When it comes to purchasing a used Hyundai or Kia vehicle, one of the most critical considerations is engine reliability. Both Korean manufacturers have produced millions of vehicles over the decades, but not all engine generations have earned equal reputations for longevity and dependability.

While Hyundai and Kia have faced well-documented engine troubles with certain Theta II and Nu engine variants, particularly those manufactured between 2011 and 2019 there exist numerous powerplants from specific production years that have proven themselves remarkably durable over time.

The concept of “safe years” refers to specific production periods when these manufacturers delivered engines with superior build quality, fewer manufacturing defects, and better long-term reliability.

These engines have accumulated hundreds of thousands of miles on countless vehicles without experiencing the catastrophic failures that plagued their problematic counterparts.

They represent the engineering excellence that Hyundai and Kia are capable of achieving when quality control processes are properly implemented and maintained throughout production.

Understanding which engines age well is particularly valuable in today’s used car market, where buyers seek maximum value and minimum unexpected repair costs.

A well-maintained Hyundai or Kia with the right engine can deliver 200,000 miles or more of dependable service, offering exceptional value compared to many competitors. However, choosing the wrong engine year can result in expensive engine replacements, endless repair bills, and significant frustration.

Whether you’re shopping for a used Hyundai Sonata, Kia Optima, Tucson, Sportage, or any other model from these manufacturers, understanding which engines to seek out and which production years to target can mean the difference between a reliable daily driver and a mechanical nightmare.

The following ten engines represent the best of what Hyundai and Kia have offered during their safest production periods, providing buyers with confidence in their purchasing decisions and peace of mind for years to come.

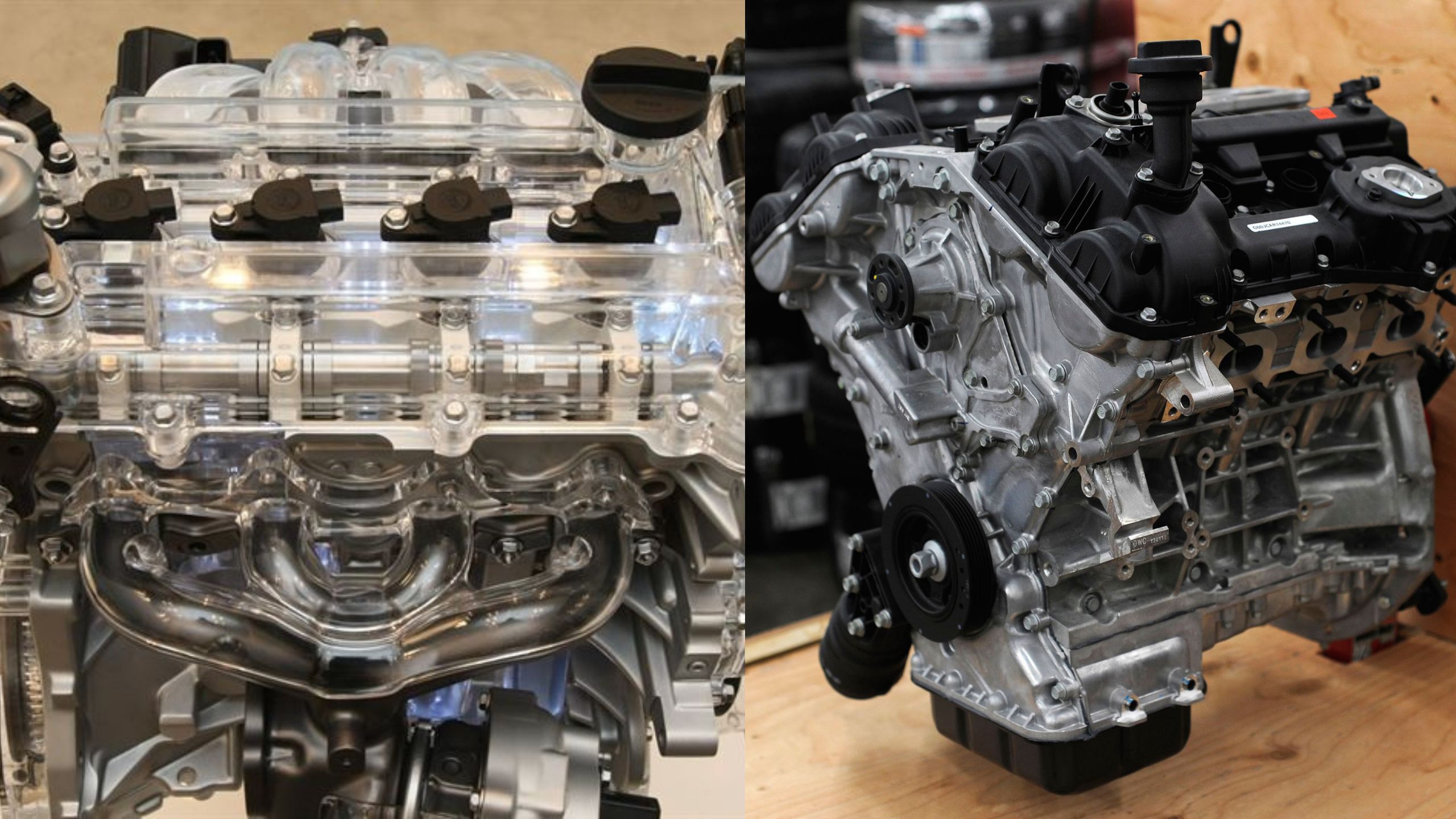

1. 2.4L Theta II GDI (2016-2019 Updated Version)

The Hyundai/Kia 2.4-liter Theta II engine underwent significant manufacturing improvements starting in 2016, making later versions considerably more reliable than their infamous predecessors.

While earlier Theta II engines from 2011-2015 suffered from widespread metal debris contamination during manufacturing that led to bearing failure and engine seizures, the updated versions incorporated improved machining processes and quality control measures that dramatically reduced these catastrophic failure rates.

The 2016-forward Theta II engines benefited from enhanced bearing surfaces, better oil flow characteristics, and more stringent assembly procedures that addressed the root causes of earlier problems.

This naturally aspirated gasoline direct injection engine produces between 185-188 horsepower depending on application and model year, offering a balanced combination of efficiency and performance suitable for midsize sedans and compact SUVs.

The engine utilizes dual continuously variable valve timing (D-CVVT) on both intake and exhaust camshafts, allowing for optimized valve timing across the entire RPM range to improve both power delivery and fuel economy.

The direct injection system operates at high pressure to precisely meter fuel directly into the combustion chambers, improving combustion efficiency while reducing emissions.

Found in popular models including the Hyundai Sonata, Tucson, Sportage, and Kia Optima, these later Theta II engines have demonstrated significantly improved longevity when properly maintained.

Owners who adhere to regular oil change intervals preferably using quality synthetic oil and keep up with routine maintenance typically see these engines reach 150,000 miles and beyond without major mechanical issues.

The key to longevity with these engines involves maintaining clean oil, as the direct injection system and tight bearing tolerances demand high-quality lubrication to prevent premature wear.

However, potential buyers should remain aware that even the improved Theta II engines aren’t completely immune to issues. Some vehicles may still be affected by manufacturing inconsistencies, and Hyundai/Kia have extended warranties covering certain engine problems on various model years.

The good news is that failure rates dropped substantially after the manufacturing improvements were implemented, and many of these engines are now accumulating high mileage without incident.

Common maintenance items include regular spark plug replacement (typically every 60,000 miles), periodic cleaning of the direct injection intake valves which can accumulate carbon deposits, and careful monitoring of oil consumption, particularly as mileage increases.

When shopping for vehicles equipped with the later Theta II engine, documentation of regular maintenance becomes crucial. Vehicles with complete service records demonstrating consistent oil changes and adherence to the manufacturer’s maintenance schedule represent the safest purchases.

Additionally, confirming whether the vehicle received any engine-related recalls or warranty extensions provides valuable peace of mind.

While the 2016-2019 Theta II engines don’t enjoy the bulletproof reputation of some older designs, they represent a substantial improvement over their troubled predecessors and can deliver reliable service when properly cared for, making them acceptable choices for buyers seeking affordable, efficient transportation from the Hyundai/Kia lineup during these model years.

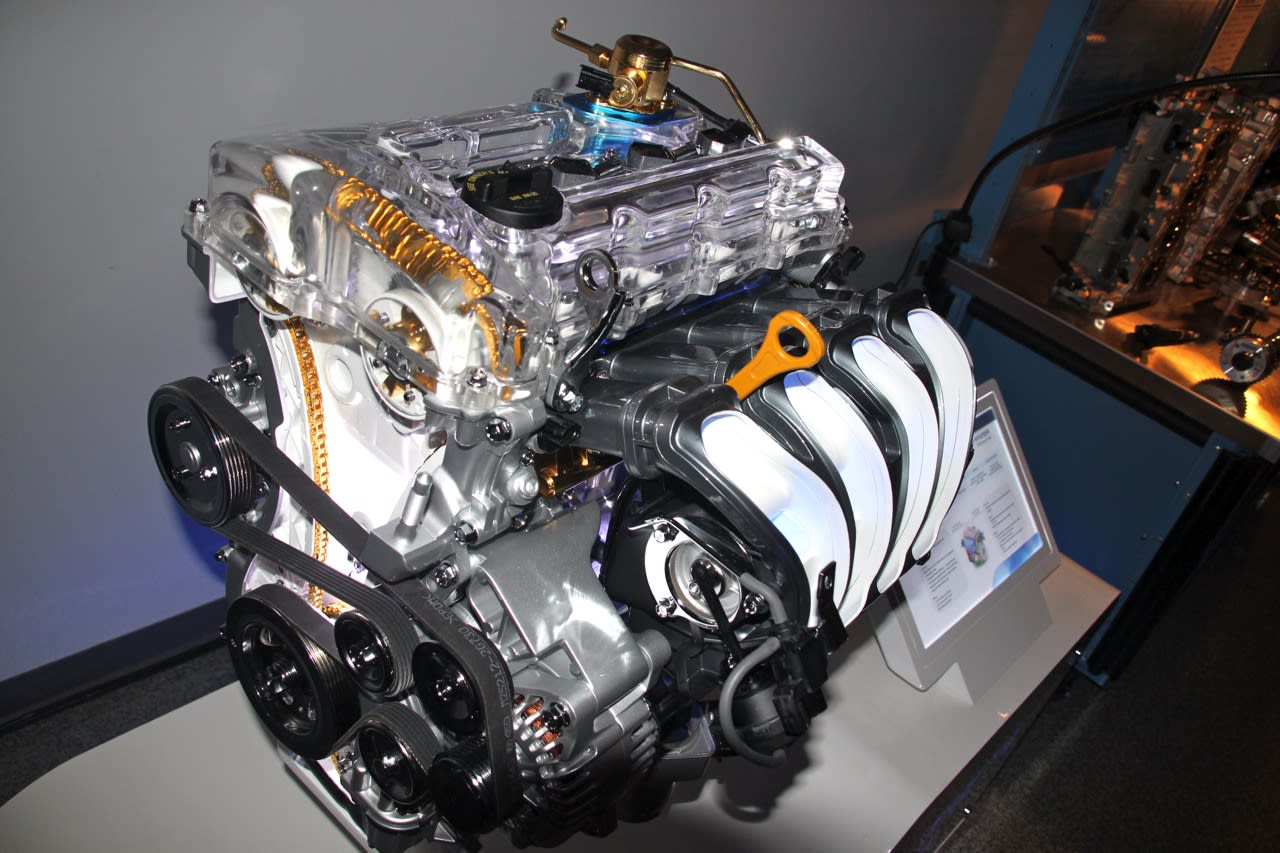

2. 3.3L Lambda II V6 (2011-2016)

The 3.3-liter Lambda II V6 engine stands as one of Hyundai and Kia’s most successful and reliable powerplants, particularly in the 2011-2016 production window.

This naturally aspirated V6 delivered approximately 290 horsepower and 252 lb-ft of torque, providing robust performance for larger sedans, SUVs, and minivans across both brands’ lineups.

Unlike the troublesome four-cylinder Theta engines of the same era, the Lambda II V6 maintained an excellent reliability record with minimal reports of catastrophic failure or widespread mechanical defects, making it a standout choice during years when Hyundai/Kia’s four-cylinder engines faced significant quality control problems.

The Lambda II engine family incorporated advanced technologies including gasoline direct injection (GDI), dual continuously variable valve timing (D-CVVT), and a variable induction system that optimized intake runner length based on engine speed and load conditions.

This combination of technologies allowed the engine to deliver strong low-end torque while maintaining impressive high-RPM power output, all while achieving competitive fuel economy figures for a naturally aspirated V6 of this displacement.

The engine’s all-aluminum construction kept weight down while providing excellent heat dissipation characteristics that contributed to its longevity and thermal efficiency.

Found in premium models such as the Hyundai Azera, Genesis, Santa Fe, and Kia Cadenza, Sorento, and Sedona, the Lambda II V6 powered some of each manufacturer’s most important vehicles.

The engine proved particularly well-suited to heavier applications like three-row SUVs and minivans, where its torque output and smooth power delivery made it a natural fit.

Owners consistently praised the engine’s refinement, with smooth operation throughout the rev range and minimal vibration even under heavy acceleration. The six-cylinder configuration provided inherently better balance than four-cylinder alternatives, contributing to a more premium driving experience.

Maintenance requirements for the Lambda II remain straightforward and reasonable. Regular oil changes using the manufacturer-specified grade (typically 5W-20 or 5W-30 synthetic oil) are essential, with 5,000-7,500 mile intervals being common recommendations.

The timing system utilizes a durable timing chain rather than a belt, eliminating the need for expensive periodic timing component replacement.

However, the direct injection system does require attention to intake valve carbon buildup, as is common with all GDI engines. Periodic intake valve cleaning typically performed every 60,000-80,000 miles helps maintain optimal performance and prevent issues related to carbon accumulation on valve surfaces.

The Lambda II’s strong reliability record is reflected in owner reports and mechanic experiences across hundreds of thousands of vehicles.

While no engine is completely trouble-free, the Lambda II experiences significantly fewer major failures than its four-cylinder counterparts from the same era.

Common issues tend to be minor and manageable, such as occasional coil pack failures or routine sensor replacements that are expected on any modern engine.

The engine’s robust internal components, conservative tuning, and well-designed oiling system all contribute to its ability to accumulate high mileage without major mechanical problems.

Many examples have surpassed 200,000 miles with only routine maintenance, and mechanics frequently cite the Lambda II as one of the most dependable engines in Hyundai/Kia’s portfolio.

For buyers seeking V6 power from a 2011-2016 Hyundai or Kia vehicle, the Lambda II represents one of the safest and most satisfying choices available.

3. 2.0L Beta II Engine (2005-2010)

The 2.0-liter Beta II engine represents a simpler era in Hyundai/Kia engineering, predating the widespread adoption of direct injection and turbocharging that would later create reliability challenges.

Produced from 2005 through 2010, this naturally aspirated four-cylinder utilized conventional port fuel injection, delivering approximately 138-156 horsepower depending on specific tuning and model year.

While these output figures seem modest by today’s standards, the Beta II’s straightforward design and conservative engineering have proven exceptionally durable, with many examples easily exceeding 200,000 miles with nothing more than routine maintenance and occasional repairs of normal wear items.

The Beta II employed proven technologies including dual overhead camshafts (DOHC), 16 valves, and continuously variable valve timing (CVVT) on the intake camshaft. This relatively simple valvetrain design provided adequate performance for compact and midsize vehicles while maintaining excellent reliability characteristics.

The port fuel injection system, while less efficient than later direct injection designs, eliminated the intake valve carbon buildup problems that plague GDI engines and provided more consistent fuel metering with fewer high-pressure fuel system components to fail.

The engine’s cast-iron block construction contributed to longevity, offering superior durability compared to the aluminum block designs that would follow.

This engine powered numerous vehicles across both brands, including the Hyundai Elantra, Tucson, Tiburon, and Kia Forte, Soul, and Sportage.

Its widespread application across multiple platforms demonstrated Hyundai/Kia’s confidence in the design and helped establish the Beta II as one of the most proven powerplants in their lineup during this period.

The engine proved particularly well-suited to compact cars and small SUVs, where its adequate power output and excellent fuel economy made it an attractive option for daily commuting and general transportation needs.

Maintenance on the Beta II is refreshingly straightforward, making it an ideal choice for budget-conscious buyers and DIY enthusiasts.

The engine uses a conventional timing belt that requires replacement approximately every 60,000-80,000 miles along with associated water pump and tensioner replacement a procedure that’s well-documented and relatively affordable compared to major engine repairs.

Regular oil changes every 3,000-5,000 miles using conventional or synthetic oil keep the engine’s simple oiling system functioning properly.

The port injection system requires only basic fuel filter changes and occasional injector cleaning to maintain optimal performance, with none of the expensive high-pressure fuel pump replacements that later GDI engines sometimes require.

The Beta II’s reputation for reliability is well-earned and widely recognized among mechanics and Hyundai/Kia enthusiasts. These engines rarely experience catastrophic failures when properly maintained, and most common issues involve routine replacement of aging components like ignition coils, spark plugs, and various sensors all relatively inexpensive and straightforward repairs.

The engine’s simple design means fewer complex systems to fail, and parts availability remains excellent even for older examples. Many Beta II engines continue running smoothly well past 200,000 miles, often outlasting other components of the vehicle.

For buyers shopping for used Hyundai or Kia vehicles from the 2005-2010 era, the Beta II-equipped models represent some of the safest, most reliable choices available, offering proven longevity and minimal risk of the expensive engine problems that affected later model years with more complex powerplants.

4. 3.8L Lambda V6 (2006-2012)

The 3.8-liter Lambda V6 engine, produced from 2006 through 2012, represents the larger-displacement sibling to the Lambda engine family and stands among Hyundai and Kia’s most reliable and satisfying powerplants.

Delivering between 260-290 horsepower depending on specific model year and tuning, this naturally aspirated V6 provided strong performance for premium sedans and larger SUVs while maintaining an exemplary reliability record.

The Lambda 3.8 predates many of the engine problems that would later affect both brands, and its proven track record of durability makes it a highly sought-after option for buyers seeking V6 power without the reliability concerns that plagued certain other engines in Hyundai/Kia’s lineup.

The Lambda 3.8 featured all-aluminum construction with dual overhead camshafts, four valves per cylinder, and continuously variable valve timing on both intake and exhaust camshafts.

This advanced valvetrain design allowed for excellent breathing characteristics throughout the RPM range, delivering smooth power from idle to redline.

The engine utilized port fuel injection rather than the direct injection technology that would be introduced on later versions, which eliminated the intake valve carbon buildup issues common to GDI engines while still providing excellent fuel metering and efficiency for its time.

The variable intake manifold system adjusted intake runner length based on engine speed, optimizing torque delivery across a wide powerband.

This engine found its home in flagship models, including the Hyundai Genesis sedan, Azera, Santa Fe, Veracruz, and Kia Borrego, along with various other premium applications.

The 3.8-liter displacement provided ample torque for larger, heavier vehicles while the smooth V6 configuration delivered a refined driving experience appropriate for luxury-oriented models.

Owners consistently praised the engine’s linear power delivery, refined operation, and surprising fuel economy given its displacement and output.

The engine proved particularly well-suited to highway cruising, where its torque reserves allowed for effortless passing and merging while maintaining comfortable cruising speeds with minimal engine strain.

Maintenance on the Lambda 3.8 is straightforward and reasonable for a V6 of its complexity. The engine utilizes a timing chain rather than a belt, eliminating the need for expensive periodic timing system replacement and significantly reducing long-term ownership costs.

Regular oil changes using quality synthetic oil (typically 5W-20 or 5W-30) at 5,000-7,500 mile intervals are the primary maintenance requirement, along with routine spark plug replacement every 60,000-100,000 miles depending on specific recommendations.

The port injection system requires minimal maintenance beyond basic fuel filter changes, and the engine’s relatively simple electronic control systems have proven reliable over time.

Common wear items include ignition coils, oxygen sensors, and various engine management sensors that typically require replacement as vehicles age past 100,000 miles all relatively affordable and straightforward repairs.

The Lambda 3.8’s outstanding reliability reputation is supported by extensive real-world evidence from hundreds of thousands of vehicles.

These engines rarely experience catastrophic failures or major mechanical problems when properly maintained, and many examples have accumulated well over 200,000 miles with only routine maintenance and minor repairs.

Unlike the troublesome Theta II four-cylinder engines from overlapping production years, the Lambda 3.8 avoided the manufacturing quality issues that led to widespread engine failures.

Mechanics frequently cite this engine as one of the most dependable in Hyundai/Kia’s history, and the used market reflects this reputation with Lambda 3.8-equipped vehicles often commanding premium prices compared to four-cylinder alternatives.

For buyers seeking a reliable, powerful V6 from Hyundai or Kia’s 2006-2012 model years, the Lambda 3.8 represents the gold standard, offering robust performance, excellent refinement, and proven long-term durability that makes it one of the safest engine choices available from this era.

Also Read: 10 BMW Models That Are Reliable When Bought Right

5. 1.6L Gamma Engine (2010-2015)

The 1.6-liter Gamma engine, produced from 2010 through 2015, represents Hyundai and Kia’s successful foray into smaller-displacement four-cylinder engines designed for compact vehicles and fuel-conscious buyers.

This naturally aspirated powerplant delivered approximately 120-138 horsepower depending on specific tuning and model year, providing adequate performance for subcompact and compact vehicles while achieving impressive fuel economy figures.

The Gamma engine utilized gasoline direct injection (GDI) technology combined with dual continuously variable valve timing (D-CVVT) to optimize both efficiency and performance, representing a modern, technologically advanced design that nonetheless avoided many of the reliability problems that plagued larger-displacement engines during this period.

The Gamma’s all-aluminum construction kept weight to a minimum, which proved particularly beneficial in smaller vehicles where every pound affects performance and efficiency.

The engine’s compact dimensions allowed for flexible packaging in engine bays designed for space efficiency, making it ideal for vehicles where interior space and cargo capacity took precedence over large engine compartments.

The direct injection system operated at high pressure to precisely meter fuel directly into the combustion chambers, improving thermal efficiency and reducing emissions while delivering crisp throttle response.

The dual CVVT system continuously adjusted valve timing on both intake and exhaust camshafts, optimizing performance across the entire operating range from idle to redline.

This engine found widespread application in popular models including the Hyundai Accent, Veloster, Elantra GT, and Kia Rio, Soul, and Forte, making it one of the most commonly encountered engines in both manufacturers’ compact vehicle lineups.

The Gamma proved particularly well-suited to city driving and commuting duties, where its small displacement and efficient operation delivered excellent fuel economy while providing adequate power for going through the urban traffic and highway merging.

The engine’s relatively modest output meant it was never overstressed in typical driving conditions, contributing to its longevity and reliability.

Maintenance requirements for the Gamma engine are reasonable and straightforward, though owners must pay attention to certain GDI-specific concerns.

Regular oil changes using quality synthetic oil at 5,000-7,500 mile intervals are essential, as the direct injection system and tight bearing tolerances demand clean, high-quality lubrication.

The engine utilizes a timing chain rather than a belt, eliminating expensive periodic timing component replacement. However, like all GDI engines, the Gamma can experience intake valve carbon buildup due to the lack of fuel washing over the intake valves.

Periodic intake valve cleaning typically performed every 60,000-80,000 miles, helps maintain optimal performance and prevent drivability issues related to carbon accumulation.

The high-pressure fuel system includes a mechanical high-pressure fuel pump driven by the camshaft, which can occasionally require replacement but generally proves durable.

The Gamma 1.6’s reliability record is generally positive, particularly compared to the larger Theta II engines that shared showroom floors during the same years.

While no engine is completely trouble-free, the Gamma avoided the catastrophic bearing failures and widespread mechanical problems that affected certain other Hyundai/Kia powerplants.

Common issues tend to be minor and manageable, such as occasional coil pack failures, routine sensor replacements, and the expected carbon buildup inherent to all GDI engines.

Many Gamma engines have accumulated 150,000 miles and beyond with only routine maintenance and normal wear item replacement.

The engine’s smaller displacement and conservative tuning meant it was never pushed to extreme limits in typical applications, which contributed significantly to its longevity.

For buyers seeking economical, reliable transportation from Hyundai or Kia’s compact vehicle lineup during the 2010-2015 period, Gamma-equipped models represent safe, practical choices that balance modern efficiency with proven durability.

6. 2.7L Delta V6 (2004-2009)

The 2.7-liter Delta V6 engine, produced from 2004 through 2009, represents one of Hyundai and Kia’s most dependable powerplants from the mid-2000s era.

This naturally aspirated V6 delivered approximately 173-185 horsepower depending on model year and application, providing smooth, reliable power for midsize sedans and SUVs.

While not particularly powerful by modern standards, the Delta V6’s conservative engineering, proven design, and straightforward technology have resulted in exceptional longevity, with many examples easily surpassing 200,000 miles when properly maintained.

This engine avoided the complexity and reliability issues that would affect later powerplants, making it a particularly attractive option for buyers seeking low-risk, dependable transportation from vehicles of this era.

The Delta V6 featured an all-aluminum block and cylinder heads with dual overhead camshafts and four valves per cylinder, representing modern engine architecture combined with conservative, proven technologies.

The engine utilized port fuel injection rather than direct injection, which provided excellent reliability and eliminated the carbon buildup issues that would later affect GDI engines.

Continuously variable valve timing (CVVT) on the intake camshaft allowed for optimized valve timing across different engine speeds and loads, improving both power delivery and fuel efficiency.

The 60-degree V6 configuration provided excellent balance and smooth operation, delivering a refined driving experience with minimal vibration throughout the RPM range.

This engine powered important models, including the Hyundai Santa Fe, Sonata, Tucson, and Kia Optima, Sportage, and Sedona, making it one of the most widespread V6 options in both manufacturers’ lineups during the mid-2000s.

The Delta V6 proved particularly well-suited to family transportation duties, providing adequate power for highway driving and towing light loads while delivering reasonable fuel economy for its time.

While not a performance engine, the Delta offered smooth, linear power delivery that satisfied most drivers’ needs for daily commuting and family hauling.

The engine’s refinement and quiet operation contributed to a more premium driving experience compared to four-cylinder alternatives.

Maintenance on the Delta V6 is straightforward and affordable, making it an excellent choice for budget-conscious buyers and DIY enthusiasts.

The engine uses a timing belt that requires replacement approximately every 60,000-90,000 miles, depending on specific manufacturer recommendations, typically performed alongside water pump and tensioner replacement.

While timing belt replacement represents a significant maintenance expense, the predictable schedule and well-documented procedure make it a manageable expense.

Many mechanics consider the Delta V6 among the most reliable engines Hyundai and Kia have produced, frequently citing examples that continue running smoothly well past 250,000 miles. The engine’s cast-iron cylinder liners within the aluminum block provide excellent wear resistance, contributing to its longevity.

For buyers shopping for used Hyundai or Kia vehicles from the 2004-2009 era who desire V6 power, Delta-equipped models represent some of the safest, most reliable choices available, offering proven durability and minimal risk of expensive engine problems that affected later, more complex powerplants.

7. 2.0L Nu MPI Engine (2011-2016)

The 2.0-liter Nu engine in its multi-point injection (MPI) configuration, produced from 2011 through 2016, represents Hyundai and Kia’s effort to provide a reliable, affordable engine option alongside their more complex direct injection variants.

Delivering approximately 147-164 horsepower, depending on specific tuning and model year, this naturally aspirated four-cylinder utilized conventional port fuel injection technology, deliberately avoiding the direct injection system that contributed to problems in other engines from this era.

The Nu MPI’s straightforward design and conservative engineering have proven considerably more reliable than its troubled GDI and turbocharged siblings, making it one of the safer choices from Hyundai/Kia’s lineup during years when engine quality control issues peaked.

The Nu MPI featured an all-aluminum block and cylinder head with dual overhead camshafts, 16 valves, and dual continuously variable valve timing (D-CVVT) on both intake and exhaust camshafts.

This modern valvetrain design provided good breathing characteristics and allowed for optimized valve timing across the operating range, delivering adequate performance while maintaining excellent efficiency.

The port fuel injection system, while less technologically advanced than direct injection, offered superior reliability with fewer complex, high-pressure components to fail.

The conventional injection system also eliminated the intake valve carbon buildup problems inherent to GDI engines, significantly reducing long-term maintenance requirements and potential drivability issues.

This engine found application in volume models, including the Hyundai Elantra, Tucson, and Kia Forte, Soul, and Sportage, typically serving as the base engine option in these vehicles.

While buyers often gravitated toward more powerful GDI or turbocharged variants, those who chose the Nu MPI benefited from its superior reliability and simpler maintenance requirements.

The engine provided adequate performance for daily driving duties, with sufficient power for highway cruising and city traffic while delivering competitive fuel economy figures.

While not exciting, the Nu MPI’s predictable, linear power delivery and smooth operation satisfied most owners’ transportation needs without drama or expensive surprises.

Maintenance on the Nu MPI is exceptionally straightforward, making it ideal for budget-conscious buyers and those seeking minimal ownership hassles.

Regular oil changes every 5,000-7,500 miles using quality synthetic oil represent the primary maintenance requirement, along with routine spark plug replacement every 60,000-100,000 miles.

The engine utilizes a timing chain rather than a belt, eliminating expensive periodic timing system replacement and significantly reducing long-term ownership costs.

While the MPI variant may lack the power and efficiency of more advanced engines, its proven reliability and minimal maintenance requirements make it one of the smartest choices available from this problematic era in Hyundai/Kia’s engine development history.

8. 1.8L Nu Engine (2010-2016)

The 1.8-liter Nu engine, produced from 2010 through 2016, occupies an interesting position in Hyundai and Kia’s engine lineup, offering a balance between the smaller 1.6-liter Gamma and the larger 2.0-liter Nu variants.

Delivering approximately 145-148 horsepower depending on model year and specific tuning, this naturally aspirated four-cylinder provided adequate power for compact and midsize vehicles while achieving competitive fuel economy.

The Nu 1.8 was offered in both multi-point injection (MPI) and gasoline direct injection (GDI) configurations, with the MPI variant generally proving more reliable due to its simpler fuel system and lack of intake valve carbon buildup issues.

This engine represents a practical, middle-ground choice for buyers seeking reasonable performance without the complexity and potential problems of larger-displacement or turbocharged alternatives.

The Nu 1.8 featured modern engine architecture including an all-aluminum construction, dual overhead camshafts, and dual continuously variable valve timing (D-CVVT) on both intake and exhaust camshafts.

This valvetrain design allowed for optimized breathing and valve timing across the entire operating range, delivering smooth power from low RPMs through to redline.

The engine’s relatively modest displacement meant it was never highly stressed in typical applications, which contributed significantly to its longevity and reliability.

The MPI variant utilized conventional port fuel injection, providing excellent reliability and eliminating the carbon buildup concerns of GDI systems. At the same time, the GDI version offered slightly improved efficiency at the cost of increased complexity and maintenance requirements.

This engine powered popular models, including the Hyundai Elantra, Elantra Coupe, and Kia Forte, making it one of the most common powerplants in both manufacturers’ compact sedan lineups.

The Nu 1.8 proved well-suited to these applications, providing sufficient power for highway driving and daily commuting while delivering fuel economy that satisfied budget-conscious buyers.

The engine’s smooth operation and refined character contributed to a comfortable driving experience, with minimal vibration or harshness even under acceleration.

While not particularly sporty or exciting, the Nu 1.8 delivered predictable, reliable performance that met most drivers’ everyday transportation needs without demanding excessive maintenance or causing reliability concerns.

Maintenance requirements for the Nu 1.8 vary somewhat depending on whether the engine features MPI or GDI fuel delivery. The MPI variant requires straightforward maintenance consisting primarily of regular oil changes every 5,000-7,500 miles using quality synthetic oil, along with periodic spark plug replacement every 60,000-100,000 miles.

The engine’s moderate displacement and conservative tuning meant it was rarely pushed to extreme limits, which contributed to its longevity. Mechanics generally consider the Nu 1.8, particularly the MPI version, among the more dependable choices from Hyundai/Kia’s 2010-2016 lineup, significantly safer than Theta II engines from the same years.

For buyers seeking reliable, economical transportation from compact Hyundai or Kia sedans during this period, Nu 1.8-equipped models, especially those with MPI fuel delivery, represent sensible choices that balance modern efficiency with proven durability and minimal ownership drama.

9. 2.4L Theta Engine (2004-2010 Early Version)

The early version of the 2.4-liter Theta engine, produced from 2004 through 2010, represents the original iteration of this engine family before the manufacturing quality issues that would plague later Theta II variants.

Delivering approximately 162-175 horsepower depending on specific model year and tuning, this naturally aspirated four-cylinder utilized port fuel injection technology, providing smooth, reliable power for midsize sedans and compact SUVs.

The early Theta engine earned a solid reliability reputation during its production run, with minimal reports of catastrophic failure or widespread mechanical problems.

This stands in stark contrast to the Theta II engines that followed, which became infamous for manufacturing defects and bearing failures that led to massive recalls and warranty extensions.

The early Theta featured an all-aluminum block and cylinder head with dual overhead camshafts and 16 valves, representing modern engine architecture combined with proven, conservative technologies.

The engine utilized continuously variable valve timing (CVVT) on the intake camshaft, allowing for optimized valve timing across different operating conditions to improve both performance and efficiency.

The port fuel injection system provided excellent fuel metering and reliability without the complexity and carbon buildup issues that would later affect direct injection engines.

The engine’s internal components, including bearings and connecting rods, were manufactured with adequate quality control during this period, avoiding the metal debris contamination problems that would devastate later Theta II production runs.

This engine found widespread application in important models, including the Hyundai Sonata, Santa Fe, Tucson, and Kia Optima, Sportage, and Rondo, making it one of the most common powerplants across both manufacturers’ lineups during the late 2000s.

The early Theta provided adequate power for family transportation duties, with sufficient torque for highway driving and light towing while delivering competitive fuel economy for its displacement and era.

The engine’s smooth operation and refined character contributed to a comfortable driving experience, with linear power delivery and minimal harshness.

While not particularly exciting or powerful by modern standards, the early Theta satisfied most owners’ daily driving needs reliably and without drama.

Maintenance on the early Theta engine is straightforward and reasonable, making it suitable for budget-conscious buyers and DIY enthusiasts.

The engine uses a timing chain rather than a belt, eliminating expensive periodic timing system replacement and significantly reducing long-term ownership costs.

Regular oil changes every 3,000-5,000 miles using quality conventional or synthetic oil represent the primary maintenance requirement, along with routine spark plug replacement every 60,000-100,000 miles, depending on specific recommendations.

The port injection system requires minimal maintenance beyond basic fuel filter changes and occasional fuel system cleaning, with none of the complex high-pressure components found in later GDI engines.

The key is ensuring potential purchases fall within the 2004-2010 production window and feature the port-injected Theta rather than the later Theta II with direct injection, as this distinction marks the dividing line between reliable and problematic variants of this engine family.

10. 3.5L Lambda II GDI V6 (2015-2019)

The 3.5-liter Lambda II GDI V6 engine, produced from 2015 through 2019, represents the evolution of Hyundai and Kia’s successful Lambda V6 family into the modern era of direct injection technology.

Delivering between 290-310 horsepower depending on specific tuning and application, this naturally aspirated V6 provided robust performance for premium sedans, larger SUVs, and minivans while maintaining the Lambda family’s excellent reliability reputation.

Unlike the troublesome four-cylinder Theta engines from the same period, the Lambda II 3.5 GDI avoided widespread mechanical problems and manufacturing defects, continuing the V6 family’s tradition of dependability.

This engine represents one of the safest choices available from Hyundai and Kia during the mid-to-late 2010s, a period when four-cylinder engines faced significant quality concerns.

The Lambda II 3.5 GDI featured advanced technologies including gasoline direct injection, dual continuously variable valve timing (D-CVVT) on both intake and exhaust camshafts, and a variable intake system that optimized intake runner length based on engine speed and load conditions. The all-aluminum construction kept weight reasonable while providing excellent heat dissipation characteristics.

Buyers should still verify complete maintenance records, confirm the vehicle received any applicable recalls or service campaigns, and ensure proper oil change intervals were maintained, but Lambda II 3.5 GDI-equipped vehicles generally represent low-risk purchases that can deliver many years of trouble-free service when properly cared for, making this engine an excellent choice for anyone seeking V6 power from Hyundai or Kia’s mid-to-late 2010s lineup.

Also Read: 10 Automatic Transmissions That Rarely Need A Rebuild