The Toyota Paseo, manufactured between 1991 and 1999, represents one of Toyota’s most endearing compact sports coupes that has developed a devoted following among enthusiasts who appreciate its nimble handling, excellent fuel economy, and distinctive styling.

Despite being discontinued over two decades ago, thousands of Paseos remain on roads worldwide, a testament to Toyota’s legendary reliability engineering.

However, as these vehicles approach or exceed their third decade of service, keeping them running requires more than standard maintenance it demands specialized knowledge and strategic interventions that address age-related vulnerabilities.

Surviving Paseos face unique challenges, including deteriorating rubber components, electrical system degradation, and the increasing difficulty of sourcing replacement parts.

Yet with proper care and targeted maintenance strategies, these resilient vehicles can continue providing reliable, economical transportation for another decade or more.

The key lies in understanding which systems require proactive attention and implementing preventive measures before problems become catastrophic failures. This comprehensive guide presents ten proven hacks developed through decades of collective Paseo ownership experience.

These strategies go beyond basic maintenance to address specific vulnerabilities that emerge as these vehicles age, offering practical solutions that can extend your Paseo’s operational life significantly while maintaining its characteristic reliability and driving enjoyment.

1. Master the Critical Cooling System Refresh

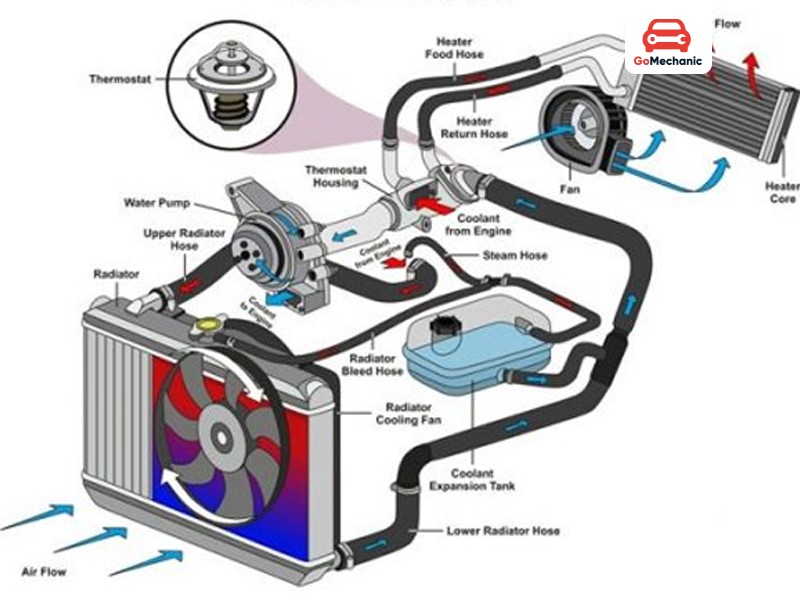

The cooling system represents the most critical maintenance area for aging Paseos, as overheating can instantly destroy the 5A-FE engine. After 25-30 years, original cooling components reach their limits, requiring comprehensive intervention to prevent catastrophic failures that plague high-mileage vehicles.

Begin with a complete system overhaul rather than piecemeal repairs. Replace the radiator, water pump, thermostat, and all rubber hoses simultaneously.

Original radiators suffer from internal corrosion and restricted flow passages that reduce cooling efficiency by up to 40%. Modern replacement radiators often feature improved core designs that enhance heat dissipation while maintaining original fit and finish. The water pump deserves special attention as failure symptoms often appear gradually.

Look for slight coolant weepage around the pump housing, bearing noise during cold starts, or minor temperature fluctuations. Replace the pump preemptively during radiator service, as the labor overlap makes this approach cost-effective while preventing roadside failures.

Install an upgraded thermostat housing using metal construction instead of the original plastic unit. The plastic housings become brittle with age and frequently crack at mounting points, causing sudden coolant loss.

Metal aftermarket units provide superior durability and often include improved bleeder valve designs that simplify cooling system maintenance. Implement a rigorous coolant maintenance schedule using only Toyota-approved long-life coolant.

Flush the system every three years regardless of mileage, and always use distilled water for mixing to prevent mineral buildup. Add a quality cooling system additive like Water Wetter to improve heat transfer efficiency and provide additional corrosion protection for aging components.

Consider installing a low-temperature fan switch to improve cooling during stop-and-go driving. The original switch engages at relatively high temperatures, but aftermarket units that activate cooling fans earlier can prevent temperature spikes that stress aging engine components. This simple modification provides insurance against overheating during hot weather operation or spirited driving sessions.

2. Implement Strategic Engine Oil Management

Engine oil management becomes increasingly critical as Paseos accumulate mileage, requiring sophisticated strategies that go beyond simple drain-and-fill maintenance.

The 5A-FE engine, while generally robust, develops specific lubrication needs that must be addressed to prevent accelerated wear and maintain reliable operation.

Transition to high-mileage specific oils that contain seal conditioners and viscosity improvers designed for engines with accumulated wear. Products like Valvoline MaxLife or Castrol GTX High Mileage provide enhanced protection for worn bearing surfaces while helping prevent seal leaks that plague aging engines.

These formulations maintain better viscosity stability under high-temperature conditions common in older engines. Reduce oil change intervals to 3,000 miles maximum, regardless of driving conditions.

High-mileage engines generate more contamination through blow-by gases and component wear, requiring more frequent oil changes to maintain protection levels.

Monitor oil condition carefully between changes, looking for metal particles, fuel dilution, or excessive darkening that might indicate developing problems.

Install an auxiliary oil cooler to reduce operating temperatures and extend oil life. Small, universal oil coolers mounted in front of the radiator can reduce oil temperatures by 20-30 degrees, significantly improving lubrication effectiveness and reducing thermal breakdown of the oil.

This modification proves especially beneficial for vehicles used in hot climates or driven enthusiastically. Add a high-quality oil treatment designed for high-mileage engines.

Products containing friction modifiers and seal swellers can help reduce oil consumption while improving lubrication effectiveness. Lucas Heavy Duty Oil Stabilizer or similar products can extend engine life by improving oil film strength and reducing internal friction.

Consider switching to synthetic blend oils that offer improved protection over conventional oils without the expense of full synthetic. These formulations provide better high-temperature stability and improved flow characteristics during cold starts, both beneficial for aging engines.

Monitor for any increase in oil consumption when switching, as some high-mileage engines may consume synthetic oils more readily than conventional formulations.

3. Electrical System Rehabilitation and Protection

The Paseo’s electrical system, while relatively simple compared to modern vehicles, requires proactive maintenance to prevent the mysterious electrical gremlins that plague aging Japanese cars.

After three decades, original wiring harnesses, connectors, and components reach the end of their service life, requiring strategic intervention to maintain reliable operation.

Begin with a comprehensive inspection of the main wiring harnesses, particularly those exposed to heat and moisture. The engine bay harness suffers from heat cycling that makes insulation brittle, while the underdash harness can develop problems from moisture intrusion.

Look for cracked insulation, corroded connections, or signs of rodent damage that could cause intermittent faults or complete failures. Clean and protect all major electrical connections using dielectric grease and proper contact cleaners.

Pay special attention to the alternator connections, starter solenoid, and main fuse box terminals. Corrosion at these points can cause charging problems, starting issues, or blown fuses that create frustrating intermittent problems difficult to diagnose.

Replace the original alternator proactively rather than waiting for failure. After 25+ years, internal components deteriorate even if the unit appears functional.

Rebuilt alternators often provide better performance than original units and include updated internal components that offer improved reliability. Consider upgrading to a slightly higher output unit if available to provide additional electrical capacity.

Install additional ground straps between the engine and chassis to improve electrical reliability. Aging vehicles often develop increased resistance in original ground paths due to corrosion or connection deterioration.

Additional ground straps provide redundant paths that ensure proper electrical function and can prevent various mysterious electrical problems. Upgrade critical electrical connections with marine-grade heat shrink connectors and waterproof junction boxes where appropriate.

The investment in quality electrical components pays dividends in reliability, especially for connections exposed to harsh environmental conditions. Replace original crimp connections with soldered joints wherever possible for maximum reliability.

Consider installing a battery disconnect switch for vehicles stored for extended periods. This simple addition prevents battery drain from parasitic loads while protecting the electrical system from potential damage caused by dead battery conditions that can stress charging system components.

4. Suspension and Steering System Renewal

The Paseo’s suspension system, designed for sporty handling and comfort, requires comprehensive attention as original components reach the end of their service life.

Worn suspension components not only compromise driving dynamics but can create safety hazards and accelerate tire wear that makes vehicle operation uneconomical.

Replace all four struts and shocks simultaneously rather than individually. Original equipment struts lose damping effectiveness gradually, making the deterioration difficult to notice until handling becomes significantly compromised.

New struts restore original ride quality and handling characteristics while improving tire contact with the road surface for better braking and cornering performance. Inspect and replace worn bushings throughout the suspension system.

The Paseo uses numerous rubber bushings that deteriorate with age and exposure to road chemicals. Pay particular attention to control arm bushings, sway bar links, and strut mount bearings. Worn bushings create a loose, imprecise steering feel and allow suspension geometry changes that accelerate tire wear.

Upgrade to adjustable coilover systems if performance is a priority, or quality replacement springs and struts for maintained original characteristics.

Aftermarket coilover systems allow customization of ride height and damping characteristics while often providing improved performance over original equipment. However, ensure any modifications maintain reasonable ride quality for daily driving use.

Replace the power steering pump and flush the entire system with fresh fluid. Original power steering pumps develop internal wear that reduces assist effectiveness and can cause steering whine or groaning noises.

Flushing the system removes contaminated fluid that can damage seals and internal components throughout the steering system. Perform a complete wheel alignment after suspension work, and also check the alignment annually, regardless of component replacement.

Aging suspension components can shift slightly over time, creating alignment changes that accelerate tire wear and affect handling characteristics. Proper alignment maximizes tire life while ensuring predictable handling characteristics, which are essential for safe operation.

Consider upgrading to performance-oriented sway bars and strut tower braces to improve chassis rigidity. The Paseo’s unibody construction benefits from additional structural reinforcement that reduces chassis flex and improves handling precision. These modifications provide performance benefits while potentially extending chassis life by reducing stress concentrations.

Also Read: 10 Steps That Keep a Nissan Sentra Running Strong for Families

5. Brake System Comprehensive Overhaul

The brake system requires complete attention as Paseos age, not only for safety reasons but because brake problems can create cascading failures that damage other expensive components.

A comprehensive brake system overhaul addresses immediate safety concerns while preventing future problems that could strand the vehicle or create dangerous situations.

Replace all brake fluid throughout the system with high-quality DOT 3 or DOT 4 fluid, depending on original specifications. Brake fluid absorbs moisture over time, reducing boiling point and creating corrosion throughout the hydraulic system.

Old fluid can cause brake fade, pedal sponginess, and internal component damage that leads to expensive repairs or dangerous brake failures.

Inspect and replace brake lines that show signs of deterioration, paying particular attention to areas where lines route near heat sources or sharp edges.

Original brake lines often develop small leaks or internal deterioration that isn’t immediately visible but can cause sudden brake failure. Stainless steel braided lines offer improved durability and pedal feel compared to original rubber lines.

Rebuild or replace the master cylinder and all wheel cylinders or calipers simultaneously. These components contain rubber seals that deteriorate with age and contaminated brake fluid.

Internal corrosion can cause pistons to stick or seals to fail, leading to brake drag, uneven braking, or complete brake failure. Professional rebuilding ensures proper operation and extends service life.

Upgrade to higher-quality brake pads and rotors designed for your driving style and conditions. Performance-oriented pads provide improved stopping power and fade resistance but may produce more noise and dust.

Conversely, low-dust ceramic pads offer quiet operation and reduced wheel contamination but may sacrifice some ultimate stopping power. Install new brake hardware, including springs, clips, and anti-rattle devices, during pad replacement.

These small components ensure proper pad operation and prevent noise, uneven wear, or premature failure. Original hardware often becomes corroded or loses tension, causing brake problems that seem mysterious but have simple solutions.

Consider adding braided stainless brake lines for improved pedal feel and durability. While not necessary for normal driving, braided lines reduce expansion under pressure and provide more precise pedal feedback.

This upgrade benefits enthusiastic drivers while providing long-term durability advantages over rubber lines susceptible to age-related deterioration.

6. Fuel System Cleaning and Modernization

The fuel system in aging Paseos requires comprehensive attention to address problems caused by ethanol-blended fuels, aging components, and accumulated deposits that can severely impact performance and reliability.

Modern fuel formulations create challenges that didn’t exist when these vehicles were new, requiring proactive maintenance strategies to prevent expensive failures.

Perform a complete fuel system cleaning using professional-grade products designed to remove deposits from injectors, intake valves, and combustion chambers.

Products like BG 44K or Chevron Techron Concentrate provide powerful cleaning action that restores fuel system performance and can improve fuel economy significantly. Run these treatments through a complete tank of fuel for maximum effectiveness.

Replace the fuel filter more frequently than recommended, particularly if the vehicle sits for extended periods or uses fuel from questionable sources.

Aging fuel systems accumulate more contaminants, and modern ethanol-blended fuels can dissolve old deposits that clog filters. Consider upgrading to a higher-capacity filter if available to provide additional protection for fuel injection components.

Inspect and potentially replace fuel lines that show signs of deterioration from ethanol exposure. Older rubber fuel lines weren’t designed for ethanol-blended fuels and can develop leaks or internal deterioration that contaminate the fuel system.

Replace questionable lines with ethanol-compatible materials to prevent dangerous fuel leaks and system contamination. Clean the fuel rail and injectors professionally every 50,000 miles or when performance problems develop.

Fuel injectors in aging vehicles often develop deposit buildup that affects spray patterns and fuel delivery. Professional cleaning restores proper operation and can eliminate rough idle, hesitation, and poor fuel economy caused by compromised injection systems.

Consider adding a quality fuel system cleaner to every fill-up to prevent deposit formation and maintain injector cleanliness. Products designed for regular use help prevent problems before they develop while providing ongoing protection against ethanol-related issues.

This preventive approach costs less than corrective treatments and maintains consistent performance. Replace the fuel pump proactively if the vehicle shows any signs of fuel delivery problems.

Original fuel pumps often develop reduced flow capacity or pressure regulation problems that cause performance issues before complete failure. Replacing the pump before total failure prevents being stranded and often reveals other fuel system problems that need attention during the repair process.

7. Interior and Exterior Preservation Strategies

Preserving the Paseo’s interior and exterior requires strategic approaches that address age-related deterioration while maintaining the vehicle’s aesthetic appeal and resale value.

These preservation strategies go beyond basic cleaning to implement protective measures that slow the aging process and repair common problem areas.

Address interior plastic deterioration using specialized restoration products and techniques. Aging plastic components often fade, crack, or become sticky due to plasticizer migration.

Products like Chemical Guys VRP or Meguiar’s Endurance Tire Gel can restore color and flexibility to faded plastics while providing UV protection to prevent further deterioration. Clean thoroughly before application and reapply regularly for best results.

Repair or replace damaged seat bolsters and door panels before deterioration spreads. The Paseo’s sport-oriented interior often shows wear at bolster areas where drivers slide across surfaces during entry and exit.

Professional repair using leather or vinyl repair compounds can restore appearance and prevent further damage that could make repairs impossible.

Protect and restore the dashboard using specialized vinyl and plastic conditioners that prevent cracking and fading. Dashboard cracks are nearly universal in aging vehicles but can be prevented with regular conditioning and UV protection.

Use products specifically designed for automotive applications rather than household cleaners that can accelerate deterioration. Address rust prevention and repair proactively, particularly around wheel wells, door frames, and the rear hatch area, where the Paseo commonly develops corrosion problems.

Clean affected areas thoroughly, apply rust converters to stop active corrosion, and protect with appropriate primers and paints. Regular undercarriage washing removes road salt and debris that accelerate corrosion.

Maintain the paint finish using modern compounds and sealers that provide long-lasting protection against environmental damage. The original single-stage paints used on many Paseos respond well to proper polishing compounds that remove oxidation and restore gloss.

Follow with quality carnauba wax or synthetic sealers that provide months of protection against UV damage and environmental contaminants. Replace weatherstripping proactively to prevent water intrusion that can damage electrical components and create interior mold problems.

Original rubber weatherstripping becomes hard and develops gaps that allow water entry during rain or car washing. New weatherstripping maintains a tight seal while preventing expensive water damage problems that can total an aging vehicle.

8. Transmission and Drivetrain Maintenance Excellence

The transmission and drivetrain components require specialized attention in aging Paseos to prevent expensive failures that can exceed the vehicle’s value.

Whether equipped with manual or automatic transmission, these components benefit from proactive maintenance that extends service life and maintains smooth operation.

For manual transmissions, replace the gear oil with high-quality synthetic lubricant designed for manual gearboxes. Original gear oil often becomes contaminated with moisture and metal particles that accelerate synchro wear and gear damage.

Synthetic oils provide superior protection and often improve shift quality in aging transmissions while extending component life significantly. Inspect and replace the clutch system components if the manual transmission shows signs of slippage or difficult engagement.

Original clutch components often last 100,000+ miles but eventually require replacement. Address clutch problems proactively rather than driving with a slipping clutch that can damage the flywheel and require expensive additional repairs.

For automatic transmissions, implement a comprehensive fluid and filter service every 30,000 miles regardless of manufacturer recommendations. Automatic transmissions generate significant heat and contamination that degrade fluid and clog filters.

Fresh fluid and filters maintain hydraulic pressure and prevent valve body problems that cause erratic shifting or complete failure. Replace CV joints and boots at the first sign of clicking noises or boot damage.

The Paseo’s CV joints endure significant stress, particularly during turning maneuvers, and worn joints can cause vibration, noise, and eventual drivetrain failure. New CV joints restore smooth operation while preventing differential damage that could occur from continued operation with worn joints.

Inspect and service the differential if equipped with a limited-slip or if the vehicle exhibits unusual tire wear patterns. Differential problems can cause handling issues and accelerated tire wear, which makes the operation uneconomical.

Regular differential service using appropriate lubricants maintains proper operation and extends component life. Consider upgrading to synthetic lubricants throughout the drivetrain for improved protection and extended service intervals.

Synthetic gear oils and differential lubricants provide superior protection under extreme conditions while often improving component efficiency. The initial cost premium pays dividends in extended component life and reduced maintenance frequency.

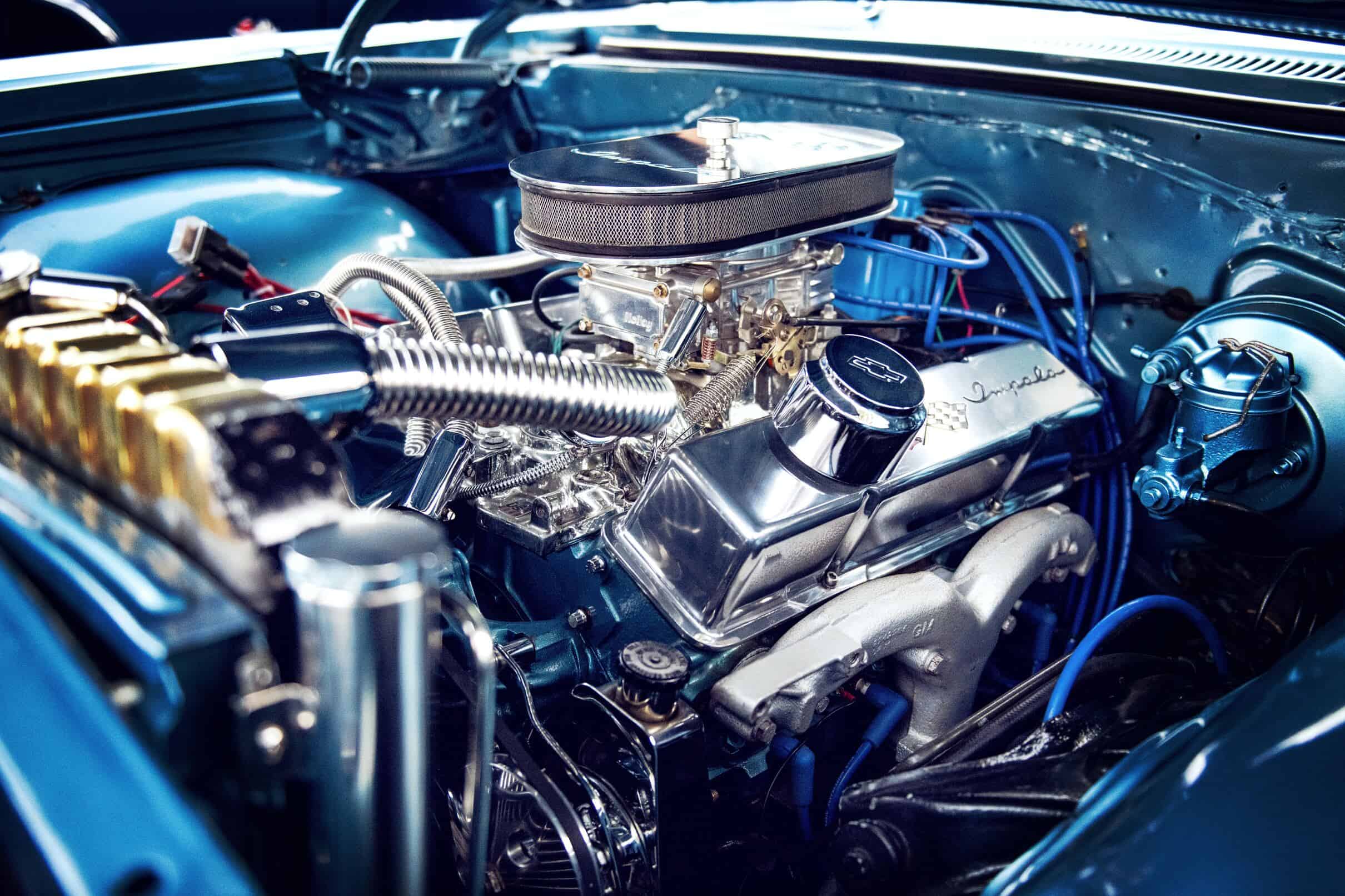

9. Engine Performance Optimization and Longevity

Optimizing engine performance while extending operational life requires understanding the specific characteristics and maintenance needs of the Paseo’s 5A-FE engine.

This power plant, while reliable, benefits from targeted modifications and maintenance practices that can significantly improve performance while extending service life.

Perform a comprehensive valve adjustment and timing belt service every 60,000 miles without exception. The 5A-FE uses an interference design where timing belt failure can cause catastrophic valve damage.

Replace the timing belt, water pump, and all associated tensioners and idler pulleys simultaneously to prevent premature failure. Proper valve adjustment ensures optimal performance and fuel economy while preventing premature wear.

Clean the intake system thoroughly to remove carbon deposits that accumulate in direct-injection engines. Use specialized intake cleaners or walnut shell blasting to remove deposits from intake valves and ports.

Carbon buildup reduces airflow and can cause a rough idle, reduced power, and poor fuel economy. Regular cleaning maintains optimal engine performance and prevents expensive carbon-related problems.

Replace the air filter with a high-quality replacement and consider upgrading to a performance-oriented filter for improved airflow. A quality air filter protects engine components while ensuring adequate airflow for proper combustion.

K&N or similar washable filters provide improved flow characteristics while offering long-term cost savings through reusability. Upgrade the ignition system with quality spark plugs, wires, and ignition coils designed for high-mileage engines.

Original ignition components often lose effectiveness gradually, making performance deterioration difficult to notice. New ignition components restore proper combustion while improving fuel economy and reducing emissions production.

Consider adding a quality fuel system cleaner regularly to prevent deposit formation and maintain injector cleanliness. Modern ethanol-blended fuels can cause deposit problems that didn’t exist when these engines were designed.

Regular use of quality fuel system additives prevents problems while maintaining optimal fuel delivery and combustion efficiency. Install an engine oil catch can to prevent crankcase vapors from contaminating the intake system.

This simple modification captures oil vapors before they enter the intake manifold, reducing carbon buildup and maintaining cleaner combustion. A catch can also allow monitoring of engine wear through captured contaminants.

10. Strategic Parts Sourcing and Emergency Preparedness

Successful long-term Paseo ownership requires developing reliable parts sources and emergency preparedness strategies that address the increasing difficulty of maintaining vehicles that have been discontinued for over two decades.

This strategic approach ensures continued operation while managing costs effectively. Establish relationships with multiple parts suppliers including Toyota dealerships, aftermarket suppliers, and salvage yards that specialize in Japanese vehicles.

Dealerships often still stock common maintenance items, while aftermarket suppliers provide cost-effective alternatives for wear items. Salvage yards can provide hard-to-find components at reasonable prices but require careful inspection before purchase.

Stockpile critical wear items and commonly failed components before they’re needed. Items like timing belts, water pumps, alternators, and starter motors are essential for vehicle operation and may become difficult to source as vehicles age.

Purchasing these items during sales or when readily available prevents emergency situations where the vehicle is stranded while waiting for parts. These communities often know alternative part numbers, compatible components from other Toyota models, and reliable suppliers for hard-to-find items.

The collective knowledge of enthusiast communities proves invaluable for maintaining aging vehicles. Consider purchasing a parts car if storage space permits and a suitable candidate becomes available.

A complete parts car provides a source for hard-to-find components while often costing less than individual parts purchased separately. Choose parts cars carefully, prioritizing vehicles with good mechanical components over those with better cosmetic condition.

Also Read: 8 Oversights That Can Ruin Your Dodge Dynasty Quickly