The debate between regular and premium gasoline has been a contentious topic among car owners for decades, often confusing the pump and causing anxiety about potential engine damage.

With premium fuel costing anywhere from 30 to 50 cents more per gallon than regular unleaded, the decision between the two can significantly impact your wallet over time.

For drivers filling up weekly, this difference can translate to hundreds of dollars annually, making it crucial to understand whether your engine truly requires premium fuel or if you’re simply wasting money on unnecessary octane.

The fundamental difference between regular and premium gasoline lies in the octane rating, which measures the fuel’s resistance to premature detonation or “knocking” inside the engine cylinder.

Regular gasoline typically has an octane rating of 87, while premium fuel ranges from 91 to 94, depending on your location. This higher octane rating doesn’t mean premium fuel contains more energy or will make your car faster rather, it simply resists compression better before igniting, which is essential for certain high-performance and high-compression engines.

In this comprehensive guide, we’ll explore five engines that perform perfectly well on regular unleaded gasoline, demonstrating that higher octane isn’t always necessary for reliable, efficient operation.

These engines represent thoughtful engineering that balances performance with practicality, allowing owners to save money without sacrificing reliability.

Then we’ll examine five engines that absolutely require premium fuel, where using regular gasoline can lead to performance degradation, inefficiency, or even mechanical failure.

Whether you’re shopping for a new vehicle or questioning your current car’s fuel requirements, understanding these distinctions will help you make informed decisions that protect both your engine and your budget.

5 Engines That Don’t Mind Cheap Gas

These exceptionally engineered powertrains feature naturally aspirated designs with conservative compression ratios, robust knock detection systems, and combustion chamber geometries that tolerate regular-grade fuel without developing detonation or performance degradation throughout their operational life.

Their thoughtful engineering includes piston crown designs minimizing hot spots that trigger pre-ignition, ignition timing maps programmed with adequate safety margins preventing knock under varying fuel quality, and port fuel injection systems that cool intake charges effectively while distributing fuel evenly across all cylinders.

From budget fuel stations with questionable octane ratings to ethanol blends that reduce effective octane numbers, these remarkable engines continue running smoothly without developing spark knock, carbon buildup, or long-term damage from lower-grade fuel usage.

Owners report hundreds of thousands of miles using regular fuel, a testament to flexible engine management adapting timing automatically, durable internal components withstanding occasional light detonation, and design philosophies prioritizing real-world fuel flexibility that prove their worth through reliable operation and reduced ownership costs throughout extended service life.

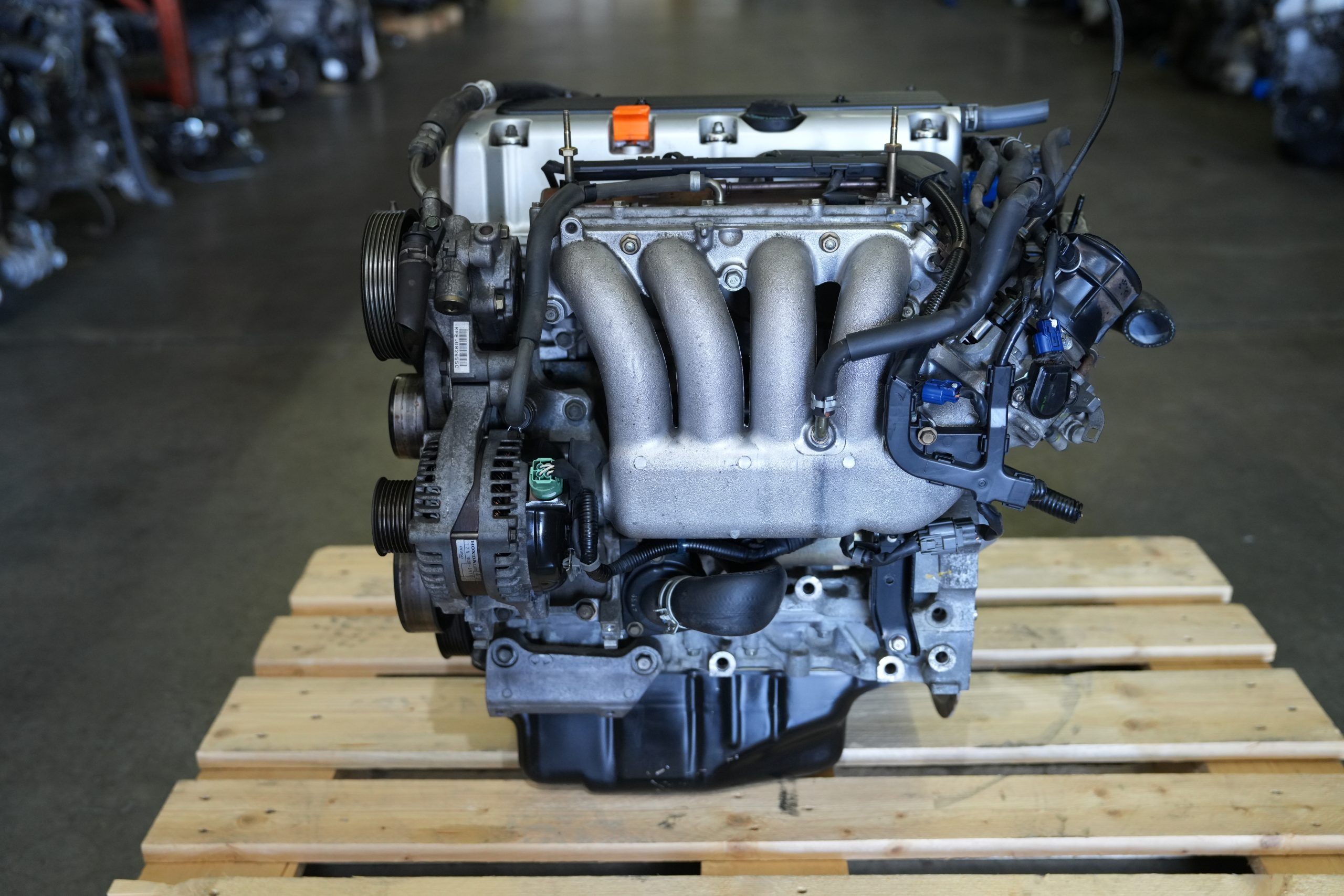

1. Honda 2.4L K24 Engine

The Honda K24 engine stands as a testament to efficient engineering that prioritizes reliability and real-world usability over unnecessary complexity. Found in popular models like the Honda Accord, CR-V, and Acura TSX, this naturally aspirated four-cylinder engine has earned a reputation for exceptional longevity while running happily on regular 87-octane gasoline.

The K24’s success with cheaper fuel stems from its conservative compression ratio of approximately 9.7:1 to 10.5:1, depending on the specific variant, which falls well within the safe operating parameters for regular unleaded fuel.

Honda’s engineering philosophy with the K24 focused on creating an engine that delivers adequate power, typically between 166 and 201 horsepower without requiring the high compression ratios that necessitate premium fuel.

The engine’s design incorporates Honda’s i-VTEC variable valve timing system, which optimizes performance across the RPM range while maintaining efficiency with regular gasoline.

This intelligent valve control allows the engine to adjust its breathing characteristics based on driving conditions, extracting respectable performance from lower-octane fuel without the risk of detonation.

One of the K24’s greatest strengths is its sophisticated engine management system that continuously monitors combustion conditions.

While the engine doesn’t require premium fuel, it can detect and adapt to different fuel qualities, making minor adjustments to ignition timing and fuel delivery to optimize performance regardless of what you pump into the tank.

This flexibility means that even if you occasionally use mid-grade or premium fuel, you won’t see dramatic performance improvements; the engine is already optimized for regular gasoline operation.

The K24’s aluminum block construction and efficient combustion chamber design contribute to its thermal management capabilities, allowing it to run cool and clean on regular fuel without excessive carbon buildup or hot spots that could trigger pre-ignition.

The engine’s relatively large displacement of 2.4 liters means it doesn’t need to work as hard as smaller, more stressed engines to produce adequate power, reducing the likelihood of knock and allowing for comfortable operation with lower-octane fuel.

Real-world experience from hundreds of thousands of K24 owners confirms that this engine can easily surpass 200,000 miles on a steady diet of regular gasoline, with many examples exceeding 300,000 miles without major mechanical issues.

The engine’s oil consumption remains minimal, and its timing chain design eliminates the maintenance concerns associated with timing belts.

Mechanics consistently report that K24 engines show minimal wear even after extensive use with regular fuel, with clean combustion chambers and healthy cylinder walls.

From an economic perspective, the K24 engine offers substantial savings over its lifetime. Consider that driving 15,000 miles annually at 28 miles per gallon requires approximately 536 gallons of fuel.

At a 40-cent-per-gallon difference between regular and premium, that’s over $200 in annual savings money that accumulates to well over $2,000 during a typical ten-year ownership period. The K24 proves that you don’t sacrifice reliability or reasonable performance by choosing an engine designed for regular fuel.

Honda’s decision to engineer the K24 for regular gasoline also reflects a customer-centric approach to vehicle design. By not requiring premium fuel, Honda made vehicle ownership more accessible and predictable for budget-conscious buyers who want reliable transportation without hidden costs.

The K24 engine demonstrates that proper engineering with appropriate compression ratios, effective cooling, and intelligent engine management can deliver satisfying performance and exceptional durability on regular unleaded gasoline, making it an ideal choice for practical daily drivers who value long-term value over maximum performance.

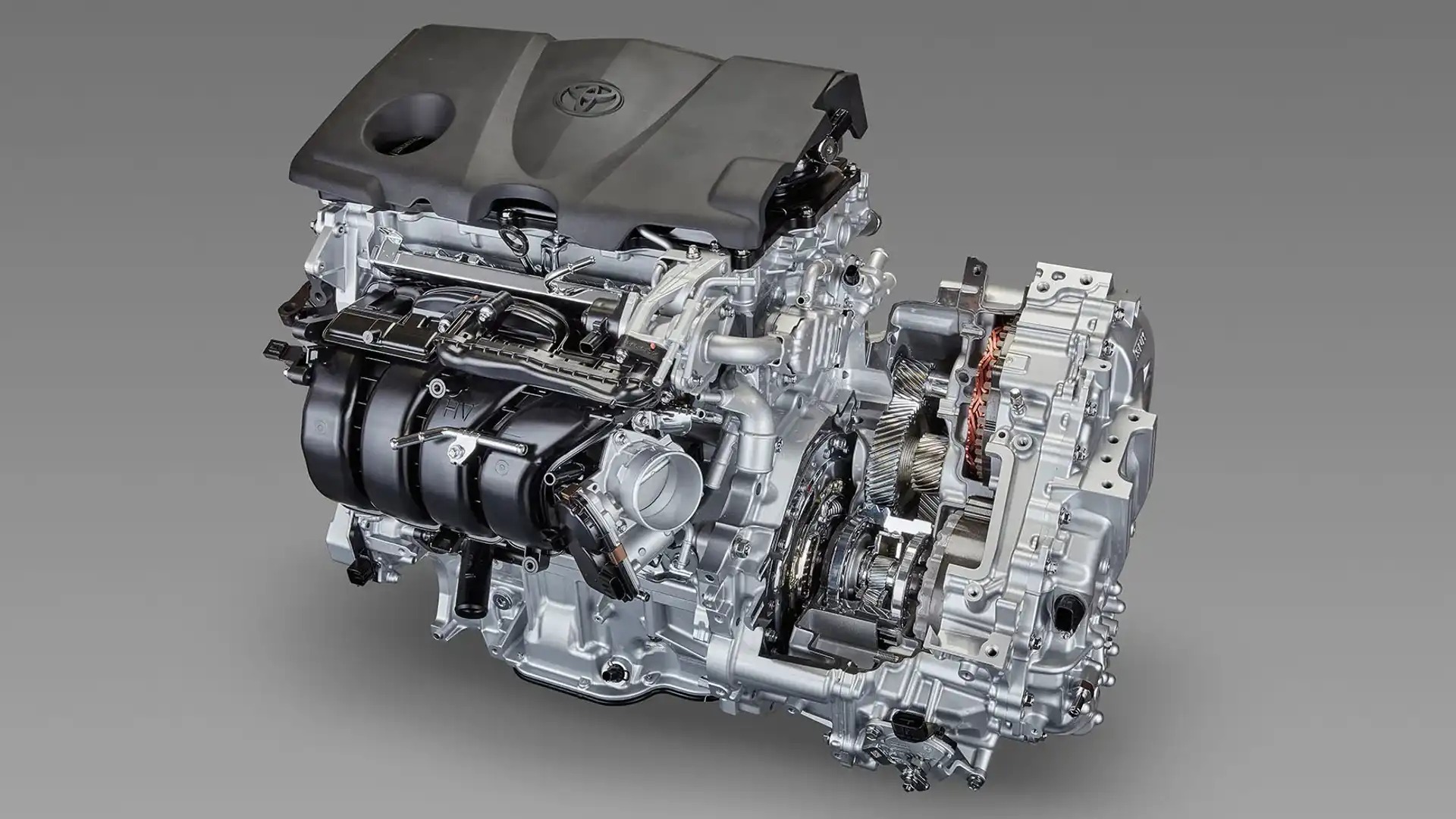

2. Toyota 2.5L Dynamic Force Engine

Toyota’s 2.5-liter Dynamic Force engine represents the pinnacle of naturally aspirated engine design for mainstream vehicles, proving that thermal efficiency and regular gasoline compatibility can coexist harmoniously.

Introduced in recent generations of the Camry, RAV4, and Highlander, this engine achieves an impressive 40-41% thermal efficiency while operating perfectly on 87-octane regular unleaded fuel a remarkable achievement that showcases Toyota’s commitment to practical, cost-effective engineering for everyday consumers.

The Dynamic Force engine’s ability to thrive on regular gasoline despite its relatively high compression ratio of approximately 13:1 might seem counterintuitive, but Toyota employed several ingenious technologies to prevent knock with lower-octane fuel.

The engine features a uniquely designed combustion chamber with a long stroke and large bore that promotes efficient flame propagation, reducing the likelihood of end-gas auto-ignition that causes knock.

Additionally, the direct fuel injection system precisely controls fuel delivery timing and spray patterns, cooling the combustion chamber charge and preventing premature detonation even with regular gasoline.

Toyota’s variable valve timing system on both intake and exhaust sides (Dual VVT-i) plays a crucial role in optimizing combustion with regular fuel.

By adjusting valve overlap and timing based on load and RPM, the engine can modify its effective compression ratio dynamically, reducing cylinder pressure when conditions might otherwise favor knock.

This intelligent management allows the engine to maintain its high geometric compression ratio for efficiency while protecting against detonation when using regular gasoline under various driving conditions.

The engine produces between 203 and 206 horsepower, depending on application, which represents excellent output from a naturally aspirated 2.5-liter engine running on regular fuel.

This power delivery comes with exceptional fuel economy, with many variants achieving over 30 mpg combined efficiency that would be compromised if the engine required the higher cost of premium fuel.

Toyota’s engineering team specifically targeted regular gasoline compatibility during the development phase, recognizing that fuel costs significantly impact total ownership expenses for mainstream buyers.

The economic advantage of running regular gasoline in a fuel-efficient engine like the Dynamic Force compounds over time. With combined fuel economy approaching 32 mpg in many applications, the annual fuel consumption for typical driving is lower than less efficient engines, and using regular rather than premium fuel amplifies these savings.

This dual benefit, excellent efficiency and regular fuel compatibility, makes the Dynamic Force engine an economically rational choice for value-conscious consumers who refuse to compromise on modern performance and refinement.

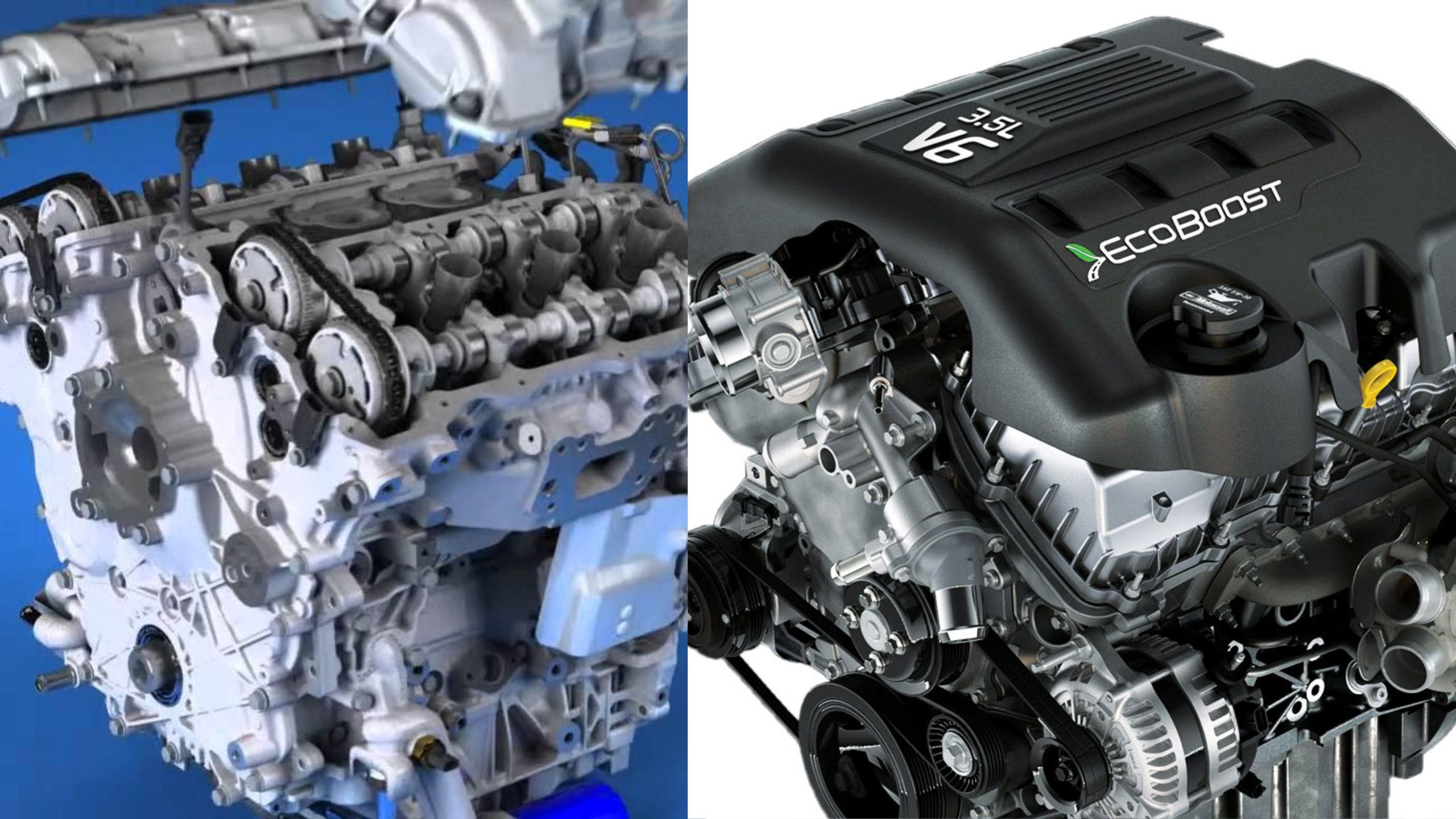

3. Ford 3.5L Ti-VCT V6 Engine

Ford’s 3.5-liter Duratec Ti-VCT V6 engine, found in vehicles like the Ford F-150 (naturally aspirated version), Explorer, and Flex, exemplifies how traditional engine architecture can deliver robust performance on regular gasoline when properly engineered.

This naturally aspirated V6 produces between 280 and 290 horsepower while running contentedly on 87-octane fuel, offering a compelling combination of smooth power delivery, proven reliability, and economical fuel requirements that make it ideal for family vehicles and light-duty truck applications.

The engine’s moderate compression ratio of approximately 10.5:1 to 11:1 represents a sweet spot for naturally aspirated engines high enough to provide good thermal efficiency and power output, but conservative enough to avoid knock issues with regular gasoline under normal operating conditions.

Ford’s Twin Independent Variable Camshaft Timing (Ti-VCT) system adjusts both intake and exhaust cam timing independently, optimizing valve overlap to improve low-end torque, midrange power, and fuel efficiency while preventing conditions that could lead to detonation with regular fuel.

One significant advantage of the naturally aspirated 3.5L V6 compared to turbocharged alternatives is its linear, predictable power delivery that doesn’t generate extreme cylinder pressures or temperatures that necessitate premium fuel.

The engine produces peak torque of around 255 lb-ft, distributed across a broad RPM range that provides excellent drivability without requiring the engine to work near its mechanical limits.

This relaxed operating character means combustion remains stable and controlled with regular gasoline, even during acceleration or when towing moderate loads.

Ford’s engine management calibration for the naturally aspirated 3.5L specifically targets regular gasoline compatibility, with ignition timing maps and fuel delivery strategies optimized for 87-octane fuel.

The knock sensor system provides backup protection, but the engine rarely needs to retard timing because its fundamental design prevents knock conditions from developing.

This proactive engineering approach building knock resistance into the engine’s architecture rather than relying solely on electronic countermeasures results in more consistent performance and better fuel economy with regular gasoline.

Ford’s decision to offer this naturally aspirated V6 alongside turbocharged EcoBoost options provides consumers a choice between maximum performance (EcoBoost with premium fuel) and practical efficiency with regular gasoline.

Many buyers find the naturally aspirated 3.5L V6 offers the optimal balance, providing adequate power for most needs without the fuel quality requirements or potential complexity of forced induction systems.

This engine proves that traditional V6 architecture remains relevant and economical for buyers prioritizing low operating costs and straightforward reliability.

4. Mazda Skyactiv-G 2.5L Engine

Mazda’s Skyactiv-G 2.5-liter four-cylinder engine represents one of the most technically advanced naturally aspirated gasoline engines available, achieving remarkable thermal efficiency while operating flawlessly on regular 87-octane fuel.

Featured in the Mazda3, Mazda6, CX-5, and CX-9 (non-turbo variants), this engine demonstrates that high compression ratios and regular gasoline compatibility aren’t mutually exclusive when sophisticated engineering solutions are properly implemented.

With compression ratios reaching 13:1 in some variants, the Skyactiv-G achieves efficiency levels approaching theoretical limits for gasoline engines while maintaining complete knock resistance with cheaper fuel.

Mazda’s engineers employed a multi-faceted approach to enable high compression with regular gasoline, starting with an exceptionally well-designed combustion chamber featuring a unique cavity shape in the piston crown that promotes rapid, controlled flame propagation.

This cavity, combined with precisely positioned fuel injectors, creates a charge stratification that prevents end-gas auto-ignition the primary cause of knock in high-compression engines.

The combustion process completes so quickly that pressure and temperature don’t reach levels where unburned fuel-air mixture would spontaneously detonate, even with regular gasoline’s lower octane rating.

The engine’s 4-2-1 exhaust system design, uncommon in modern vehicles, plays a crucial role in knock prevention by reducing exhaust gas temperature and preventing hot residual gases from remaining in the combustion chamber.

By spacing exhaust pulses from cylinders that fire consecutively, this design minimizes interference and scavenging losses, allowing cooler, denser fresh charge into the cylinders.

Cooler intake charge temperatures directly improve knock resistance, enabling the engine to safely operate at high compression ratios with regular gasoline while producing between 184 and 187 horsepower in naturally aspirated form.

Mazda’s calibration philosophy emphasizes real-world performance with regular gasoline rather than optimizing for premium fuel and compromising when lower octane is detected.

The engine management system’s base calibration assumes regular 87-octane fuel, with ignition timing and fuel delivery maps specifically developed for optimal performance with this octane rating.

This approach ensures drivers experience the engine’s full potential using regular gasoline, rather than feeling like they’re operating a compromised version of an engine designed for premium fuel.

Mazda’s Skyactiv-G engine demonstrates that through innovative combustion chamber design, intelligent thermal management, and precise calibration, naturally aspirated engines can achieve both high thermal efficiency and compatibility with regular gasoline.

This engineering achievement provides consumers with vehicles that are economical to operate, responsive to drive, and reliable over the long term, all while utilizing the most affordable gasoline available at the pump.

Also Read: 5 SUVs That Refuse to Rattle Inside vs 5 That Sound Old Too Soon

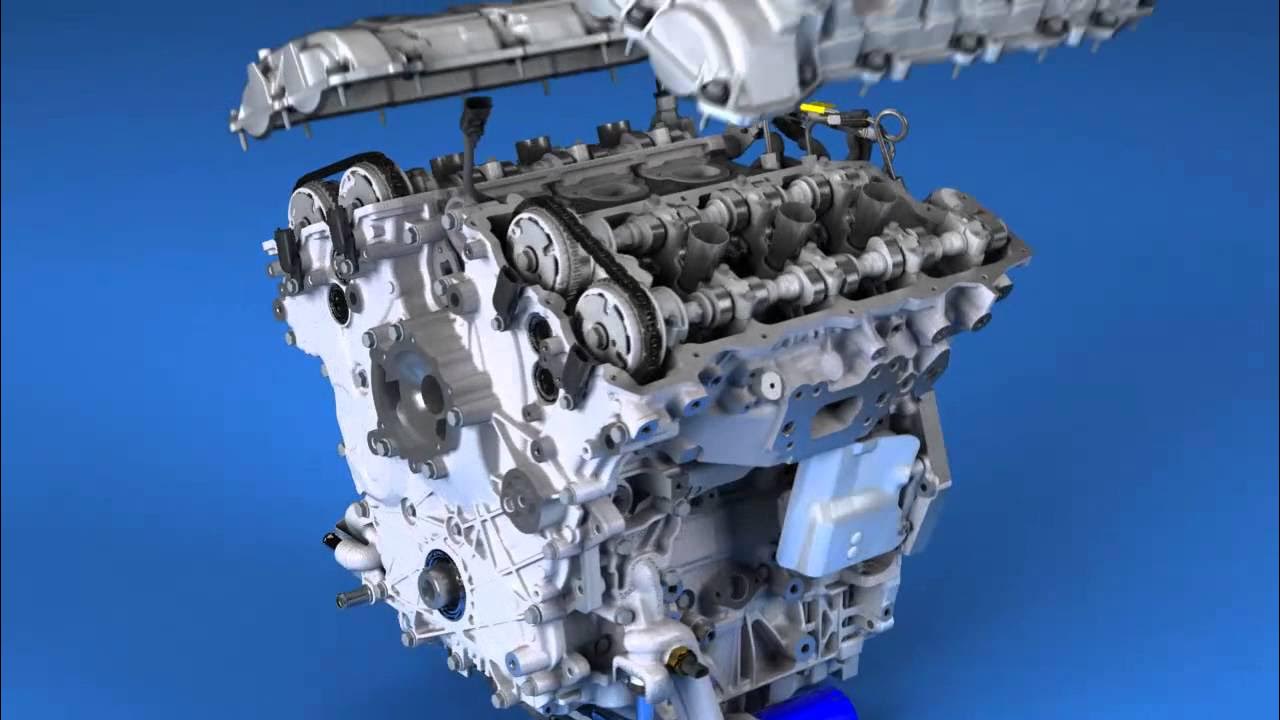

5. GM 3.6L LGX V6 Engine

General Motors’ 3.6-liter LGX V6 engine represents the evolution of GM’s highly successful high-feature V6 architecture, delivering impressive power output while operating efficiently on regular 87-octane gasoline.

Found in popular vehicles like the Chevrolet Camaro V6, Cadillac CT6, GMC Acadia, and Chevrolet Traverse, this naturally aspirated V6 produces between 305 and 335 horsepower depending on tuning, making it one of the most powerful engines that doesn’t require premium fuel.

The LGX demonstrates that sophisticated variable valve timing, direct injection, and modern engine management can extract substantial performance from regular gasoline when the fundamental engine architecture is properly designed.

The LGX engine’s compression ratio of approximately 11.5:1 represents an aggressive specification for a naturally aspirated engine designed for regular gasoline, but GM incorporated several advanced technologies that enable this combination.

The direct fuel injection system precisely controls fuel delivery timing and spray patterns, creating a charge cooling effect that reduces combustion chamber temperatures and prevents knock.

By injecting fuel directly into the cylinder during the compression stroke, the evaporating fuel absorbs heat, effectively lowering the charge temperature and increasing the fuel’s effective octane rating through this cooling effect.

GM’s Active Fuel Management (cylinder deactivation) and Variable Valve Timing on both camshafts work synergistically to optimize combustion characteristics across the engine’s operating range.

Under light loads, the system can deactivate cylinders and adjust valve timing to improve fuel economy, while under heavy acceleration, all cylinders operate with valve timing optimized for maximum power, all while maintaining knock resistance with regular gasoline.

The engine’s sophisticated control algorithms continuously adjust these parameters based on real-time conditions, ensuring optimal performance regardless of load, ambient temperature, or driving style.

The all-aluminum construction of the LGX contributes significantly to its thermal management capabilities, with the block and heads efficiently dissipating heat to prevent hot spots that could trigger detonation with regular fuel.

The engine’s cooling system features precisely controlled coolant flow patterns that prioritize cooling critical areas like the combustion chambers and exhaust valve seats, where temperatures reach their peak.

This targeted cooling strategy maintains temperatures within safe ranges for regular gasoline operation even during sustained high-load conditions like mountain driving or trailer towing.

The GM LGX V6 engine exemplifies modern naturally aspirated engine design, proving that with direct injection, sophisticated variable valve timing, and intelligent engine management, high power output and regular gasoline compatibility can coexist successfully, providing consumers with performance and efficiency without premium fuel requirements.

5 Engines That Fail Without Premium

These problematic powertrains suffer from aggressive turbocharging requiring high-octane fuel, excessive compression ratios demanding premium grades, and inadequate knock control systems that allow destructive detonation when owners attempt to use regular fuel to reduce operating costs.

Their flawed engineering includes direct-injection systems creating carbon deposits that increase compression ratios beyond design specifications, small-displacement turbocharged engines operating at extreme boost pressures, and engine management calibrations with insufficient timing retard authority to prevent knock when detecting lower octane fuels.

From piston ring land failures caused by sustained detonation to melted spark plug electrodes from pre-ignition events, these troublesome engines create catastrophic damage when fed regular fuel.

1. BMW S55 3.0L Twin-Turbo Inline-6

The BMW S55 engine, found in high-performance M models like the M3 and M4, represents the absolute pinnacle of forced induction inline-six design, producing between 425 and 503 horsepower depending on specification.

This engine absolutely requires premium 91+ octane fuel, and using regular gasoline will result in dramatically reduced performance, potential engine damage, and voided warranty coverage.

The S55’s requirement for premium fuel stems from its extreme engineering specifications: a compression ratio around 10.2:1 combined with twin turbochargers producing substantial boost pressure creates cylinder pressures that regular gasoline simply cannot withstand without detonating prematurely.

The S55’s twin-turbocharger system generates peak boost pressures approaching 18-22 psi, depending on tuning, which multiplies the effective compression ratio far beyond what regular gasoline can tolerate.

When compressed and heated by turbocharging, regular 87-octane fuel’s molecular structure becomes unstable, leading to uncontrolled detonation before the spark plug fires.

This pre-ignition creates devastating shock waves inside the cylinders that can destroy pistons, bend connecting rods, and crack cylinder heads within seconds under full-throttle conditions.

BMW’s engine management system will detect knock immediately and retard ignition timing drastically, but this protective measure reduces power output by 80-100 horsepower and increases exhaust gas temperatures to potentially damaging levels.

From a performance perspective, the S55 engine represents what’s possible when engineers design without the constraint of regular gasoline compatibility.

The engine’s specific power output of approximately 142 horsepower per liter in standard tune and over 167 hp/liter in Competition specification represents near-exotic levels of specific output, achievements made possible only through premium fuel’s superior knock resistance enabling aggressive calibration with high boost pressure and advanced ignition timing.

2. Mercedes-AMG M177/M178 4.0L Twin-Turbo V8

Mercedes-AMG’s M177 and M178 twin-turbocharged 4.0-liter V8 engines power the brand’s most prestigious performance vehicles, including the AMG GT, E63, and C63, producing between 469 and 630 horsepower depending on specification.

These engines absolutely demand premium 91+ octane fuel, with the owner’s manual explicitly warning that using regular gasoline will cause severe performance degradation and potential engine damage.

The M177/M178 engines’ requirement for premium fuel stems from their unique “hot-vee” turbocharger configuration and extreme specific output that creates combustion conditions regular gasoline cannot withstand.

The innovative hot-vee design positions both turbochargers inside the engine’s V-valley, mounted directly to the cylinder heads where exhaust temperatures exceed 1,800°F during high-load operation.

This configuration minimizes turbo lag but creates an extremely thermally challenging environment where combustion chamber temperatures reach levels that would cause regular gasoline to pre-ignite destructively.

The engine’s compression ratio of approximately 10.5:1, combined with peak boost pressures approaching 21 psi in higher-output variants, creates effective compression ratios exceeding 15:1 under boost far beyond regular gasoline’s knock resistance capabilities.

Mercedes-AMG’s calibration of the M177/M178 engines pushes performance boundaries by optimizing ignition timing for premium fuel’s superior knock resistance.

The engines use advanced knock sensors on each cylinder bank that can detect and respond to detonation within individual cylinders, but using regular gasoline forces the engine management system into constant intervention mode, retarding timing by 10-15 degrees or more to prevent engine damage.

This timing retardation causes incomplete combustion, dramatically reduced power output (sometimes exceeding 100 horsepower loss), significantly increased exhaust gas temperatures, and accelerated catalyst degradation.

The direct injection system operates at pressures exceeding 3,000 psi, with injection events precisely timed to maximize power while controlling combustion temperatures.

These injection strategies assume premium fuel’s chemical properties and knock resistance, with parameters optimized for fuel that maintains stability under extreme pressure and temperature.

Regular gasoline’s lower octane rating means it begins auto-igniting before the flame front from the spark plug completes propagation across the combustion chamber, creating multiple flame fronts that collide and generate destructive pressure waves the characteristic “pinging” sound of detonation.

From an engineering perspective, the M177/M178 engines represent what’s achievable when designers optimize exclusively for premium fuel, extracting specific outputs exceeding 150 horsepower per liter while maintaining reasonable reliability.

This performance level would be impossible with regular gasoline constraints, demonstrating why some engines absolutely require premium fuel to function as designed.

3. Ford 3.5L EcoBoost High-Output

Ford’s 3.5-liter EcoBoost V6 in high-output configuration, particularly the version powering the F-150 Raptor and F-150 Limited producing 450 horsepower and 510 lb-ft of torque, represents one of the most powerful production truck engines available.

This engine explicitly requires premium 91+ octane fuel, with Ford’s owner manual clearly stating that using regular gasoline will result in reduced performance and potential engine damage.

The high-output EcoBoost’s premium fuel requirement stems from its aggressive turbocharger calibration and high compression ratio that create combustion conditions regular gasoline cannot handle without destructive detonation.

The high-output 3.5L EcoBoost uses larger turbochargers than standard EcoBoost variants, generating peak boost pressures approaching 18-20 psi to achieve its impressive power figures.

Combined with the engine’s 10.5:1 compression ratio, these boost levels create effective compression ratios that far exceed regular gasoline’s octane rating capabilities.

When turbocharged air compresses the fuel-air mixture to these extreme pressures and temperatures, regular 87-octane fuel’s molecular chains break down and auto-ignite before the spark plug fires, creating uncontrolled explosions that generate severe mechanical stress on engine components.

Ford’s calibration of the high-output EcoBoost optimizes ignition timing, boost pressure, and fuel delivery specifically for premium fuel’s knock resistance.

The engine produces maximum torque at just 3,500 RPM, requiring very advanced ignition timing and high boost pressure to achieve this low-RPM torque peak.

Using regular gasoline forces the engine management system to retard ignition timing substantially, sometimes by 15-20 degrees, and reduce turbocharger boost pressure by 3-5 psi to prevent knock.

These protective measures reduce power output by 50-80 horsepower and torque by 60-80 lb-ft, transforming the truck’s performance from explosive to merely adequate.

Financial considerations make premium fuel a necessary cost of high-output EcoBoost ownership rather than an optional expense. While premium fuel costs approximately $300-400 more annually for typical driving, the performance degradation and potential repair costs from knock damage far exceed these fuel cost differences.

Ford’s warranty explicitly requires premium fuel for high-output EcoBoost engines, and warranty claims will be denied if engine damage results from documented use of incorrect fuel.

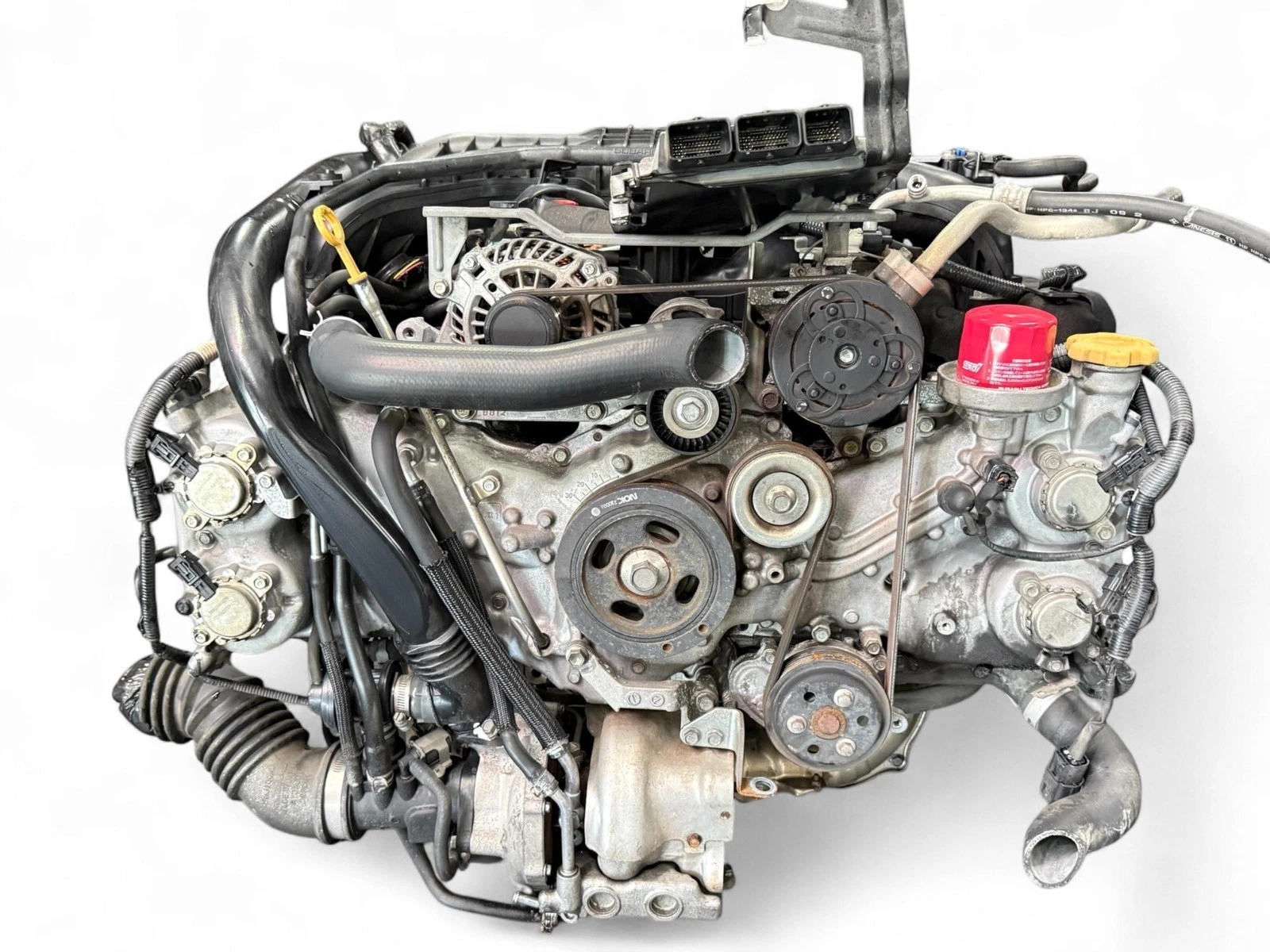

4. Subaru FA20DIT 2.0L Turbo

The Subaru FA20DIT turbocharged 2.0-liter flat-four engine powers the WRX performance sedan, producing 268 horsepower and 258 lb-ft of torque, and represents Subaru’s commitment to turbocharged performance in its iconic all-wheel-drive platform.

This engine absolutely requires premium 91+ octane fuel, with Subaru’s documentation explicitly warning that using regular gasoline will cause severe knock, reduced performance, and potential engine damage.

The FA20DIT’s premium fuel requirement stems from its combination of direct injection, relatively high compression ratio for a turbocharged engine (10.6:1), and aggressive boost calibration that creates combustion conditions incompatible with regular gasoline’s knock resistance.

Subaru’s engineering of the FA20DIT focused on extracting maximum performance from a relatively small displacement, with the turbocharger generating peak boost pressures around 15-16 psi to achieve the engine’s impressive specific output of 134 horsepower per liter.

The horizontally-opposed “boxer” configuration creates unique combustion chamber shapes with longer flame travel distances compared to conventional inline or V-configuration engines, making controlled combustion even more critical.

When operating on regular gasoline, the fuel-air mixture in areas furthest from the spark plug reaches critical temperature and pressure before the flame front arrives, causing end-gas auto-ignition and destructive knock.

The FA20DIT’s direct injection system operates at high pressures to precisely control fuel delivery and mixture formation, with calibrations optimized specifically for premium fuel’s chemical properties.

The engine management system uses a sophisticated strategy combining injection timing, ignition timing, boost pressure control, and variable valve timing to maximize power while maintaining knock-free operation on premium fuel.

Using regular gasoline overwhelms these control strategies, forcing the system into protective mode where ignition timing is severely retarded, sometimes by 12-15 degrees or more and boost pressure is reduced by 2-4 psi, resulting in power losses exceeding 40-50 horsepower.

Subaru’s flat-four engine design, while providing packaging and center-of-gravity advantages, creates thermal management challenges that make premium fuel even more critical.

The horizontally-opposed cylinders have unequal cooling efficiency, with the lower cylinders receiving better coolant flow while upper cylinders run slightly hotter.

This thermal imbalance means that the hotter cylinders are more prone to knock, and using regular gasoline exacerbates this issue. The engine’s knock sensors must work overtime to detect and compensate for these conditions, but the fundamental problem insufficient octane rating cannot be fully mitigated through electronic intervention.

WRX owners who’ve attempted to use regular gasoline report immediate and noticeable performance degradation, with the car feeling dramatically slower and less responsive.

The characteristic turbocharged surge of power that defines the WRX driving experience becomes muted and hesitant when the engine management system limits boost and retards timing to prevent knock.

Multiple owners have reported audible pinging or rattling sounds during acceleration despite the knock control measures, indicating that combustion conditions are approaching or exceeding safe limits even with the engine’s protective interventions.

From a performance perspective, the FA20DIT on premium fuel delivers an engaging, responsive driving experience with strong acceleration and the characteristic turbocharged power delivery Subaru enthusiasts expect.

On regular gasoline, this same engine becomes frustratingly sluggish, with delayed throttle response, reduced boost, and power delivery that feels strangled by the engine management system’s protective measures.

5. Porsche 3.0L Twin-Turbo Flat-6 (991.2 911 Carrera)

Porsche’s 3.0-liter twin-turbocharged flat-six engine introduced in the 991.2 generation 911 Carrera models represents the pinnacle of turbocharged sports car engineering, producing between 370 and 450 horsepower depending on specification.

This engine absolutely demands premium 91+ octane fuel (93+ recommended), with Porsche explicitly stating that using regular gasoline will cause severe engine damage and void all warranty coverage.

The engine’s requirement for premium fuel stems from its extreme engineering specifications: a compression ratio around 10.0:1 combined with twin turbochargers, variable turbine geometry, and aggressive calibration creates combustion conditions that regular gasoline cannot withstand without immediate, catastrophic detonation.

Porsche’s engineering philosophy prioritizes performance and driver engagement above all else, and the 3.0L twin-turbo flat-six exemplifies this approach.

The twin turbochargers with variable turbine geometry (VTG) technology eliminate virtually all turbo lag while generating substantial boost pressures across the entire RPM range.

This sophisticated turbocharging system requires premium fuel’s superior knock resistance to enable the aggressive boost curves and advanced ignition timing that give the 911 its legendary throttle response and linear power delivery.

Using regular gasoline disrupts these carefully calibrated parameters so severely that the engine cannot function properly, with knock occurring almost immediately under any moderate load conditions.

From an engineering perspective, Porsche’s twin-turbo flat-six demonstrates what’s achievable when designers optimize without regular gasoline constraints exceptional specific output, instantaneous throttle response, and performance delivery across an extraordinary RPM range.

These achievements require premium fuel’s superior knock resistance as a fundamental enabling technology, making premium fuel not optional but essential for proper operation.

Also Read: 5 Cars That Rarely Need Alternators vs 5 That Burn Through Them