The Chevrolet Astro Van, produced from 1985 to 2005, stands as one of America’s most enduring workhorses.

Whether you’re using it for family adventures, commercial deliveries, or converting it into the ultimate camping companion, the Astro Van’s rear-wheel-drive platform and robust Vortec engine have earned it a legendary reputation for durability.

However, like any vehicle approaching or exceeding two decades of age, proper maintenance becomes crucial for ensuring continued reliability and performance. What sets the Astro Van apart from many modern vehicles is its relatively simple, serviceable design.

Built during an era when mechanics could actually work on vehicles without specialized computer diagnostic equipment, the Astro features straightforward systems that respond well to preventive maintenance and careful attention.

The 4.3-liter Vortec V6 engine, when properly maintained, can easily surpass 300,000 miles, while the sturdy transmission and rear differential are known for their longevity.

The key to Astro Van longevity lies not in expensive repairs or modifications, but in understanding the vehicle’s specific maintenance needs and addressing them proactively.

These vans have particular vulnerabilities from cooling system challenges to fuel system quirks that, when properly managed, can be prevented from becoming major problems.

This comprehensive guide presents ten professional-grade maintenance strategies that will help your Astro Van deliver reliable service for years to come.

Each tip is based on decades of collective experience from mechanics, fleet operators, and dedicated Astro enthusiasts who have learned what it takes to keep these vans running strong.

Whether you’re maintaining a high-mileage daily driver or preserving a low-mileage gem, these proven techniques will help you avoid costly breakdowns while maximizing your van’s operational lifespan.

1. Master the Cooling System Maintenance

The cooling system represents the most critical aspect of Astro Van maintenance, and mastering its care will prevent the majority of catastrophic engine failures.

The 4.3-liter Vortec engine generates substantial heat, and the van’s configuration can create cooling challenges that require proactive attention. Understanding and maintaining this system properly can mean the difference between a van that runs for 300,000 miles and one that suffers premature engine failure.

Start with regular coolant system flushes every 30,000 miles or three years, whichever comes first. The Astro’s cooling system is particularly sensitive to contaminated coolant, which can cause corrosion in the radiator, water pump, and engine block.

Use only GM-approved Dex-Cool coolant, and never mix different coolant types, as this can create a gel-like substance that clogs the system. When performing flushes, use a proper flushing solution to remove built-up deposits and ensure complete removal of old coolant.

The radiator requires special attention due to its location and the van’s work-oriented nature. Clean the radiator fins monthly, removing debris, leaves, and dirt that accumulate between the fins, and reduce cooling efficiency.

Use compressed air blown from the engine side toward the front, or carefully use a soft brush with water. A clogged radiator can cause overheating even with a perfect cooling system otherwise. Hose replacement should be performed every five years or 75,000 miles, regardless of appearance.

Astro Van cooling hoses are subject to extreme temperature cycling and pressure changes that cause deterioration from the inside out. Replace all hoses simultaneously, including the small heater hoses that are often overlooked but can cause significant problems when they fail.

2. Implement Religious Oil Change Intervals

Oil change frequency represents the single most important factor in Astro Van engine longevity, and the 4.3-liter Vortec engine rewards careful attention to lubrication with exceptional durability.

While modern oils and filters have improved dramatically since the Astro’s introduction, the engine’s design and typical usage patterns demand shorter intervals than many newer vehicles.

Implementing a religious oil change schedule will prevent the vast majority of engine wear and internal damage. Establish a 3,000-mile oil change interval regardless of manufacturer recommendations or oil type used.

While synthetic oils can theoretically extend change intervals, the Astro’s engine design includes some areas where oil circulation is marginal, and shorter intervals ensure these areas receive adequate lubrication.

The relatively low cost of frequent oil changes compared to engine replacement makes this conservative approach economically sensible. Choose the correct oil viscosity for your climate and driving conditions.

For most applications, 5W-30 conventional or synthetic blend oil provides optimal protection. In extremely hot climates or for heavy-duty use, 10W-30 may be appropriate.

Avoid thick oils like 20W-50 unless specifically recommended for high-mileage engines, as they can reduce oil flow to critical engine components during cold starts. Perform oil changes when the engine is warm but not hot, allowing contaminants to remain suspended in the oil for complete removal.

Check the drain plug and oil pan threads regularly for damage, and replace the drain plug gasket each change to prevent leaks. A small oil leak can quickly become a major mess and a potential fire hazard in the engine compartment.

3. Maintain the Fuel System for Optimal Performance

The Astro Van’s fuel system requires specific attention to prevent performance problems and ensure reliable operation, particularly as these vehicles age and accumulate miles.

The Central Port Injection (CPI) system used in most Astro Vans is generally reliable but has specific maintenance requirements that differ from traditional fuel injection systems. Proper fuel system maintenance prevents costly repairs while maintaining optimal fuel economy and performance.

Fuel filter replacement represents the most critical aspect of fuel system maintenance and should be performed every 30,000 miles without exception. The Astro’s fuel filter is located along the frame rail and is relatively easy to access, making regular replacement straightforward.

A clogged fuel filter can cause poor performance, reduced fuel economy, and potential damage to the fuel pump, which is expensive to replace. When replacing the filter, always relieve fuel system pressure first and have a fire extinguisher nearby.

Fuel pump longevity depends heavily on maintaining adequate fuel levels and using quality gasoline. Never allow the fuel tank to drop below one-quarter full, as this forces the pump to work harder and generates more heat.

The fuel pump relies on gasoline for cooling and lubrication, and running on low fuel can cause premature failure. When the pump does require replacement, always install an OEM or equivalent quality unit, as cheap aftermarket pumps often fail quickly.

Consider upgrading to a high-flow fuel filter if your van is used for heavy-duty applications or towing. High-flow filters maintain adequate fuel pressure under demanding conditions while providing superior filtration.

However, ensure any upgrades are compatible with the existing fuel system and don’t adversely affect fuel pressure regulation.

4. Keep the Transmission Properly Serviced

The 4L60E automatic transmission used in most Astro Vans is generally reliable when properly maintained, but neglect can lead to expensive failures that often total the vehicle’s value.

Understanding proper transmission maintenance and implementing a proactive service schedule will ensure smooth shifting and a long transmission life. The key lies in regular fluid changes, proper driving habits, and attention to early warning signs of developing problems.

Transmission fluid changes should occur every 50,000 miles or four years, whichever comes first, despite GM’s claims of “lifetime” fluid. Transmission fluid degrades over time due to heat, contamination, and chemical breakdown, losing its ability to lubricate and protect internal components.

Use only Dexron III or approved substitute fluids, and ensure the correct quantity is installed. Overfilling can cause foaming and poor shifting, while underfilling leads to pump cavitation and component damage.

When changing transmission fluid, always replace the filter and pan gasket simultaneously. The transmission filter removes contaminants that would otherwise circulate through the system, causing wear and valve body problems.

Use only OEM or equivalent quality filters, as cheap alternatives may not provide adequate filtration or may collapse under pressure. Clean the pan thoroughly, removing all residue and metal particles that indicate internal wear.

Consider installing a transmission temperature gauge if your van is used for towing or other demanding applications. Monitoring transmission temperature allows you to modify driving habits to prevent overheating and extend component life.

Normal operating temperature should remain below 200°F under most conditions, with temperatures above 220°F indicating potential problems requiring immediate attention.

Also Read: 10 Tricks That Keep a GMC Envoy Reliable for 300,000 Miles

5. Address the Notorious Fuel Tank Issues

Astro Vans are notorious for developing fuel tank problems that can range from minor annoyances to significant safety hazards, making proactive tank maintenance essential for reliable operation.

The steel fuel tank is susceptible to corrosion, particularly in areas where road salt is used, and the tank’s location makes it vulnerable to damage from road debris.

Understanding these issues and implementing preventive measures can save thousands of dollars in repairs while ensuring safe operation. Fuel tank corrosion typically begins at the tank’s upper surfaces, where condensation and road splash create ideal conditions for rust formation.

Regular inspection of the tank and associated components should be performed during routine maintenance, looking for signs of surface rust, scaling, or actual perforation.

Pay particular attention to the area around the fuel pump access panel and filler neck, where corrosion often first appears. Use a flashlight to inspect areas that aren’t easily visible, and don’t hesitate to have suspect areas professionally evaluated.

The fuel filler neck represents a common failure point that can cause fuel spillage and vapor leaks. Inspect the filler neck regularly for corrosion, particularly where it connects to the tank and passes through the body panels.

A corroded filler neck can allow fuel to leak during filling or create vapor leaks that trigger the check engine light. Replacement involves significant labor but is essential for safe operation and environmental compliance. When replacement becomes necessary, consider upgrading to a higher-quality tank or one with improved corrosion resistance.

While OEM replacement tanks are adequate, some aftermarket options offer superior materials or design improvements that enhance durability. Ensure any replacement tank meets or exceeds original specifications and includes all necessary emissions control connections.

6. Inspect and Maintain the Electrical System

The electrical system in Astro Vans requires systematic attention to prevent the frustrating intermittent problems that can leave you stranded or cause expensive diagnostic bills.

Unlike modern vehicles with sophisticated computer systems, the Astro’s relatively simple electrical architecture makes it possible for owners to perform much of the maintenance themselves.

However, the vehicle’s age means that many electrical components are approaching or have exceeded their design life, making proactive replacement and maintenance essential.

Battery maintenance forms the foundation of electrical system reliability and should be performed monthly. Clean battery terminals with a wire brush and baking soda solution to remove corrosion, then apply terminal protectant to prevent future buildup.

Check battery fluid levels in serviceable batteries, adding distilled water as needed. Test battery condition annually using a professional load test, as batteries can fail gradually without obvious symptoms.

A weak battery places additional strain on the alternator and starter, potentially causing premature failure of these expensive components. The alternator represents a critical component that often fails without warning, leaving you stranded with a dead battery.

Monitor charging system performance by observing the voltmeter or warning lights while driving, and have the system tested professionally if you notice dimming lights or slow cranking.

The Astro’s alternator is typically robust, but brush wear and bearing failure become more common as mileage increases. Replace the alternator at the first sign of problems rather than attempting repairs, as rebuilt units often fail quickly. Consider upgrading critical electrical connections to improve reliability, particularly if your van is used commercially or for long-distance travel.

Heavy-duty battery cables, upgraded alternator wiring, and improved ground connections can prevent many common electrical problems while improving system performance. While not strictly necessary, these upgrades provide peace of mind and can prevent costly roadside emergencies.

7. Maintain Proper Tire Care and Rotation

Tire maintenance on the Astro Van goes beyond simple pressure checks and requires understanding the vehicle’s unique characteristics and how they affect tire wear patterns.

The rear-wheel-drive configuration, weight distribution, and typical loading patterns create specific tire wear challenges that, when properly managed, can significantly extend tire life while improving safety and fuel economy.

Implementing a comprehensive tire maintenance program will save money while ensuring optimal traction and handling. Tire pressure monitoring should be performed weekly using an accurate gauge, as the Astro’s tires are prone to pressure loss due to aging valve stems and rim corrosion.

Check pressure when tires are cold, preferably in the morning before driving. Maintain pressures according to the door placard specifications, not the maximum pressure molded into the tire sidewall.

Underinflation causes excessive wear on the tire shoulders and increases fuel consumption, while overinflation reduces the contact patch and can cause center wear and poor wet traction.

Tire rotation should be performed every 5,000 miles to ensure even wear patterns and maximize tire life. The Astro’s rear-wheel-drive configuration tends to cause faster wear on the rear tires, particularly if the van is loaded heavily or used for towing.

Use the appropriate rotation pattern for your tire type radial tires should be rotated front-to-rear on the same side, while bias-ply tires can be crossed. Always inspect tires for damage during rotation, including sidewall cracking, tread separation, or embedded objects.

Spare tire maintenance is often overlooked, but becomes critical when you need it most. Check spare tire pressure monthly, as temporary spares typically require higher pressures than regular tires.

Inspect the spare for signs of aging or damage, and consider replacing it if it’s more than six years old, regardless of appearance. Ensure you have all necessary tools for tire changing, including a properly functioning jack, lug wrench, and wheel chocks.

8. Service the Brakes Systematically

Brake system maintenance on the Astro Van requires understanding the vehicle’s dual-circuit hydraulic system and the specific requirements of both front disc and rear drum brakes.

The brake system represents the most critical safety component on your van, and systematic maintenance prevents not only expensive repairs but also potential accidents.

Proper brake maintenance involves more than simply replacing pads when they wear out it requires attention to the entire system, including fluid, lines, calipers, and adjustment mechanisms.

Brake fluid maintenance forms the foundation of brake system longevity and should be performed every two years regardless of mileage. Brake fluid absorbs moisture over time, which lowers its boiling point and causes internal corrosion of brake system components.

Use only DOT 3 brake fluid that meets or exceeds original specifications, and never mix different types of brake fluid. When changing brake fluid, ensure complete system flushing to remove all old fluid, starting with the brake furthest from the master cylinder and working toward the closest.

Brake pad inspection should be performed every oil change, checking both pad thickness and wear patterns. The Astro’s front disc brakes typically show wear through the brake pad inspection windows, while rear drum brakes require removal of the inspection plugs.

Replace brake pads when the thickness reaches 3mm or when the wear indicators begin contacting the rotors. Uneven pad wear indicates problems with calipers, rotors, or suspension components that should be addressed during pad replacement.

Brake rotor maintenance involves regular inspection for scoring, warping, or excessive wear that can cause vibration or poor braking performance.

Minor rotor scoring can be corrected through resurfacing, but rotors should be replaced if they’re worn beyond minimum thickness specifications or show signs of heat damage.

Always replace rotors in pairs to maintain even braking, and consider upgrading to premium rotors if your van is used for towing or heavy-duty applications.

Rear drum brake adjustment becomes critical as the self-adjusting mechanisms can stick or fail over time, causing uneven brake wear and poor pedal feel.

The Astro’s rear brakes should self-adjust during reverse braking, but manual adjustment may be necessary if the self-adjusters stick. Learn the proper adjustment procedure or have it performed professionally, as incorrect adjustment can cause brake drag or inadequate braking force.

Anti-lock brake system (ABS) maintenance, if equipped, requires attention to both the hydraulic components and the electronic sensors. Keep wheel speed sensors clean and properly gapped, and inspect sensor wiring for damage.

Have ABS problems diagnosed professionally, as improper repairs can affect system operation. While the base brake system will function without ABS, maintaining the system ensures optimal braking performance under all conditions.

9. Regularly Check Suspension Components

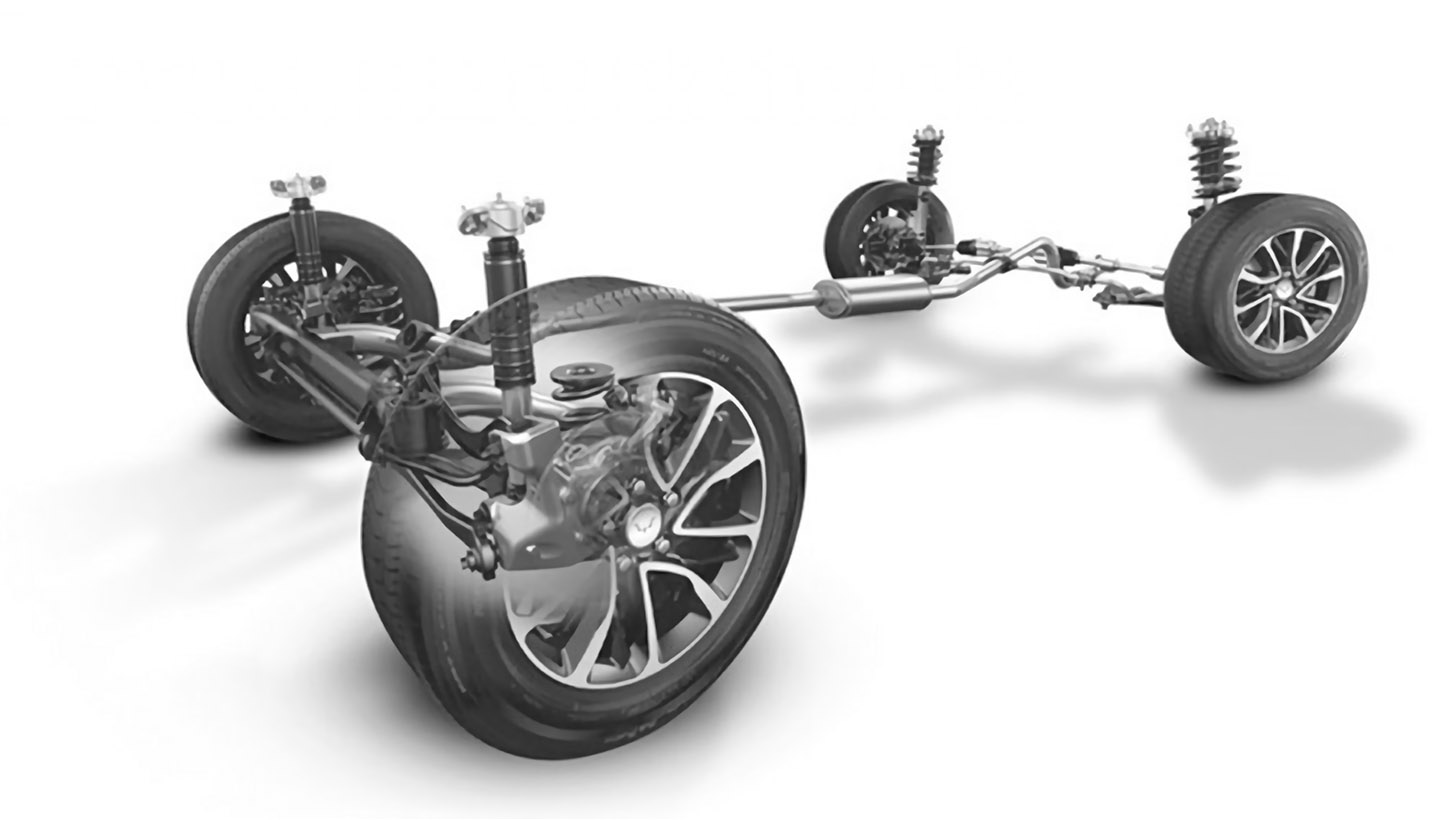

The Astro Van’s suspension system endures significant stress from the vehicle’s weight, typical loading patterns, and the rear wheel drive configuration that affects weight distribution.

Regular inspection and maintenance of suspension components prevents not only expensive repairs but also maintains the safe handling characteristics essential for a vehicle of this size and weight.

Understanding the specific components and their typical failure patterns allows you to address problems proactively rather than waiting for complete failure.

Shock absorber maintenance begins with a monthly visual inspection for signs of leakage or physical damage. The Astro’s shocks work hard due to the vehicle’s weight and typical use patterns, and worn shocks affect not only ride comfort but also tire wear and handling safety.

Test shock absorber function by pushing down firmly on each corner of the vehicle it should rebound once and settle without bouncing. Replace shocks in pairs (front or rear) to maintain even handling characteristics, and consider heavy-duty units if your van is frequently loaded or used for towing.

Ball joint inspection requires careful attention as these components bear significant loads and can fail catastrophically if neglected. Check for excessive play by lifting the vehicle and using a pry bar to test for movement between the control arm and spindle.

Listen for clicking or popping noises when turning, particularly when parking or maneuvering at low speeds. Replace ball joints at the first sign of excessive wear, as failure can cause loss of vehicle control. Always replace ball joints in pairs to maintain even suspension geometry.

Tie rod end inspection should be performed during every alignment check or tire rotation, as these components directly affect steering response and tire wear.

Check for excessive play in the steering linkage by having an assistant turn the steering wheel while you observe the tie rod ends for looseness. Worn tie rod ends cause poor steering response, wandering, and rapid tire wear. Replace tie rod ends in pairs and have the alignment checked afterward to ensure proper toe settings.

Sway bar link inspection often reveals worn or broken components that affect handling stability, particularly during cornering or emergency maneuvers. The Astro’s sway bar links are subject to stress from road irregularities and normal suspension movement.

Listen for clunking noises over bumps or during parking lot maneuvers, and inspect the links visually for cracked bushings or bent components. Replace sway bar links in pairs to maintain even handling characteristics.

Load-leveling system maintenance, if equipped, requires attention to both the mechanical components and the air or hydraulic systems. Inspect air lines and fittings for leaks, and ensure the system maintains proper vehicle height under load.

Address any problems with load-leveling systems promptly, as improper vehicle height affects handling and can cause excessive wear on other suspension components.

10. Perform Comprehensive Preventive Inspections

The final and perhaps most important aspect of Astro Van maintenance involves implementing a systematic inspection routine that identifies developing problems before they become expensive failures or safety hazards.

Comprehensive preventive inspections require more time and attention than basic maintenance, but they provide invaluable insight into your van’s condition while preventing the majority of unexpected breakdowns. This proactive approach to maintenance pays dividends through improved reliability, lower operating costs, and enhanced safety.

Monthly inspection routines should become second nature for any serious Astro Van owner, covering all major systems and components during a systematic walk-around.

Start with fluid level checks, including engine oil, coolant, brake fluid, power steering fluid, and windshield washer fluid. Inspect belts and hoses for signs of cracking, fraying, or deterioration, paying particular attention to the serpentine belt and cooling system hoses.

Check battery terminals for corrosion and ensure all lights function properly. This monthly routine takes less than 30 minutes but can identify most developing problems before they cause failures.

Seasonal inspections should be performed before the summer and winter seasons to prepare the van for extreme conditions and address wear items that might fail under stress.

Summer preparation includes thorough cooling system inspection, air conditioning service, and tire condition assessment. Winter preparation involves battery and charging system testing, heating system inspection, and preparation of emergency equipment.

These seasonal inspections provide opportunities to address maintenance items during convenient times rather than during emergencies. Annual comprehensive inspections should be performed by qualified technicians who can identify problems that aren’t apparent during routine maintenance.

Professional inspections include items like brake system evaluation, exhaust system inspection, emissions system testing, and detailed chassis examination.

While these inspections cost money upfront, they prevent expensive failures and provide documentation of vehicle condition for resale purposes. Consider having annual inspections performed just before vehicle registration renewal to address any safety issues.

Mileage-based inspection intervals provide systematic attention to wear items based on actual vehicle usage rather than arbitrary time periods. Create a maintenance schedule based on mileage intervals 15,000, 30,000, 45,000 miles, etc that includes specific inspection items for each interval.

This approach ensures that wear items receive attention based on actual use patterns while providing flexibility for vehicles with unusual usage patterns.

Remember that comprehensive preventive inspection is an investment in reliability and safety that pays dividends through reduced operating costs and improved peace of mind.

The time spent on systematic inspection and maintenance is minimal compared to the time lost dealing with breakdowns and emergency repairs. By implementing these ten professional maintenance strategies, your Astro Van can provide reliable service for many years and hundreds of thousands of miles.

Also Read: 7 Mistakes That Kill a Jeep Wrangler Sahara Too Soon