The world of automotive engines presents a fascinating dichotomy between robust, forgiving powerplants and delicate, high-maintenance units that demand meticulous care.

Understanding these differences is crucial for anyone considering a vehicle purchase, whether you’re a casual driver seeking reliability or an enthusiast willing to invest time and money in performance maintenance.

Engines that handle neglect well typically share certain characteristics: simple designs with fewer complex components, robust materials, conservative engineering tolerances, and proven reliability across decades of production.

These engines often prioritize longevity over peak performance, using time-tested technologies that can withstand irregular maintenance schedules, poor fuel quality, and less-than-ideal operating conditions.

They’re the workhorses of the automotive world, designed to run reliably with basic care and continue functioning even when maintenance intervals are stretched.

Conversely, high-maintenance engines usually achieve their performance through sophisticated engineering, tight tolerances, exotic materials, and complex systems that optimize power output, efficiency, or refinement.

These engines often feature advanced technologies like variable valve timing, direct injection, turbocharging, or high-compression ratios that demand precise maintenance schedules and high-quality fluids.

While they may offer superior performance, fuel economy, or emissions characteristics, they typically require more frequent servicing, premium components, and skilled technicians familiar with their intricacies.

The choice between these engine types often reflects different priorities and lifestyles. Those seeking maximum reliability with minimal fuss gravitate toward proven, simple designs that can handle occasional neglect without catastrophic failure.

Meanwhile, performance enthusiasts and those prioritizing cutting-edge technology may accept higher maintenance requirements in exchange for superior capabilities. Understanding these trade-offs helps inform better decisions about vehicle ownership costs, expected reliability, and maintenance commitment levels.

5 Engines That Handle Neglect Well

These exceptionally forgiving powerplants feature robust construction and conservative engineering approaches that maintain reliable operation despite owner neglect and deferred maintenance schedules that would destroy lesser engines.

Their thoughtful design includes oversized oil pumps, generous bearing clearances, and simple valve train configurations that resist the damage patterns typically created by extended oil change intervals and contaminated fluids.

From timing chains that stretch gracefully rather than snap catastrophically to cooling systems with massive capacity margins that prevent overheating during low-coolant emergencies, these remarkable engines continue operating faithfully without experiencing the catastrophic failures that punish careless owners elsewhere.

Strategic component oversizing ensures adequate lubrication even with degraded oil, while cast-iron construction provides thermal mass that moderates temperature spikes during abuse scenarios.

Owners report these bulletproof engines surviving 15,000-mile oil change intervals, cooling system neglect, and air filter replacement delays that would require complete rebuilds in more delicate powerplants.

The combination of agricultural-grade durability, massive safety margins, and simple maintenance requirements creates engines that prove their worth by protecting irresponsible owners from their own poor decisions, delivering dependable transportation even when basic care is ignored.

1. Toyota 22R/22RE (1981-1995)

The Toyota 22R and its fuel-injected successor, the 22RE, represent the pinnacle of bulletproof engine design. This 2.4-liter four-cylinder engine powered millions of Toyota pickups, 4Runners, and Celicas throughout the 1980s and early 1990s, earning a legendary reputation for reliability that persists decades after production ended.

The 22R’s robust construction begins with its cast-iron block and aluminum head configuration, providing excellent durability while maintaining reasonable weight.

The engine’s conservative design features a single overhead cam, two valves per cylinder, and a relatively low compression ratio of 9.3:1, contributing to its forgiving nature.

The timing chain, rather than a belt, eliminates one common failure point that plagues many engines when maintenance is deferred. What makes the 22R particularly tolerant of neglect is its simple, accessible design.

The carburetor version (22R) uses proven technology that can run acceptably even with dirty fuel systems, while the fuel-injected 22RE maintains simplicity with its basic port injection system. The engine’s large oil capacity and robust oil pump help maintain lubrication even with extended drain intervals, though this isn’t recommended practice.

The 22R’s reputation for handling abuse stems from countless real-world examples. These engines routinely exceed 300,000 miles with basic maintenance, and many have survived severe neglect that would destroy more sophisticated powerplants.

Stories abound of 22R engines running for thousands of miles without oil changes, overheating incidents that merely required coolant refills, and continued operation despite rattling timing chains or worn components.

Maintenance requirements remain refreshingly simple. Regular oil changes, periodic coolant flushes, air filter replacements, and basic tune-ups keep these engines running smoothly.

The valve adjustment procedure, while necessary every 60,000 miles, is straightforward enough for competent DIY mechanics. Parts availability remains excellent due to the engine’s popularity and long production run.

The 22R’s greatest weakness is its modest power output of around 105-116 horsepower, depending on the year and emissions requirements. However, this conservative tuning contributes directly to its longevity and reliability.

The engine’s torque characteristics suit its typical applications well, providing adequate power for daily driving while maintaining excellent fuel economy in the mid-20s MPG range.

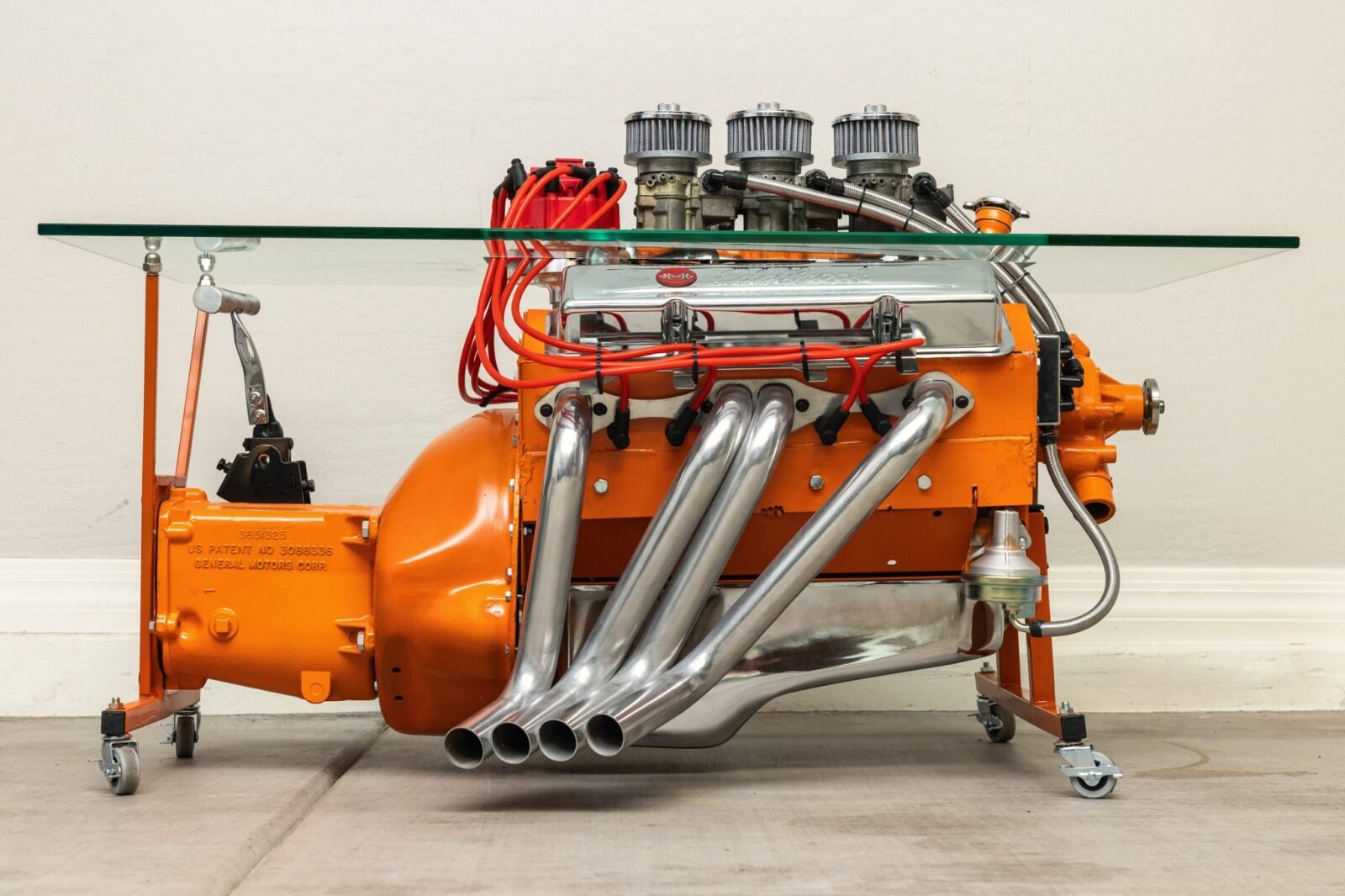

2. Chevrolet Small Block V8 (1955-2003)

The Chevrolet Small Block V8 stands as perhaps America’s most successful engine family, with over 100 million units produced during its nearly five-decade run.

From the original 265 cubic inch version introduced in 1955 to the final 350 variants in 2003, this engine family established benchmarks for durability, serviceability, and tolerance of less-than-perfect maintenance.

The Small Block’s enduring success stems from its fundamentally sound design principles. The cast-iron block construction provides exceptional strength and heat dissipation, while the overhead valve configuration with pushrods keeps the valvetrain simple and robust.

The engine’s generous bearing surfaces, substantial crankshaft design, and proven oiling system contribute to its ability to withstand high mileage and occasional abuse.

What truly sets the Small Block apart in terms of neglect tolerance is its massive aftermarket support and serviceability. When something does fail, parts are universally available and typically inexpensive.

The engine’s straightforward design means that most repairs can be performed with basic tools, and countless mechanics worldwide are familiar with its operation and maintenance requirements.

The Small Block’s robust construction allows it to handle significant neglect while continuing to run. These engines commonly exceed 200,000 miles with basic maintenance, and many examples have surpassed 300,000 miles.

The engine’s conservative internal stresses, particularly in lower-performance applications, contribute to its longevity. Even when maintenance is deferred, Small Blocks often continue running with reduced efficiency rather than suffering catastrophic failure.

Maintenance requirements focus on basics: regular oil changes, cooling system service, and periodic tune-ups. The engine’s conventional ignition system and simple fuel delivery make troubleshooting straightforward.

Valve adjustments aren’t required due to the hydraulic lifter design, eliminating one maintenance item that plagues other engines. The timing chain setup, while requiring eventual replacement at high mileage, typically provides a warning through noise before failure occurs.

The Small Block’s versatility across numerous applications, from economy cars to high-performance muscle cars, demonstrates its adaptable nature.

Lower-performance versions, particularly those in trucks and family cars, prove especially tolerant of neglect due to their conservative tuning and robust construction.

3. Honda D-Series (1984-2005)

Honda’s D-Series engines represent the Japanese approach to building reliable, efficient powerplants that can withstand real-world use and occasional neglect.

Spanning over two decades of production, these 1.2 to 1.7-liter four-cylinder engines powered millions of Civics, CRXs, and other Honda models, establishing a reputation for exceptional longevity and minimal maintenance requirements.

The D-Series design philosophy emphasizes simplicity and proven technology. The aluminum block construction reduces weight while providing adequate strength for the engine’s modest power outputs.

The single overhead cam configuration keeps the valvetrain uncomplicated, while the timing belt system, though requiring periodic replacement, is generally more forgiving than the interference designs found in many modern engines.

Honda’s meticulous engineering tolerances contribute significantly to the D-Series’ neglect tolerance. The engines feature excellent oil circulation systems, robust bearing designs, and conservative internal stresses that allow continued operation even when maintenance intervals are extended.

The variable intake design in later versions improves power delivery without adding significant complexity or maintenance requirements. Real-world durability of D-Series engines is legendary among Honda enthusiasts.

These engines routinely achieve 250,000 to 300,000 miles with basic maintenance, and many examples exceed these numbers. The engines demonstrate remarkable tolerance for extended oil change intervals, poor fuel quality, and less-than-ideal operating conditions. Even when timing belts break, many D-Series variants are non-interference designs, meaning valve damage is avoided.

Maintenance requirements remain straightforward and inexpensive. Basic oil changes, timing belt replacement every 90,000 miles, and periodic valve adjustments keep these engines running smoothly.

The valve adjustment procedure, while necessary every 30,000 miles, is relatively simple and can be performed by dedicated DIY enthusiasts. Parts costs remain reasonable due to the engines’ popularity and Honda’s commitment to long-term parts availability.

The D-Series engines excel in fuel economy, often achieving 30-40 MPG in lighter Honda models. This efficiency, combined with their reliability, makes them popular choices for budget-conscious drivers and those seeking minimal ownership costs.

The engines’ modest power output, typically ranging from 70 to 130 horsepower depending on the specific variant, suits their applications well while contributing to their longevity.

4. Ford 300 Inline Six (1965-1996)

Ford’s 300 cubic inch inline six, affectionately known as the “Ford 300,” represents one of the most durable and neglect-tolerant engines ever produced by an American manufacturer.

This 4.9-liter powerplant served as the workhorse engine for Ford trucks and vans for over three decades, earning an unshakeable reputation for reliability and longevity in commercial and heavy-duty applications.

The 300’s exceptional durability stems from its conservative design and robust construction. The seven-main-bearing crankshaft provides exceptional rigidity and smooth operation, while the cast-iron block and head construction offer superior heat dissipation and strength.

The engine’s low compression ratio and conservative tuning prioritize longevity over peak performance, resulting in an engine that can withstand significant abuse while continuing to operate.

The inline six configuration provides inherent balance advantages over V-engines, reducing vibration and internal stresses that can lead to premature wear.

The engine’s long stroke design produces excellent low-end torque characteristics ideal for truck applications, while the conservative rpm limits keep internal stresses manageable. The simple overhead valve design with pushrods eliminates complex timing systems that can fail when maintenance is neglected.

Ford 300 engines demonstrate extraordinary tolerance for poor maintenance practices. These engines commonly exceed 300,000 miles in commercial service, with many examples surpassing 400,000 miles.

The engines can continue operating with severely degraded oil, coolant system problems, and other issues that would quickly destroy more sophisticated powerplants. Fleet operators particularly value these engines for their ability to keep working despite inconsistent maintenance schedules and hard use.

Maintenance requirements focus on fundamentals: regular oil and filter changes, cooling system service, and basic tune-ups. The engine’s conventional ignition system and simple carburetor or basic fuel injection setup make servicing straightforward.

The hydraulic lifter design eliminates valve adjustments, while the timing chain system provides long service life without the periodic replacement requirements of timing belts. The 300’s greatest asset is its torque production, generating substantial low-end pulling power that makes it ideal for truck applications.

While horsepower output remains modest at around 145-150 hp, the engine’s 265 lb-ft of torque provides excellent real-world performance for its intended applications. Fuel economy, while not exceptional by modern standards, remains acceptable for a large displacement engine in heavy vehicles.

Also Read: 5 Engines That Rarely Leak Oil vs 5 That Constantly Drip

5. Mitsubishi 4G63 Non-Turbo (1987-2006)

Mitsubishi’s naturally aspirated 4G63 engine represents a fascinating case study in robust engineering that can handle neglect while maintaining performance.

While the turbocharged version of this 2.0-liter four-cylinder gained fame in performance applications, the naturally aspirated variant served as a reliable workhorse in various Mitsubishi models, demonstrating exceptional durability and tolerance for less-than-perfect maintenance.

The non-turbo 4G63’s strength lies in its robust internal construction, originally designed to handle forced induction applications. Even in naturally aspirated form, the engine retains the forged crankshaft, robust connecting rods, and strong block construction that make the turbo version capable of handling significant power increases.

This over-engineering for its naturally aspirated application contributes directly to its exceptional durability and neglect tolerance. The engine’s iron block construction provides excellent heat dissipation and strength, while the aluminum head keeps the weight reasonable.

The dual overhead cam design, while more complex than single cam engines, uses proven technology that remains reliable with basic maintenance.

The timing belt system requires periodic replacement but typically provides adequate warning before failure, and the non-interference design in most applications prevents valve damage if replacement is delayed.

Real-world durability of naturally aspirated 4G63 engines is impressive, with many examples exceeding 250,000 miles with basic maintenance. The engine’s robust construction allows it to continue operating even when oil change intervals are extended or other maintenance is deferred.

The conservative tuning and lower stress levels compared to turbocharged applications contribute to its longevity and reliability. Maintenance requirements remain manageable despite the more complex valve train.

Regular oil changes, timing belt replacement every 60,000-90,000 miles depending on the application, and basic tune-ups keep these engines running well.

The valve adjustment procedure, while more involved than engines with hydraulic lifters, isn’t overly complex for competent mechanics. Parts availability varies by application, but generally remains adequate for common models.

The naturally aspirated 4G63 provides good power output for its displacement, typically producing 120-140 horsepower depending on the specific application and year.

The engine’s smooth operation and linear power delivery make it well-suited for daily driving applications, while its robust construction ensures long-term reliability with basic care.

5 Engines That Need Constant Care

These catastrophically intolerant power plants suffer from fundamental over-engineering, including tight manufacturing tolerances and sophisticated systems, which create perfect conditions for expensive failures when maintenance schedules are compromised even slightly.

Their precision construction shows in razor-thin bearing clearances that are immune to minor oil degradation, complex variable valve timing systems that jam from oil, and direct injection components that clog permanently from low-quality fuel.

These engines represent the unfortunate intersection of cutting-edge technology and profit-maximizing service requirements, creating powerplants that transform routine maintenance into financial emergencies while punishing owners who cannot afford constant premium care, often resulting in catastrophic failures that exceed the vehicle’s total value within the first few years of ownership.

1. BMW N54 Twin-Turbo (2006-2016)

BMW’s N54 engine represents the pinnacle of performance engineering, delivering impressive power and refinement through sophisticated twin-turbocharged technology.

However, this 3.0-liter inline-six also exemplifies the high-maintenance requirements that often accompany cutting-edge automotive engineering, demanding meticulous care and regular attention to maintain optimal performance and reliability.

The N54’s complex architecture includes numerous advanced systems that require precise maintenance. The twin-turbocharger setup uses wastegate-controlled boost regulation, high-pressure fuel injection operating at over 2,000 PSI, variable valve timing on both intake and exhaust camshafts, and a sophisticated engine management system that monitors dozens of parameters.

Each of these systems introduces potential failure points and specific maintenance requirements that cannot be ignored without consequences. Carbon buildup on intake valves represents one of the N54’s most significant maintenance challenges.

The direct injection system, while improving performance and efficiency, prevents fuel from washing over intake valves as in traditional port injection systems.

This results in carbon deposits that accumulate over time, requiring professional cleaning services every 30,000-50,000 miles. Neglecting this maintenance leads to reduced performance, rough idle, and potential engine damage.

The high-pressure fuel pump, a critical component in the direct injection system, is particularly sensitive to fuel quality and maintenance schedules.

These pumps frequently fail when maintenance is deferred, leading to expensive repairs and potential engine damage. The turbocharger wastegates, initially problematic in early production, require specific oil specifications and change intervals to prevent premature failure.

Using incorrect oil or extending change intervals often results in wastegate rattle and expensive turbocharger replacements. Cooling system maintenance proves critical for N54 longevity.

The engine requires full synthetic oil meeting specific BMW specifications, and many owners find that 5,000-7,500 mile intervals provide better long-term reliability. The oil changes must be performed precisely, as overfilling or underfilling can cause turbocharger damage or engine problems.

Despite these maintenance demands, properly maintained N54 engines provide exceptional performance and refinement. The twin-turbo configuration produces smooth, linear power delivery with minimal turbo lag, while the sophisticated engine management system optimizes performance across all operating conditions.

However, the complexity and precision required for proper maintenance make this engine unsuitable for owners seeking low-maintenance operation.

2. Audi 2.7T Bi-Turbo (1999-2005)

Audi’s 2.7-liter bi-turbo V6 engine stands as one of the most technologically advanced and simultaneously maintenance-intensive engines of its era.

Featured in high-performance models like the S4 and Allroad, this engine delivers exceptional power and sophistication but demands religious adherence to maintenance schedules and procedures that brook no compromise or neglect.

The 2.7T’s complexity begins with its twin-turbocharger configuration mounted in the valley between the cylinder banks. This packaging creates exceptional performance characteristics but also generates intense heat and makes routine maintenance significantly more challenging.

The turbos are cooled by both oil and coolant systems, creating multiple points of failure if maintenance is neglected. The intricate maze of vacuum lines, intercooler plumbing, and boost control systems requires constant attention to prevent leaks that can cause performance problems or engine damage.

Carbon buildup represents a persistent challenge for 2.7T engines, particularly in the intake manifold and on valve surfaces. The engine’s aggressive tuning and high operating temperatures accelerate carbon formation, requiring regular cleaning services that can cost thousands of dollars. Neglecting carbon cleaning leads to reduced performance, increased emissions, and potential engine knock that can cause serious internal damage.

The 2.7T’s timing belt system demands absolute adherence to replacement intervals. Unlike many engines, where timing belt failure results in inconvenience, the 2.7T is an interference engine where belt failure typically causes catastrophic valve and piston damage requiring complete engine rebuilding.

The timing belt service interval of 75,000 miles cannot be extended without risking expensive engine damage, and the service requires removing significant portions of the engine bay components.

Cooling system maintenance proves critical and complex for the 2.7T. The engine features multiple cooling circuits serving the block, heads, turbos, and intercoolers.

The system includes various pumps, thermostats, and control modules that must function perfectly to prevent overheating. Coolant changes require specific procedures to properly bleed air from the complex system, and using incorrect coolant specifications can cause corrosion and component failure.

Oil system maintenance demands exceed those of naturally aspirated engines due to the turbocharger requirements. The 2.7T requires full synthetic oil meeting strict Audi specifications, with many experts recommending 5,000-mile change intervals despite Audi’s longer official recommendations.

The oil must maintain specific viscosity characteristics under extreme heat and pressure conditions. Oil pump failure, while relatively uncommon, can cause immediate and catastrophic engine damage.

Despite these intensive maintenance requirements, properly maintained 2.7T engines provide exceptional performance and driving satisfaction. The bi-turbo configuration delivers tremendous torque across a wide rpm range, while the sophisticated engine management system provides impressive refinement and efficiency for its performance level.

3. Porsche M96/M97 Flat-Six (1997-2008)

Porsche’s M96 and M97 flat-six engines represent the marque’s attempt to modernize its traditional air-cooled formula with water cooling and increased displacement.

While these 3.4 to 3.8-liter engines provide impressive performance and the distinctive Porsche sound, they also require meticulous maintenance and suffer from several well-documented issues that make them unsuitable for casual ownership or maintenance neglect.

The M96/M97’s most notorious problem is intermediate shaft bearing failure, a design flaw that can cause catastrophic engine damage without warning. The intermediate shaft drives the oil pump and operates under high stress, particularly during cold starts and high-rpm operation.

When the bearing fails, metal debris contaminates the oil system, typically requiring complete engine rebuilding. Prevention requires religious oil change intervals with high-quality oil, avoiding extended cold-weather operation, and some owners proactively replace the bearing as preventive maintenance.

Rear main seal leakage represents another persistent issue with these engines. The seal’s design and the engine’s installation in the vehicle make replacement extremely expensive, requiring transmission removal and significant labor.

The leakage often starts gradually but can accelerate, leading to oil starvation if not monitored closely. Many owners live with minor leakage, but major leaks require immediate attention to prevent engine damage.

The air-oil separator system, designed to control crankcase emissions, requires regular maintenance and eventual replacement. When this system fails, it can cause excessive oil consumption, rough idle, and potential engine damage.

The symptoms often develop gradually, making diagnosis challenging for inexperienced technicians. Replacement requires specialized knowledge and can be expensive if performed incorrectly.

Cooling system maintenance proves critical for M96/M97 longevity. Unlike traditional air-cooled Porsche engines, these water-cooled units depend entirely on their cooling systems for temperature regulation.

The system includes multiple radiators, thermostats, and pumps that must function perfectly. Coolant changes require specific procedures and Porsche-approved coolants to prevent corrosion and component failure.

Ignition system maintenance demands premium components and frequent attention. The flat-six configuration places unique stresses on ignition components, particularly the coils and spark plugs.

The flat-six configuration offers unique sound and handling characteristics, while the water cooling provides consistent temperature regulation and improved performance compared to earlier air-cooled designs.

4. Subaru EJ25 Turbo (2002-2014)

Subaru’s turbocharged EJ25 engine, found in STI and other performance models, exemplifies the challenges of maintaining a high-performance boxer engine under extreme operating conditions.

While capable of exceptional performance and rally-proven durability when properly maintained, this 2.5-liter flat-four demands meticulous attention and cannot tolerate maintenance neglect without serious consequences.

The EJ25 turbo’s flat-four configuration creates unique maintenance challenges related to oil circulation and cooling. The horizontal cylinder layout makes oil drainage more difficult than conventional engines, often leaving residual oil in the cylinders and passages during changes.

This characteristic makes frequent oil changes even more critical, as contaminated oil cannot be completely removed during service intervals. Many experts recommend 3,000-mile oil change intervals despite Subaru’s longer official recommendations.

Head gasket failure represents the EJ25’s most notorious issue, particularly affecting certain model years and applications. The combination of turbocharging stress, aluminum heads on an iron block, and the flat-four configuration creates conditions that stress head gaskets beyond their design limits.

Prevention requires maintaining perfect cooling system function, using correct coolant specifications, avoiding overheating, and maintaining proper engine tune. When head gaskets fail, repair costs often exceed the vehicle’s value.

The turbocharger system demands exceptional maintenance attention due to the engine’s aggressive tuning and high-stress operating environment.

The turbo relies entirely on the engine’s oil system for lubrication and cooling, making oil quality and change intervals critical. Heat soak after shutdown creates extreme conditions that can carbonize oil in the turbo bearings.

Many owners install turbo timers or follow specific cooldown procedures to extend turbocharger life. Ignition system components face extreme stress in the turbocharged environment, requiring premium parts and frequent replacement.

Spark plugs require replacement every 20,000-30,000 miles with specific heat range selections based on modifications and usage. Ignition coils operate under extreme conditions and often fail prematurely when maintenance is neglected.

5. Mercedes M272 V6 (2004-2011)

Mercedes-Benz’s M272 3.0-liter and 3.5-liter V6 engines represent sophisticated European engineering that delivers impressive performance and refinement while demanding meticulous maintenance that cannot be compromised.

These engines feature advanced technologies including variable valve timing, sophisticated engine management, and precision manufacturing that requires specific maintenance procedures and premium components.

The M272’s balance shaft system represents one of its most maintenance-intensive components. The system uses gears and chains to counteract the V6 configuration’s inherent vibrations, but these components are sensitive to oil quality and maintenance intervals.

When the balance shaft chain stretches or the tensioner fails, it can cause catastrophic engine damage. Prevention requires strict adherence to oil change intervals with Mercedes-approved synthetic oil and immediate attention to any unusual engine noises.

Camshaft adjuster problems plague M272 engines, particularly those with extended maintenance intervals or poor oil quality. The variable valve timing system relies on oil pressure to operate cam position adjusters, making it extremely sensitive to oil contamination and viscosity.

When adjusters fail, they can cause timing chain damage, valve train problems, and expensive engine damage. Symptoms often develop gradually, requiring experienced technicians for proper diagnosis.

Intake manifold problems affect many M272 engines due to design flaws in the plastic manifold construction. The manifold can develop cracks or flap motor failures that affect performance and drivability. Replacement requires significant disassembly and expensive genuine Mercedes parts.

The problem is often accelerated by improper maintenance or the use of incorrect fuel additives. Carbon buildup represents a persistent issue due to the direct injection system used in later M272 variants.

Like other direct injection engines, fuel doesn’t wash over the intake valves, allowing carbon deposits to accumulate over time. Professional cleaning services are required every 30,000-40,000 miles to maintain optimal performance and prevent engine damage. The service is expensive and requires specialized equipment and procedures.

Oil system maintenance demands exceed those of most engines due to Mercedes’ complex specifications and the engine’s sophisticated variable valve timing system.

Despite these intensive maintenance requirements, properly maintained M272 engines provide exceptional refinement, performance, and efficiency. The sophisticated engineering delivers smooth operation, impressive power output, and excellent fuel economy when all systems function correctly.

Also Read: 5 Toyota Camry Years Worth Owning vs 5 That Aren’t