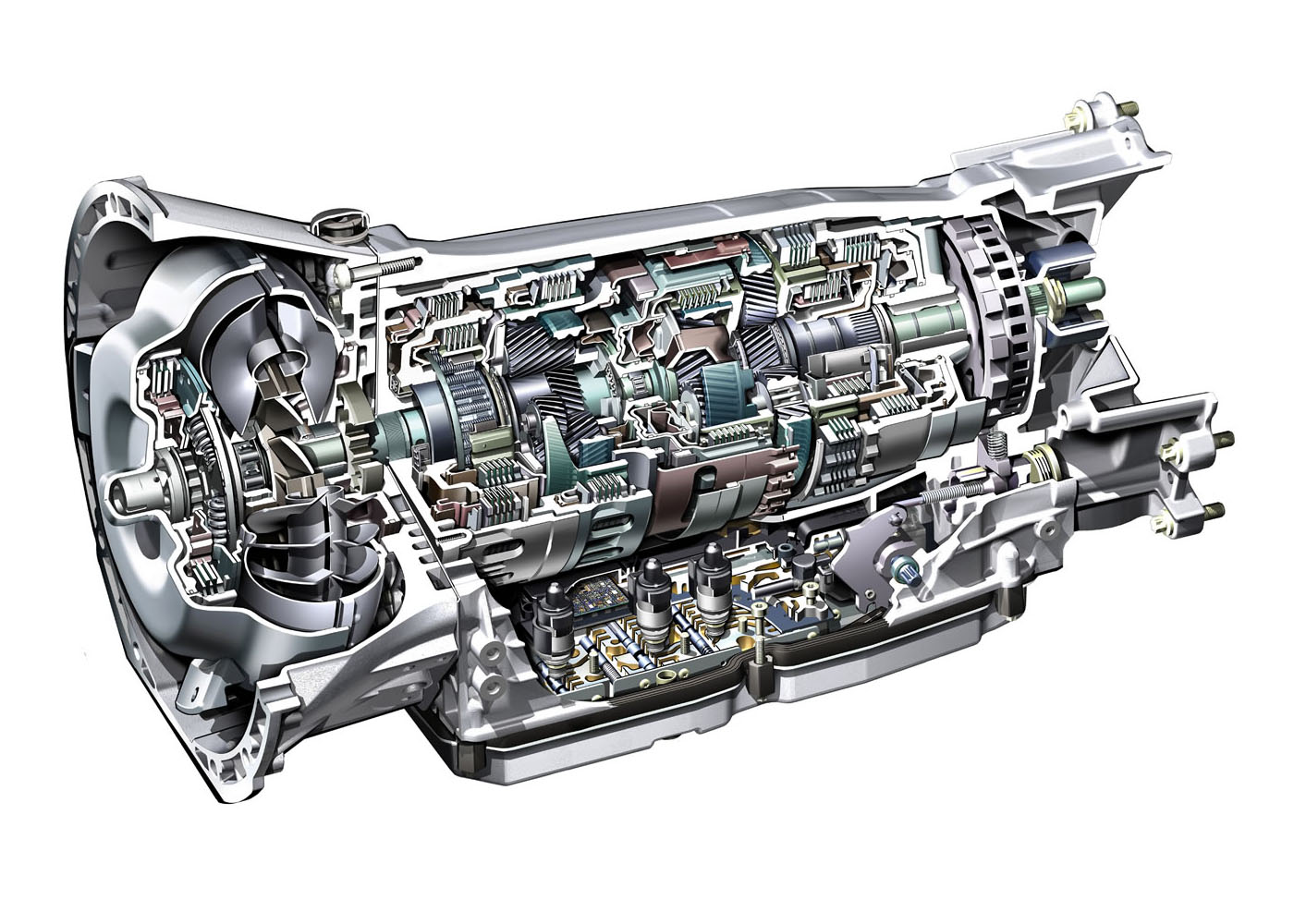

When it comes to automotive reliability, few components inspire as much concern or as much relief when they perform flawlessly as the automatic transmission.

This complex assembly of gears, clutches, torque converters, and hydraulic systems represents one of the most critical yet vulnerable parts of any vehicle.

A transmission failure can transform a reliable daily driver into an expensive paperweight, often requiring repairs that rival or exceed the vehicle’s remaining value.

Yet not all automatic transmissions are created equal. While some have earned notorious reputations for premature failure, demanding rebuilds at relatively low mileage, others have proven themselves remarkably resilient, delivering hundreds of thousands of miles of trouble-free operation.

The difference between a transmission that fails prematurely and one that lasts the lifetime of the vehicle often comes down to fundamental engineering decisions, manufacturing quality, and design philosophy.

The best automatic transmissions share several key characteristics: robust construction with adequate cooling capacity, conservative power handling that doesn’t push components to their limits, well-designed hydraulic systems that maintain proper pressure and fluid flow, and electronic controls that adapt shifting patterns to reduce wear.

These transmissions benefit from years of refinement, with manufacturers identifying and correcting weak points through successive generations.

Understanding which automatic transmissions have earned reputations for exceptional longevity can guide both vehicle purchase decisions and maintenance priorities.

Some transmissions have become legendary for their durability, serving faithfully in taxi fleets, commercial applications, and high-mileage personal vehicles with minimal intervention beyond regular fluid changes.

These units have proven themselves across millions of vehicles and billions of miles, establishing track records that inspire confidence among mechanics, fleet managers, and informed consumers alike.

While no mechanical component is truly immune to failure especially when subjected to abuse, neglect, or extreme operating conditions these ten automatic transmissions stand out for their resistance to the common failure modes that plague lesser designs.

They represent smart engineering choices for anyone seeking long-term reliability, reduced ownership costs, and peace of mind. Whether you’re shopping for a used vehicle, planning to keep your current car for the long haul, or simply interested in automotive engineering excellence, understanding what makes these transmissions special offers valuable insights into the intersection of design, durability, and real-world performance.

1. Toyota/Aisin A340/A750 Series

The Toyota A340 and its successor, the A750, represent some of the most bulletproof automatic transmissions ever engineered. Developed collaboratively between Toyota and Aisin, these four-speed and five-speed automatics have achieved legendary status among enthusiasts and mechanics for their ability to withstand extraordinary abuse while requiring minimal maintenance.

The A340E (electronic control) and A340F (four-wheel drive variant) have been installed in millions of Toyota and Lexus vehicles since the late 1980s, powering everything from Camrys and 4Runners to Land Cruisers and Tacomas.

The secret to this transmission’s longevity lies in its fundamentally conservative design philosophy. Rather than pushing the boundaries of efficiency or performance, Toyota engineers prioritized durability above all else.

The transmission features robust steel internals, generously sized clutch packs with substantial friction material, and a hydraulic system designed with ample pressure margins.

The planetary gear sets are manufactured to tolerances that ensure minimal play even after hundreds of thousands of miles, while the valve body incorporates proven designs that resist the wear and contamination issues that plague more complex units.

One of the A340’s most significant advantages is its relatively simple electronic control system. Unlike modern transmissions with dozens of sensors and complex adaptive algorithms, the A340E uses straightforward electronic management that focuses on essential functions: gear selection, torque converter lockup, and basic shift timing.

This simplicity translates directly into reliability, as there are fewer electronic components to fail and fewer opportunities for software glitches to cause problems.

When issues do occur, diagnosis is straightforward, and repairs rarely require expensive specialized equipment or dealer-only tools. The transmission’s cooling system deserves special mention for its contribution to longevity.

Toyota equipped most A340-fitted vehicles with substantial transmission coolers, often incorporating both radiator-based heat exchangers and auxiliary air-cooled units on vehicles with towing packages or off-road capabilities.

Maintaining proper operating temperatures is critical for transmission longevity, as excessive heat accelerates fluid degradation and component wear. The A340’s robust cooling capacity helps maintain fluid integrity even under demanding conditions, extending service intervals and component life.

Perhaps the most compelling testament to the A340’s durability comes from its widespread use in commercial and fleet applications.

Taxi companies, delivery services, and emergency responders have logged millions of miles on A340-equipped vehicles, often with minimal transmission maintenance beyond regular fluid changes.

It’s not uncommon to find Toyota vehicles with original A340 transmissions still operating flawlessly with 300,000, 400,000, or even 500,000 miles on the odometer.

When failures do occur, they’re typically the result of severe neglect, such as never changing the transmission fluid, or external factors like contaminated fluid from a failed radiator allowing coolant into the transmission.

The A750 series, which succeeded the A340 in the mid-2000s, carried forward all the durability characteristics of its predecessor while adding a fifth gear for improved fuel efficiency and highway refinement.

This transmission has proven equally reliable in Toyota’s larger SUVs and trucks, including the Tundra, Sequoia, and Land Cruiser, where it routinely handles significant towing loads and off-road abuse without complaint.

For anyone seeking a vehicle with a transmission that will likely outlast the rest of the vehicle, any Toyota or Lexus equipped with an A340 or A750 represents an excellent choice.

2. Honda 5-Speed Automatic (5AT)

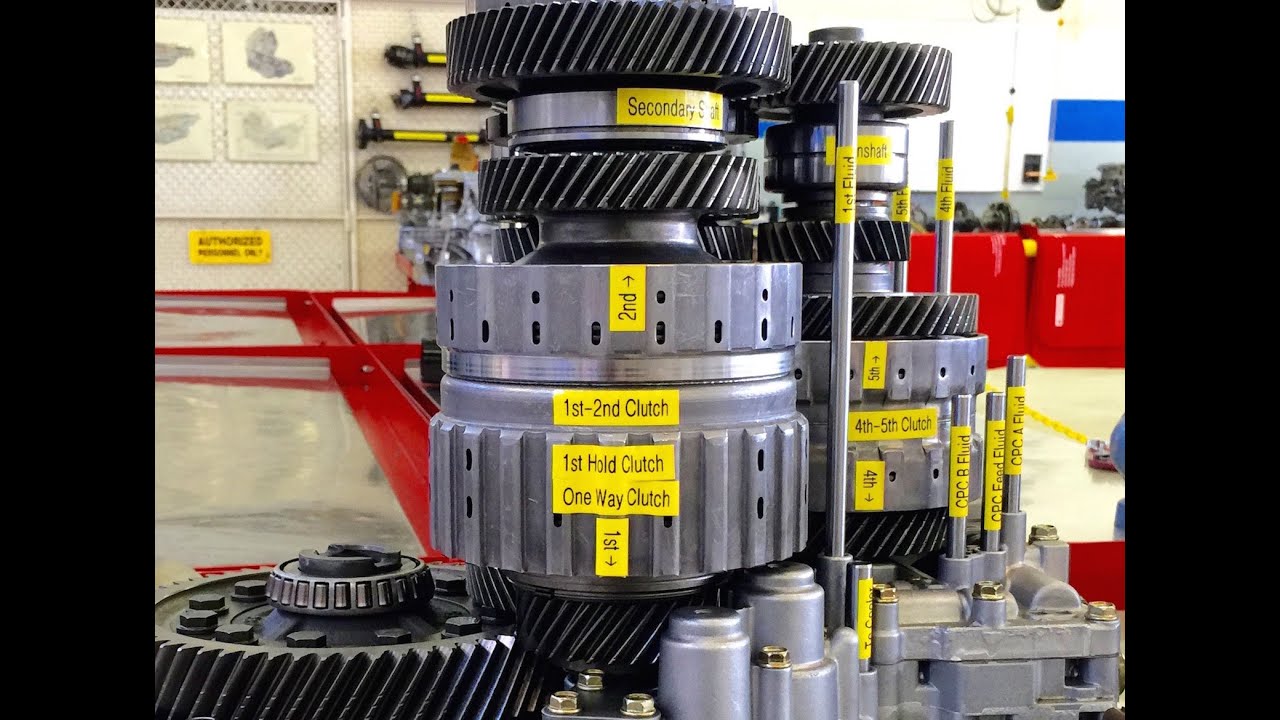

Honda’s five-speed automatic transmission, used extensively across the company’s lineup from the late 1990s through the mid-2010s, stands as a remarkable achievement in transmission engineering.

While Honda experienced some well-publicized issues with their earlier four-speed automatics and certain V6 applications, their conventional five-speed design proved exceptionally reliable, particularly in four-cylinder applications.

This transmission powered millions of Accords, Civics, CR-Vs, and Elements, establishing a reputation for smooth operation and remarkable longevity when properly maintained.

The Honda five-speed automatic distinguishes itself through precision manufacturing and intelligent design choices that prioritize longevity over outright performance.

Honda engineers employed multiple friction clutches rather than bands for gear changes, which provides smoother shifts and more consistent engagement over the transmission’s lifespan.

Bands tend to wear and require adjustment or replacement, while properly designed clutch packs, when adequately sized and cooled, can last indefinitely with proper maintenance.

Honda’s implementation featured clutch packs with generous friction material and sophisticated hydraulic control that modulates pressure to minimize shock loads during shifts.

One of this transmission’s most impressive characteristics is its fluid dynamics. Honda developed a proprietary transmission fluid formulation specifically optimized for their automatic transmissions, with friction modifiers and additives designed to work synergistically with their clutch pack materials.

While Honda specifies their ATF-Z1 (later DW-1) fluid, and using the correct fluid is important for optimal performance, the transmission’s fundamental design is forgiving enough that it continues to function reliably even when fluid condition degrades somewhat between service intervals.

However, adhering to Honda’s recommended fluid change schedule typically every 30,000 miles under severe conditions or 60,000 miles under normal use virtually guarantees the transmission will last the vehicle’s lifetime.

The electronic control system in Honda’s five-speed automatic represents a masterclass in practical engineering. Rather than implementing overly aggressive shift programming that maximizes EPA test cycle performance at the expense of durability, Honda calibrated their transmissions to shift smoothly and predictably.

The transmission control module monitors input shaft speed, output shaft speed, throttle position, and engine load to determine optimal shift points, but it does so conservatively, avoiding unnecessary shifts that would increase wear.

The torque converter lockup strategy is particularly well-executed, engaging smoothly without the shudder that plagues some competing designs while maximizing efficiency in higher gears.

Honda’s five-speed automatic also benefits from excellent heat management. Most applications include both radiator-integrated transmission coolers and, in vehicles with higher power outputs or towing capabilities, supplemental air-cooled heat exchangers.

The transmission fluid pump is sized generously, ensuring adequate flow even at idle, which helps maintain proper pressure and lubrication throughout the transmission under all operating conditions.

This attention to thermal management pays dividends in transmission longevity, as heat is the primary enemy of transmission fluid and internal components.

Real-world experience with Honda’s five-speed automatic confirms its excellent durability. It’s routine to encounter Honda vehicles with well over 200,000 miles showing no signs of transmission distress, shifting smoothly and reliably with original internal components.

When failures do occur, they’re typically traced to deferred maintenance, particularly extended intervals between fluid changes that allow the transmission fluid to break down and lose its protective properties.

For anyone purchasing a used Honda, a vehicle equipped with this five-speed automatic and documented regular maintenance represents one of the safest transmission choices available.

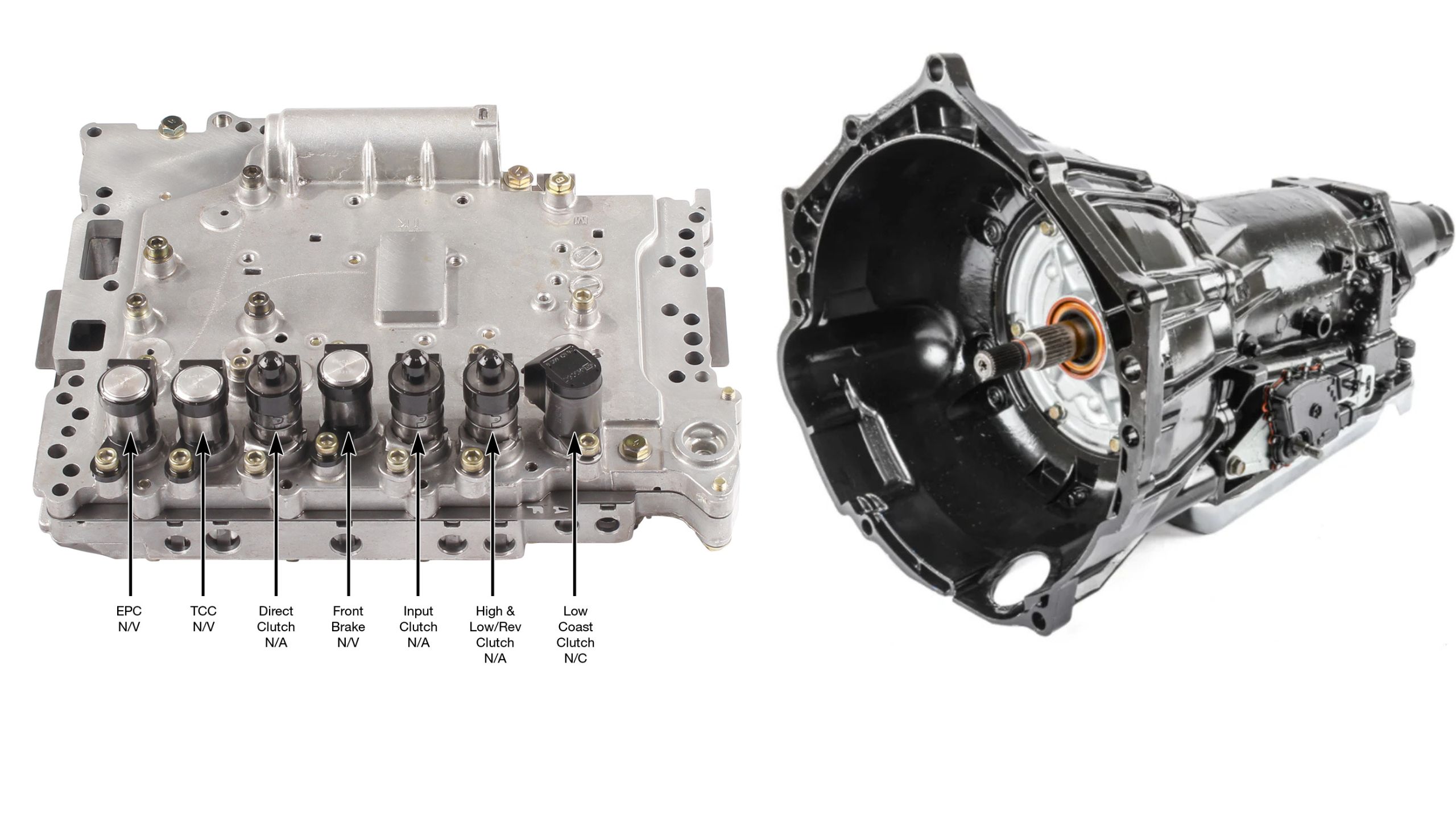

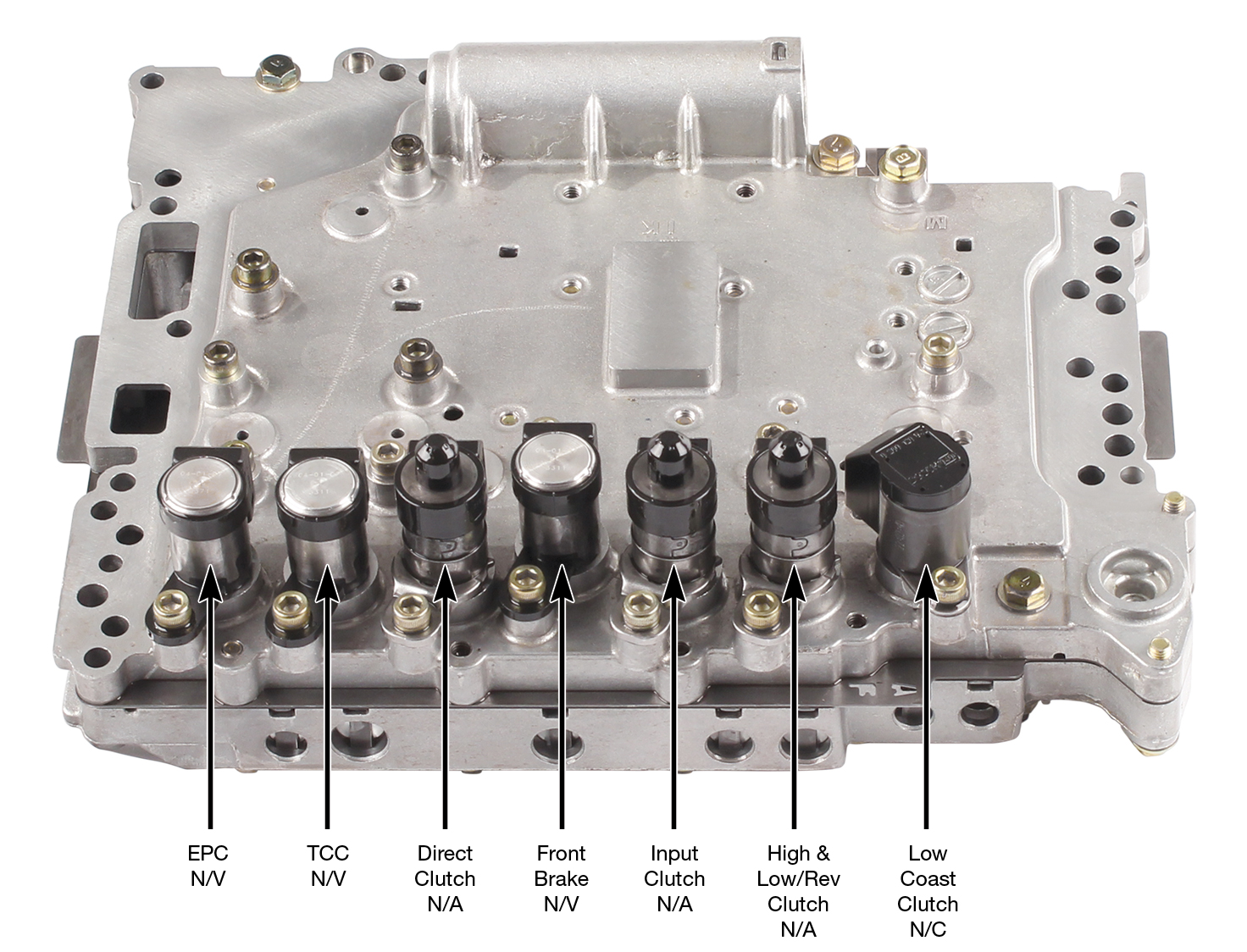

3. GM 4L60E/4L65E/4L70E Series

General Motors’ 4L60E series represents one of the most successful and long-lived automatic transmission designs in automotive history.

Introduced in 1992 as an electronically controlled evolution of the venerable 700R4, the 4L60E and its strengthened variants have powered countless GM trucks, SUVs, and performance cars for over three decades.

While earlier 4L60E units had some weaknesses that were well-documented, GM progressively strengthened the design, culminating in the 4L65E and 4L70E variants that proved remarkably durable when properly maintained and not subjected to extreme abuse.

The 4L60E’s longevity stems from its roots in a proven mechanical design combined with continuously refined electronic controls. The basic architecture a Simpson planetary gear set with overdrive planetary unit, three multiple-disc clutches, and a band for second gear traces its lineage back to the THM700R4, which itself evolved from earlier proven GM designs.

This evolutionary approach allowed GM to refine and strengthen known weak points rather than starting from scratch with untested concepts.

By the time the 4L65E appeared in 2001 with stronger materials in critical components, followed by the 4L70E in 2006 with further enhancements, GM had addressed virtually all the common failure modes that affected early units.

One of the 4L60E’s significant advantages is its widespread use and the resulting extensive aftermarket support. Because GM installed these transmissions in millions of vehicles from Silverados and Suburbans to Corvettes and Camaros the aftermarket developed comprehensive upgrade and repair solutions.

When rebuilding becomes necessary, which typically only occurs after severe abuse or extreme mileage, upgraded components are readily available at reasonable costs.

Hard parts like sun shell assemblies, input shafts, and servo pistons can be replaced with strengthened versions that exceed original equipment specifications. However, with proper maintenance and reasonable use, these upgrades typically aren’t necessary as the transmission will outlast the vehicle.

The 4L65E and 4L70E variants deserve special recognition for their enhanced durability. These strengthened versions feature improvements including more robust sun shell assemblies, upgraded input shafts, enhanced clutch pack materials, and refined hydraulic control.

In trucks and SUVs subjected to towing or heavy loads, these enhanced transmissions have proven exceptionally reliable, routinely accumulating 200,000 to 300,000 miles without internal repairs.

When paired with appropriate cooling an external transmission cooler is highly recommended for towing applications these transmissions can handle remarkably heavy-duty use while maintaining reliable operation throughout the vehicle’s service life.

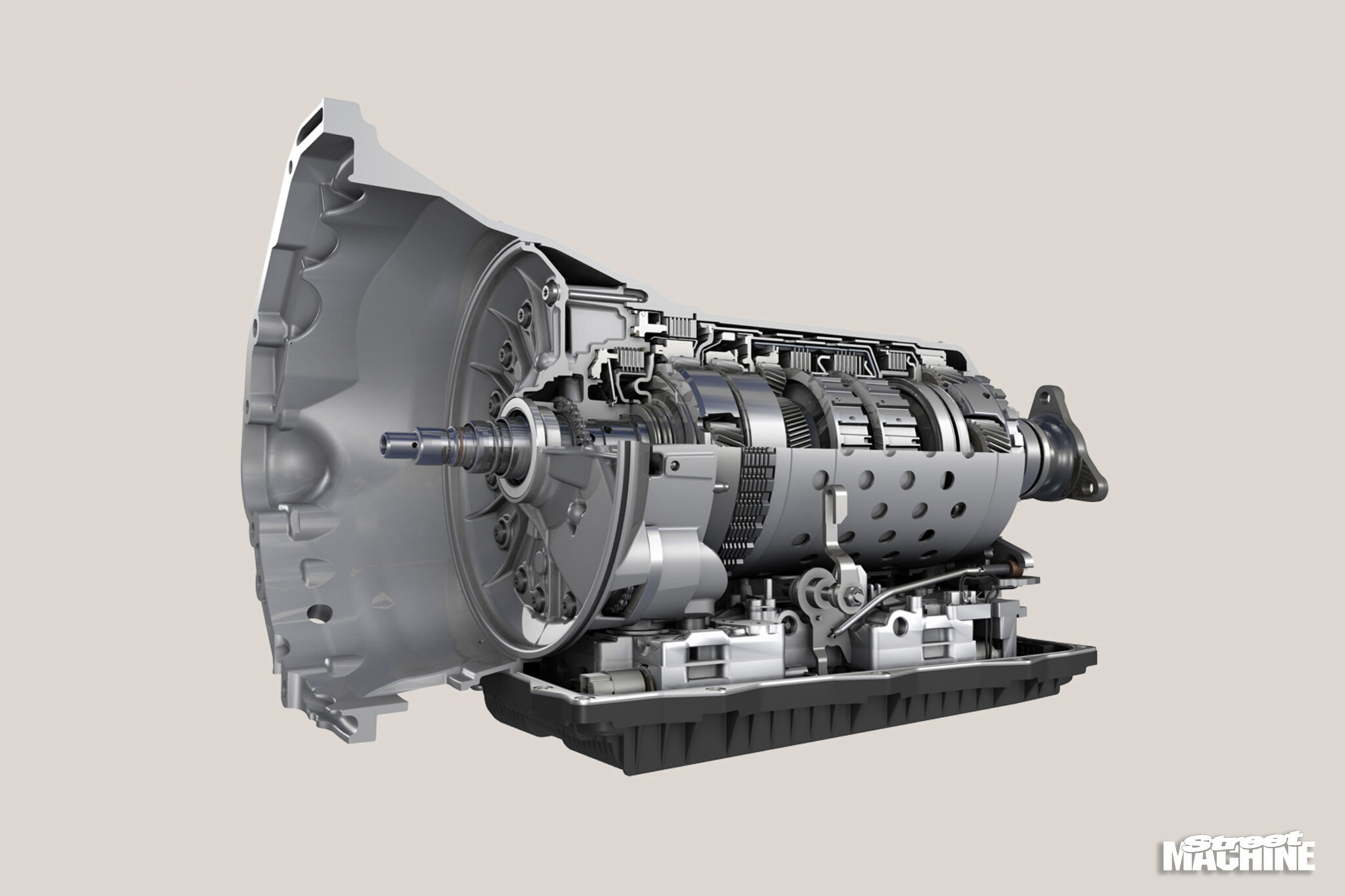

4. ZF 8HP Series

The ZF 8HP (8-speed Hydraulic Planetary) series represents a quantum leap in automatic transmission technology, combining exceptional efficiency with remarkable reliability.

Introduced in 2008, this eight-speed transmission has been adopted by numerous manufacturers, including BMW, Chrysler, Jaguar, Land Rover, Aston Martin, and many others, becoming one of the most widely used transmissions across multiple brands.

Despite its complexity eight forward gears require sophisticated control systems and numerous internal components, the 8HP has proven surprisingly durable, with failure rates significantly lower than many simpler designs it replaced.

ZF’s engineering philosophy for the 8HP prioritized both efficiency and longevity. The transmission features four simple planetary gear sets and five shift elements (multi-plate clutches and brakes), which enable the eight forward gears without requiring excessively complex controls or fragile components.

The gear ratios are well-spaced, allowing the engine to operate in its optimal efficiency range across a broad spectrum of driving conditions.

The wide ratio spread means the difference between first gear and eighth gear, which means the transmission can provide both strong acceleration in lower gears and relaxed, economical cruising in top gear without compromising durability.

One of the 8HP’s most impressive characteristics is its excellent thermal management. ZF designed the transmission with generous oil flow capacity, ensuring all internal components receive adequate lubrication and cooling even under demanding conditions.

The torque converter is sophisticated, featuring a multi-plate lockup clutch that can partially engage to dampen vibrations while still providing some slip for smoothness, or fully lock for maximum efficiency.

This advanced torque converter management contributes to both improved fuel economy and reduced wear on transmission components by minimizing unnecessary slip and heat generation.

Real-world reliability data for the 8HP has been remarkably positive across multiple manufacturers and applications. Despite initially being deployed in high-performance vehicles where transmissions traditionally face severe demands, the 8HP has proven exceptionally durable.

Failure rates are notably low, and when issues do occur, they’re often related to electronic controls or external components rather than internal mechanical failures.

Taxis and fleet vehicles equipped with 8HP transmissions regularly accumulate 200,000-plus miles without transmission problems, and many enthusiast owners report trouble-free operation well beyond this mileage.

For anyone seeking a modern, efficient automatic transmission with excellent long-term reliability prospects, vehicles equipped with the ZF 8HP represent an excellent choice.

Also Read: 10 Nissan Models That Quietly Deliver Long Service

5. Nissan/JATCO RE5R05A

The Nissan RE5R05A, manufactured by JATCO (Japan Automatic Transmission Company), is a five-speed automatic transmission that has earned a reputation for exceptional durability, particularly in heavy-duty applications.

This transmission has been used extensively in Nissan and Infiniti trucks and SUVs, including the Titan, Armada, Pathfinder, QX56, and others, where it’s often paired with powerful V8 engines and subjected to towing and off-road use.

Despite these demanding applications, the RE5R05A has proven remarkably reliable, routinely accumulating high mileage without requiring rebuilds when properly maintained.

The RE5R05A’s robust design reflects Japanese engineering philosophy applied to heavy-duty applications. The transmission features substantial internal components, including generously sized clutch packs with ample friction material, robust planetary gear sets manufactured from high-quality materials, and a valve body designed to maintain consistent hydraulic pressure under all operating conditions.

The torque converter is particularly well-engineered, capable of handling significant power and torque while providing smooth engagement and reliable lockup function. This transmission was designed from the outset to handle V8 power and substantial towing loads, so even in demanding applications, it’s not operating near its design limits.

One aspect that sets the RE5R05A apart is its sophisticated cooling system integration. Recognizing that heat is the primary enemy of automatic transmissions, particularly in trucks and SUVs often used for towing, Nissan equipped RE5R05A-fitted vehicles with substantial cooling capacity.

Most applications include both radiator-mounted heat exchangers and auxiliary transmission coolers, and the hydraulic system is designed to ensure adequate fluid flow through these coolers even at idle.

The transmission also includes temperature monitoring with protective strategies if temperatures become excessive, the transmission control module can modify shift patterns or activate warning lights to alert the driver before damage occurs.

Real-world experience confirms the RE5R05A’s excellent durability. Nissan trucks and SUVs with this transmission routinely accumulate 200,000 miles and beyond, with original transmissions still functioning flawlessly.

Fleet operators, particularly those using Nissan Titans and Armadas for commercial purposes, report exceptional transmission reliability when maintenance schedules are followed.

When failures do occur, they’re typically traced to deferred maintenance, extreme abuse, or external factors such as contaminated fluid from radiator failures.

For anyone seeking a full-size truck or SUV with a transmission capable of handling heavy-duty use while delivering long-term reliability, vehicles equipped with the RE5R05A represent an excellent choice.

6. Mercedes-Benz 7G-Tronic (722.9)

Mercedes-Benz’s 7G-Tronic, internally designated 722.9, represents German engineering excellence applied to automatic transmissions. Introduced in 2003, this seven-speed automatic was revolutionary for its time, offering unprecedented smoothness, efficiency, and refinement.

Despite its complexity seven forward gears require sophisticated control systems and numerous internal components the 7G-Tronic has proven remarkably durable across millions of vehicles and billions of miles.

Mercedes deployed this transmission across their entire lineup, from compact C-Class sedans to full-size S-Class luxury cars and heavy SUVs, subjecting it to a wide range of operating conditions and power outputs.

The 7G-Tronic’s reliability stems from Mercedes-Benz’s trademark over-engineering approach. The transmission features exceptionally robust internal components, including planetary gear sets manufactured to extremely tight tolerances, generously sized multi-disc clutches with high-quality friction materials, and a precision-machined valve body that maintains exact hydraulic pressure control.

Mercedes didn’t simply design the transmission to handle the specified torque ratings with minimal safety margins; they engineered substantial reserve capacity, ensuring components operate well below their stress limits under normal conditions.

This conservative approach translates directly into longevity, as components wear gradually rather than being stressed near their failure points.

One of the 7G-Tronic’s most impressive features is its sophisticated torque converter. Unlike simpler designs with basic lockup clutches, the 7G-Tronic employs a torque converter with multiple damper stages and progressive lockup capability.

This allows the converter to partially lock under certain conditions, reducing slippage and heat generation while still providing some dampening of engine vibrations for refinement.

The result is both improved efficiency and reduced wear on transmission components, as the torque converter isn’t constantly slipping and generating heat. The system is so well-calibrated that many drivers never notice the converter locking and unlocking, experiencing only seamless power delivery.

Real-world reliability data for the 7G-Tronic has been excellent, particularly for units that receive proper maintenance. Mercedes taxis throughout Europe routinely accumulate 300,000 to 400,000 miles with original transmissions still functioning perfectly, a testament to the design’s fundamental robustness.

In the United States, where maintenance intervals are often extended beyond recommendations, the 7G-Tronic still performs well, though regular fluid changes significantly improve longevity.

When issues do occur, they’re most commonly related to external components like the valve body, conductor plate, or transmission control module rather than fundamental mechanical failures.

For anyone considering a used Mercedes-Benz, a vehicle with documented regular transmission maintenance represents an excellent reliability prospect.

7. Ford 6R80/10R80 Series

Ford’s 6R80 and its successor, the 10R80 (co-developed with General Motors), represent American engineering excellence in automatic transmissions.

The 6R80, introduced in 2009, quickly earned a reputation for reliability in demanding applications, powering F-150 trucks, Mustangs, and various SUVs.

The revolutionary 10R80, introduced in 2017, took this reputation further, offering ten forward gears with remarkable smoothness and efficiency while maintaining the durability expectations established by its predecessor.

Both transmissions have proven exceptionally reliable across millions of vehicles subjected to everything from daily commuting to heavy towing and performance driving.

The 6R80’s design reflects lessons learned from previous Ford transmission programs. After experiencing issues with some earlier designs, Ford engineers prioritized durability alongside efficiency when developing the 6R80.

The result is a transmission featuring robust internal components, including substantial planetary gear sets, generously sized clutch packs, and a sophisticated valve body capable of maintaining precise hydraulic control.

The transmission was designed from the outset to handle significant power and torque the 6R80 is rated for up to 650 lb-ft in some applications which means that in typical truck or SUV installations, it operates well within its capabilities with ample safety margins.

The 10R80 represents an even more impressive engineering achievement. Co-developed with General Motors and featuring essentially identical internal components regardless of manufacturer (Ford calls it 10R80, GM designates it 10L80), this ten-speed transmission combines complexity with reliability in ways that seemed impossible just years earlier.

The transmission features four simple planetary gear sets and six clutches/brakes, enabling ten forward gears through sophisticated but reliable gear combinations.

Despite the increased number of gears, Ford and GM engineers actually simplified some aspects of the design compared to previous six-speed transmissions, eliminating potential failure points while enabling the additional ratios.

Real-world reliability data for the 6R80 has been excellent across diverse applications. F-150 trucks with the 6R80 routinely accumulate 200,000-plus miles with original transmissions still shifting smoothly, even when subjected to regular towing and heavy loads.

Mustang GT owners, who often drive more aggressively than typical truck drivers, report similar reliability. The 10R80, though newer, is already demonstrating comparable durability, with early adopters approaching 100,000 miles without issues.

Fleet operators, particularly those using F-150 trucks for commercial purposes, have embraced both transmissions for their combination of efficiency and reliability.

For anyone seeking a modern truck or performance vehicle with excellent transmission longevity prospects, Ford vehicles equipped with the 6R80 or 10R80 represent excellent choices.

8. Toyota U660E/U760E Series

The Toyota U660E and U760E represent the next generation of Toyota’s legendary transmission reliability, succeeding the A340/A750 series in many applications.

These six-speed automatics, introduced in the mid-2000s, power a wide range of Toyota and Lexus vehicles, from Camrys and Highlanders to RX crossovers and ES sedans.

Despite adding complexity with their additional gears and more sophisticated electronic controls, these transmissions have maintained Toyota’s reputation for exceptional durability, routinely accumulating high mileage without requiring rebuilds when properly maintained.

The U660E and U760E series reflect Toyota’s continuing commitment to prioritizing reliability over other considerations. While competitors were rushing to add ever-more gears and complex features, Toyota took a measured approach, thoroughly testing and refining its six-speed design before widespread deployment.

The transmissions feature robust internal components manufactured to Toyota’s exacting quality standards, including precision-machined planetary gear sets, generously sized multi-disc clutches with high-quality friction materials, and sophisticated valve bodies that maintain precise hydraulic control.

Toyota’s conservative power ratings the transmissions are typically installed in applications well below their maximum torque capacity ensure components operate with substantial safety margins, contributing to longevity.

One of these transmissions’ most significant advantages is its evolutionary relationship with proven predecessors. Rather than starting with a clean sheet design, Toyota engineers built upon the reliable foundation established by the A series transmissions, incorporating lessons learned from decades of real-world experience.

This evolutionary approach allowed Toyota to avoid the teething problems that often plague all-new designs, instead delivering mature transmissions from their introduction.

The fundamental architecture, hydraulic control strategies, and electronic management systems all benefited from this evolutionary development, resulting in transmissions that felt refined and reliable from day one.

Real-world reliability data for the U660E and U760E series confirms their excellent durability. Toyota Camrys, Highlanders, and Lexus RX models with these transmissions routinely accumulate 200,000 miles and beyond, with original transmissions still functioning flawlessly.

Toyota’s hybrid vehicles, which pair these transmissions with complex hybrid drive systems, demonstrate particular reliability, as the electric motor assist actually reduces stress on transmission components during acceleration.

Fleet operators and taxi companies, who subject vehicles to some of the most demanding operating conditions possible, consistently report exceptional transmission reliability from Toyota vehicles equipped with these units.

For anyone seeking a reliable midsize sedan, SUV, or luxury vehicle with a transmission that will likely outlast the rest of the vehicle, Toyota and Lexus products with the U660E or U760E represent outstanding choices.

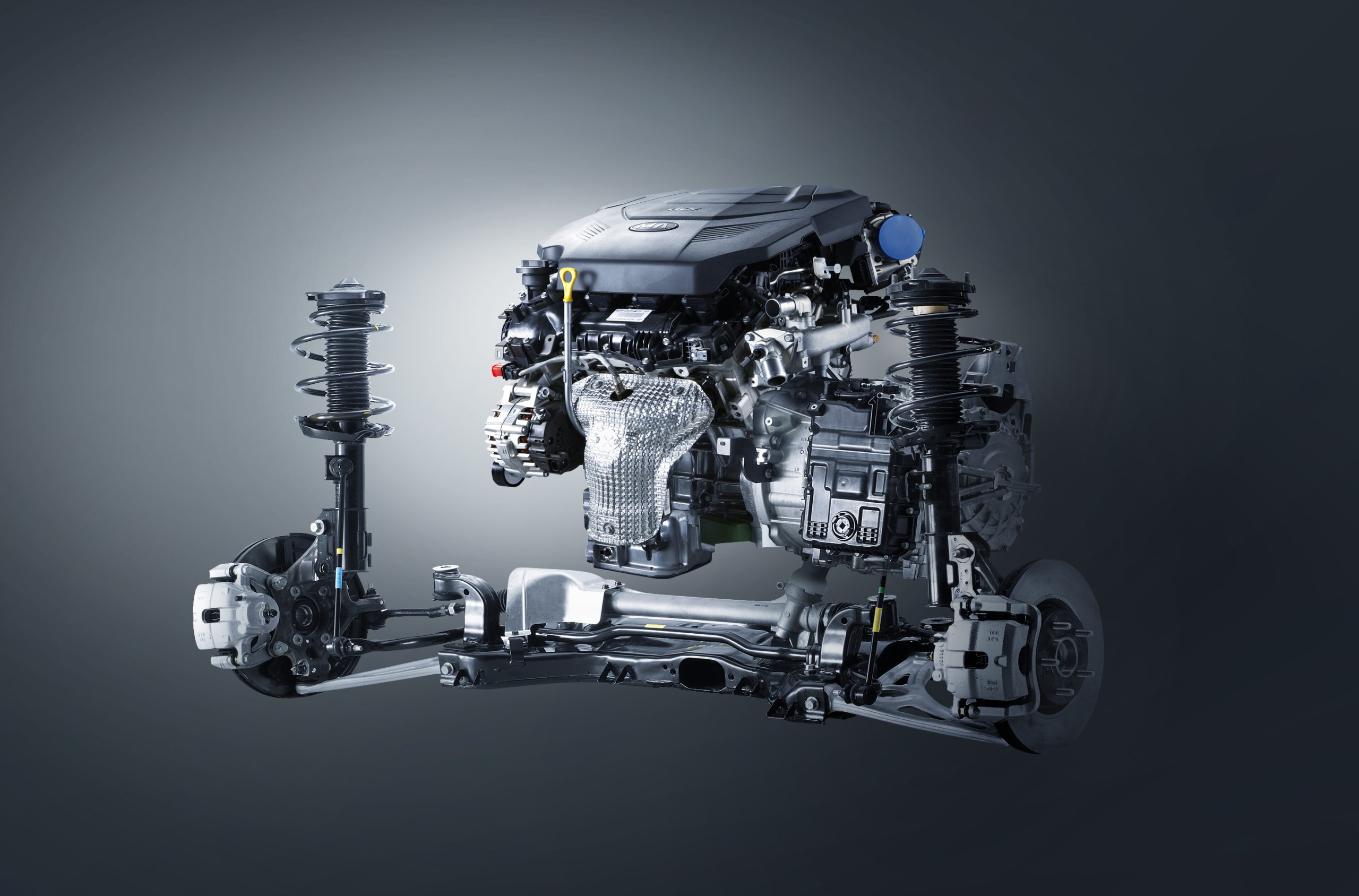

9. Hyundai/Kia 8-Speed Automatic

Hyundai and Kia’s in-house developed eight-speed automatic transmission represents a remarkable achievement for a relative newcomer to advanced transmission design.

Introduced in the mid-2010s, this transmission has been deployed across both manufacturers’ lineups in progressively more applications, from Genesis luxury sedans to Kia Stinger sports sedans to various SUV platforms.

Despite coming from manufacturers that previously relied heavily on licensed or purchased transmissions, this in-house design has proven surprisingly reliable, with failure rates notably lower than many established competitors while delivering smooth, refined performance.

The Hyundai/Kia eight-speed’s reliability stems from a conservative design philosophy that prioritizes durability over absolute performance.

Rather than attempting to match or exceed competitors’ power density or gear count, Hyundai engineers focused on creating a fundamentally sound transmission with robust components and generous safety margins.

The transmission features substantial planetary gear sets manufactured from high-quality materials, well-sized clutch packs with ample friction material, and a precision valve body that maintains consistent hydraulic pressure.

Hyundai conducted extensive testing before widespread deployment, including severe duty cycles that would exceed typical customer usage, identifying and correcting potential weak points before they could affect production vehicles.

One aspect that sets this transmission apart is its excellent shift calibration. Hyundai engineers spent considerable effort refining shift timing and clutch pressure modulation to achieve smooth, nearly imperceptible gear changes under normal driving conditions while still providing quick, firm shifts when the driver demands performance.

This calibration represents a careful balance shifts that are too soft can cause excessive clutch slippage and wear, while shifts that are too harsh create uncomfortable operation and increased stress on driveline components.

Hyundai’s eight-speed achieves this balance remarkably well, contributing to both pleasant driving experiences and long transmission life. Real-world reliability data for this transmission has been encouraging, particularly considering its relatively recent introduction.

Genesis sedans and Kia Stingers, often driven more enthusiastically than typical family vehicles, are accumulating high mileage without transmission issues.

Owners of Hyundai and Kia SUVs with this transmission report trouble-free operation even when regularly towing or driving in challenging conditions.

While the transmission hasn’t accumulated the decades of service history that some older designs enjoy, early indications suggest it will prove as durable as more established competitors.

For anyone considering a Hyundai, Kia, or Genesis vehicle, the presence of this in-house eight-speed automatic should be viewed as a reliability positive rather than a concern about unproven technology.

10. Subaru Lineartronic CVT (High-Torque Version)

Continuously variable transmissions (CVTs) have earned mixed reputations for reliability, with some designs proving troublesome while others have demonstrated excellent durability.

Subaru’s high-torque Lineartronic CVT, used in their larger vehicles including Outback, Ascent, and Legacy models, represents one of the most reliable CVT designs in the industry.

While Subaru’s earlier CVT applications experienced some issues, the company progressively strengthened the design, and the current high-torque variants have proven remarkably durable, challenging common assumptions about CVT reliability when properly engineered and maintained.

The Subaru Lineartronic CVT’s reliability stems from fundamental design improvements that address the common failure modes plaguing earlier CVT designs.

Subaru engineers recognized that CVTs face unique challenges; the steel belt or chain must maintain precise contact with conical pulleys under tremendous clamping force while smoothly varying the contact diameter to change ratios.

The high-torque Lineartronic features a robust steel chain rather than a belt, providing superior strength and durability. The chain rides on precisely machined pulley surfaces with advanced coatings that reduce friction and wear, while the hydraulic system maintains optimal clamping pressure under all operating conditions.

These improvements, combined with generous thermal capacity, have transformed the Lineartronic from a potential reliability concern into a genuinely durable transmission.

One of the most significant factors in the high-torque Lineartronic’s reliability is its sophisticated cooling system. Subaru learned from earlier CVT applications that heat management is absolutely critical for CVT longevity, the fluid must maintain precise friction characteristics for proper belt/chain grip on the pulleys, and this fluid is extremely sensitive to thermal degradation.

The high-torque Lineartronic incorporates substantial cooling capacity, typically including both radiator-integrated heat exchangers and auxiliary transmission coolers.

In Ascent models configured for towing, Subaru installs even larger auxiliary coolers that dramatically increase cooling capacity. This robust thermal management keeps fluid temperatures within optimal ranges even under demanding conditions, extending both fluid life and component longevity.

It’s worth noting that while this CVT has proven reliable, it still requires more attentive maintenance than the best conventional automatics, and the consequences of neglect can be severe.

However, for drivers who appreciate the smooth, seamless power delivery that only a CVT can provide, along with the excellent fuel efficiency and all-wheel-drive capability that characterizes Subaru vehicles, the high-torque Lineartronic represents a viable choice.

The key is commitment to regular maintenance and realistic expectations about the transmission’s capabilities it’s designed for efficient all-weather transportation rather than extreme performance or heavy-duty towing.

Within these parameters, properly maintained high-torque Lineartronic CVTs are proving capable of delivering reliable service throughout a vehicle’s typical ownership period and beyond.

Also Read: 10 Best Cars For Ride-share Drivers in 2025 To Hit 300,000 Miles