Engine oil leaks represent one of the most persistent and frustrating automotive problems that vehicle owners face. The difference between an engine that maintains its integrity throughout hundreds of thousands of miles versus one that begins marking its territory from the moment it leaves the warranty period often comes down to fundamental design philosophies, manufacturing quality, and material choices.

Understanding these distinctions can save drivers thousands of dollars in repair costs and countless hours of inconvenience. When examining engine reliability, particularly regarding oil containment, several factors emerge as critical determinants.

Engineering tolerances, gasket materials, seal design, operating pressures, and thermal management all play crucial roles in determining whether an engine will maintain its fluids or become a perpetual source of garage stains.

The five engines notorious for constant dripping demonstrate how complex designs, aggressive performance targets, and cost-cutting measures can create persistent maintenance headaches. This comparison will help vehicle buyers make informed decisions and current owners understand what they might expect from their engines as mileage accumulates.

5 Engines That Rarely Leak Oil

These exceptionally engineered powerplants feature premium sealing materials and precision manufacturing tolerances that maintain perfect oil containment through hundreds of thousands of demanding miles and extreme operating conditions.

Their thoughtful construction includes high-temperature gasket compounds, precisely machined sealing surfaces, and robust crankcase ventilation systems that resist the pressure buildup patterns typically created by blow-by gases and thermal cycling.

From extreme summer heat that degrades rubber seals to winter cold that causes material contraction, these remarkable engines continue operating without the weeping valve covers, leaking oil pans, or failing front seals that create unsightly stains and environmental concerns.

The combination of premium sealing materials, precision manufacturing, and conservative crankcase pressure management creates powerplants that prove their worth through environmental responsibility and maintained professional appearance even after hundreds of thousands of miles.

1. Toyota 2AR-FE 2.5L 4-Cylinder

The Toyota 2AR-FE stands as a testament to the Japanese manufacturer’s unwavering commitment to reliability and engineering conservatism. Found in millions of Camrys, RAV4s, and other Toyota models since 2008, this naturally aspirated 2.5-liter four-cylinder engine has earned legendary status among mechanics and owners for its exceptional oil containment properties.

The engine’s design philosophy prioritizes longevity over peak performance, resulting in a powerplant that consistently operates for 200,000+ miles with minimal oil seepage.

Toyota’s reputation for reliability remains strong in 2024, and the 2AR-FE exemplifies this commitment through meticulous attention to sealing surfaces and gasket design.

The engine employs high-quality rubber compounds in its gaskets that maintain elasticity even after prolonged exposure to heat cycling. The valve cover gasket, often the first failure point in many engines, utilizes a robust multi-layer design with integrated spark plug tube seals that rarely require replacement before 150,000 miles.

The oil pan gasket represents another area where Toyota’s conservative engineering shines. Rather than using complex multi-piece oil pan designs that create additional potential leak points, the 2AR-FE employs a simple stamped steel pan with a full-perimeter gasket that maintains its seal integrity throughout the engine’s operational life.

The crankshaft seals, both front and rear, utilize proven designs with secondary lips and spring-loaded elements that compensate for normal wear patterns.

Manufacturing quality control plays a crucial role in the 2AR-FE’s leak-resistant characteristics. Toyota’s production facilities maintain extremely tight tolerances on sealing surfaces, ensuring proper gasket compression and eliminating the micro-gaps that can lead to oil weepage over time.

The engine block and cylinder head machining operations include multiple quality checkpoints that verify surface finish specifications meet the stringent requirements necessary for long-term seal reliability.

Operating characteristics also contribute to the engine’s excellent oil retention. The 2AR-FE operates at relatively modest internal pressures and temperatures compared to turbocharged or high-performance alternatives.

This conservative operating envelope reduces stress on sealing components and extends their service life significantly. The engine’s oil change intervals, typically 10,000 miles with synthetic oil, help maintain proper lubrication of sealing elements while preventing degradation that can lead to leakage.

2. Honda K24A/K24Z 2.4L 4-Cylinder

Honda’s K24 series engines represent over two decades of refinement in four-cylinder design, with the K24A and K24Z variants achieving remarkable reliability records in terms of oil containment.

Honda’s port-injected engines, including variants of the K24, have proven quite reliable and long-lasting. These engines power millions of Accords, CR-Vs, and Pilots worldwide, consistently delivering hundreds of thousands of miles of service with minimal oil leakage issues.

The K24’s exceptional oil retention stems from Honda’s VTEC system design, which, despite its complexity, actually contributes to sealing reliability.

The VTEC solenoid and associated oil passages are engineered with redundant sealing systems that prevent the high-pressure oil required for variable valve timing from escaping.

The cylinder head design incorporates precision-machined oil galleries with press-fit plugs that maintain their integrity throughout the engine’s service life.

Honda’s approach to gasket technology in the K24 series emphasizes proven materials and conservative designs. The head gasket utilizes a multi-layer steel construction with specialized coatings that provide excellent sealing properties while accommodating thermal expansion.

The valve cover gasket system features integrated PCV valve sealing and spark plug tube seals that rarely develop leaks before 200,000 miles of service. The oil pan and related sealing systems showcase Honda’s attention to manufacturing detail.

The aluminum oil pan bolts to the engine block through a precisely machined surface with chamfered edges that promote proper gasket seating. The oil drain plug features a crush washer design that provides reliable sealing through multiple oil change cycles, while the oil filter mount incorporates a spin-on design that eliminates the potential leak points associated with cartridge-style systems.

Quality control throughout the K24’s production life has remained exceptionally high, with Honda maintaining strict adherence to sealing surface specifications across multiple manufacturing facilities.

The engine’s design allows for easy visual inspection of potential leak points during routine maintenance, enabling proactive replacement of sealing components before failure occurs. This accessibility, combined with reasonable parts costs, contributes to the engine’s reputation for long-term reliability and low maintenance costs.

3. Mazda Skyactiv-G 2.0L and 2.5L 4-Cylinders

Mazda’s Skyactiv-G engine family represents a modern approach to naturally aspirated engine design that prioritizes efficiency and reliability without sacrificing performance.

Introduced in 2011, these engines have accumulated impressive service records across the CX-5, Mazda3, Mazda6, and CX-9 model lines, with oil leakage issues remaining remarkably rare even as examples approach high mileage territories.

The Skyactiv-G’s oil containment excellence begins with its high-compression ratio design, which paradoxically contributes to better sealing. The engines operate at compression ratios between 12:1 and 14:1, requiring extremely precise manufacturing tolerances and high-quality sealing components.

This attention to precision manufacturing carries over to all sealing surfaces, resulting in superior oil retention throughout the engine’s service life. Mazda’s approach to gasket design emphasizes simplicity and proven technologies.

The aluminum cylinder head features a flat-deck design with a conventional multi-layer steel head gasket that provides excellent sealing properties while remaining cost-effective to replace when necessary.

The valve cover system utilizes a composite gasket with integrated PCV components that maintain their sealing properties through extended service intervals.

The oil pan sealing system demonstrates Mazda’s commitment to leak prevention through design. The stamped steel oil pan features a reinforced sealing surface with a high-quality silicone gasket that accommodates thermal expansion while maintaining its integrity.

The oil drain plug incorporates a tapered thread design with a metal washer that provides superior sealing compared to rubber gasket alternatives commonly used in other engines.

Manufacturing quality plays a crucial role in the Skyactiv-G’s reliable oil containment. Mazda’s production facilities utilize advanced machining centers that maintain extremely tight tolerances on all sealing surfaces, while comprehensive quality control procedures ensure proper surface finish specifications.

The engines undergo extensive testing procedures that include pressure testing of oil galleries and sealing systems before leaving the factory. The Skyactiv-G’s operating characteristics contribute to its excellent sealing longevity.

Despite high compression ratios, the engines operate at moderate temperatures and pressures due to efficient combustion chamber designs and effective cooling systems.

This moderate operating environment reduces stress on sealing components while the engines’ direct injection systems help maintain clean oil conditions that preserve gasket and seal materials over extended service intervals.

4. GM LS Series V8 Engines (LS1, LS2, LS3, LS7)

General Motors’ LS series V8 engines have achieved legendary status not only for their performance capabilities but also for their exceptional reliability and oil containment characteristics.

Spanning nearly three decades of production across numerous applications, from Corvettes to Silverados, LS engines consistently deliver hundreds of thousands of miles of service with minimal oil leakage issues when properly maintained.

The LS engine’s superior oil retention begins with its deep-skirt engine block design, which provides exceptional structural rigidity and reduces flexing that can compromise gasket sealing.

The cast aluminum or iron blocks feature precision-machined sealing surfaces with consistent finish specifications that promote proper gasket compression.

The cylinder heads bolt to the block through a proven torque-to-yield bolt system that maintains proper clamping force throughout thermal cycling.

Gasket technology in LS engines represents decades of refinement and proven designs. The head gaskets utilize multi-layer steel construction with special coatings that provide excellent sealing properties while accommodating the thermal expansion characteristics of aluminum components.

The valley pan gasket, unique to the LS design, seals the intake manifold to the engine block and rarely develops leaks due to its protected location and high-quality materials.

The oil pan sealing system showcases GM’s attention to leak prevention through engineering. The stamped steel or cast aluminum oil pans feature robust mounting flanges with precisely machined sealing surfaces.

The gasket systems vary by application but consistently utilize high-quality materials that maintain their sealing properties throughout extended service intervals. The rear main seal design incorporates a two-piece configuration that allows for replacement without engine removal, encouraging proactive maintenance.

Manufacturing quality control throughout LS production has remained consistently high across multiple facilities and decades of production. GM’s investment in advanced machining equipment and comprehensive quality assurance programs ensures that sealing surfaces meet stringent specifications regardless of production location.

The engines undergo extensive testing procedures, including oil pressure and leak testing, before shipment to assembly facilities. The LS engine’s moderate operating characteristics, despite impressive performance figures, contribute to excellent sealing longevity.

The engines operate at reasonable oil temperatures and pressures due to efficient cooling systems and well-designed oil circulation paths. The pushrod valve actuation system eliminates the complex oil passages required by overhead cam designs, reducing potential leak points while simplifying maintenance procedures.

Also Read: 5 Vehicles That Run Cheap Forever vs 5 That Drain Wallets

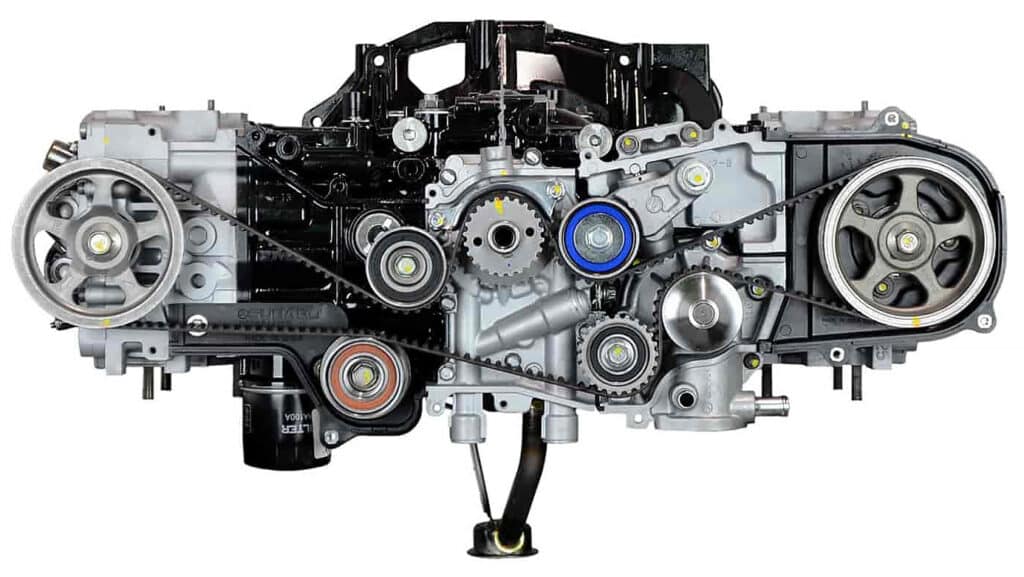

5. Subaru EJ25 2.5L Boxer Engine (Later Versions)

While Subaru’s EJ25 boxer engine experienced some reliability issues in its earlier iterations, the later versions (2010+) have demonstrated significantly improved oil containment characteristics while maintaining the unique performance and handling benefits of the horizontally opposed design.

These engines power the Outback, Legacy, and Forester models, with many examples now approaching high mileage with minimal oil leakage concerns.

The improved EJ25’s oil retention excellence stems from redesigned sealing systems that address the unique challenges of the boxer engine configuration.

The horizontal cylinder orientation creates specific sealing challenges due to gravity’s effect on oil distribution, requiring specialized gasket designs and sealing strategies.

Subaru’s engineers developed revised valve cover gaskets with enhanced sealing profiles and integrated baffle systems that manage oil flow effectively.

The cylinder head gasket represents the most significant improvement in later EJ25 engines. Earlier versions suffered from head gasket failures that led to oil and coolant leaks, but the redesigned gaskets feature improved materials and enhanced sealing surfaces that provide reliable service throughout the engine’s operational life.

The multi-layer steel construction with specialized coatings accommodates the thermal expansion characteristics of the aluminum heads and iron block. Oil pan sealing in the EJ25 presents unique challenges due to the engine’s low-mounted position and horizontal configuration.

The revised oil pan gasket system utilizes high-quality silicone materials with enhanced resistance to road debris and environmental factors. The oil drain plug location and design minimize the risk of damage from road hazards while providing reliable sealing through multiple service intervals.

Subaru has shown strong reliability performance with models like the Forester and Impreza scoring above average, reflecting improvements in overall build quality, including sealing systems.

The manufacturing processes for later EJ25 engines incorporate lessons learned from earlier versions, with enhanced quality control procedures and improved machining specifications for sealing surfaces.

The EJ25’s operating characteristics benefit from Subaru’s conservative tuning approach and effective thermal management systems. The boxer configuration provides natural balance and reduced vibration, which minimizes stress on sealing components over time.

The engines’ all-wheel-drive applications typically involve moderate duty cycles that don’t stress sealing systems excessively, contributing to long-term reliability and oil containment success.

5 Engines That Constantly Drip

These problematic powerplants suffer from fundamental cost-cutting in sealing systems, including bargain-basement gasket materials and inadequate machining tolerances that create perfect conditions for continuous oil leakage under normal operating conditions.

Their penny-pinching construction shows in cheap rubber seals that harden and crack within years, poorly finished mating surfaces that prevent proper gasket sealing, and inadequate crankcase ventilation that builds pressure and forces oil past weakened seals.

These engines represent the unfortunate consequences of prioritizing initial cost over long-term reliability, creating power plants that transform routine parking into environmental disasters while requiring constant monitoring and expensive repairs to address leaks that develop faster than they can be economically fixed, often leaving owners choosing between costly repairs or accepting permanent oil staining.

1. BMW N54 3.0L Twin-Turbo Inline-6

BMW’s are notorious for oil leaks, particularly in inline-six engines like the N54, with valve cover gaskets being a common failure point. The N54 engine, despite its impressive performance credentials and technological sophistication, has earned an unfortunate reputation as one of the most leak-prone powerplants in modern automotive history.

Found in popular models like the 335i, 135i, and Z4, this twin-turbocharged marvel delivers exceptional power but demands constant attention to its numerous sealing systems.

The N54’s oil leakage problems stem from its complex design and high operating pressures required for turbocharging. The engine operates under significantly higher internal pressures than naturally aspirated alternatives, placing tremendous stress on gaskets and seals throughout the system.

The turbocharger oil feed and return lines represent particular problem areas, with both high-pressure feed lines and low-pressure return lines developing leaks that can dump substantial quantities of oil.

BMW’s performance-oriented design philosophy prioritizes power and driving pleasure, which can contribute to oil loss issues, particularly around valve cover gaskets and other engine seals.

The valve cover gasket system represents one of the most problematic areas, with the plastic valve cover often warping due to heat cycling, compromising gasket sealing. The integrated PCV system and complex vacuum lines add additional potential failure points that can lead to both oil leaks and excessive crankcase pressure.

The oil filter housing gasket on the N54 has achieved particular notoriety among BMW technicians and owners. Located at the top of the engine, this housing contains the oil filter and connects to various oil lines.

The gaskets consistently fail, often before 100,000 miles, causing oil to leak onto the exhaust system and create both fire hazards and unpleasant odors. The repair requires significant disassembly and can cost thousands of dollars at dealership service rates.

High-pressure fuel pump issues compound the N54’s leakage problems. The direct injection system requires extremely high fuel pressures, and the fuel pump drive mechanism can leak oil into the fuel system while simultaneously allowing fuel contamination of the engine oil.

This cross-contamination accelerates seal degradation throughout the engine, creating a cascade of leakage issues that become progressively worse over time. The N54’s complex accessory drive system includes multiple components that contribute to oil leakage issues.

The variable valve timing system utilizes high-pressure oil to actuate cam phasers, and the associated solenoids and oil lines frequently develop leaks. The power steering system, integrated with the engine oil circulation, adds additional complexity and potential failure points that can result in significant oil loss if not promptly addressed.

2. Audi/VW 2.0T TSI Engine

The Audi and VW 2.0 TSI engines, particularly in the 2009-2012 Volkswagen Tiguan, suffer from common rear main crankshaft seal leaks, representing one of the most widespread oil leakage problems in modern European automotive engineering.

This turbocharged four-cylinder engine powers numerous Audi and Volkswagen models, from the Golf GTI to the Audi A4, and has developed a reputation for persistent oil seepage that often begins well before warranty expiration.

The 2.0T TSI’s rear main seal problem represents the most significant and costly leak issue owners face. This pattern failure occurs across various VW, Audi, and even Porsche models using the 2.0TSI engine, typically manifesting as oil dripping from the transmission bell housing area.

The repair requires transmission removal, making it an expensive fix that many owners defer until the leakage becomes severe enough to cause environmental concerns or mechanical problems.

Carbon buildup represents another factor contributing to the 2.0T TSI’s sealing problems. The direct injection system, while providing excellent performance and fuel economy, creates carbon deposits on intake valves and internal engine components.

These deposits can interfere with PCV system operation, leading to excessive crankcase pressure that overwhelms sealing systems throughout the engine. The timing chain tensioner and associated sealing systems represent additional problem areas in the 2.0T TSI.

The tensioner uses engine oil pressure for operation, and the seals around the tensioner mechanism frequently fail, causing oil to leak from the front of the engine. The timing chain cover gaskets also prove problematic, often requiring replacement multiple times throughout the engine’s service life.

Audi engines may be more prone to oil leaks due to their high-pressure operation, and the 2.0T TSI exemplifies this characteristic through its aggressive turbocharging system.

The turbocharger oil feed and drain systems operate under extreme conditions, with oil temperatures reaching levels that accelerate seal degradation. The oil cooler and associated lines frequently develop leaks that can be difficult to locate and expensive to repair.

The intake manifold and associated vacuum systems in the 2.0T TSI create additional leak points that compound the engine’s oil retention problems.

The plastic intake manifold components can crack due to heat cycling, creating vacuum leaks that affect PCV system operation and contribute to oil seepage throughout the engine.

The numerous vacuum lines and connections required for the engine’s emissions and performance systems provide multiple opportunities for seal failures that can lead to oil loss.

3. Mercedes-Benz M272/M273 V6/V8 Engines

Mercedes-Benz’s M272 V6 and M273 V8 engines, despite their smooth operation and impressive performance characteristics, have developed notorious reputations for persistent oil leakage issues that affect models ranging from the C-Class to the S-Class.

These engines, produced from 2004 to 2016, showcase how complex modern engine designs can create multiple opportunities for oil seepage that become increasingly problematic as vehicles age.

The valve cover gaskets on M272/M273 engines represent one of the most consistent failure points, typically beginning to leak before 100,000 miles of service.

The aluminum valve covers expand and contract significantly during thermal cycling, placing stress on the gasket materials that leads to hardening and eventual failure.

The complex shape of the valve covers, with multiple bolt locations and integrated components, makes proper gasket sealing challenging even with fresh parts. Oil-air separator systems in these Mercedes engines create significant leakage problems that can be expensive to diagnose and repair.

The separator units, designed to reduce emissions by capturing oil vapors from the crankcase, frequently fail and allow oil to leak into the intake system. This contamination not only creates performance problems but also accelerates the degradation of other sealing components throughout the engine.

The timing chain tensioner systems in M272/M273 engines utilize hydraulic operation that depends on engine oil pressure, and the associated sealing components frequently fail.

Oil leaks from the timing chain area can be particularly problematic because they often drip onto the exhaust system, creating smoke and odors that alarm owners.

The complex timing chain cover design, with multiple sealing surfaces and integrated components, provides numerous opportunities for leakage development.

Crankcase ventilation systems in these Mercedes engines contribute to oil leakage through their complex design and multiple connection points. The engines utilize sophisticated PCV systems with multiple valves, separators, and connecting hoses that can develop leaks or blockages.

When these systems fail, excessive crankcase pressure can overwhelm sealing systems throughout the engine, leading to widespread oil seepage.

The oil pan and related sealing systems in M272/M273 engines present unique challenges due to the engines’ installation in various vehicle platforms.

The oil pans often feature complex shapes to accommodate steering and suspension components, creating sealing surfaces that are difficult to properly seal and maintain.

The oil drain plugs and related hardware frequently develop leaks that require careful attention during routine maintenance to prevent recurring problems.

4. Volkswagen VR6 Engine

Volkswagen’s VR6 engine, while beloved by enthusiasts for its unique narrow-angle V6 design and distinctive exhaust note, has earned a reputation for persistent oil leakage that affects both early and late production examples.

The engine’s compact design, achieved by using a narrow 15-degree cylinder bank angle, creates unique sealing challenges that result in multiple common leak points throughout its service life.

The cylinder head gasket system in VR6 engines faces unusual stresses due to the narrow angle between cylinder banks and the resulting complex combustion chamber shapes.

The head gasket must seal between cylinders that are positioned much closer together than in conventional V6 designs, creating areas of high stress that can lead to oil seepage.

The aluminum cylinder head’s thermal expansion characteristics, combined with the cast iron block, create additional challenges for long-term gasket integrity. Upper timing chain cover leaks represent one of the most visible and persistent problems with VR6 engines.

The complex timing chain system requires multiple sealing surfaces on the front of the engine, and these gaskets consistently fail, causing oil to leak onto the accessory drive belt system. The leak often appears as oil spraying from the front of the engine, creating both mechanical concerns and environmental issues.

The oil pan gasket system in VR6 engines proves problematic due to the engine’s unusual configuration and installation requirements. The narrow engine width requires a correspondingly wide oil pan to maintain adequate oil capacity, creating a large sealing surface that’s prone to warpage and gasket failure.

The oil pan’s location in the vehicle often makes leak detection and repair challenging, leading to delayed maintenance that can worsen the problem. Valley pan sealing represents another unique challenge in VR6 engines, where the narrow cylinder bank angle creates a confined space between the cylinder heads that must be properly sealed.

The intake manifold mounts in this valley area, requiring complex gasket systems that frequently develop leaks. Oil seepage in this area can contaminate the intake system and create performance problems in addition to the obvious oil loss.

Crankshaft sealing systems in VR6 engines face unusual challenges due to the engine’s compact crankcase design and high rotational speeds. Both front and rear main seals experience accelerated wear due to the engine’s vibration characteristics and the space constraints that limit seal size.

The resulting leaks can be particularly problematic because they often affect the clutch system in manual transmission applications or contaminate the torque converter in automatic transmission vehicles.

5. Land Rover Discovery/Range Rover V8 Engines

Land Rover’s V8 engines, particularly those found in Discovery and Range Rover models from the 1990s through 2000s, have achieved legendary status for all the wrong reasons when it comes to oil containment.

These engines, despite their robust performance in off-road applications and impressive torque delivery, consistently develop multiple oil leaks that can transform a pristine driveway into an environmental hazard zone.

The cylinder head gasket failures in Land Rover V8 engines represent perhaps the most catastrophic and expensive leak problems owners face. The aluminum cylinder heads combined with cast iron blocks create thermal expansion mismatches that stress the head gaskets beyond their design limits.

When these gaskets fail, the results often include not only oil leaks but also coolant contamination and potential engine damage that can cost more than the vehicle’s remaining value to repair properly.

Valley gasket leaks represent another chronic problem with Land Rover V8 engines, where the intake manifold sealing to the engine block consistently fails.

The plastic intake manifold components, subjected to extreme heat cycling in the confined engine bay, frequently crack or warp, compromising the gasket sealing.

Oil seepage in this area can contaminate the intake system while creating persistent leak problems that are expensive to address comprehensively.

The timing chain cover systems in these Land Rover engines develop leaks with predictable regularity, often beginning before 100,000 miles of service.

The complex timing chain arrangements require multiple cover pieces with numerous sealing surfaces, providing abundant opportunities for gasket failure. The resulting oil leaks typically affect the front accessory drive system, potentially causing belt slippage and additional mechanical problems.

Oil pan gasket problems in Land Rover V8s are exacerbated by the vehicles’ intended off-road use and the resulting exposure to road debris and environmental contaminants.

The power steering pump, driven by the engine and using a shared oil supply in some configurations, frequently develops leaks that affect both systems. The complex routing of oil lines and connections throughout the engine bay provides multiple potential failure points that can result in significant oil loss if not promptly addressed.

Also Read: 5 Vehicles That Rarely See Major Engine Work vs 5 That Constantly Do