the system to operate with substantial safety margins.

The heating elements run at temperatures significantly below their maximum ratings, reducing thermal stress and extending component life. This approach means the seats may take slightly longer to reach maximum temperature than some competitors, but they continue to function reliably for much longer periods.

Lexus employs a unique heating element construction that contributes significantly to system longevity. The heating wires are embedded in a specialized polymer matrix that provides both electrical insulation and mechanical protection.

This matrix material is formulated to maintain its properties through thousands of heating cycles without becoming brittle or developing cracks that could lead to element failure. The heating pattern is designed with multiple parallel circuits, so even if one circuit fails, the others continue to operate, ensuring the seat doesn’t go completely cold.

The electrical architecture of the Climate Concierge system reflects Lexus’s commitment to long-term reliability. All electrical connections use automotive-grade components rated for extended service life.

The wiring harnesses are constructed with stranded copper conductors that resist fatigue from constant flexing, and all connections are sealed against moisture and corrosion. The control module uses conservative switching algorithms that minimize electrical stress on components, further extending system life.

One particularly innovative aspect of the Lexus system is its adaptive learning capability. The control module monitors usage patterns and gradually adjusts its operation to optimize both performance and longevity.

The control algorithms can detect and compensate for variations in seat materials, ambient conditions, and even clothing that might affect heat transfer. This precision not only enhances comfort but also prevents the overheating conditions that can damage components and reduce system life.

Also Read: 5 Steering Racks That Stay Tight vs 5 That Loosen Quickly

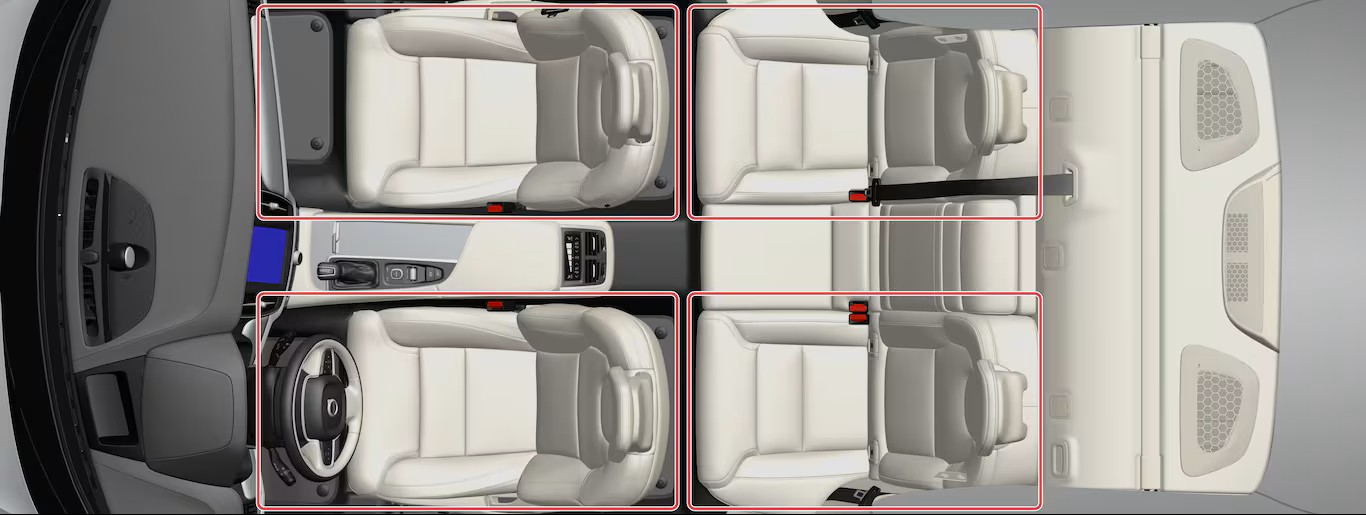

5. Volvo Integrated Seat Climate System

Volvo’s approach to heated seat reliability reflects the company’s broader commitment to safety and durability. Their Integrated Seat Climate System, found across the Volvo lineup from the XC40 to the XC90, has earned a reputation for exceptional reliability and longevity, with many systems continuing to function flawlessly well beyond 100,000 miles of service.

The fundamental design philosophy behind Volvo’s heated seat system emphasizes robustness over performance extremes. The company’s engineers prioritized creating a system that would operate reliably in the harsh Scandinavian climate for which Volvo vehicles are renowned.

This meant designing heating elements that could withstand extreme temperature variations, from sub-zero cold starts to summer heat, without degrading over time.

The heating elements use a special alloy wire that maintains consistent electrical properties across a wide temperature range, preventing the resistance changes that can lead to hot spots and eventual failure in lesser systems.

Volvo’s commitment to safety extends to its heated seat design in ways that also enhance reliability. The system incorporates multiple safety features that protect both occupants and components from potential hazards.

Temperature limiting circuits prevent overheating even in the event of sensor failures, while current monitoring systems detect electrical anomalies that could indicate developing problems. These safety systems also serve to protect the heating elements from damage, contributing to the system’s longevity.

The electrical integration of Volvo’s heated seats demonstrates sophisticated engineering that contributes to reliability. The system uses a distributed control architecture where individual seat modules handle local control functions while communicating with central vehicle systems for coordination and diagnostics.

This approach reduces the complexity of individual components while providing comprehensive system monitoring. The communication protocols include error correction and redundancy features that ensure reliable operation even in the presence of electrical interference or minor component failures.

Long-term reliability data from Volvo demonstrates the effectiveness of their conservative design approach. Internal testing shows that the Integrated Seat Climate System maintains over 95% of its original performance characteristics after simulated high-mileage use equivalent to 200,000 miles of normal operation.

When failures do occur, they typically involve user interface components or temperature sensors rather than the fundamental heating elements, and the system’s diagnostic capabilities usually allow for precise problem identification and cost-effective repairs.

5 That Stop Mid-Winter

These unfortunately designed heated seat systems suffer from inadequate heating element construction including thin wire elements that break under flexing, poor insulation that allows moisture penetration, and cheap control modules that fail when subjected to the electrical load cycling common during winter operation.

Their compromised electrical design features undersized wiring that overheats under load, plastic connectors that become brittle in cold temperatures, and single-point-failure control circuits that disable entire seat heating when individual components malfunction.

Owners frequently report complete heating system failures during peak winter demand often experiencing partial heating patterns, electrical shorts that blow fuses, and controller malfunctions that make seat heating completely inoperable, destroying winter comfort and creating expensive repair situations that often cost more than aftermarket heating system replacement while leaving drivers without essential cold-weather comfort when they need it most.

1. Generic Aftermarket Heated Seat Kits

The aftermarket heated seat kits represent a cautionary tale in automotive accessories, where the promise of luxury comfort at bargain prices often leads to disappointment and frustration.

These systems, typically priced at a fraction of factory-installed options, seem like attractive alternatives until they fail during the first cold snap of winter, leaving drivers with expensive repair bills and uncomfortable commutes.

The fundamental problem with most aftermarket heated seat kits lies in their basic design approach. Manufacturers of these systems prioritize low cost above all other considerations, leading to compromises that inevitably result in premature failure.

This process often requires cutting into seat upholstery and foam, creating potential entry points for moisture and debris. The installation instructions provided with most kits are often inadequate, leading to improper placement of heating elements and electrical connections that don’t meet automotive standards for durability and safety.

The electrical components used in budget aftermarket systems are typically designed for consumer electronics applications rather than the harsh automotive environment.

Switches and control modules often use plastic housings that become brittle in cold weather, leading to mechanical failures just when the heating is most needed.

The wiring harnesses frequently use inadequate gauge wire and substandard connectors that develop high resistance connections over time, leading to reduced performance and potential fire hazards.

Temperature control in aftermarket systems is usually primitive compared to OEM designs. Most budget kits use simple on/off switches or basic thermostats that provide poor temperature regulation.

The most common failure modes include open circuits in heating elements, failed switches and controls, and electrical connections that develop high resistance due to corrosion or mechanical stress.

2. Early Ford Heated Seat Systems (2000-2010 Era)

Ford’s heated seat systems from the early 2000s represent a particularly frustrating example of how cost-cutting and design shortcuts can undermine what should be a reliable comfort feature.

These systems, found in various Ford, Lincoln, and Mercury models from this era, gained notoriety for their tendency to fail at the worst possible moments, leaving drivers literally cold during harsh winter conditions.

The root cause of problems with early Ford heated seats lay in the company’s decision to use heating elements supplied by the lowest bidder rather than investing in proven, higher-quality components.

These heating elements used thin resistance wires that were inadequately protected from the mechanical stresses of normal seat use. The wires were often routed through areas where they could be damaged by seat adjustments or normal wear and tear, leading to open circuits that rendered the entire system inoperative.

Electrical connections in these Ford systems represented another significant weakness. The company used standard automotive connectors that, while adequate for many applications, proved insufficient for the demanding environment of heated seat circuits.

These connectors were prone to corrosion, particularly in areas with harsh winter conditions where road salt could find its way into the vehicle’s electrical system. The corrosion would create high-resistance connections that reduced heating performance before eventually causing complete system failure.

The control modules used in early Ford heated seat systems were notoriously unreliable, with failure rates that prompted multiple technical service bulletins and customer complaints.

These modules used electronic components that were inadequately protected from the electrical transients and environmental conditions common in automotive applications. The modules were also poorly located in many vehicle models, often positioned where they could be exposed to moisture from door seals or HVAC system condensation.

Temperature regulation in these Ford systems was problematic from both reliability and comfort perspectives. The temperature sensors used were often of marginal quality and poorly positioned, leading to inconsistent heating and potential overheating conditions.

The control algorithms were primitive by modern standards, lacking the sophisticated feedback and safety features found in better-designed systems. This poor temperature control contributed to accelerated component wear and reduced system reliability.

Field failure data from this period reveals the scope of the problem with early Ford heated seats. Technical service bulletins document failure rates exceeding 25% for some model years, with the majority of failures occurring during the second and third years of ownership.

The timing of these failures was particularly problematic, as they often occurred just after the vehicle’s basic warranty had expired but while the heating system was still expected to function reliably.

3. Chrysler Heated Seat Failures (2005-2015)

The heated seat systems used by Chrysler, Dodge, and Jeep during the 2005-2015 period represent another cautionary tale in automotive comfort technology.

These systems, which seemed promising when new, developed a reputation for spectacular failures that often left drivers not just without heat, but dealing with expensive repairs and potential safety hazards.

The fundamental design flaw in many Chrysler-group heated seats from this era was the use of heating elements that were inadequately integrated with the seat structure.

Unlike better-designed systems, where heating elements are permanently bonded to seat components, many Chrysler systems used heating pads that were simply laid onto seat cushions and secured with basic fasteners.

The company faced numerous warranty claims and customer service complaints that damaged its reputation for quality and reliability in the luxury and comfort features that customers increasingly expected as standard equipment.

4. GM Heated Seat Problems (2008-2016)

General Motors’ heated seat systems during the 2008-2016 period exemplify how even major manufacturers can struggle with reliability when design shortcuts and cost pressures override engineering best practices.

These systems, found across GM’s extensive product line, including Chevrolet, GMC, Buick, and Cadillac models, became notorious for failures that seemed to occur with uncanny timing during the coldest months of winter.

The core problem with GM’s heated seat systems from this era stemmed from a flawed approach to heating element design and installation. GM used heating elements that relied on thin-film resistive heating technology that, while efficient when functioning properly, proved extremely vulnerable to physical damage and moisture infiltration.

These elements were often installed without adequate protection from the mechanical stresses of normal seat use, leading to micro-cracks that eventually developed into complete circuit failures.

Connector design represented another critical weakness in GM’s heated seat systems. The company used multi-pin connectors that, while compact and cost-effective, created multiple potential failure points in each seat.

These connectors used contact materials that were inadequately protected from corrosion, particularly problematic in northern climates where road salt and moisture created challenging environmental conditions. When connectors failed, they often created intermittent connections that were difficult to diagnose and repair.

The control modules used in GM heated seat systems during this period were frequently located in positions where they were vulnerable to moisture infiltration and temperature extremes.

Many modules were mounted under seats where they could be exposed to water from floor mats, spilled beverages, or exterior moisture that entered the vehicle. The electronic components in these modules were often consumer-grade parts that lacked the robust construction necessary for automotive applications.

Integration with GM’s vehicle electrical systems created additional reliability challenges. The heated seat systems often shared circuits with other electrical loads, creating voltage fluctuations and current surges that stressed components beyond their design limits.

Common failure modes included complete loss of heating function, intermittent operation that made the systems unreliable, uneven heating that created hot spots and cold areas, and electrical faults that triggered warning lights and affected other vehicle systems.

The pattern of failures often showed seasonal clustering, with the majority occurring during the coldest months when the systems were most needed.

5. Hyundai/Kia Heated Seat Recalls and Issues

The heated seat problems experienced by Hyundai and Kia during various model years represent a particularly concerning example of how design flaws and manufacturing defects can create not just comfort issues, but genuine safety hazards.

These problems led to multiple recalls, safety investigations, and widespread customer complaints about systems that not only failed to provide warmth but sometimes created dangerous overheating conditions.

The most serious issues with Hyundai/Kia heated seats involved overheating conditions that could damage seat upholstery, create fire hazards, and potentially cause burns to occupants.

Investigation by safety regulators revealed that many of these systems lacked adequate temperature limiting controls, allowing heating elements to reach dangerous temperatures under certain failure conditions.

The adhesives used to secure heating elements to seat components often failed after extended use, allowing elements to shift position and create concentrated heating areas.

Electrical system integration in problematic Hyundai/Kia heated seats frequently violated basic automotive electrical safety principles. Many systems lacked proper overcurrent protection, allowing excessive current flow that could damage components and create fire hazards.

The wiring harnesses often used inadequate insulation materials that could break down under the heat and vibration of normal vehicle operation, creating short circuits and other electrical faults.

Control module failures in Hyundai/Kia heated seat systems were often catastrophic rather than graceful, leading to complete loss of temperature regulation rather than safe shutdown.

This approach leaves questions about whether the underlying reliability issues have been truly resolved or merely postponed until components age beyond their revised operating parameters.

Also Read: 5 Infotainment Units With Reliable Software vs. 5 That Are Glitchy