The transmission is one of the most complex and crucial components in any vehicle, responsible for transferring power from the engine to the wheels while allowing the driver to control speed and torque.

At the heart of every transmission’s operation is transmission fluid a specialized lubricant that serves multiple critical functions. It reduces friction between moving parts, dissipates heat, maintains hydraulic pressure for gear changes, and protects internal components from wear and corrosion.

Over time, this fluid degrades, losing its protective properties and accumulating contaminants that can compromise transmission performance. For many vehicle owners, the question of whether to service their transmission fluid becomes a source of confusion and anxiety.

Mechanics and automotive forums are filled with conflicting advice: some insist that regular fluid changes are essential for transmission longevity, while others warn that changing old fluid in high-mileage transmissions can actually cause more harm than good.

This debate isn’t just theoretical it reflects real differences in how various transmission designs respond to maintenance.

Understanding which category your transmission falls into is essential for making informed maintenance decisions.

This comprehensive guide examines seven transmission types that respond positively to fluid changes, experiencing improved performance and extended service life, alongside seven transmission types where fluid service provides minimal benefit or may even precipitate problems.

By exploring the engineering principles, design characteristics, and real-world experiences associated with each transmission type, vehicle owners can develop a nuanced understanding of when to embrace fluid service as preventive maintenance and when to approach it with caution.

Whether you’re maintaining a daily driver, restoring a classic vehicle, or simply trying to maximize your transmission’s lifespan, this information will help you make the best decision for your specific situation.

7 Transmissions That Respond Well to Fluid Changes

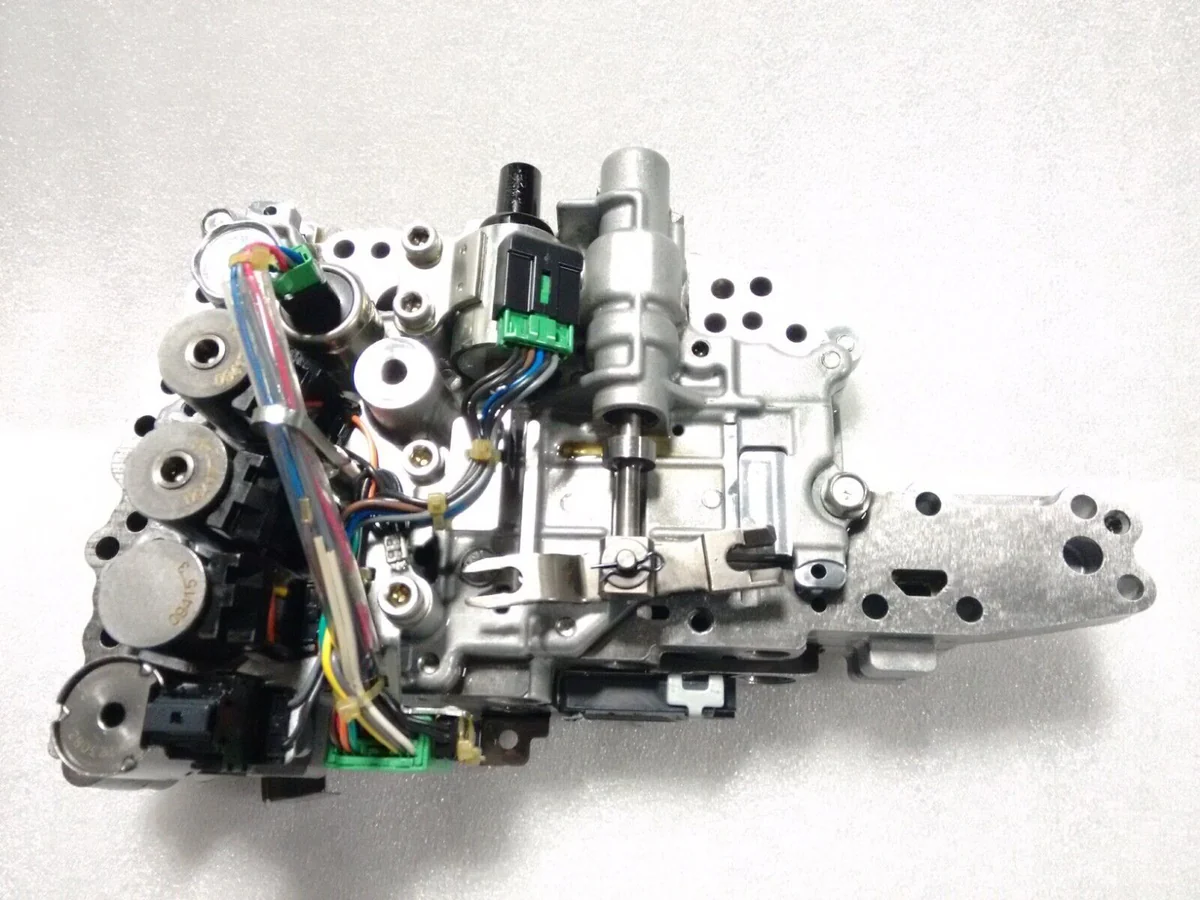

These exceptionally engineered gearboxes feature hydraulically actuated clutch packs with generous friction surface area, planetary gear sets with robust lubrication pathways, and valve body assemblies using precision-machined components that benefit dramatically from fresh fluid restoring proper hydraulic pressure and cleaning away accumulated debris.

Their thoughtful engineering includes torque converters with effective filtration preventing clutch material contamination, internal passages sized adequately for fluid circulation maintaining consistent operating temperatures, and clutch pack designs tolerating moderate wear without complete failure when serviced appropriately at manufacturer-specified intervals.

From noticeably smoother shifting after fluid replacement to restored line pressure eliminating slippage, these remarkable transmissions demonstrate immediate improvement following proper maintenance.

1. Honda Automatic Transmissions (Pre-2010 Models)

Honda’s automatic transmissions manufactured before 2010, particularly the popular four-speed and five-speed units found in Accords, Civics, and CR-Vs, represent some of the most maintenance-responsive transmissions ever produced.

These transmissions were engineered with serviceability as a core design principle, featuring accessible drain plugs, external filters in many models, and a hydraulic system that thrives on clean fluid.

The engineering philosophy behind these units emphasized simplicity and durability, with generous tolerances that could accommodate minor contamination while still benefiting tremendously from regular maintenance.

The fluid capacity in these Honda transmissions typically ranges from 2.5 to 3.5 quarts for a drain-and-fill service, which replaces approximately 40-50% of the total fluid.

Honda recommends using their genuine ATF-Z1 fluid (or DW-1 in later models), which is specifically formulated for the friction characteristics of their clutch materials.

When fresh fluid is introduced, owners consistently report immediate improvements in shift quality, with smoother transitions between gears and reduced shift flare or hesitation.

The transmission’s temperature also tends to drop by 10-20 degrees Fahrenheit, which significantly extends the life of internal components.

Real-world longevity data supports the benefits of regular fluid service in these transmissions. Well-maintained Honda automatics from this era routinely exceed 200,000 miles without requiring major repairs, while neglected units often experience issues between 100,000 and 150,000 miles.

Common problems in unmaintained transmissions include third-gear clutch pack failure, torque converter shudder, and valve body scoring all issues that can be prevented or significantly delayed through consistent fluid changes.

The cost-effectiveness of this maintenance is remarkable: spending $100-150 every 30,000 miles on fluid changes can prevent a $2,500-4,000 transmission rebuild or replacement, making it one of the best investments a Honda owner can make in their vehicle’s longevity.

2. Toyota/Lexus U-Series Transmissions

The Toyota U-series transmissions, found in Camrys, Avalons, Highlanders, and various Lexus models, exemplify Japanese engineering excellence and represent another category of automatics that respond exceptionally well to regular fluid maintenance.

These four-speed, five-speed, and six-speed units were designed with an emphasis on durability and refinement, featuring robust construction that can easily surpass 300,000 miles with proper care.

The U-series designation encompasses several specific models, including the U140, U151, U250, and U660, each sharing similar design philosophies and maintenance requirements.

Toyota’s approach to transmission fluid is notably conservative and quality-focused. The company specifies Toyota Genuine ATF WS (World Standard) for most U-series transmissions, a synthetic fluid with enhanced thermal stability and friction characteristics.

This fluid is engineered to maintain its properties over extended service intervals, but Toyota’s official recommendation of “inspect at 60,000 miles, change if necessary” has created some confusion among owners.

In practice, transmission specialists nearly universally recommend proactive fluid changes at 60,000-mile intervals, as the benefits far outweigh the minimal cost, and waiting for visible contamination often means damage has already begun.

Service procedures for U-series transmissions are straightforward but should be performed correctly to maximize benefits. A drain-and-fill through the transmission pan typically replaces 3-4 quarts of the 9-12 quart total capacity.

Many owners and shops perform a double drain-and-fill, changing fluid, driving 50-100 miles, then repeating the process to replace a higher percentage of the old fluid.

The transmission pan should be removed and cleaned, though many U-series models use a non-serviceable internal filter that’s designed to last the transmission’s lifetime.

Inspecting the pan for metal particles provides valuable insight into transmission health a light metallic dust is normal, but chunks or excessive debris indicate wear that may require professional evaluation.

With consistent maintenance every 60,000 miles, U-series transmissions have proven capable of delivering 400,000+ miles of reliable service.

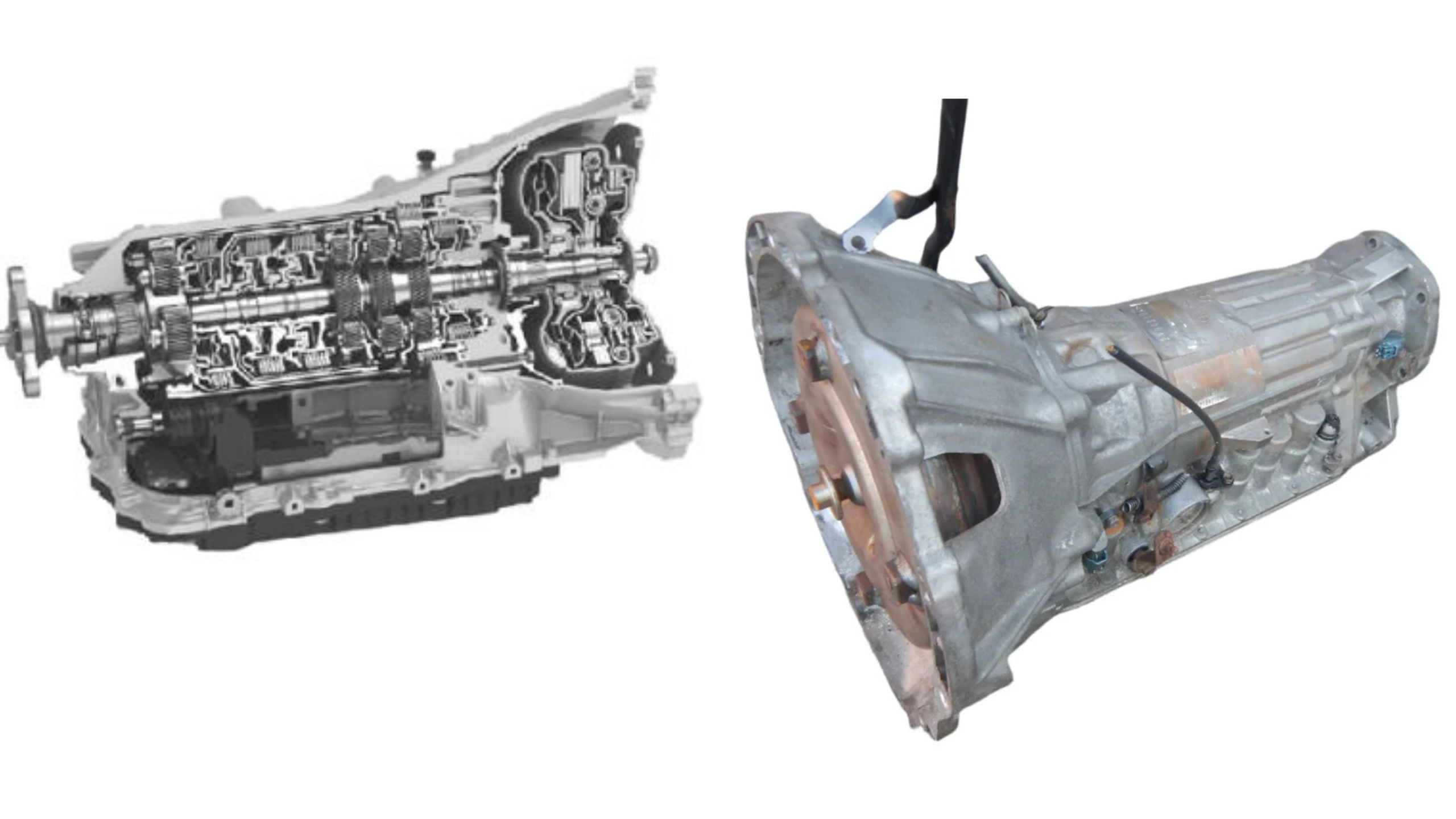

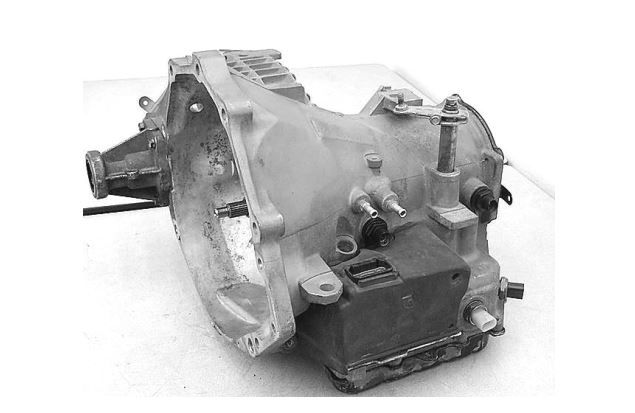

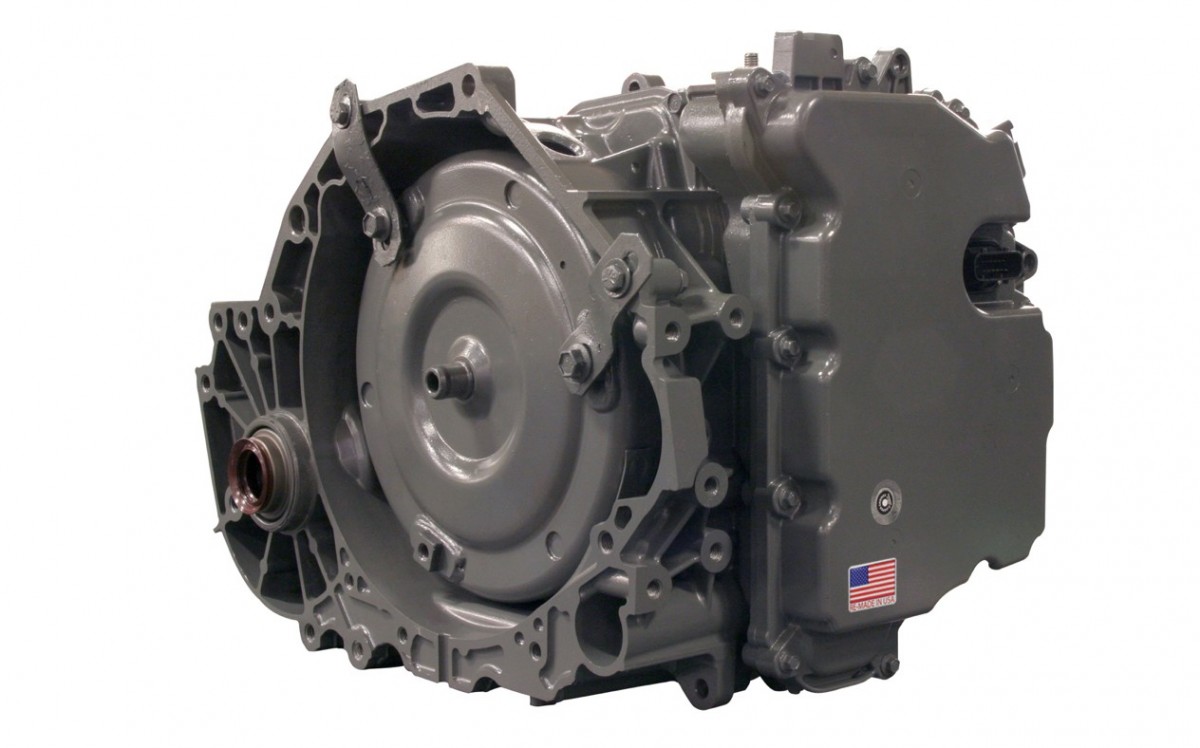

3. GM 4L60E and 4L80E Transmissions

General Motors’ 4L60E and 4L80E transmissions represent workhorses of the American automotive industry, found in countless trucks, SUVs, and performance vehicles from the 1990s through the 2010s.

These electronically controlled four-speed automatics are renowned for their serviceability and robust response to regular maintenance, making them favorites among enthusiasts and fleet operators alike.

The “E” designation indicates electronic control, which allows for precise shift timing and adaptability, but also means these transmissions rely heavily on proper fluid condition for optimal electronic and hydraulic coordination.

The 4L60E, the lighter-duty variant, was installed in vehicles ranging from Chevrolet Silverados and GMC Sierras to Cadillac Escalades and various performance applications like the Camaro and Corvette.

Its heavy-duty sibling, the 4L80E, found homes in three-quarter-ton and one-ton trucks, as well as high-performance applications requiring greater torque capacity.

Both transmissions share similar design philosophies and maintenance requirements, though the 4L80E’s more robust construction gives it slightly more tolerance for abuse.

What makes both transmissions exceptional candidates for fluid service is their straightforward hydraulic design, accessible components, and the dramatic improvements users report after maintenance.

These GM transmissions hold approximately 11-12 quarts of fluid, with a drain-and-fill replacing about 5-6 quarts. GM originally specified Dexron III fluid, later superseding it with Dexron VI, a synthetic formulation with superior thermal stability and longer service life.

The improvement in shift quality after a fluid change in these transmissions is often described as transformative, particularly in high-mileage units.

Shifts become firmer and more decisive, shift timing improves, and common issues like 1-2 shift flare (where engine RPM rises during the shift) often diminish or disappear entirely.

These changes occur because fresh fluid restores proper hydraulic pressure and allows the pressure control solenoids to function within their designed parameters.

Inspecting the removed fluid and pan contents provides valuable diagnostic information dark, burnt-smelling fluid indicates overheating, while metal particles on the magnet reveal the extent of internal wear.

Performance enthusiasts often install aftermarket transmission coolers and reduce service intervals to 25,000 miles, effectively doubling the transmission’s service life.

With proper maintenance, 4L60E and 4L80E transmissions regularly exceed 200,000-250,000 miles, and rebuilds primarily replace wear items rather than addressing catastrophic failures.

4. Ford C4 and C6 Transmissions

Ford’s C4 and C6 transmissions represent classic American automatic transmission engineering, produced from the 1960s through the 1990s and installed in millions of vehicles ranging from Mustangs to F-Series trucks.

These three-speed automatics are beloved by enthusiasts and restoration specialists for their simplicity, durability, and remarkable responsiveness to basic maintenance.

Unlike modern transmissions with complex electronics and intricate valve bodies, the C4 and C6 rely on straightforward hydraulic principles and robust mechanical construction, making them exceptionally tolerant of various service conditions while still benefiting tremendously from fresh fluid.

The C4, designed for lighter vehicles and smaller engines, found extensive use in Mustangs, Falcons, and compact trucks, while the heavier C6 powered full-size vehicles and heavy-duty applications.

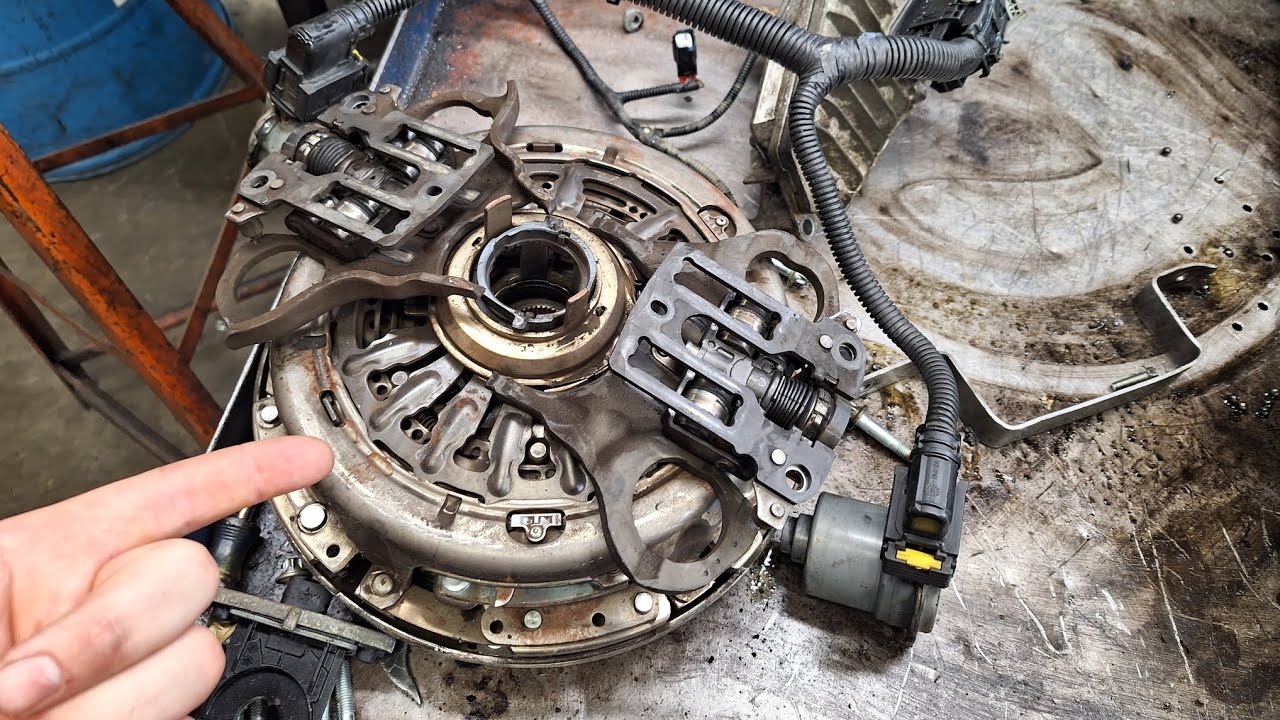

Both transmissions share similar design DNA but differ primarily in torque capacity and physical size. What makes these transmissions particularly maintenance-responsive is their simple planetary gearset arrangement, robust clutch packs, and valve bodies with relatively few components.

The hydraulic circuits are straightforward, with fewer restrictions and passages than modern designs, meaning fresh fluid can quickly circulate throughout the system and deliver immediate benefits.

Recommended service intervals for C4 and C6 transmissions vary based on application, but 25,000-40,000 miles is generally considered appropriate for normal use, with more frequent changes recommended for towing or performance applications.

The service procedure is beautifully simple: drain the pan, replace the inexpensive filter, clean the pan and magnet, and refill with the specified fluid.

Many owners of classic vehicles with these transmissions adopt a simple rule: change the fluid whenever you perform an oil change, effectively servicing the transmission every 3,000-5,000 miles.

While this is more frequent than necessary, it ensures optimal performance and extends component life indefinitely. The low cost of service (Type F fluid is inexpensive, and filters cost $10-15) makes frequent maintenance practical.

With proper fluid maintenance, C4 and C6 transmissions regularly outlast the vehicles they’re installed in, with many units exceeding 300,000 miles with only basic wear-item replacements. Their continued popularity in hot rods, race cars, and restored classics testifies to their durability and maintenance responsiveness.

Also Read: 10 Automatic Transmissions That Rarely Need A Rebuild

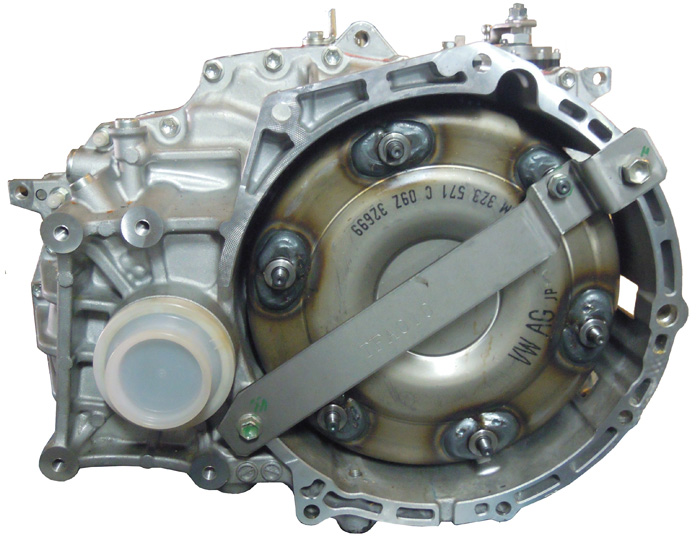

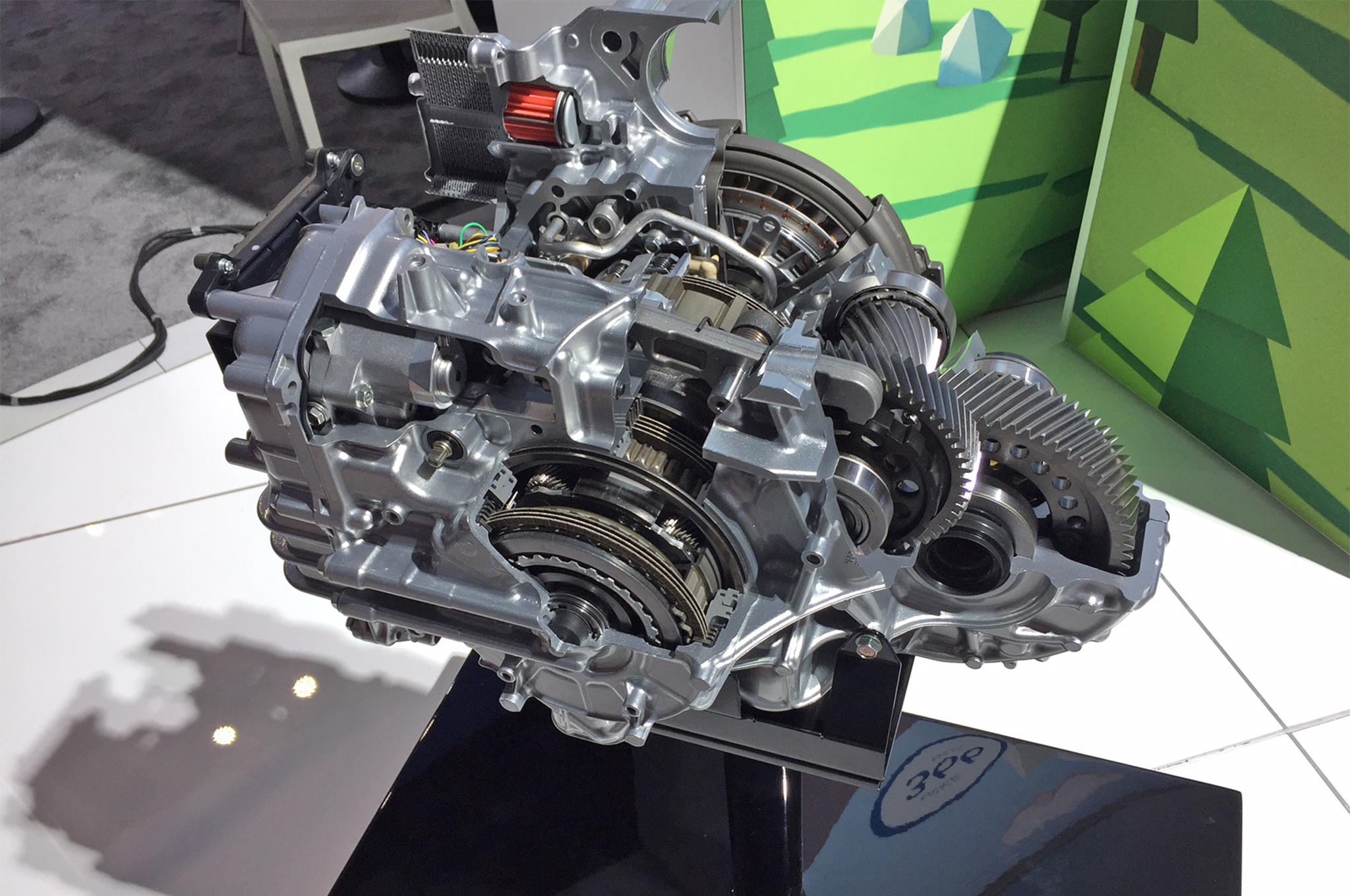

5. ZF 6-Speed and 8-Speed Automatic Transmissions

ZF’s 6-speed (6HP) and 8-speed (8HP) automatic transmissions represent the pinnacle of modern transmission engineering, combining sophisticated electronics, advanced materials, and precision manufacturing to deliver exceptional performance and efficiency.

These transmissions, found in BMWs, Audis, Jaguars, Ram trucks, and numerous other premium applications, are technically complex but remarkably responsive to proper maintenance when service protocols are followed correctly.

The 8HP series in particular has gained a reputation as one of the finest automatic transmissions ever produced, offering seamless shifts, impressive fuel economy, and surprising durability when maintained according to manufacturer specifications.

What distinguishes ZF transmissions is their design philosophy emphasizing low friction, compact packaging, and precise hydraulic control.

The 8HP series achieves eight forward speeds through an innovative planetary gearset arrangement that requires only four clutches and two brakes, far simpler than competing designs.

This efficiency reduces parasitic losses and heat generation, but it also means the transmission depends heavily on proper fluid viscosity and friction characteristics for reliable operation.

ZF specifies Lifeguard synthetic transmission fluid, available in several formulations (6, 8, and 9) matched to specific transmission models. This fluid is engineered with precise friction modifiers and viscosity characteristics that the transmission’s control algorithms expect.

The responsiveness of ZF transmissions to fluid changes manifests differently than in older designs. Rather than dramatic shifts from “bad” to “good,” properly maintained ZF units remain consistently excellent, while neglected units progressively develop issues.

Fresh fluid maintains the transmission’s renowned smoothness, with imperceptible shifts and seamless ratio changes. The adaptive shift logic continues to optimize performance based on driving style, and fuel economy remains optimal as shift timing and torque converter lockup function properly.

When fluid becomes degraded typically after 60,000-80,000 miles symptoms include slightly delayed engagement when shifting from Park to Drive, occasional harshness during downshifts, and the transmission taking longer to “learn” after initialization.

This method is preferable to simple drain-and-fill, which only replaces about 40% of the fluid due to the absence of a traditional pan.

BMW, Audi, and other manufacturers specify service intervals ranging from 50,000 to 100,000 miles, though many transmission specialists recommend 60,000-mile intervals as a conservative approach that maximizes longevity.

The filter in ZF transmissions is integrated into the pan assembly and must be replaced during service, adding to the cost but ensuring complete system maintenance.

When serviced properly at appropriate intervals, ZF 6-speed and 8-speed transmissions routinely exceed 200,000 miles without issues, maintaining their exceptional performance throughout their service life.

6. Aisin Warner AW-4 Transmission

The Aisin Warner AW-4 transmission represents Japanese engineering at its finest, earning legendary status among off-road enthusiasts and Jeep owners for its durability and remarkable responsiveness to maintenance.

This four-speed automatic was primarily used in Jeep Cherokees, Grand Cherokees, and Wranglers from 1987 through 2001, though Aisin variants also appeared in various Toyota and Mitsubishi applications.

The AW-4’s reputation for reliability and longevity, particularly when properly maintained, has made it one of the most sought-after transmissions for Jeep builds and swaps, with many enthusiasts specifically seeking vehicles equipped with this transmission.

What makes the AW-4 exceptional is its overbuilt construction relative to its applications. The transmission was engineered to handle significantly more torque than most factory Jeep applications produced, giving it generous safety margins that contribute to longevity.

The gear train uses helical-cut gears for quiet operation, and the clutch packs feature quality friction materials that maintain their properties well over time.

The valve body, while containing more components than simpler American designs, is logically laid out and accessible for service or rebuilding.

These factors combine to create a transmission that not only tolerates abuse but actively rewards proper maintenance with decades of reliable service.

The AW-4 typically holds approximately 8.5 quarts of ATF, with a standard drain-and-fill replacing about 4 quarts. Dexron III was the original specification, though Dexron VI provides enhanced protection and is backward compatible.

The improvements after a fluid change in an AW-4 are immediately noticeable, particularly in off-road applications where the transmission experiences frequent shifting and load changes.

Shifts become more positive and predictable, the transmission’s response to throttle inputs improves, and operating temperatures decrease.

Many Jeep owners report that their AW-4 feels like a different transmission after service, with the “sloppiness” that had gradually developed over time disappearing completely.

Many AW-4 owners adopt a simple policy of changing transmission fluid with every other oil change, effectively servicing the transmission every 6,000-10,000 miles.

While this seems excessive, the low cost of fluid and filters makes it practical, and transmissions maintained this way routinely exceed 300,000 miles without issues.

The AW-4’s combination of robust construction and maintenance responsiveness has created a devoted following, with these transmissions commanding premium prices in the used market despite their age.

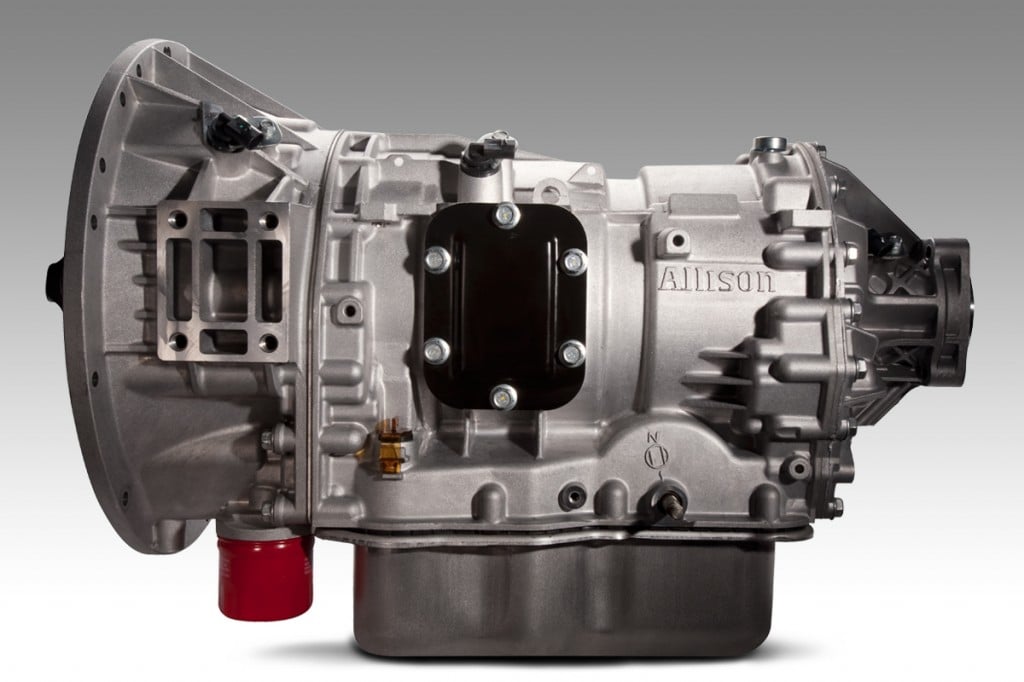

7. Allison 1000/2000 Series Transmissions

The Allison 1000 and 2000 series transmissions represent the gold standard for heavy-duty automatic transmissions, designed for commercial and severe-service applications but found in consumer vehicles like Chevrolet and GMC heavy-duty trucks.

These five-speed and six-speed automatics are engineered to handle enormous torque loads while delivering exceptional longevity, and they respond remarkably well to proper maintenance.

Unlike lighter-duty consumer transmissions, Allison units are designed from the ground up as serviceable components, with maintenance not just recommended but essential to their operational philosophy.

The Allison 1000, introduced in 2001, revolutionized the heavy-duty truck market with its adaptive electronic controls, robust construction, and impressive towing capacity.

The transmission uses a combination of clutches (no bands) to achieve gear ratios, with five or six forward speeds depending on the model year.

The hydraulic system is sophisticated but robust, featuring large fluid passages, substantial filtration, and generous component sizing that provides tolerance for contamination while still benefiting from clean fluid.

The transmission control module continuously adapts shift characteristics based on load, temperature, and driving conditions, but this adaptation depends on the transmission operating within normal parameters something only possible with proper fluid condition.

Allison transmissions have substantial fluid capacity, holding 13-14 quarts in the 1000 series and more in the 2000 series. Allison specifies TES-295 approved fluid (Dexron VI meets this specification), and the company provides detailed service recommendations based on application severity.

For normal use in consumer trucks, Allison recommends 50,000-mile service intervals, but for severe service including heavy towing, trailer hauling, or frequent extreme-temperature operation, intervals of 25,000 miles are specified.

The difference in longevity between properly maintained and neglected Allison transmissions is stark well-maintained units routinely exceed 400,000-500,000 miles with only basic wear-item replacement, while neglected units may require overhaul at 150,000-200,000 miles.

The transmission control module should be checked for stored fault codes, and the adaptive shift learning should be reset after service to allow the transmission to relearn shift characteristics with fresh fluid.

For owners of heavy-duty trucks used for towing or commercial purposes, the cost of regular Allison transmission service ($300-500) is a minor investment compared to the $5,000-8,000 cost of overhaul or replacement.

The Allison’s reputation for longevity is well-deserved, but that reputation is built on proper maintenance these transmissions respond exceptionally well to fluid changes, but they also suffer noticeably when maintenance is neglected.

7 Transmissions Where Service Barely Helps

These problematic gearboxes suffer from fundamental design flaws, including dual-clutch assemblies that wear beyond specification, creating judder that fresh fluid cannot remedy, continuously variable transmissions with belt friction surfaces that degrade permanently, and planetary gear sets with inherent bearing weaknesses where lubrication changes provide only temporary improvement before underlying mechanical issues resurface.

Their flawed engineering includes clutch packs with inadequate surface area that slip regardless of fluid condition, valve bodies with worn bore surfaces allowing pressure leaks that new ATF cannot seal, and torque converters with lockup clutches that shudder from warped friction surfaces unaffected by fluid replacement.

From persistent harsh shifting despite multiple fluid changes to continuing slippage indicating mechanical wear beyond the fluid’s ability to compensate, these troublesome transmissions show minimal improvement from service.

1. Nissan/JATCO CVT Transmissions (RE0F09A/B and JF011E)

Nissan’s continuously variable transmissions, manufactured by JATCO and used across much of the Nissan and Infiniti lineup from the mid-2000s onward, have earned a notorious reputation for unreliability and poor response to maintenance attempts.

The RE0F09A/B (used in vehicles like the Altima, Maxima, and Murano) and JF011E (used in smaller vehicles like the Sentra and Versa) exemplify a category of transmissions where fluid changes provide minimal benefit and may actually precipitate failure.

These CVTs operate on fundamentally different principles than traditional automatics, using a steel belt or chain running between variable-diameter pulleys rather than fixed gears, and this design creates unique maintenance challenges.

The fundamental problem with these JATCO CVTs lies in their design tolerance for wear and contamination. The transmission relies on extremely high clamping force between the pulleys and belt to transfer torque, and this force creates metal-to-metal contact that generates microscopic metal particles.

In a properly functioning new CVT, these particles remain suspended in the fluid and are captured by the filter, but as mileage accumulates, the volume of particles increases.

The CVT fluid contains special friction modifiers designed to allow controlled slip between the belt and pulleys, but these modifiers deplete over time, and the accumulation of metal particles fundamentally changes the fluid’s properties.

When owners attempt to service these CVTs after extended use typically past 60,000-80,000 miles they frequently report that problems begin almost immediately afterward.

The transmission may develop shuddering during acceleration, slipping sensations, or even complete failure within a few thousand miles of service.

This occurs because introducing fresh fluid with different friction characteristics disrupts the equilibrium the transmission had established with degraded fluid.

The new fluid may cause the belt to slip differently against the pulleys, accelerating wear. Additionally, the service process itself can dislodge accumulated debris in the valve body, causing blockages in critical passages or contaminating solenoids.

Owners of vehicles with these transmissions face difficult decisions: spend money on fluid service that may provide little benefit and might cause harm, or accept that transmission replacement or vehicle replacement is likely needed regardless of maintenance.

The prevalence of these CVTs in Nissan’s lineup and their high failure rates has significantly damaged the company’s reputation for reliability and created a substantial market for remanufactured and replacement transmissions.

For potential used car buyers, vehicles equipped with these JATCO CVTs should generally be avoided, as no amount of maintenance can provide confidence in their long-term reliability.

2. Ford PowerShift DPS6 Dual-Clutch Transmission

Ford’s PowerShift DPS6 dual-clutch transmission, used in Focus and Fiesta models from 2011-2016, represents one of the most problematic transmission designs in modern automotive history and a clear example of a transmission where fluid service provides virtually no benefit.

This six-speed dual-clutch automated manual transmission was designed to improve fuel economy over traditional automatics, but fundamental design flaws, inadequate calibration, and cost-cutting measures created a transmission that experiences widespread issues regardless of maintenance.

The DPS6 has been the subject of multiple class-action lawsuits, countless Technical Service Bulletins, and extended warranty programs, yet it remains fundamentally unreliable.

The DPS6’s failings extend beyond just reliability to include fundamental drivability issues that make affected vehicles unpleasant to operate.

The shuddering and jerking during normal driving conditions create a driving experience that feels broken even when the transmission is operating “within specification” according to Ford’s standards.

Owners report difficulty merging into traffic, unpredictable behavior in parking lots, and embarrassment when passengers comment on the transmission’s behavior.

Ford has spent hundreds of millions of dollars on warranty repairs, settlements, and extended warranty programs for these transmissions, yet the fundamental design cannot be fixed through any reasonable maintenance or repair protocol.

For owners of vehicles with the DPS6, options are limited: live with the problems, pursue repair or replacement under warranty or settlement programs, or trade the vehicle.

Fluid changes simply aren’t part of any effective solution because the transmission’s problems exist at a fundamental design level that maintenance cannot address.

The DPS6 stands as a cautionary tale about the risks of cost-optimized transmission designs and the limitations of attempting to maintain fundamentally flawed components.

3. Mercedes-Benz 722.6 and 722.9 Transmissions (High Mileage)

Mercedes-Benz’s 722.6 (five-speed) and 722.9 (seven-speed) automatic transmissions represent an interesting case study in how well-engineered transmissions can become maintenance-resistant once they accumulate significant mileage without proper service.

These transmissions, used across Mercedes’ lineup from the late 1990s through the mid-2010s, were sophisticated designs featuring electronic control, adaptive shift logic, and generally solid engineering.

When properly maintained from new, they respond well to fluid changes and deliver reliable service. However, if allowed to go without service past 100,000-150,000 miles, these transmissions often develop a sensitivity where fluid changes can precipitate rather than prevent problems.

The 722.6 and 722.9 were marketed with extended or “lifetime” fluid fill recommendations in many markets, though Mercedes issued conflicting guidance over the years about service intervals.

This confusion led many owners to neglect transmission service entirely, running original factory fluid for 150,000, 200,000, or even more miles.

Over this extended period, the transmission’s internal components clutch packs, valve body components, sealing surfaces—wear gradually and condition themselves to operate with significantly degraded fluid.

The fluid becomes contaminated with metal particles, develops varnish and deposits throughout the system, and loses its designed friction and viscosity properties.

Paradoxically, the transmission adapts to these degraded conditions, with the control module adjusting shift parameters to compensate for the altered fluid characteristics.

The lesson from these Mercedes transmissions is that maintenance timing matters critically. Regular service from new conditions these transmissions to operate with proper fluid characteristics, and continued regular service maintains reliability.

But once extended neglect occurs, the window for beneficial maintenance closes, and attempting remedial service can trigger cascading failures.

This creates an unfortunate situation for second and third owners of Mercedes vehicles who inherit deferred maintenance they face the choice of expensive transmission replacement or continuing to operate with degraded fluid while hoping the transmission survives. Fluid changes in these scenarios become not preventive maintenance but rather a gamble that often doesn’t pay off.

4. Volkswagen/Audi 09G/09M Six-Speed Automatic

Volkswagen and Audi’s 09G and 09M six-speed automatic transmissions, used across numerous models in the 2000s and 2010s, represent another case where fluid service provides limited benefit and significant risk, particularly in higher-mileage examples.

These transmissions were designed as compact, efficient units to improve fuel economy and packaging, but the compromises made to achieve these goals created transmissions with tight tolerances, complex valve bodies, and sensitivity to contamination.

The 09G (front-wheel drive applications) and 09M (Quattro all-wheel drive applications) share similar design DNA and similar problematic characteristics that make them poor candidates for late-life fluid service.

The fundamental design issue with these transmissions involves their mechatronic unit a complex assembly combining the transmission control module, valve body, solenoids, and numerous sensors in a single integrated component mounted on top of the transmission.

This mechatronic unit contains extremely small fluid passages, precision-calibrated solenoids, and delicate electronic components all operating in proximity.

The unit is sealed and considered non-serviceable, meaning that contamination entering the mechatronic cannot be removed through cleaning the entire expensive assembly must be replaced. This design creates a situation where any debris circulating in the transmission fluid poses a significant risk to the mechatronic unit.

When these transmissions are serviced, particularly if service has been deferred beyond VW/Audi’s recommended intervals of 40,000-60,000 miles, the risk is that fresh fluid with detergent properties will dislodge accumulated varnish and debris from throughout the transmission.

This contamination then circulates through the system and can enter the mechatronic unit, where it blocks small passages, interferes with solenoid operation, or damages sensors.

The symptoms of mechatronic contamination include erratic shifting, unexpected gear selection, harsh engagement, or complete failure to shift. Mechatronic unit replacement typically costs $2,500-4,000, making it one of the most expensive non-failure repairs possible on these vehicles.

The 09G/09M situation creates a frustrating dilemma for owners. The transmissions are known to be problematic and sensitive to contamination, suggesting that clean fluid should be beneficial.

However, practical experience shows that servicing these units often precipitates the very failures it’s meant to prevent.

The tight tolerances and integrated mechatronic design that were meant to improve efficiency and packaging have created transmissions that are intolerant of both contamination and the service procedures meant to remove contamination.

For owners, the best approach is often to maintain these transmissions religiously from new, changing fluid every 40,000 miles to prevent the accumulation of contamination that makes later service risky.

For those who have inherited deferred maintenance, the unfortunate reality is that fluid service may do more harm than good, and planning for eventual transmission replacement becomes more pragmatic than attempting remedial maintenance.

5. Chrysler 41TE/42LE/62TE Transmissions (Neglected Units)

Chrysler’s 41TE, 42LE, and 62TE transmissions represent a family of four-speed and six-speed automatics that were widely used across the company’s minivans, sedans, and crossovers from the 1990s through the 2010s.

When properly maintained from new, these transmissions can provide adequate service, but they have earned a reputation as some of the most maintenance-sensitive transmissions ever produced.

Once neglected past critical service intervals, these transmissions develop characteristics that make fluid changes not only ineffective but potentially harmful, as the degraded internal components cannot benefit from fresh fluid and may actually be disturbed by it.

The fundamental weakness of the 41TE/42LE/62TE family lies in their solenoid pack and valve body design. These transmissions use a large number of solenoids mounted in a pack on the valve body, and these solenoids are particularly sensitive to fluid contamination and varnish buildup.

The valve body itself contains numerous small passages, check balls, and springs that can be affected by debris. As these transmissions accumulate mileage, particularly if operated with degraded fluid, the solenoids develop varnish deposits on their plungers, affecting their operation.

The valve body accumulates particles and deposits that alter hydraulic flow. The clutch packs, which use friction materials not particularly known for durability, develop wear that contaminates the fluid with particles.

When a high-mileage 41TE/42LE/62TE with deferred maintenance receives a fluid change, several problems commonly emerge. The most frequent is that the solenoid pack, which had adapted to operate despite varnish buildup, suddenly experiences different hydraulic pressures with fresh fluid and begins to malfunction.

This manifests as delayed engagement, harsh shifts, or the transmission defaulting to “limp mode” with only second gear available. The fresh fluid’s detergents may partially clean some deposits while dislodging others, creating inconsistent operation across different solenoids.

Particles freed from elsewhere in the transmission can enter the solenoid pack, causing intermittent electrical problems or complete solenoid failure.

The reality with neglected 41TE/42LE/62TE transmissions is that they exist in a state of equilibrium with their degraded fluid. The transmission has adapted through its control module’s learning algorithms to compensate for worn components and altered fluid properties.

Disturbing this equilibrium with fresh fluid can cause the house of cards to collapse. For owners, this creates an impossible situation: continue operating with bad fluid and accept that failure is likely, or change the fluid and potentially trigger immediate failure.

Many transmission specialists counsel that once these transmissions reach high mileage without service, the best approach is to leave them alone and budget for eventual replacement rather than attempting maintenance that may accelerate failure.

This represents a complete failure of serviceability a transmission design that becomes maintenance-resistant and where the most prudent approach is often to do nothing rather than perform the very maintenance that should extend its life.

6. GM 6T40/6T45 Six-Speed Automatic

General Motors’ 6T40 and 6T45 six-speed automatic transmissions, used in numerous front-wheel-drive and all-wheel-drive vehicles from the late 2000s onward, represent a departure from GM’s traditionally service-friendly transmission designs.

These compact six-speed units were developed to improve fuel economy and meet increasingly stringent efficiency standards, but the cost-optimization and packaging constraints led to transmissions with several weaknesses that make them poor candidates for fluid service, particularly after extended use.

The 6T40/6T45 family has developed a reputation for problems that fluid changes cannot remedy and may actually exacerbate. The primary issues with these transmissions involve their wave plate clutch design, pressure control solenoid quality, and valve body configuration.

Unlike traditional flat steel clutch plates, these transmissions use wave plates with a wave pattern stamped into them to reduce clutch pack size and improve efficiency.

While this design achieves packaging goals, the wave plates are more sensitive to proper engagement force and fluid properties than traditional designs.

As the fluid degrades and the plates accumulate wear, they condition themselves to operate within a narrow range of parameters. Introducing fresh fluid with different viscosity and friction characteristics can upset this balance.

The pressure control solenoids in 6T40/6T45 transmissions have proven problematic, with high failure rates reported across numerous model years and applications.

These solenoids are responsible for modulating hydraulic pressure to control shift quality and clutch engagement, and they contain fine screen filters that can become blocked by contamination.

When a transmission with marginal solenoids receives a fluid change, the fresher fluid with its active detergents can dislodge particles that then block these filters, causing sudden solenoid failure.

This manifests as harsh shifts, slipping, or the transmission defaulting to a fail-safe mode. Solenoid replacement requires valve body removal and can cost $1,000-1,500.

For owners of high-mileage vehicles with 6T40/6T45 transmissions that have never been serviced, the decision about fluid changes becomes a calculated risk. Some transmission specialists recommend performing a partial exchange replacing only 40-50% of the fluid to minimize disruption while providing some benefit.

Others suggest leaving the fluid alone entirely and simply operating the vehicle until the transmission fails, then replacing it with a remanufactured unit.

The unfortunate reality is that these transmissions, once neglected, exist in a state where maintenance provides minimal benefit and carries significant risk.

They lack the robust design margins and quality construction that would allow them to respond positively to remedial service, and their compact, efficiency-optimized design makes them intolerant of both contamination and the procedures meant to remove it.

7. Honda/Acura Nine-Speed and Ten-Speed Automatics (2014-2018)

Honda and Acura’s nine-speed (used in Pilot, Passport, Odyssey, and MDX) and ten-speed (co-developed with GM, used in various models) automatic transmissions represent modern engineering complexity taken to a point where serviceability and maintenance response suffer.

These transmissions were developed to maximize fuel economy through numerous closely spaced gear ratios, but the complexity required to package nine or ten forward gears in a reasonably sized transmission created designs with multiple weaknesses.

Early examples of these transmissions, particularly from 2014-2018, have proven problematic in ways that fluid service cannot address and may even worsen.

The nine-speed transmission developed by ZF (designated 9HP) and used by Honda/Acura exemplifies the problems. This transmission was designed to be compact and efficient, but achieving nine forward speeds required a complex arrangement of four simple planetary gearsets and six shift elements.

The hydraulic control is managed by a sophisticated mechatronic unit with numerous solenoids and intricate fluid passages. The shift logic is complex, with the transmission constantly deciding which of its nine ratios is most appropriate for current conditions.

This complexity creates numerous points of potential failure, and the tight packaging means that components operate closer to their stress limits than in more conservative designs.

Honda and GM have continued to improve these transmissions through software updates and mechanical revisions, with later model years showing better reliability and shift quality. However, for owners of 2014-2018 vehicles with early versions of these transmissions, fluid service provides minimal benefit.

The problems aren’t fluid-related, and changing fluid doesn’t address the underlying calibration and design issues. Some owners report slight improvements after fluid changes, but these are often placebo effects or coincidental with software updates performed at the same time.

The harsh reality is that these early nine-speed and ten-speed transmissions represent a generation of overtly complex designs where the push for maximum efficiency and numerous gear ratios created transmissions that are fundamentally difficult to calibrate and control smoothly. Fluid service, while not harmful in most cases, simply doesn’t address the real issues these transmissions face.

Also Read: 10 Hyundai/Kia Engines From The ‘Safe Years’ That Age Well