The cooling system is one of your vehicle’s most critical components, working tirelessly to prevent your engine from overheating and suffering catastrophic damage.

When functioning properly, this intricate network of radiators, water pumps, thermostats, hoses, and coolant maintains optimal engine temperatures under all driving conditions. However, not all vehicles are created equal when it comes to cooling system reliability.

Understanding which cars have bulletproof cooling systems and which ones are notorious for overheating can save you thousands in repair bills and prevent the frustration of roadside breakdowns.

The source of the issue could include low coolant levels, a cooling system leak, a bad radiator fan, a faulty water pump, low engine oil levels, or thermostat failure. These problems can range from minor inconveniences to engine-destroying catastrophes.

Lexus, Buick, and Mazda were rated the three most reliable car brands in the U.S. for 2025, and their cooling systems generally reflect this reliability. Meanwhile, certain models from various manufacturers have earned reputations for cooling system woes that can plague owners for years.

This comprehensive guide examines ten vehicles that represent opposite ends of the cooling system reliability spectrum. We’ll explore the engineering differences, common failure points, maintenance requirements, and real-world experiences that separate the champions from the problematic.

Whether you’re shopping for a used car or trying to understand your current vehicle’s potential issues, this analysis will help you make informed decisions about cooling system reliability and maintenance strategies.

5 Cars That Rarely Need Cooling System Work

These exceptionally engineered vehicles feature robust cooling systems and oversized thermal capacity that maintain perfect operating temperatures through hundreds of thousands of demanding miles and extreme operating conditions.

Their thoughtful construction includes large capacity radiators, heavy-duty water pumps with metal impellers, and premium hoses that resist the deterioration patterns typically created by constant thermal cycling and chemical exposure.

From mountain climbing that challenges cooling capacity to stop-and-go traffic that stresses thermal management, these remarkable vehicles continue operating at ideal temperatures without experiencing the overheating, coolant leaks, or component failures that plague lesser alternatives.

The combination of oversized components, premium materials, and conservative engineering creates cooling systems that prove their worth through maintained engine longevity and reliable operation even under the most demanding thermal stress conditions, protecting expensive internal engine components from heat-related damage.

1. Toyota Camry (1997-2001 & 2007-2017)

The Toyota Camry has earned legendary status for cooling system reliability, particularly the fourth and seventh-generation models. Toyota’s engineering philosophy prioritizes long-term durability over cutting-edge complexity, and nowhere is this more evident than in the Camry’s cooling system design.

The 2.4-liter four-cylinder and 3.5-liter V6 engines feature robust water pumps with metal impellers, oversized radiators with excellent heat dissipation, and thermostats that rarely fail prematurely.

What sets the Camry apart is Toyota’s conservative approach to cooling system components. Rather than pushing boundaries with lightweight materials or complex electronic controls, Toyota uses proven technologies with generous safety margins.

The radiator capacity is deliberately oversized for the engine’s heat output, ensuring the system never operates at maximum capacity under normal conditions. The water pump is driven by a timing belt or chain rather than complex electronic systems, reducing potential failure points significantly.

The cooling system’s layout is also remarkably serviceable. Hoses are positioned for easy access during routine maintenance, and the radiator cap is clearly visible for regular inspection.

Toyota’s choice of high-quality rubber compounds for hoses means they typically last 8-10 years before requiring replacement, compared to 5-6 years for many competitors.

The thermostat housing is designed to prevent the common cracking issues that plague other manufacturers, using thicker aluminum castings with proper thermal expansion accommodations.

Owners consistently report minimal cooling system issues, even at high mileages. Many Camrys exceed 200,000 miles with only routine coolant changes and perhaps one water pump replacement.

The original radiator often lasts the vehicle’s lifetime, a testament to Toyota’s quality control and material choices. When problems do occur, they’re typically predictable wear items rather than catastrophic failures, giving owners warning signs and time to address issues before major damage occurs.

The secret to the Camry’s cooling system success lies in Toyota’s extensive real-world testing program. Before any cooling system component reaches production, it undergoes thousands of hours of testing in extreme conditions, from Arizona desert heat to Minnesota winter cold.

This rigorous validation process eliminates marginal designs before they can cause customer problems, resulting in cooling systems that consistently exceed their design lifespan.

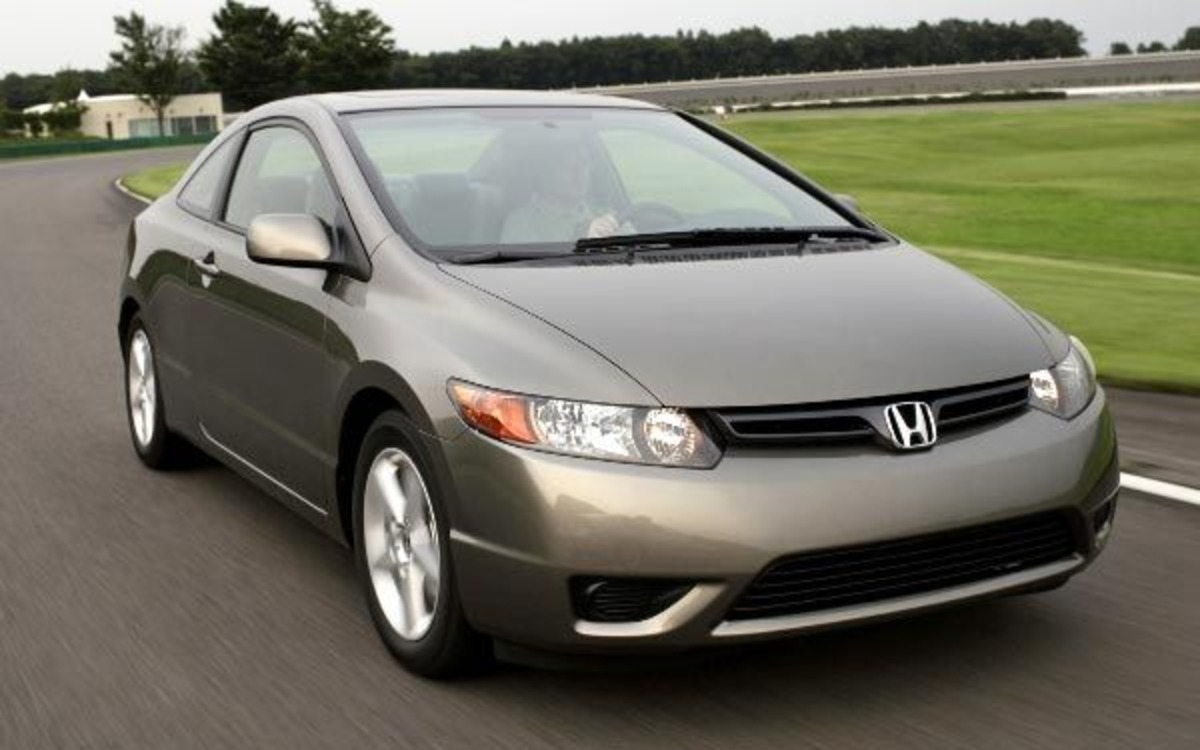

2. Honda Civic (2006-2015)

Honda’s eighth and ninth-generation Civic models represent the pinnacle of reliable cooling system engineering, combining Japanese precision manufacturing with practical design philosophy.

The 1.8-liter R18 engine and its cooling system were developed together as an integrated system, ensuring optimal compatibility and longevity. Honda’s approach emphasizes simplicity and redundancy, creating cooling systems that rarely fail and are inexpensive to maintain when they do require service.

The Civic’s cooling system features several innovative design elements that contribute to its exceptional reliability. The radiator uses a cross-flow design with aluminum construction and plastic tanks, but Honda’s manufacturing process ensures the plastic-to-metal joints remain leak-free for decades.

The cooling fans are electronically controlled with multiple speed settings, allowing precise temperature management while reducing system stress. This smart fan control prevents the common cycling failures that plague single-speed fan systems.

Honda’s water pump design deserves particular recognition for its longevity. Unlike many manufacturers who use plastic impellers to reduce costs, Honda employs metal impellers with precision-machined surfaces that resist cavitation and erosion.

The pump shaft runs on high-quality bearings with extended-life seals, typically lasting 150,000-200,000 miles before requiring replacement. When replacement is necessary, Honda’s modular design makes the job straightforward and affordable.

The thermostat system represents another area where Honda’s engineering excellence shines. Rather than using the industry-standard single thermostat, the Civic employs a dual-thermostat setup that provides redundancy and more precise temperature control.

If one thermostat fails, the system continues operating normally while providing diagnostic codes to alert the driver. This fail-safe approach has virtually eliminated thermostat-related overheating incidents in these model years.

Real-world reliability data support the Civic’s reputation for cooling system dependability. Independent surveys consistently rank the 2006-2015 Civic among the top vehicles for cooling system reliability, with fewer than 2% of owners reporting significant cooling system repairs during the first ten years of ownership.

Many owners report completing their vehicle’s entire service life with nothing more than routine coolant changes and perhaps one water pump replacement near the end of the vehicle’s useful life.

3. Lexus ES 350 (2007-2018)

The Lexus ES 350 represents the luxury segment’s gold standard for cooling system reliability, combining Toyota’s proven engineering with premium materials and meticulous quality control.

Built on the same platform as the Toyota Camry but with enhanced components and more stringent manufacturing tolerances, the ES 350’s cooling system delivers exceptional performance with minimal maintenance requirements. Lexus owners expect perfection, and the cooling system consistently delivers with failure rates well below industry averages.

Lexus employs premium materials throughout the cooling system that justify the vehicle’s higher price point. The radiator features all-aluminum construction with TIG-welded seams rather than the crimped joints common in mainstream vehicles.

This construction method eliminates the most common radiator failure point and ensures decades of leak-free operation. The coolant used from the factory is a long-life formula that maintains its protective properties for up to 10 years, reducing maintenance frequency and system stress.

The water pump in the ES 350 represents overengineering at its finest. Lexus uses a cast-iron pump housing with a stainless-steel impeller and high-grade ceramic seals that resist heat and chemical degradation.

The pump is driven by the timing chain rather than an accessory belt, eliminating belt-related failures while ensuring perfect timing throughout the engine’s rev range. This design choice, while more expensive to manufacture, virtually eliminates premature water pump failures.

Electronic cooling system management in the ES 350 is exceptionally sophisticated, utilizing multiple sensors and computer controls to optimize performance.

The system monitors coolant temperature, flow rate, and system pressure continuously, making micro-adjustments to fan speed, thermostat operation, and coolant circulation. This active management prevents the temperature spikes that can damage cooling system components in other vehicles, contributing significantly to the system’s longevity.

The ES 350’s cooling system also benefits from Lexus’s comprehensive pre-delivery inspection process. Every vehicle undergoes extensive cooling system testing before customer delivery, including pressure tests, thermal cycling, and computer diagnostics.

This quality control process catches marginal components before they reach customers, ensuring that only perfectly functioning systems leave the factory. Combined with Lexus’s excellent dealer service network, owners enjoy virtually trouble-free cooling system operation throughout their ownership experience.

4. Mazda CX-5 (2013-2021)

The Mazda CX-5 has quickly established itself as a leader in cooling system reliability among compact SUVs, thanks to Mazda’s SKYACTIV engineering philosophy and commitment to long-term durability.

Mazda was rated the three most reliable car brands in the U.S. for 2025, and their cooling system engineering reflects this brand excellence.

The CX-5’s 2.0-liter and 2.5-liter SKYACTIV engines feature advanced cooling systems that operate efficiently across a wide range of conditions while maintaining exceptional reliability.

Mazda’s approach to cooling system design emphasizes thermal efficiency and component longevity. The radiator is sized generously for the engine’s heat output, with additional cooling capacity built in for trailer towing and severe-duty operation.

The core design uses a high-efficiency aluminum construction with optimized fin spacing that maximizes heat transfer while minimizing pressure drop. This design reduces system stress and extends component life significantly compared to marginally sized systems common in competitive vehicles.

The water pump represents one of the CX-5’s strongest reliability features. Mazda engineered a chain-driven pump with a cast aluminum housing and precision-balanced impeller that operates quietly and efficiently throughout its service life.

The pump’s bearing assembly uses high-quality Japanese components with extended-life seals that typically last 200,000+ miles. When replacement eventually becomes necessary, Mazda’s modular design makes the job straightforward and cost-effective.

Electronic cooling system controls in the CX-5 demonstrate Mazda’s attention to system optimization. The cooling fans operate on variable speed control rather than simple on/off cycling, reducing electrical loads and mechanical stress while providing precise temperature management.

The system includes smart diagnostics that can detect developing problems early, allowing preventive maintenance rather than emergency repairs. This proactive approach has virtually eliminated catastrophic cooling system failures in these model years.

Real-world performance data confirms the CX-5’s cooling system excellence. Owner surveys consistently show cooling system satisfaction rates above 95%, with most reported issues being minor items like coolant level sensors rather than major component failures.

Many CX-5 owners report completing their lease or financing periods without any cooling system work beyond routine coolant changes, a remarkable achievement in today’s complex automotive environment.

Also Read: 5 Plug-In Hybrids That Outlast Rivals vs 5 That Constantly Break

5. Subaru Forester (2014-2018)

The fourth-generation Subaru Forester has earned recognition for exceptional cooling system reliability, particularly impressive given Subaru’s historically challenging cooling system reputation in earlier models.

Subaru’s Symmetrical AWD system is one of the best in the game, and the cooling system engineering supports this all-weather capability with robust performance in extreme conditions.

The 2.5-liter naturally aspirated boxer engine features a redesigned cooling system that addresses previous Subaru weaknesses while maintaining the brand’s signature durability.

Subaru completely redesigned the Forester’s cooling system for the 2014 model year, incorporating lessons learned from previous generations’ weaknesses.

The new system features an enlarged radiator with improved airflow design and more efficient heat exchanger cores. The horizontally-opposed engine layout, while presenting unique cooling challenges, allows for superior weight distribution and a lower center of gravity that benefits handling and stability.

The water pump design represents a significant improvement over earlier Subaru units. The new pump features a reinforced housing with better sealing and a redesigned impeller that improves coolant flow while reducing cavitation.

Subaru addressed the head gasket issues that plagued earlier models with improved gasket materials and updated engine machining processes. These changes have virtually eliminated the head gasket failures that gave Subaru a poor cooling system reputation in the past.

Electronic cooling system management includes sophisticated all-wheel-drive integration that monitors drivetrain temperatures and adjusts cooling accordingly.

This system prevents overheating during severe-duty operation, like climbing mountain passes or towing, situations where AWD vehicles generate additional heat.

The cooling fans are programmed with specific strategies for different driving conditions, ensuring optimal temperature management regardless of the operating environment.

The Forester’s cooling system also benefits from Subaru’s extensive cold-weather testing program. Given the brand’s popularity in harsh climates, the cooling system is designed to function perfectly in extreme cold while providing rapid warm-up for passenger comfort.

The system includes features like engine block heater provisions and cold-weather optimized coolant formulations that maintain fluidity at extremely low temperatures while providing excellent high-temperature protection.

5 Cars That Always Overheat

These catastrophically unreliable vehicles suffer from fundamental under-engineering in their cooling systems, including inadequate radiator capacity and cheap components that create perfect conditions for chronic overheating under normal operating conditions.

Their cost-cutting construction shows in undersized radiators that cannot handle routine thermal loads, plastic water pumps with impellers that disintegrate from normal use, and cheap hoses that crack and leak within years of service.

Poor coolant routing creates hot spots that accelerate component degradation, while insufficient cooling capacity means these vehicles operate dangerously close to overheating temperatures even during normal driving conditions.

These cars represent the unfortunate consequences of aggressive cost-cutting in critical engine protection systems, creating vehicles where routine driving becomes anxiety-inducing due to constant temperature monitoring and the ever-present threat of catastrophic overheating that can destroy entire engines, leaving owners facing repair bills that often exceed vehicle value.

1. BMW 3 Series (2006-2013)

The BMW 3 Series from this era has become notorious among automotive technicians and owners for persistent cooling system problems that can plague the vehicle throughout its ownership cycle.

While BMW’s engineering creates impressive performance and luxury, the cooling system represents a significant weakness that has cost owners thousands in repairs and created a thriving aftermarket for cooling system components.

The issues stem from BMW’s pursuit of lightweight construction and complex electronic integration that prioritizes performance over long-term reliability.

BMW’s cooling system problems begin with the extensive use of plastic components in critical areas. The radiator uses plastic tanks that become brittle with age and thermal cycling, leading to catastrophic failures often without warning.

The plastic expansion tank is particularly problematic, with the mounting tabs and seams frequently cracking and causing coolant loss. These plastic components are designed to last the warranty period, but often fail shortly after, creating expensive repair bills for owners.

The water pump represents the most notorious failure point in the BMW cooling system. BMW uses an electronically-controlled electric water pump that, while sophisticated, has proven unreliable in real-world conditions.

The pump’s electronic control module is sensitive to voltage fluctuations and overheating, often failing between 60,000 and 80,000 miles. When the pump fails, it typically does so catastrophically, leaving drivers stranded and potentially causing engine damage if not immediately addressed.

The thermostat system adds another layer of complexity and potential failure. BMW uses an electronically-controlled thermostat that’s integrated with the engine management system.

While this provides precise temperature control, it also creates additional failure modes. The electronic thermostat can fail in either open or closed positions, and replacement requires specialized diagnostic equipment and programming.

Many independent repair shops cannot properly service these systems, forcing owners to expensive dealer repairs. BMW’s cooling system design also suffers from poor serviceability.

Many components require extensive disassembly to access, turning routine maintenance into expensive repairs. The cooling system bleed procedure is complex and requires special tools, often leading to improper service that creates air pockets and subsequent overheating.

These design choices reflect BMW’s focus on new-car performance rather than long-term owner satisfaction, creating vehicles that become expensive to maintain as they age.

2. Range Rover Evoque (2012-2019)

The Range Rover Evoque has earned an unfortunate reputation for cooling system reliability issues that can begin early in the vehicle’s life and continue throughout ownership.

Land Rover’s pursuit of sophisticated luxury and compact packaging has created a cooling system that operates at the limits of its capacity, with minimal redundancy and complex electronic controls that frequently malfunction. These problems are particularly frustrating given the vehicle’s premium price point and luxury positioning.

The Evoque’s primary cooling system weakness stems from inadequate radiator capacity for the turbocharged engines’ heat output. Land Rover prioritized aerodynamic styling over cooling efficiency, resulting in a radiator that’s marginally sized for the engine’s needs.

Under heavy load conditions or in hot weather, the system operates at maximum capacity with no safety margin. This constant high-stress operation accelerates component wear and increases the likelihood of overheating incidents.

The turbocharger cooling system adds significant complexity and additional failure points. The Evoque uses a sophisticated intercooler system that requires precise coolant flow and temperature control.

The electronic controls that manage this system are prone to software glitches and sensor failures that can cause erratic cooling performance. When these systems malfunction, the symptoms can be intermittent and difficult to diagnose, leading to expensive diagnostic fees and multiple repair attempts.

Electronic cooling system controls in the Evoque represent both sophistication and fragility. The system uses multiple temperature sensors, electronic thermostats, and computer-controlled fan speeds that require constant communication with the vehicle’s central computer systems.

When any component in this network fails, it can trigger cascade failures that disable multiple systems simultaneously. The complexity makes field repairs nearly impossible and often requires expensive dealer diagnostics to properly identify problems.

The water pump system presents another significant reliability concern. Land Rover uses an electric auxiliary water pump in addition to the mechanical primary pump, creating two potential failure points instead of one.

The auxiliary pump is particularly prone to failure, often due to electrical issues or internal seal degradation. When either pump fails, the cooling system’s capacity is severely compromised, leading to overheating and potential engine damage if not immediately addressed.

3. Jeep Grand Cherokee (2011-2016)

The Jeep Grand Cherokee from this generation has developed a troubling reputation for cooling system problems that can begin early and persist throughout the vehicle’s life.

Chrysler’s cost-cutting measures and complex engine options have created cooling systems that are prone to multiple failure modes, often leaving owners with expensive repair bills and unreliable transportation.

The problems are particularly severe with the V6 and V8 engine options, where inadequate cooling capacity meets demanding performance requirements.

The most notorious issue involves the cooling system’s plastic components, particularly the radiator and expansion tank. Chrysler uses low-grade plastic materials that become brittle with age and thermal stress, leading to sudden failures that can strand drivers without warning.

The radiator’s plastic tanks are particularly problematic, often cracking along seam lines or where mounting brackets attach. These failures typically occur between 50,000 and 80,000 miles, well before owners expect major cooling system work.

The water pump represents another significant failure point, with design weaknesses that lead to premature failure. The pump uses plastic impellers that can crack or lose blades, causing catastrophic coolant circulation failure.

The pump housing also suffers from porosity issues that can cause external leaks and internal passage erosion. When the water pump fails, it often does so suddenly, creating emergency repair situations that can result in engine damage if not immediately addressed.

Electronic cooling system controls add layers of complexity that increase failure potential without corresponding reliability benefits. The Grand Cherokee uses electronic thermostats and computer-controlled cooling fans that require constant communication with the vehicle’s central computers.

These systems are prone to software glitches, sensor failures, and electrical problems that can cause erratic cooling performance. The diagnostic complexity often leads to misdiagnosis and unnecessary component replacement, inflating repair costs significantly.

The cooling system’s design also suffers from poor maintenance accessibility. Many components require extensive disassembly to reach, turning routine service into expensive repairs.

The coolant drain locations are poorly positioned, making complete system flushes difficult and often incomplete. This maintenance difficulty leads to poor service quality and accelerated component wear, creating a cycle of reliability problems that can persist throughout the vehicle’s ownership.

4. Volkswagen Jetta (2005-2014)

The Volkswagen Jetta from this era has become synonymous with cooling system reliability problems that can plague owners throughout their ownership experience.

VW’s pursuit of advanced technology and cost reduction has created cooling systems that feature sophisticated designs with poor execution, leading to frequent failures and expensive repairs. The problems span multiple engine options but are particularly severe with the turbocharged variants that generate additional heat stress.

Volkswagen’s cooling system problems begin with the extensive use of plastic components in critical applications. The radiator features plastic tanks that are joined to aluminum cores using crimped seams that frequently fail with age and thermal cycling.

The plastic becomes brittle over time, leading to sudden catastrophic failures that can leave drivers stranded. The expansion tank is similarly problematic, with mounting brackets and internal baffles that crack and cause coolant loss.

The water pump system represents one of the Jetta’s most notorious reliability issues. VW uses a timing belt-driven water pump that, while mechanically simple, suffers from poor component quality and inadequate sealing.

The pump’s impeller can separate from the shaft, causing complete coolant circulation failure and immediate overheating. The timing belt integration means water pump failure can also cause catastrophic engine damage if the belt breaks or jumps timing.

Electronic cooling system controls add unnecessary complexity without corresponding reliability benefits. The Jetta uses electronic thermostats and computer-controlled cooling fans that are prone to electrical failures and software glitches.

The temperature sensors are particularly problematic, often providing erratic readings that cause the engine management system to make inappropriate cooling decisions. These electronic failures can be difficult to diagnose and often require expensive dealer equipment to properly service.

The cooling system’s design also suffers from poor real-world engineering. The radiator is sized marginally for the engine’s heat output, with no safety margin for extreme conditions or component degradation.

The coolant passages in the engine are prone to scaling and corrosion, particularly in areas with hard water. VW’s specified coolant intervals are too long for real-world conditions, leading to coolant degradation and system damage that could be prevented with more frequent service.

5. Nissan Altima (2013-2018)

The Nissan Altima from this generation has developed a concerning reputation for cooling system problems that can begin early in the vehicle’s life and escalate throughout ownership.

Nissan’s cost-reduction efforts and complex CVT transmission integration have created cooling systems that operate at the margins of their design capacity while incorporating failure-prone components. The problems are particularly severe in hot climates where the cooling system operates under constant stress.

The primary cooling system weakness involves the radiator design and construction quality. Nissan uses aluminum radiators with plastic tanks that are prone to cracking along seam lines and mounting points.

The plastic formulation appears inadequate for long-term thermal cycling, becoming brittle after just a few years of service. When these tanks fail, they typically do so catastrophically, causing complete coolant loss and potential engine damage if not immediately addressed.

The CVT transmission cooling system adds significant complexity and heat load to the cooling package. The continuously variable transmission generates substantial heat that must be dissipated through the main cooling system, often overwhelming the radiator’s capacity in stop-and-go traffic or hot weather conditions.

The CVT cooler is prone to internal leaks that can contaminate the engine cooling system with transmission fluid, creating expensive repair scenarios that require complete system flushes and component replacement.

Electronic cooling system controls represent another significant failure point. The Altima uses computer-controlled cooling fans with variable speed operation that’s managed by the engine control module.

These systems are prone to software glitches and electrical failures that can cause erratic fan operation or complete cooling system failure. The diagnostic complexity often leads to misdiagnosis and multiple repair attempts before the actual problem is identified and corrected.

The water pump design incorporates cost-reduction measures that compromise long-term reliability. Nissan uses a plastic impeller water pump with minimal bearing support and inadequate sealing.

The pump is driven by the timing chain, which creates additional mechanical stress and increases the likelihood of catastrophic failure. When the water pump fails, it can cause chain timing issues that result in expensive engine damage, making timely replacement critical but often overlooked until failure occurs.

Also Read: 5 Honda Accord Years That Run Forever vs 5 That Don’t