The Dodge Dynasty, produced from 1988 to 1993, represented Chrysler Corporation’s ambitious attempt to compete in the mid-size sedan market during a crucial period of automotive evolution.

Built on the Chrysler AA platform, this front-wheel-drive sedan was designed to offer American families a reliable, comfortable, and reasonably priced alternative to imported competition.

However, despite its noble intentions and decent initial reception, the Dynasty became notorious for several critical weaknesses that could transform a promising vehicle into a maintenance nightmare almost overnight.

Understanding these potential pitfalls is essential for anyone considering purchasing a used Dynasty, current owners looking to maintain their vehicles, or automotive enthusiasts studying the lessons learned from this era of American automotive manufacturing.

The Dynasty’s problems weren’t merely cosmetic or minor inconveniences they were fundamental design and manufacturing oversights that could lead to catastrophic failures, expensive repairs, and ultimately, premature vehicle retirement.

These eight critical oversights represent the most common and devastating issues that Dynasty owners have encountered over the decades. From transmission failures that could strand drivers without warning to electrical gremlins that defied logic and repair, each oversight has the potential to transform what should be routine ownership into a costly ordeal.

Recognizing these warning signs early and taking preventive action can mean the difference between years of reliable service and an expensive paperweight sitting in your driveway.

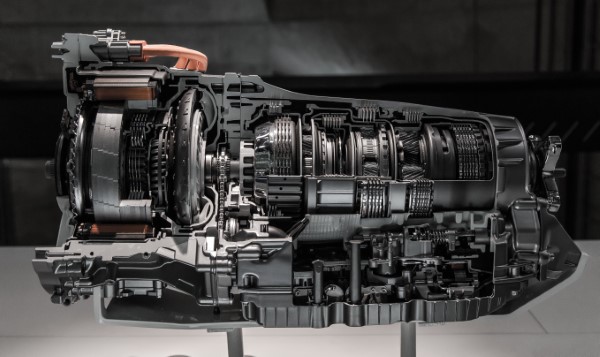

1. Transmission Neglect

The Dodge Dynasty’s transmission system represents perhaps the most critical oversight that can destroy the vehicle’s reliability and value in record time.

The majority of Dynasty models came equipped with Chrysler’s A604 four-speed automatic transmission, later redesigned as the 41TE. While this transmission was advanced for its time, featuring electronic controls and adaptive shift patterns, it proved to be exceptionally sensitive to maintenance neglect and operating conditions.

The A604/41TE transmission’s Achilles heel lies in its complex hydraulic and electronic control systems. Unlike simpler three-speed automatics of the era, this transmission relies on precise fluid pressures, clean transmission fluid, and properly functioning solenoids to operate correctly.

When owners skip regular transmission service intervals or use incorrect fluid types, the results can be catastrophic. The transmission begins to exhibit harsh shifts, delayed engagement, and eventually, complete failure of the internal clutch packs and bands.

One of the most devastating aspects of transmission neglect in the Dynasty is how quickly problems can escalate. What begins as slightly rough shifting can progress to complete transmission failure within weeks or even days.

The electronic control module that manages shift points becomes confused when receiving incorrect signals from contaminated fluid or worn components, leading to erratic behavior that accelerates internal wear.

Many Dynasty owners have reported their transmissions failing with little to no warning, leaving them stranded and facing repair bills that often exceed the vehicle’s value.

The financial impact of transmission failure cannot be overstated. A complete transmission rebuild or replacement for a Dynasty can cost anywhere from $2,500 to $4,000, assuming parts are still available.

Given that most surviving Dynasty vehicles are worth significantly less than this repair cost, transmission failure effectively totals the vehicle economically.

This oversight has single-handedly eliminated thousands of Dynasty vehicles from American roads, as owners faced the impossible choice between expensive repairs and vehicle abandonment.

Prevention requires religious adherence to transmission service intervals, typically every 30,000 miles or less under severe conditions. Using only the correct ATF+4 fluid specification is crucial, as substitute fluids can cause seal degradation and valve body problems.

Regular inspection of transmission mounts, cooling lines, and the transmission cooler can also prevent secondary problems that lead to premature failure.

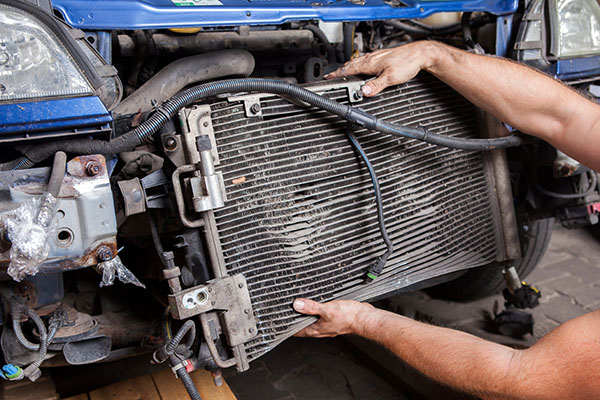

2. Cooling System Catastrophes

The cooling system oversight in Dodge Dynasty vehicles represents a ticking time bomb that can destroy the engine in a matter of minutes once problems begin.

The Dynasty’s cooling system design, while adequate when new and properly maintained, contains several inherent weaknesses that make it particularly vulnerable to catastrophic failure when neglected or when individual components begin to deteriorate.

The most critical vulnerability lies in the Dynasty’s radiator design and the integration of the automatic transmission cooler. The radiator, constructed with plastic end tanks connected to an aluminum core, becomes brittle over time due to repeated heating and cooling cycles.

When these plastic components fail and they inevitably do after 15-20 years the results are immediate and devastating. A sudden radiator failure can dump the entire cooling system’s contents in seconds, leaving the engine running without coolant protection.

Equally problematic is the Dynasty’s water pump design, which utilizes a plastic impeller that can separate from its metal shaft without warning. When this separation occurs, the water pump continues to turn but no longer circulates coolant through the engine.

This creates a particularly insidious failure mode because the engine continues running normally for several minutes before temperatures begin rising rapidly. By the time warning lights illuminate or temperature gauges show problems, severe engine damage may have already occurred.

The thermostat housing represents another critical weak point that many Dynasty owners overlook until it’s too late. Constructed from plastic and subjected to constant thermal cycling, this component frequently cracks or warps, leading to coolant leaks that can quickly escalate from minor seepage to major failures.

When the thermostat housing fails, it can dump coolant directly onto hot engine components, creating dangerous steam clouds and potential fire hazards.

Heater core failures, while not immediately engine-threatening, can create secondary problems that lead to cooling system catastrophes. A leaking heater core often goes unnoticed initially, slowly depleting coolant levels while creating humidity problems inside the vehicle.

Owners may not realize their coolant levels are dropping until the system runs dry during high-demand situations like highway driving or stop-and-go traffic.

The interconnected nature of these cooling system components means that failure of any single element can quickly cascade into multiple problems. A small radiator leak, if ignored, can lead to water pump bearing failure due to running with low coolant levels.

This, in turn, can cause thermostat problems as the engine begins running hotter than designed. The result is often complete cooling system failure that requires the replacement of multiple expensive components simultaneously, turning a simple repair into a major overhaul that may not be economically justifiable on an older Dynasty.

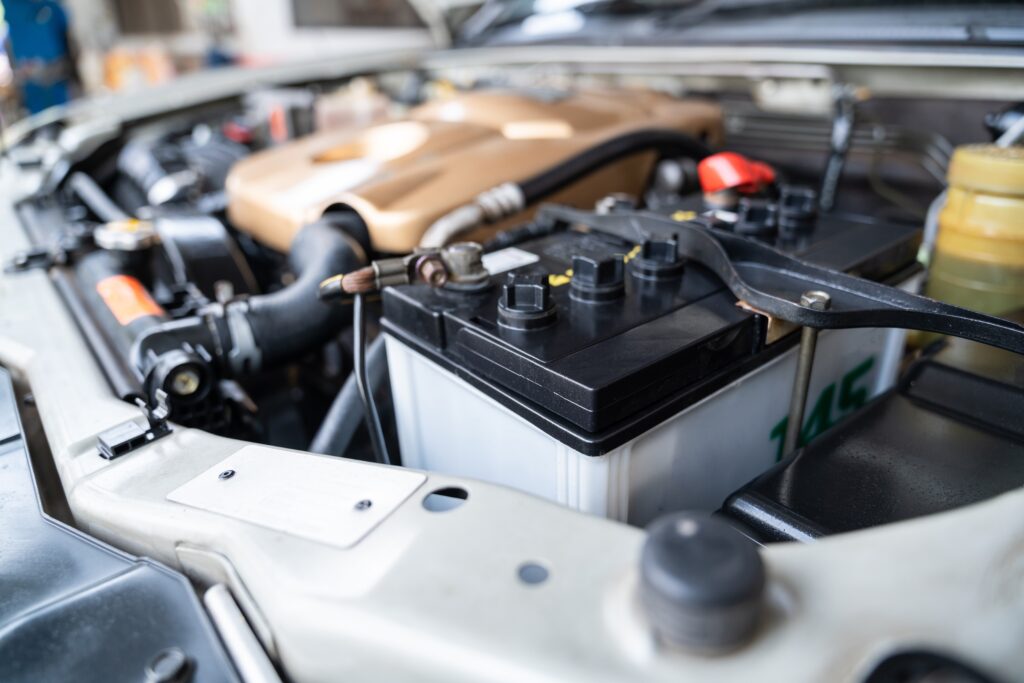

3. Electrical System Gremlins

The electrical system oversights in Dodge Dynasty vehicles represent some of the most frustrating and expensive problems owners can encounter.

Unlike mechanical failures that often provide clear symptoms and straightforward solutions, electrical problems in the Dynasty can manifest in seemingly unrelated ways, creating diagnostic nightmares that challenge even experienced technicians while draining owners’ wallets through repeated failed repair attempts.

The Dynasty’s electrical troubles stem primarily from poor ground connections, inadequate wire gauge selections for high-current applications, and the use of materials that degrade rapidly in automotive environments.

The ground strap system, crucial for proper electrical operation, utilizes connections that corrode and loosen over time. When these ground paths deteriorate, the electrical system begins seeking alternative paths to complete circuits, often routing current through sensitive electronic components never designed to handle such loads.

One of the most devastating electrical oversights involves the alternator and charging system design. The Dynasty’s alternator, while adequate when new, operates at the very edge of its capacity to meet the vehicle’s electrical demands.

As the alternator ages and its output diminishes, the charging system begins struggling to maintain proper voltage levels throughout the electrical system. This marginal operation creates a cascade of problems affecting everything from engine management computers to basic lighting systems.

The Body Control Module (BCM) and Engine Control Module (ECM) represent particular vulnerabilities in the Dynasty’s electrical system. These early automotive computers were not designed with the robust protection circuits found in later systems, making them susceptible to voltage spikes, electromagnetic interference, and moisture intrusion.

When these modules begin failing, they can create intermittent problems that are nearly impossible to diagnose using conventional methods. Symptoms may include random stalling, incorrect gauge readings, inoperative accessories, and even complete vehicle shutdown without warning.

Wiring harness degradation presents another major electrical oversight that can destroy a Dynasty’s reliability. The insulation materials used in Dynasty wiring harnesses were not formulated to withstand long-term exposure to automotive fluids, temperature extremes, and vibration.

Over time, these harnesses develop internal breaks, shorts, and corrosion that create intermittent connections. These problems are particularly challenging because they often occur only under specific conditions when the harness flexes during turns, when temperatures reach certain levels, or when vibration reaches specific frequencies.

The dashboard and interior electrical systems suffer from similar degradation issues, with particular problems in the instrument cluster and climate control systems.

Printed circuit boards within these components develop cracks and corrosion that create erratic operation. The cost of diagnosing and repairing these electrical gremlins often exceeds the vehicle’s value, as technicians may spend hours tracking down intermittent problems that require expensive specialized equipment to identify accurately.

4. Suspension System Failures

The suspension system oversight in Dodge Dynasty vehicles represents a critical structural weakness that can transform a comfortable sedan into an unsafe, uncontrollable vehicle in remarkably short order.

The Dynasty’s suspension design, while innovative for its time with its independent front suspension and semi-independent rear setup, contains several fundamental flaws that accelerate wear and can lead to catastrophic failures when neglected or subjected to normal driving stresses over time.

The front suspension’s most critical vulnerability lies in its strut assemblies and the integration of steering components. The Dynasty utilizes MacPherson struts that combine spring support, damping, and steering pivot functions in a single assembly.

While this design offers packaging advantages and reduces manufacturing costs, it creates a situation where failure of any single component within the strut assembly can compromise the entire corner’s functionality.

When strut bearings fail a common occurrence after 80,000-100,000 miles, the result isn’t just poor ride quality but potential loss of steering control.

Ball joint failures represent another devastating suspension oversight that can occur without adequate warning. The Dynasty’s lower ball joints bear significant loads while operating in harsh environments exposed to road salt, water, and debris.

These components utilize boot seals that deteriorate over time, allowing contamination to enter the joint while permitting lubricant to escape. Once contamination occurs, ball joint wear accelerates rapidly, often progressing from acceptable play to dangerous looseness in just a few thousand miles.

The rear suspension system presents its own unique set of catastrophic failure modes, particularly in the trailing arm bushings and shock absorber mounts.

The trailing arm bushings, constructed from rubber compounds that harden and crack over time, control wheel alignment and suspension geometry.

When these bushings deteriorate, they create excessive play that allows the rear wheels to move independently of intended suspension travel. This can result in sudden changes in vehicle handling characteristics, particularly during emergency maneuvers or when encountering road irregularities at highway speeds.

Shock absorber failures, while seemingly less critical than structural component problems, can create dangerous vehicle dynamics that catch drivers unprepared.

The Dynasty’s shock absorbers often fail internally, losing damping capability gradually before suffering complete failure. During this degradation process, the vehicle develops oscillating motions after encountering bumps, reduced tire contact with the road surface, and unpredictable handling characteristics that can trigger accidents during normal driving situations.

The interconnected nature of suspension components means that failure of one element often accelerates wear in related parts. A failed strut bearing places additional stress on steering components, while worn ball joints create vibrations that damage shock absorbers and wheel bearings.

This cascade effect can transform a single component replacement into a comprehensive suspension overhaul that may cost more than the vehicle’s remaining value, effectively ending its useful life.

Also Read: 5 Transmissions Built for Abuse vs 5 That Kill Torque Converters Early

5. Engine Oil System Neglect

Engine oil system neglect in the Dodge Dynasty represents one of the most preventable yet devastating oversights that can destroy an otherwise serviceable vehicle in remarkably short order.

The Dynasty’s engine designs, whether the base 2.5-liter four-cylinder or the optional 3.0-liter V6, incorporate several design elements that make them particularly sensitive to oil maintenance neglect, creating conditions where minor oversights can quickly escalate into catastrophic engine failures.

The 2.5-liter engine’s most critical vulnerability lies in its hydraulic valve lifter system, which depends on consistent oil pressure and clean oil to function properly.

These lifters operate in extremely tight tolerances and rely on filtered oil flow to maintain proper valve lash adjustment. When oil change intervals are extended beyond recommended limits or when inferior oil filters are used, the lifters begin experiencing inadequate lubrication.

This initially manifests as valve train noise, but quickly progresses to lifter collapse, bent pushrods, and potentially damaged camshaft lobes. The 3.0-liter V6 engine presents its own unique oil system challenges, particularly in the timing chain and sprocket assembly.

This engine utilizes a timing chain that depends on proper oil pressure to maintain tension through its hydraulic tensioner system. When oil viscosity breaks down due to extended service intervals or when oil levels drop due to leaks or consumption, the timing chain tensioner loses its ability to maintain proper chain tension.

A loose timing chain can jump timing marks, resulting in interference between pistons and valves that requires complete engine rebuilding or replacement.

Oil pump failures represent another critical oversight that can destroy Dynasty engines without warning. Both engine variants utilize oil pumps driven directly by the crankshaft, making them susceptible to wear when contaminated oil or inadequate lubrication occurs.

When oil pumps begin failing, they initially lose pressure gradually, often not triggering warning lights until damage has already occurred. The loss of oil pressure can destroy main bearings, rod bearings, and camshaft bearings in a matter of minutes once complete failure occurs.

The oil filter bypass valve system presents a particularly insidious failure mode that many Dynasty owners never consider. When oil filters become clogged due to extended service intervals, the bypass valve opens to maintain oil flow to critical engine components.

While this prevents immediate engine seizure, it also means unfiltered oil circulates through the engine, accelerating wear in all moving parts. This condition can exist for thousands of miles before symptoms become apparent, by which time extensive internal engine damage has occurred.

Sludge formation represents the most devastating long-term consequence of oil system neglect in Dynasty engines. Both engine variants are prone to sludge accumulation when oil change intervals are extended or when stop-and-go driving conditions prevail.

Sludge buildup restricts oil passages, blocks pickup screens, and creates hot spots within the engine that accelerate component wear. Once significant sludge formation occurs, it’s often impossible to remove completely without extensive engine disassembly, effectively requiring engine replacement to restore proper operation.

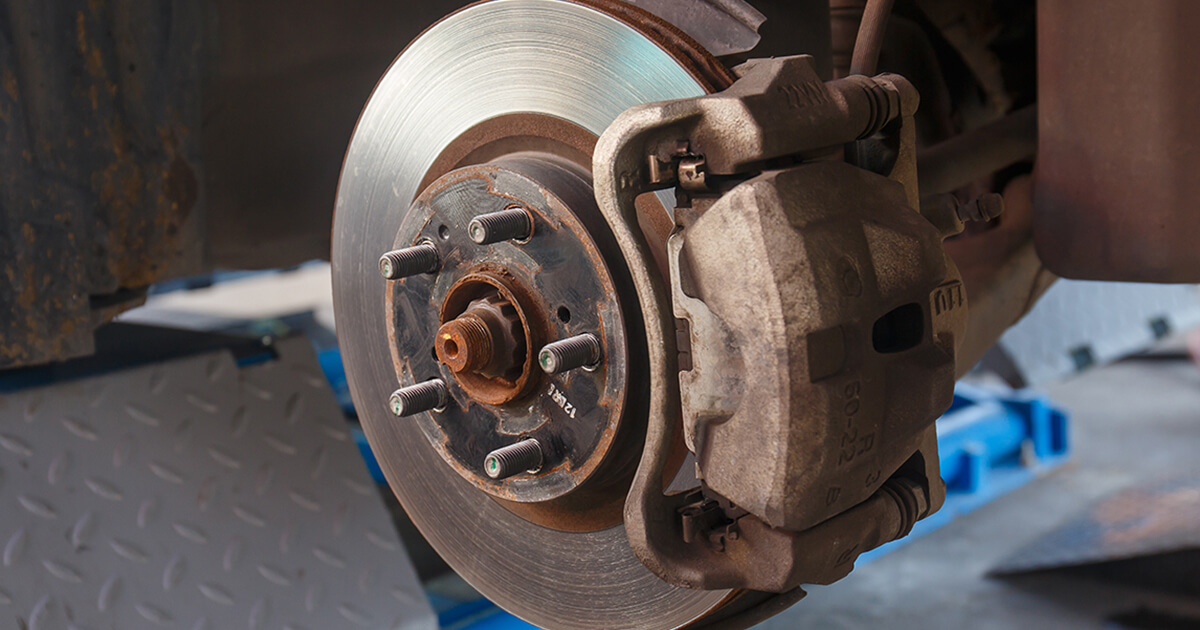

6. Brake System Deterioration

Brake system deterioration in the Dodge Dynasty represents a critical safety oversight that can transform routine stops into emergencies while simultaneously destroying other vehicle systems through neglect-induced failures.

The Dynasty’s brake system, while conventional in design, incorporates several components and design elements that make it particularly susceptible to rapid deterioration when maintenance is deferred or when early warning signs are ignored by owners.

The front disc brake system’s most critical vulnerability lies in its single-piston floating caliper design and the integration of the brake hose routing. These calipers depend on proper lubrication of slide pins and seals to maintain even pad contact with rotors.

When routine maintenance is neglected, the caliper slide pins seize due to corrosion and dried lubricant, causing the caliper to hang up and maintain constant contact with the rotor.

This condition creates excessive heat that warps rotors, destroys brake pads prematurely, and can even cause brake fluid to boil, resulting in complete brake failure.

Brake line corrosion represents another devastating oversight that can occur gradually over years before manifesting as sudden, catastrophic brake failure.

The Dynasty’s brake lines, constructed from steel with protective coatings, are routed through areas where they’re exposed to road salt, moisture, and debris.

Over time, these lines develop external corrosion that penetrates through to the inner walls, creating weak points that can rupture without warning. A catastrophic brake line failure can result in complete loss of braking ability with no warning beyond a sudden pedal-to-floor condition.

The rear drum brake system presents its own unique set of failure modes that can compromise braking effectiveness while damaging related components.

The rear brake shoes and hardware are designed to operate within specific tolerances and depend on proper adjustment to maintain effectiveness.

When rear brakes are neglected, the shoes wear beyond their intended limits, allowing the brake cylinders to over-extend and potentially leak brake fluid into the drum assembly. This contamination destroys friction material and can create glazed surfaces that never regain proper braking capability.

Master cylinder deterioration represents perhaps the most insidious brake system oversight because it often develops gradually and can affect multiple vehicle systems simultaneously.

When the booster diaphragm fails, it can create a massive vacuum leak that affects engine operation while simultaneously eliminating power brake assist. This dual failure mode can leave drivers with both poor engine performance and extremely heavy brake pedal effort, creating dangerous driving conditions.

7. Fuel System Contamination

Fuel system contamination in the Dodge Dynasty represents a progressive oversight that can systematically destroy engine performance, fuel economy, and emissions compliance while creating repair cascades that often exceed the vehicle’s remaining value.

The Dynasty’s fuel system design, incorporating both carburetor and fuel injection variants depending on model year and engine choice, contains several components that are particularly sensitive to fuel quality and contamination, making prevention and early intervention crucial for long-term reliability.

The fuel injection system’s most critical vulnerability lies in its injector design and fuel rail configuration. The Dynasty’s fuel injectors operate with extremely tight tolerances and depend on clean fuel to maintain proper spray patterns and flow rates.

When contaminated fuel enters the system whether through poor fuel quality, water contamination, or debris from deteriorating fuel tanks, the injectors begin developing restricted flow patterns that create lean running conditions in affected cylinders.

This condition initially manifests as rough idle and hesitation but quickly progresses to catalyst damage and potential engine internal damage from lean detonation.

Fuel pump failures represent another devastating consequence of fuel system contamination that can leave Dynasty owners stranded without warning.

The electric fuel pump, located within the fuel tank on fuel-injected models, depends on fuel for both lubrication and cooling. When water or debris contamination occurs, the fuel pump’s internal components experience accelerated wear while operating temperatures increase beyond design limits.

Fuel pump failure typically occurs suddenly and completely, leaving the engine unable to start or run, often requiring expensive tank removal for pump replacement.

The fuel tank itself becomes a source of contamination over time, particularly in Dynasty vehicles that have experienced extended periods of storage or infrequent use.

The fuel tank’s internal surfaces can develop rust and corrosion that creates metal particles in the fuel system. Additionally, the fuel level sending unit and associated wiring within the tank can deteriorate, creating electrical contamination that affects fuel pump operation and fuel gauge accuracy.

Once significant tank contamination occurs, it often requires complete fuel system cleaning and tank replacement to restore proper operation. Fuel filter neglect creates a particularly insidious contamination pathway that many Dynasty owners overlook until major problems develop.

Water contamination often requires complete fuel system replacement rather than cleaning, making it an economically devastating problem for older Dynasty vehicles.

8. Body and Frame Corrosion

Body and frame corrosion in the Dodge Dynasty represents the ultimate oversight that can render an otherwise mechanically sound vehicle unsafe and unrepairable, effectively ending its useful life regardless of the condition of other systems.

The Dynasty’s unibody construction, while offering advantages in weight and manufacturing efficiency, creates unique vulnerabilities to structural corrosion that can progress hidden from view until catastrophic failure occurs or repair costs exceed any reasonable economic justification.

The most critical corrosion vulnerability lies in the Dynasty’s rear suspension mounting points and floor pan structure. These areas are particularly susceptible to salt exposure and water intrusion while being difficult to inspect without lifting the vehicle.

When corrosion begins in these structural areas, it typically progresses rapidly due to the thin metal sections and box-section designs that trap moisture and debris.

By the time corrosion becomes visible from the exterior, internal structural integrity may have been severely compromised, creating dangerous conditions where suspension components can separate from the vehicle structure.

Door frame and rocker panel corrosion represents another devastating structural weakness that affects both safety and usability. The Dynasty’s door frames utilize welded construction with seams that can trap moisture and road salt, creating ideal conditions for corrosion initiation.

Once corrosion begins in door frames, it often spreads to adjacent structural members while compromising the door’s ability to provide crash protection. Rocker panel deterioration can progress to the point where floor pan sections separate from the vehicle structure, creating openings that allow exhaust gases to enter the passenger compartment.

The front subframe and engine mounting areas present unique corrosion challenges that can affect vehicle safety and drivability simultaneously. The subframe, constructed from stamped steel sections welded together, contains numerous pockets and recesses where corrosion can initiate and progress unseen.

When subframe corrosion becomes severe, it can affect engine and transmission mounting point integrity, potentially allowing powertrain components to shift during operation. This condition creates dangerous handling characteristics while potentially damaging expensive mechanical components.

Rear wheel well and quarter panel corrosion often begins as minor surface rust but can quickly progress to structural problems that affect suspension mounting points and fuel system integrity.

The Dynasty’s rear quarter panels contain suspension mounting reinforcements that can corrode from inside out, weakening the attachment points for critical suspension components.

Additionally, fuel filler neck corrosion can create fuel system contamination while potentially creating fire hazards from fuel vapors escaping through corroded areas.

Unlike body-on-frame vehicles, where individual frame sections can be replaced, Dynasty unibody repair often requires cutting and welding in multiple areas simultaneously, making professional repair economically unfeasible for most owners of these aging vehicles.

Also Read: 5 Steering Racks That Stay Tight vs 5 That Loosen Quickly