The Ford Probe, produced from 1989 to 1997, represents an interesting chapter in Ford’s history as a sports coupe developed in partnership with Mazda.

Built on Mazda’s GD platform and sharing many components with the Mazda MX-6, the Probe was designed to capture the hearts of driving enthusiasts with its sleek aerodynamic styling and engaging performance characteristics.

However, like any vehicle that has now been out of production for over 25 years, the Ford Probe requires careful attention to specific maintenance areas to ensure longevity.

Understanding what can damage your Ford Probe is crucial for preservation, whether you’re a current owner trying to keep your vehicle running strong or a potential buyer looking to avoid problematic examples.

The Probe ranks 8th in reliability out of 44 Ford models. Owners have made 58 complaints complaints over 8 model years, mostly about engine issues. While this suggests reasonable reliability, there are specific areas where neglect or improper maintenance can quickly turn a solid vehicle into an expensive headache.

The Probe’s Japanese-influenced engineering means it shares both the strengths and potential weaknesses of its Mazda counterparts. The interference engine design, timing belt dependency, and specific cooling system requirements all demand attention to detail that goes beyond basic maintenance.

The transmission systems, cooling components, and electrical systems all have known weak points that require proactive maintenance to avoid expensive repairs or complete vehicle loss.

1. Ignoring Timing Belt Replacement Intervals

The most catastrophic mistake any Ford Probe owner can make is neglecting the timing belt replacement schedule. Both the 2.0-liter four-cylinder and 2.5-liter V6 engines in the Probe are interference engines, meaning that if the timing belt breaks, the pistons will collide with the valves, causing extensive internal engine damage that often exceeds the vehicle’s total value.

Most Ford engines with overhead cam timing belts have a recommended replacement interval of 60,000 miles, and this applies directly to the Ford Probe.

However, many owners make the mistake of pushing these intervals, thinking they can squeeze a few more thousand miles out of an aging belt. This gamble rarely pays off and almost always results in complete engine destruction.

The timing belt in a Ford Probe doesn’t just control valve timing; it also drives the water pump in most configurations. This means that when the belt fails, you’re not only looking at valve and piston damage but also potential overheating damage as the water pump stops circulating coolant.

The cascade of failures that can result from a broken timing belt can easily cost $3,000 to $5,000 or more, far exceeding the value of most Probe vehicles today.

Signs that your timing belt may be approaching failure include a high-pitched squealing noise from the engine bay, particularly during cold starts, visible cracking or fraying on the belt itself, and oil contamination on the belt from leaking seals.

However, many timing belts fail without warning, which is why adherence to the replacement schedule is absolutely critical. When replacing the timing belt, it’s essential to replace the entire timing belt kit, including tensioners, idler pulleys, and the water pump.

Many Probe owners make the mistake of replacing only the belt itself, only to have a tensioner or idler pulley fail shortly afterward, requiring the entire job to be done again.

The labor cost for timing belt replacement is significant due to the amount of disassembly required, so doing the job completely the first time is always the most economical approach.

Professional installation is strongly recommended unless you have significant mechanical experience. Improper timing belt installation can result in bent valves even without belt failure, and the specific timing procedures for the Probe’s engines require precision and the right tools.

Many shade-tree mechanics have destroyed perfectly good Probe engines by attempting timing belt replacement without proper knowledge or equipment.

2. Neglecting the Cooling System Maintenance

The Ford Probe’s cooling system is more complex and sensitive than many owners realize, and neglect in this area can quickly lead to engine destruction.

The Probe’s engines, particularly the V6, run relatively hot and depend on a properly functioning cooling system to prevent overheating damage that can warp cylinder heads, blow head gaskets, or crack engine blocks.

One of the most common cooling system failures in the Ford Probe involves the radiator itself. The original radiators were prone to developing leaks at the plastic tank-to-aluminum core joints, particularly as the vehicle ages and heat cycles take their toll on the plastic components.

Many owners make the mistake of trying to band-aid these leaks with stop-leak products or temporary fixes, rather than replacing the radiator when leaks first appear. The water pump, which is typically replaced along with the timing belt, can also fail independently and cause overheating.

Water pump failure often presents as coolant leaks from the weep hole, bearing noise, or play in the pump shaft. Continuing to drive with a failing water pump will eventually lead to complete pump failure and immediate overheating.

Thermostat failure is another common issue that can cause both overheating and overcooling problems. A thermostat that sticks closed will cause rapid overheating, while one that sticks open will prevent the engine from reaching proper operating temperature, leading to poor fuel economy, increased emissions, and accelerated engine wear.

The Probe’s thermostats should be replaced every 60,000 miles as preventive maintenance. The cooling system also depends on proper coolant mixture and regular coolant replacement.

Many Probe owners use incorrect coolant types or allow the coolant to become contaminated with rust and sediment. The aluminum components in the Probe’s cooling system are particularly susceptible to corrosion from improper coolant, and once corrosion begins, it can quickly spread throughout the system.

Cooling fan operation is critical, especially in stop-and-go traffic. The Probe’s cooling fans are controlled by temperature sensors and relays that can fail, leaving the engine without adequate cooling during idle periods. Regular inspection of fan operation and replacement of failed components is essential to prevent overheating damage.

3. Poor Transmission Fluid Maintenance

The automatic transmission in the Ford Probe is a Mazda-sourced unit that, while generally reliable, is extremely sensitive to fluid condition and level.

Poor transmission maintenance is one of the fastest ways to destroy a Probe’s transmission and render the vehicle worthless, as transmission replacement costs typically exceed the vehicle’s value.

The most common mistake owners make is following outdated advice about “lifetime” transmission fluid. Despite some manufacturers’ claims, no automatic transmission fluid truly lasts the lifetime of the vehicle, especially in a car that’s now 25+ years old.

The transmission fluid in a Ford Probe should be changed every 30,000 to 40,000 miles under normal driving conditions, or more frequently under severe conditions such as frequent stop-and-go traffic, trailer towing, or extreme temperatures. Using the incorrect transmission fluid type is another critical error that can quickly damage the transmission.

The Probe’s Mazda transmission requires specific fluid characteristics, and using generic or incorrect fluid can cause seal damage, clutch slippage, and internal component wear. Always use the manufacturer-specified fluid type or an exact equivalent from a reputable brand.

Checking transmission fluid level and condition should be part of regular maintenance, but many owners either don’t check it at all or check it incorrectly. The transmission fluid should be checked with the engine running and the transmission warm, with the vehicle on level ground.

The fluid should be bright red and smell sweet dark, burnt-smelling fluid indicates internal damage and the need for immediate attention. External leaks are common in aging Probes and should be addressed immediately.

Transmission fluid leaks not only lead to low fluid levels and potential transmission damage but also create environmental hazards and fire risks. Common leak points include the pan gasket, axle seals, and cooling line connections. Even small leaks can quickly become major problems if ignored.

Internal transmission problems often start as minor symptoms such as delayed engagement, rough shifting, or slipping, but these symptoms tend to progress rapidly if not addressed.

Many owners make the mistake of continuing to drive with transmission problems, hoping they’ll resolve themselves or can be fixed with a simple fluid change. In reality, continuing to drive with transmission problems almost always makes the damage worse and more expensive to repair.

4. Ignoring Oil Change Intervals and Using Wrong Oil Specifications

Engine oil is the lifeblood of any internal combustion engine, but the Ford Probe’s engines have specific oil requirements that, when ignored, can lead to premature engine failure.

Both the four-cylinder and V6 engines in the Probe have tight tolerances and depend on proper lubrication to prevent bearing damage, cam wear, and other internal problems.

The most fundamental mistake is extending oil change intervals beyond manufacturer recommendations. While modern oils have improved significantly since the Probe was manufactured, these engines still require oil changes every 3,000 to 5,000 miles, depending on driving conditions.

Many owners, influenced by modern long-life oil marketing, attempt to stretch intervals to 7,500 or even 10,000 miles, which is far too long for these older engines.

Using the incorrect oil viscosity is another critical error. The Probe’s engines were designed for specific oil viscosity ranges, typically 5W-30 or 10W-30, depending on climate conditions.

Using oil that’s too thick can cause poor circulation and inadequate lubrication during cold starts, while oil that’s too thin won’t provide adequate protection under high-temperature conditions.

Oil quality is just as important as change intervals. Many Probe owners make the mistake of using bargain-basement oil that doesn’t meet current API specifications or using oil that has been sitting on store shelves for extended periods.

Old or poor-quality oil can break down rapidly, form sludge, and fail to protect engine components adequately. The oil filter is just as critical as the oil itself, yet many owners either skip filter changes or use inferior aftermarket filters.

A clogged or bypassed oil filter can allow contaminated oil to circulate through the engine, causing accelerated wear and potential bearing damage. Always replace the oil filter with every oil change using a quality filter that meets or exceeds OEM specifications.

Oil leaks are common in aging Ford Probes and should be addressed promptly. External leaks not only waste oil and create environmental hazards but can also indicate internal problems such as worn seals or gaskets.

Checking the oil level weekly and maintaining it between the minimum and maximum marks on the dipstick can prevent expensive engine damage from oil starvation.

Also Read: 10 Steps That Keep a Nissan Sentra Running Strong for Families

5. Failing to Address Electrical System Issues Promptly

The Ford Probe’s electrical system, while relatively simple by modern standards, contains several critical components that can cause significant problems if they fail.

The charging system, ignition system, and various sensors all play crucial roles in engine operation and vehicle reliability. Ignoring electrical problems or attempting quick fixes often leads to more extensive and expensive problems down the road.

The alternator is one of the most critical electrical components, responsible for charging the battery and powering all electrical systems while the engine runs.

Probe alternators are prone to failure due to age, with symptoms including dimming lights, slow engine cranking, and dashboard warning lights. Many owners make the mistake of continuing to drive with a failing alternator, which can lead to complete electrical failure and potential engine damage from loss of ignition or fuel injection power.

The starter system is another common failure point, particularly in high-mileage vehicles. Starter problems often begin as slow cranking or intermittent no-start conditions, but many owners ignore these early warning signs until complete failure occurs.

A failing starter can also damage the flywheel ring gear, turning a relatively inexpensive starter replacement into a much more costly transmission removal job.

Ignition system components, including spark plugs, plug wires, and the distributor (on earlier models), require regular replacement to maintain proper engine operation.

Ford Probe problem is: Engine Runs Rough, Stalls, Hesitates on Acceleration, Hard Starting, Poor Performance and many of these symptoms can be traced to ignition system problems.

Worn spark plugs can cause misfiring, poor fuel economy, and catalytic converter damage, while failing plug wires can cause random misfires and poor performance.

The Probe’s various engine sensors, including oxygen sensors, mass airflow sensors, and temperature sensors, all play critical roles in engine management.

These sensors provide feedback to the engine control module, which adjusts fuel delivery and ignition timing for optimal performance and emissions. Failed sensors can cause poor running conditions, failed emissions tests, and potential engine damage from incorrect fuel delivery.

Corroded battery terminals can cause charging problems and starting issues, while an aging battery may not provide adequate power for starting or electrical system operation. Battery problems can also cause damage to the alternator and other charging system components if not addressed promptly.

6. Improper Brake System Maintenance and Repair

The brake system is obviously critical for safety, but improper maintenance can also lead to expensive repairs and reduced vehicle longevity. The Ford Probe’s brake system includes several components that require regular maintenance and proper repair techniques to ensure safe and reliable operation.

Brake pad replacement is the most common brake maintenance item, but many owners make critical mistakes during this process. Using incorrect pad compounds can lead to premature rotor wear, noise problems, and reduced braking performance.

Cheap, low-quality brake pads may save money initially, but often cost more in the long run due to accelerated rotor wear and more frequent replacement intervals.

The Probe is known to suffer from rear brake calliper problems. If you have noticed that the rear brakes are sometimes sticking or ceasing up then you have rear calliper problems.

Sticking brake calipers not only reduce braking performance but also cause uneven pad wear, rotor damage, and reduced fuel economy due to constant drag.

Many owners ignore the early signs of caliper problems, such as uneven brake pad wear or vehicle pulling during braking, until complete caliper failure occurs.

Brake rotor maintenance is often overlooked, with many owners assuming that rotors can be resurfaced indefinitely. In reality, brake rotors have minimum thickness specifications, and rotors that have been machined below these specifications can crack, warp, or fail.

Always check rotor thickness and condition during brake service and replace rotors that are at or near minimum thickness. Brake fluid is often the most neglected component of the brake system, yet it’s critical for proper brake operation.

Brake fluid absorbs moisture over time, which lowers its boiling point and can cause brake fade under heavy braking conditions. More critically, moisture in brake fluid causes corrosion of brake system components, including calipers, wheel cylinders, and the master cylinder.

Brake fluid should be replaced every two years or 24,000 miles, regardless of appearance. The brake master cylinder is the heart of the hydraulic brake system, and failure can result in complete brake loss.

Flexible brake hoses can also deteriorate, causing bulging, cracking, or internal collapse that restricts brake fluid flow. Regular inspection of all brake lines and hoses can prevent dangerous brake failures.

7. Suspension and Steering Component Neglect

The Ford Probe’s suspension and steering systems are designed to provide responsive handling and comfortable ride quality, but neglecting these components can lead to poor handling, tire wear, and safety issues.

Many suspension and steering problems start as minor symptoms but progress to more serious and expensive problems if ignored. The 1993 Ford Probe seems to have a common issue with a clunk noise in the steering when turning from left to right.

This problem might indicate wear and tear in the steering components, and similar issues affect other model years as well. Worn steering components not only create noise and poor steering feel but can also cause dangerous handling problems and accelerated tire wear.

Shock absorbers and struts are critical for maintaining tire contact with the road and controlling body motion during cornering and braking. Worn shocks and struts not only reduce ride comfort but also increase stopping distances, cause poor handling, and accelerate tire wear. Many owners don’t realize that worn suspension components can affect braking performance and vehicle safety.

Ball joints are critical suspension components that connect the steering knuckles to the control arms. Worn ball joints can cause steering wander, tire wear, and in extreme cases, complete separation of the wheel from the vehicle.

Ball joint problems often start as minor clicking or clunking noises during turning, but can progress to dangerous failures if ignored. Control arm bushings are another common wear item that affects handling and tire wear. Worn control arm bushings can cause alignment problems, steering instability, and accelerated tire wear.

Many owners attribute handling problems to other causes and don’t realize that worn bushings are the root cause of their vehicle’s poor road manners.

Tie rod ends are part of the steering linkage and connect the steering rack to the steering knuckles. Worn tie rod ends can cause steering play, wandering, and tire wear.

Power steering pump failure can leave you with heavy steering and potential rack and pinion damage if metal contamination circulates through the system.

8. Exhaust System and Emissions Component Failures

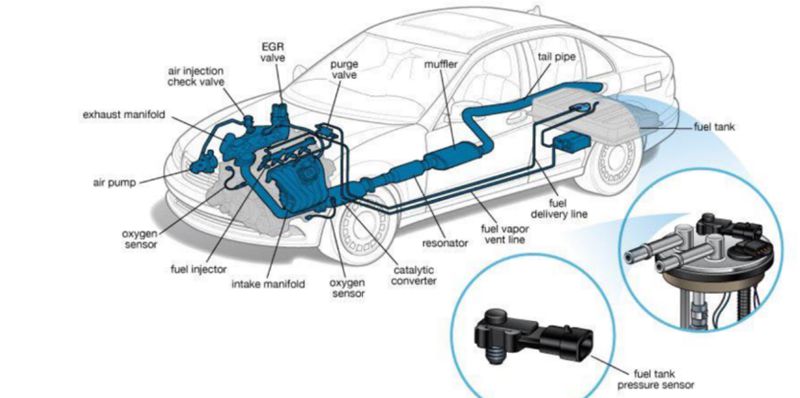

The exhaust system serves multiple critical functions beyond simply routing exhaust gases away from the vehicle. Modern emission control components integrated into the exhaust system are expensive to replace and can cause significant problems if they fail or are neglected.

The only way to resolve this issue is to fit a new catalytic converter on the car when catalytic converter problems occur, and this can be one of the most expensive single repairs on a Ford Probe.

Catalytic converters can fail due to contamination from oil consumption, coolant leaks, or rich fuel mixtures, and replacement converters are expensive, often costing $500 to $1,500 or more.

Many Probe owners make the mistake of ignoring early signs of catalytic converter problems, such as reduced performance, poor fuel economy, or sulfur smells from the exhaust.

O2 sensors wear out as normal maintenance items, but many owners neglect to replace them until check engine lights or failed emissions tests force the issue.

The exhaust manifold and associated gaskets are prone to cracking and leaking in the Ford Probe, particularly on the V6 engine. Exhaust leaks not only cause noise and smell problems but can also allow oxygen to enter the exhaust stream, causing incorrect oxygen sensor readings and poor fuel mixture control.

Exhaust leaks can also create fire hazards if hot gases contact flammable materials. Mufflers and exhaust pipes are subject to corrosion from both internal and external sources. Internal corrosion occurs from acidic combustion byproducts, while external corrosion results from road salt and moisture.

Many owners ignore small exhaust leaks until major repairs become necessary, when early intervention could have prevented more extensive damage. The EGR (Exhaust Gas Recirculation) system, if equipped, can cause significant problems if it fails or becomes clogged with carbon deposits.

A stuck EGR valve can cause poor idle quality, stalling, and failed emissions tests. EGR system problems are often misdiagnosed as other engine problems, leading to unnecessary repairs and continued poor performance.

9. Fuel System Contamination and Component Failures

The fuel system in the Ford Probe is more complex than many owners realize, and contamination or component failures can cause a wide range of problems from poor performance to complete engine failure.

Understanding and maintaining the fuel system properly is critical for vehicle longevity and reliable operation. Fuel contamination is one of the most common yet preventable fuel system problems.

Water contamination can occur from condensation in the fuel tank, poor-quality fuel, or damaged fuel tank venting systems. Water in the fuel system can cause corrosion of fuel system components, fuel injector problems, and poor engine performance.

Many owners make the mistake of buying fuel from questionable sources or allowing their vehicles to sit with nearly empty fuel tanks, which promotes condensation formation.

The fuel pump, located in the fuel tank, is a critical component that can fail without warning. Fuel pump problems often start as intermittent stalling or hard starting conditions, but can progress to complete pump failure and vehicle breakdown.

Many owners ignore early fuel pump symptoms until complete failure occurs, often leaving them stranded. Running the fuel tank consistently low on fuel can cause premature fuel pump failure by reducing cooling and lubrication of the pump components.

Fuel injectors require clean fuel and proper operating pressures to function correctly. Contaminated fuel or incorrect fuel pressure can cause injector clogging, which leads to poor engine performance, misfiring, and potential engine damage.

Many owners attempt to fix injector problems with fuel additives rather than addressing the root cause of contamination or pressure problems. The fuel filter is designed to remove contaminants from the fuel before they reach the fuel injectors, but many owners neglect fuel filter replacement until flow restrictions cause fuel delivery problems.

A clogged fuel filter can cause fuel starvation, poor performance, and fuel pump damage from excessive pressure buildup. Fuel filters should be replaced according to manufacturer recommendations, typically every 30,000 to 40,000 miles.

The fuel pressure regulator maintains proper fuel pressure for optimal injector operation. A failed fuel pressure regulator can cause either high or low fuel pressure, both of which can cause engine performance problems and potential damage.

High fuel pressure can cause rich fuel mixtures and catalytic converter damage, while low fuel pressure can cause lean conditions and potential engine damage from detonation.

Regular highway driving and occasional high-RPM operation can help minimize carbon buildup, but professional cleaning may be necessary on high-mileage vehicles.

Also Read: 8 Oversights That Can Ruin Your Dodge Dynasty Quickly