Engine oil is the lifeblood of any vehicle, serving as the critical barrier between metal components grinding against each other at thousands of revolutions per minute.

It lubricates, cools, cleans, and protects your engine from premature wear and catastrophic failure. But not all engines are created equal when it comes to their tolerance for extended oil change intervals or their propensity to develop harmful sludge buildup.

The debate over oil change intervals has evolved dramatically over the past few decades. Gone are the days when the universal 3,000-mile oil change rule applied to every vehicle on the road.

Modern synthetic oils, improved engine designs, and advanced filtration systems have extended these intervals significantly for many vehicles. Some manufacturers now confidently recommend 10,000 miles or even longer between services.

However, this extended maintenance schedule doesn’t apply universally, and understanding your specific engine’s characteristics can mean the difference between a powertrain that lasts 300,000 miles and one that requires a costly rebuild at 100,000 miles.

In this comprehensive guide, we’ll explore five engines renowned for their resilience and tolerance to less-than-perfect maintenance schedules, followed by five engines that demand unwavering adherence to oil change intervals.

Whether you’re considering a used vehicle purchase, diagnosing issues with your current car, or simply curious about automotive engineering, understanding these differences will help you make informed decisions about vehicle selection and maintenance practices.

Remember, even the most tolerant engines benefit from regular oil changes, and even the most finicky engines can provide reliable service with proper care.

5 Engines That Tolerate Long Oil Changes

These exceptionally engineered powertrains feature simple port fuel injection systems that don’t contaminate oil with fuel dilution, generous oil capacity providing extended service intervals, and robust positive crankcase ventilation systems effectively removing combustion byproducts and moisture that would otherwise accumulate and degrade lubricant quality throughout extended drain intervals.

Their thoughtful engineering includes large-capacity oil pans maintaining adequate lubrication volume despite consumption, effective oil filtration systems with substantial media surface area capturing contaminants before they cause wear, and combustion chamber designs that minimize blow-by gases entering crankcase and contaminating oil with acidic combustion products.

From highway driving that maintains optimal operating temperatures promoting oil longevity to occasional extended drain intervals when life circumstances prevent timely maintenance, these remarkable engines continue operating reliably without developing sludge accumulation, bearing wear, or catastrophic failures that plague engines intolerant of maintenance lapses.

1. Toyota 2JZ-GTE Inline-Six

The legendary Toyota 2JZ-GTE inline-six engine, which powered the iconic fourth-generation Toyota Supra from 1993 to 2002, stands as one of the most bulletproof engines ever produced.

This 3.0-liter turbocharged powerplant has achieved near-mythical status in automotive circles, and its tolerance for extended oil changes is just one facet of its remarkable durability.

The 2JZ-GTE’s resilience stems from several critical design elements. First, Toyota engineered this engine with an iron block and aluminum head, providing exceptional strength and heat dissipation characteristics.

The closed-deck block design adds rigidity that prevents distortion under extreme conditions. The engine’s internal components were massively over-engineered for its stock 320 horsepower output, with forged internals that could handle substantially more power.

This conservative engineering approach meant the engine operated well within its stress limits under normal conditions, reducing wear and extending component life.

Oil capacity plays a crucial role in the 2JZ-GTE’s tolerance for extended intervals. With approximately 5 liters of oil capacity, the engine maintains adequate lubrication even as oil degrades.

The substantial oil volume means contaminants become diluted, and the oil’s protective additives last longer before depletion. Additionally, the engine features an excellent oiling system with a robust oil pump that maintains consistent pressure across the RPM range.

The galleries and passages are well-designed to ensure all critical components receive adequate lubrication, even when oil quality begins to deteriorate.

The 2JZ-GTE’s sequential twin-turbo system, while complex, actually contributes to longevity by reducing stress compared to a large single turbo.

The turbos spool progressively, minimizing abrupt power delivery that can strain components. Furthermore, the engine’s relatively simple variable valve timing system (VVT-i on later models) is far less complex than modern implementations, reducing potential sludge-related failures.

For owners of vehicles equipped with the 2JZ-GTE, this tolerance offers peace of mind but shouldn’t encourage complacency. Using quality synthetic oil and maintaining reasonable intervals even if somewhat extended will ensure this legendary engine delivers the longevity for which it’s famous.

The 2JZ-GTE proves that thoughtful engineering, conservative design parameters, and quality construction create engines capable of withstanding real-world conditions where maintenance isn’t always perfect.

2. Honda K-Series Four-Cylinder

Honda’s K-series four-cylinder engines, introduced in 2001, represent some of the most reliable and maintenance-tolerant powerplants in modern automotive history.

Found in vehicles ranging from the Civic Si to the CR-V, Accord, and even the Acura TSX, these engines have built a reputation for exceptional longevity and surprising resilience to less-than-perfect maintenance schedules.

The K-series family includes various displacements from 2.0 to 2.4 liters, but they share fundamental design characteristics that contribute to their sludge resistance.

Honda engineered these engines with an aluminum block and head construction, which provides excellent heat dissipation. Proper heat management is crucial for preventing oil breakdown and sludge formation.

The engines maintain relatively cool operating temperatures, which extends oil life and prevents the thermal degradation that plagues many modern powerplants.

One of the K-series’ most significant advantages is Honda’s legendary build quality and precision manufacturing. The engines feature tight tolerances without being excessively restrictive.

This balance allows for efficient operation while providing adequate clearances that don’t immediately suffer when oil quality degrades slightly.

The cylinder walls receive a specialized coating that reduces friction and wear, further extending the period before degraded oil causes measurable damage.

The K-series’ i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system represents an evolution of Honda’s earlier VTEC technology.

While variable valve timing systems can be vulnerable to sludge buildup, Honda designed the K-series implementation with larger oil passages feeding the VTEC mechanism.

This design choice ensures adequate oil flow even when some contamination exists. The VTEC solenoid and rocker arm assembly are positioned to receive priority oil flow, reducing the likelihood of starvation due to sludge accumulation.

Oil capacity in K-series engines is generous relative to displacement. The K20 and K24 variants typically hold around 4.5 liters of oil, providing substantial volume for a four-cylinder engine.

This larger capacity means the oil can absorb more contaminants before reaching critical saturation levels. Additionally, the positive crankcase ventilation (PCV) system is well-designed, efficiently removing blow-by gases and moisture that contribute to sludge formation.

Real-world reliability data strongly supports the K-series’ tolerance for extended maintenance. Automotive forums are filled with accounts of these engines exceeding 200,000 miles with minimal issues.

Many owners report accidentally extending oil change intervals to 8,000 or even 10,000 miles without immediate consequences. While this certainly isn’t recommended practice, it demonstrates the engine’s built-in resilience.

Mechanics frequently encounter high-mileage K-series engines that have received inconsistent maintenance yet continue running smoothly, albeit with gradual wear rather than catastrophic failure.

The K-series proves that Japanese engineering precision, combined with conservative design and quality materials, creates engines that forgive occasional maintenance lapses while rewarding proper care with extraordinary longevity.

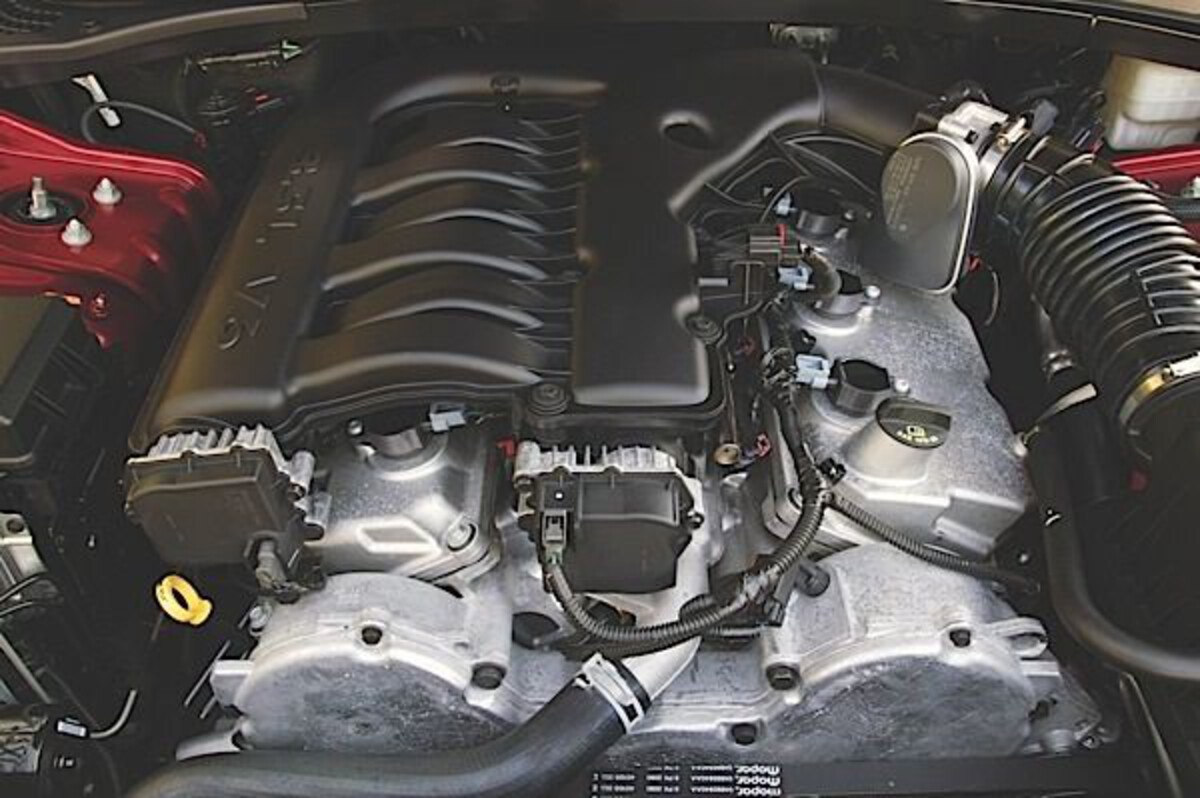

3. General Motors LS-Series V8

General Motors’ LS-series V8 engines represent American engineering at its finest, combining impressive performance with remarkable durability and surprising tolerance for less-than-ideal maintenance practices.

Introduced in 1997 with the LS1 in the Corvette, this engine family has proliferated across GM’s lineup and become the enthusiast community’s engine of choice for swaps and performance builds.

Their reputation for bulletproof reliability extends to impressive resistance against sludge formation and damage from extended oil change intervals.

The LS-series’ architecture provides inherent advantages for longevity and maintenance tolerance. These pushrod V8 engines feature an aluminum block in most variants, with iron blocks in truck applications.

The overhead valve design with pushrods and rocker arms is mechanically simpler than overhead cam configurations, with fewer components requiring precise lubrication.

This simplicity translates to fewer potential failure points when oil quality degrades. The engine’s deep-skirt block design adds rigidity and supports the crankshaft along its entire length, reducing stress and wear.

Oil capacity in LS engines varies by application but typically ranges from 5.5 to 8 quarts, providing substantial volume for a modern engine.

This generous capacity dilutes contaminants and extends the period before oil additives become depleted. The oiling system itself is well-engineered, with a robust oil pump and thoughtfully designed galleries that ensure consistent pressure and flow.

The system prioritizes critical components like main bearings and connecting rod bearings, ensuring they receive adequate lubrication even as oil quality diminishes.

One of the LS-series’ most significant advantages is its relatively cool operating temperature. While modern engines often run hotter for emissions purposes, LS engines maintain temperatures that favor oil longevity.

The efficient cooling system and good heat dissipation from the aluminum construction prevent the excessive temperatures that accelerate oil breakdown and sludge formation.

Additionally, the Active Fuel Management (AFM) system in some variants, while controversial for other reasons, actually reduces engine stress during light-load cruising by deactivating cylinders, potentially extending oil life during highway driving.

The LS engine family’s reputation for high-mileage durability is well-documented. Police departments have logged hundreds of thousands of miles on LS-powered Crown Victoria alternatives without major issues.

Taxi services, delivery companies, and countless individual owners report these engines easily exceeding 200,000 miles. Many of these high-mileage examples didn’t receive dealership-perfect maintenance, yet continued operating reliably.

Stories abound of LS engines discovered with oil that hasn’t been changed in 15,000 miles or more, yet still running without catastrophic damage upon inspection.

The LS’s tolerance partly stems from its generous bearing clearances and robust oiling system design. Unlike some modern engines with extremely tight tolerances that demand pristine oil, LS engines maintain adequate oil film even when viscosity has degraded somewhat.

The hydraulic roller lifters, while requiring proper lubrication, aren’t as sensitive to oil degradation as some competing designs. The LS-series demonstrates that traditional American V8 architecture, when executed with modern materials and precision manufacturing, creates engines that combine performance, efficiency, and remarkable tolerance for real-world conditions where maintenance isn’t always perfect.

This resilience, combined with strong aftermarket support and widespread availability, explains why LS engines remain incredibly popular decades after introduction.

4. Subaru EJ25 (Non-Turbo) Boxer Four-Cylinder

Subaru’s naturally aspirated EJ25 boxer engine, while not without its quirks and specific weaknesses, demonstrates surprising tolerance for extended oil change intervals when properly maintained in its earlier iterations.

Found in millions of Subarus from the late 1990s through the mid-2010s, this horizontally-opposed four-cylinder engine powers everything from Foresters to Outbacks and Legacy sedans. Understanding the nuances of this engine reveals why proper specification matters when discussing maintenance tolerance.

The EJ25’s boxer configuration places cylinders horizontally opposed, creating a low center of gravity and balanced operation. This layout affects oil distribution, as gravity pulls oil to the sides of the engine rather than straight down as in conventional inline or V configurations.

Subaru engineered the oiling system to accommodate this unique challenge, with oil galleries designed to ensure adequate lubrication in all orientations.

The oil pump maintains consistent pressure across the rev range, and the system includes passages that feed oil upward to cylinder heads and across to cylinder walls.

Oil capacity in the EJ25 is approximately 4.2-4.4 quarts depending on the specific variant and whether an oil cooler is equipped. While this isn’t exceptionally large for a 2.5-liter engine, it’s adequate for normal operation.

The key to the EJ25’s tolerance lies in its relatively unstressed nature in naturally aspirated form. Producing between 165-175 horsepower in most applications, these engines operate well within their design limits during typical driving. Lower stress translates to less blow-by, less heat generation, and slower oil degradation.

The EJ25’s resistance to sludge formation particularly applies to pre-2010 models before Subaru implemented certain emissions-driven design changes.

Earlier engines featured slightly more generous oil passages and less aggressive emissions control measures. The PCV system, while sometimes criticized for complexity, generally performs adequately when maintained.

Regular PCV valve replacement often overlooked in maintenance schedules significantly reduces moisture and contaminant accumulation that contributes to sludge.

Real-world experience with naturally aspirated EJ25 engines shows remarkable longevity when basic maintenance is observed. Many owners report these engines exceeding 200,000 miles with only routine service.

The boxer configuration, while presenting unique challenges, actually provides some advantages for oil circulation. The short distance from the crankshaft to cylinder heads means oil reaches critical components quickly after cold starts, reducing initial wear.

The naturally aspirated EJ25 represents a middle-ground case study: not as invincible as the legendary Toyota 2JZ or Honda K-series, but certainly more tolerant than the problem engines we’ll discuss later.

With attention to PCV system health, regular coolant changes to prevent head gasket issues, and reasonable oil change intervals, the EJ25 can provide reliable service well into six-figure mileage territory.

5. Ford 300 Cubic Inch Inline-Six

Ford’s 300 cubic inch (4.9-liter) inline-six engine represents old-school American engineering at its most durable. Produced from 1965 through 1996, this pushrod engine powered countless Ford trucks and some full-size vans, earning a legendary reputation for unkillable reliability.

While ancient by modern standards, lacking fuel injection until the late 1980s and offering modest power output, the “Ford 300” remains revered for its ability to tolerate neglect that would destroy contemporary engines.

The 300’s durability stems from its fundamentally conservative design. This long-stroke, seven-main-bearing inline-six was never designed for high-performance applications.

Instead, Ford engineered it as a workhorse meant to operate reliably under difficult conditions with minimal maintenance. The cast-iron block and head construction, while heavy, provides exceptional strength and heat dissipation.

The simple pushrod valve train eliminates complex overhead cam components that require precise lubrication. With just a dozen pushrods, a single camshaft, and hydraulic lifters, the engine has fewer components than modern multi-cam designs, reducing potential failure points.

Oil capacity in the Ford 300 is approximately 5 quarts, adequate for its displacement and design. More importantly, the engine’s generous bearing clearances and simple oiling system tolerate oil degradation that would starve modern engines.

The inline configuration provides inherent oiling advantages, as oil drains straight down to the pan through gravity. The seven main bearings supporting the crankshaft more than many V6 and V8 designs, distribute loads effectively and reduce the stress on each bearing surface.

The 300’s legendary tolerance for extended oil changes is documented in countless anecdotes from owners, mechanics, and fleet managers.

Farm trucks that received oil changes based on seasons rather than mileage, work trucks that went 15,000-20,000 miles between services, vehicles that accidentally went an entire year without oil changes yet continued running.

While such extreme neglect inevitably causes wear and eventually requires rebuilding, the remarkable aspect is that these engines often continued operating rather than seizing immediately.

Several factors explain this extraordinary tolerance. First, the 300’s low specific output typically around 150 horsepower from nearly 5 liters of displacement means the engine operates with minimal stress.

Low piston speeds and modest combustion pressures reduce blow-by and contaminant generation. Second, the simple design lacks variable valve timing, cylinder deactivation, or other technologies that introduce tight-tolerance components vulnerable to sludge.

Third, the engine’s robust construction provides mechanical strength that withstands marginal lubrication better than lightweight modern designs.

Modern engine designs prioritize efficiency, emissions, and specific power output, requiring tighter tolerances and more complex systems. These advancements improve performance but reduce maintenance tolerance.

The Ford 300 represents an earlier philosophy where simplicity, strength, and generous design margins created engines that tolerated real-world conditions, even when those conditions were far from ideal.

For owners lucky enough to still operate vehicles with the venerable 300, continuing reasonable maintenance ensures this legendary engine lives up to its reputation for seemingly endless reliability.

5 Engines That Sludge If You Blink

These problematic powertrains suffer from direct-injection systems that contaminate oil with fuel dilution, inadequate crankcase ventilation allowing moisture and combustion byproducts to accumulate, and turbocharger bearing lubrication that creates extreme thermal stress causing oil coking and sludge formation with alarming speed when drain intervals extend even slightly beyond manufacturer recommendations.

Their flawed engineering includes small oil capacities providing minimal contamination dilution volume, complex variable valve timing systems with tight oil passages that clog rapidly from sludge buildup, and turbochargers positioned in high-heat areas where inadequate cool-down periods cause oil carbonization in bearing passages.

From short-trip driving that prevents oil from reaching temperatures that evaporate moisture to turbocharged operation creating extreme oil temperatures accelerating degradation, these troublesome engines develop sludge rapidly.

1. Volkswagen/Audi 1.8T

The Volkswagen/Audi 1.8-liter turbocharged four-cylinder engine, particularly the early versions produced from approximately 1997 to 2005, has earned an infamous reputation as one of the most sludge-prone engines in modern automotive history.

Found in popular vehicles like the VW Passat, Jetta, Golf, Audi A4, and A6, this engine affected hundreds of thousands of vehicles and resulted in numerous lawsuits, service campaigns, and countless expensive repairs for unsuspecting owners.

The 1.8T’s sludge problem stems from multiple design and operational factors working in concert to create the perfect storm for oil degradation. First, the engine runs exceptionally hot, particularly in the cylinder head area where the turbocharger is integrated.

This heat accelerates oil breakdown, causing it to oxidize and form sludge far more quickly than in naturally aspirated engines. The turbocharger itself, with its high-speed bearing requiring constant oil flow, becomes both a cause and victim of sludge formation.

Volkswagen’s specified oil change interval during this period 10,000 miles or even longer in some markets proved disastrously inadequate for this engine’s characteristics.

While modern synthetic oils can handle extended intervals in well-designed engines, the 1.8T’s unique challenges demanded more frequent service.

The combination of high heat, turbocharger stress, and extended intervals created sludge accumulation that blocked oil passages, starved components of lubrication, and led to catastrophic failures.

The engine’s design includes several features that exacerbate sludge susceptibility. The PCV system, which should remove moisture and blow-by gases from the crankcase, proved inadequate in many examples.

When the PCV valve or associated passages become blocked often by sludge itself pressure builds in the crankcase, forcing oil past seals and increasing contamination in the oil that remains.

Additionally, the 1.8T’s cylinder head design includes small oil passages feeding the camshafts and variable valve timing components. These narrow passages quickly become restricted by sludge, causing timing chain tensioner failures and variable valve timing malfunction.

Real-world failures of the 1.8T due to sludge are legendary. Owners who followed Volkswagen’s recommended maintenance schedules found their engines failing prematurely, often between 60,000 and 100,000 miles.

Symptoms included rough running, check engine lights triggered by variable valve timing errors, excessive oil consumption, and eventually complete engine failure. Teardowns of failed engines revealed cylinder heads packed with sludge, oil passages completely blocked, and critical components destroyed by oil starvation.

The 1.8T demonstrates how well-intentioned engineering turbocharged efficiency, extended maintenance intervals can create reliability disasters when the complete operating environment isn’t adequately considered.

It serves as a reminder that manufacturer maintenance schedules aren’t always sufficient for engine longevity, particularly in designs pushing thermal and mechanical boundaries.

2. Toyota 2AZ-FE Four-Cylinder

It seems almost sacrilegious to include a Toyota engine on a list of sludge-prone powerplants, given the manufacturer’s well-deserved reputation for reliability.

However, the 2AZ-FE 2.4-liter four-cylinder engine, produced from approximately 2000 to 2017 and found in millions of Camrys, Solaras, Scion tCs, and RAV4s, developed a significant oil consumption and sludge problem that affected many examples, particularly 2006-2011 model years.

The 2AZ-FE’s issues are multifaceted but center on a design flaw in the piston rings that causes excessive oil consumption. Toyota engineered these pistons with rings that, under certain conditions, fail to properly control oil, allowing excessive amounts into the combustion chamber.

This oil consumption creates multiple problems: owners who don’t vigilantly monitor oil levels can run the engine with insufficient lubrication, and the oil that remains becomes contaminated more quickly as blow-by increases due to a compromised ring seal.

The sludge formation in 2AZ-FE engines follows a cascading failure pattern. As oil consumption increases, some owners reported needing to add a quart every 1,000 miles. The reduced oil volume means contaminants become more concentrated.

Additionally, the excessive oil burning creates deposits in combustion chambers and on valves, with some of this contamination working back into the crankcase oil.

The engine’s relatively small oil capacity, approximately 4.4 quarts, exacerbates this issue by providing less margin for contamination before oil quality deteriorates critically.

Toyota’s initial response to oil consumption complaints was inadequate, with the company initially claiming that consumption rates up to one quart per 1,000 miles were within “normal” specifications.

This stance left many owners operating their engines with marginal lubrication, accelerating sludge formation. The company eventually acknowledged the problem, implementing several service campaigns and extending warranties for affected vehicles.

Solutions included piston ring replacement or, in severe cases, complete engine replacement. The sludge accumulation in 2AZ-FE engines particularly affects the cylinder head and valve train.

The engine uses Variable Valve Timing with intelligence (VVT-i), which relies on oil pressure to adjust cam timing. Sludge buildup restricts oil flow to the VVT-i actuator, causing timing errors, rough running, and check engine lights. Additionally, sludge can clog the oil passages feeding the camshafts, leading to accelerated wear or seizure.

The PCV system in the 2AZ-FE also contributes to sludge susceptibility. The system’s design can allow oil vapors to condense in intake components, eventually forming sludge-like deposits that restrict airflow and affect engine performance.

When combined with the excessive oil consumption issue, the PCV system becomes overwhelmed, unable to effectively manage the increased blow-by gases.

Real-world failures of 2AZ-FE engines typically manifest after extended operation with high oil consumption. Owners who weren’t diligent about checking oil levels between changes experienced catastrophic engine failures seized engines requiring complete replacement.

Even owners who maintained proper oil levels but followed standard 5,000-7,500 mile change intervals sometimes discovered sludge accumulation during repairs for other issues.

The 2AZ-FE case demonstrates that even manufacturers with stellar reliability reputations can produce problem engines.

It also illustrates how a specific design flaw the piston ring issue can cascade into multiple problems including sludge formation, requiring owners to adapt maintenance practices accordingly.

3. Chrysler 2.7L V6

Few engines have earned as uniformly negative a reputation as Chrysler’s 2.7-liter V6, produced from 1998 through 2010.

Found in popular vehicles including the Dodge Intrepid, Chrysler Sebring, Chrysler 300M, Dodge Charger, and Chrysler Concorde, this engine affected hundreds of thousands of vehicles and remains one of the most problematic designs in modern American automotive history.

Its propensity for catastrophic sludge-related failures is legendary among mechanics and unfortunate owners alike. The 2.7L V6’s fundamental design includes several features that make it exceptionally vulnerable to sludge formation.

First, the engine runs significantly hotter than many contemporaries, with operating temperatures that accelerate oil degradation. The aluminum block, while lightweight, doesn’t dissipate heat as effectively as the iron blocks in more robust designs.

Second, the engine uses a timing chain rather than a belt, and while chains typically offer longevity advantages, the 2.7L’s chain runs through an area particularly susceptible to sludge accumulation. When sludge blocks oil flow to the timing chain guides and tensioner, catastrophic failure follows quickly.

Perhaps the most problematic design element is the water pump placement. Chrysler positioned the water pump inside the engine, driven by the timing chain.

This seemingly clever packaging choice creates a nightmare scenario: when the water pump fails—which it does with disturbing frequency on this engine, coolant can contaminate the oil, accelerating sludge formation exponentially.

Additionally, replacing the water pump requires extensive disassembly, making it an expensive service that some owners delayed, allowing problems to worsen.

Oil capacity in the 2.7L is adequate at approximately 5 quarts, but the engine’s design negates this advantage. The vertical orientation of the V6 creates challenges for oil drainage.

After shutdown, oil takes time to drain back to the pan, and if sludge forms in the drain-back passages which it does readily oil becomes trapped in the cylinder heads. This trapped oil, subjected to intense heat during operation, oxidizes rapidly, forming more sludge in a self-perpetuating cycle.

The 2.7L’s reputation became so poor that its presence significantly impacts used vehicle values. Knowledgeable buyers avoid vehicles equipped with this engine, and dealers struggle to sell them even at reduced prices.

For owners still operating vehicles with the 2.7L, survival requires extreme vigilance. Oil changes every 3,000-4,000 miles maximum, using high-quality synthetic oil, are essential.

Regular coolant changes to reduce water pump corrosion, monitoring for any coolant loss that might indicate water pump failure, and watching for any unusual noises from the timing chain area provide the best chance for longevity.

However, even with meticulous maintenance, this engine carries inherent risks that make it one to avoid when possible.

4. BMW N63 V8 Twin-Turbo

BMW’s N63 4.4-liter twin-turbocharged V8 engine, introduced in 2008 and found in various high-end BMW models including the 550i, 650i, 750i, X5, and X6, represents German over-engineering gone wrong.

Despite powering six-figure luxury vehicles, this engine has developed one of the worst reliability records among modern premium powerplants, with sludge formation being just one of numerous serious issues plaguing owners.

The N63’s most unique and problematic feature is its “hot-vee” turbocharger configuration. BMW positioned both turbochargers in the valley between the cylinder banks, nestled directly between the exhaust manifolds.

While this arrangement offers packaging advantages and improved throttle response, it creates extreme heat in the engine’s center, precisely where critical oil passages and components reside. Oil flowing through this superheat zone degrades rapidly, forming sludge at accelerated rates.

The turbos themselves, operating in this thermal nightmare, demand pristine oil for their high-speed bearings, yet they’re positioned in the worst possible location for oil quality.

The engine’s complex design includes numerous additional vulnerabilities. The direct injection system, while efficient, doesn’t clean intake valves like port injection, allowing carbon buildup that affects combustion quality and increases blow-by.

The variable valve timing system, which relies on precise oil pressure and clean oil passages, becomes compromised when sludge forms. The engine uses a wet-sump oiling system that some critics argue is inadequate for the performance demands and heat generation of this turbocharged V8.

Oil capacity in the N63 is approximately 7.5-8 quarts, which seems adequate for a 4.4-liter engine. However, the extreme operating conditions particularly the heat generated by the hot-vee turbo configuration, mean this oil works much harder than in conventional designs.

BMW initially specified 10,000-mile oil change intervals, which proved disastrously inadequate. The company eventually acknowledged problems and reduced recommended intervals, but damage was done to countless early examples.

Real-world N63 failures are numerous and expensive. Common issues include turbocharger failures often attributed to oil starvation from sludge-blocked passages, timing chain problems caused by tensioner and guide failures related to compromised lubrication, valve stem seal failures leading to excessive oil consumption, and complete engine failures requiring replacement or comprehensive rebuilding.

Many failures occur between 60,000 and 100,000 miles, unacceptably low for a premium engine. The financial impact of N63 problems is staggering. Turbocharger replacement costs $5,000-8,000 per side, meaning both turbos can exceed $15,000 with labor.

Timing chain service, which requires engine removal in many cases, costs $8,000-12,000. Complete engine replacement or comprehensive rebuilding can approach or exceed $20,000-25,000. These costs often exceed the vehicle’s value, leaving owners facing total loss scenarios.

BMW has issued numerous technical service bulletins and implemented several redesigns attempting to address N63 problems.

Later S63 versions (the high-performance variant) and revised N63 engines incorporate improvements, including redesigned turbochargers, improved oil spray cooling for pistons, updated timing chain components, and revised valve stem seals.

However, these changes don’t help owners of earlier problematic engines. The N63 serves as a cautionary tale about prioritizing performance and packaging over fundamental reliability.

The hot-vee turbo configuration, while offering certain advantages, creates an environment hostile to oil longevity.

Combined with BMW’s initially optimistic maintenance intervals and the complexity inherent in modern turbocharged engines, the result is a powerplant that demands perfect maintenance yet still suffers reliability issues at unacceptable rates for a premium vehicle.

5. Nissan VQ35DE V6

Nissan’s VQ35DE 3.5-liter V6 engine occupies a unique position on this list. Unlike the universally problematic designs discussed earlier, the VQ35DE is generally a solid, reliable engine that has powered millions of vehicles, including the Altima, Maxima, 350Z, Infiniti G35, and many others.

However, specific variants and model years, particularly those produced between 2002 and 2006, developed a significant propensity for sludge accumulation that earned this otherwise respectable engine a place among the problematic designs.

The VQ35DE’s sludge issues don’t stem from fundamental design flaws like the Chrysler 2.7L or the extreme conditions of the BMW N63.

Instead, they result from a combination of factors, including manufacturing variations, owner maintenance practices, and the engine’s specific operating characteristics.

The VQ family runs fairly hot, particularly in the cylinder heads where the dual overhead cams reside. This heat, combined with extended oil change intervals, can lead to oil degradation and sludge formation, especially in the intricate passages feeding the variable valve timing system.

The VQ35DE’s variable valve timing system represents both a performance advantage and a vulnerability. The system requires precise oil pressure to adjust cam timing.

When sludge forms in the oil control valves, solenoids, or passages feeding the VVT components, timing becomes erratic. Symptoms include rough idle, reduced power, poor fuel economy, and check engine lights with timing-related error codes.

In severe cases, the timing chain can jump or break if the guides and tensioners don’t receive adequate lubrication due to sludge-blocked passages.

Oil capacity in the VQ35DE is approximately 5 quarts, adequate for its displacement but not generous. The engine’s relatively high specific output, typically 280-300 horsepower from 3.5 liters in most applications, means it works harder than lower-stressed designs.

This increased stress generates more heat and combustion byproducts that contaminate oil. Additionally, the VQ’s aggressive cam profiles and high-revving nature mean the valve train demands consistent lubrication quality.

The sludge problem in VQ35DE engines became significant enough that Nissan implemented a service campaign extending warranties for affected vehicles.

Many owners who discovered sludge during repairs for other issues found their engines required expensive cleaning or, in severe cases, replacement.

The problem particularly affected vehicles driven primarily in short-trip, stop-and-go conditions where engines never fully reached optimal operating temperature, allowing moisture and fuel contamination to accumulate in the oil.

Real-world manifestations of VQ35DE sludge issues typically begin subtly. The variable valve timing system starts showing occasional errors, often dismissed as sensor issues. Idle quality degrades slightly.

Oil consumption may increase as sludge accumulation allows oil past worn valve seals. If unaddressed, the problems escalate: timing chain noise emerges, power decreases noticeably, and eventually catastrophic failure can occur if the timing chain jumps or breaks.

The financial impact of VQ35DE sludge damage varies considerably depending on severity and whether warranty coverage applies. Simple cleaning of the variable valve timing system costs $500-1,000.

Unlike inherently flawed designs, the VQ can provide reliable service with proper care, but it lacks the tolerance for neglect that characterizes truly bulletproof engines. Understanding this distinction helps owners maintain their vehicles appropriately and avoid becoming another sludge-related casualty.

Also Read: 5 Legendary Trucks With Indestructible Transfer Cases vs 5 With Costly 4×4 Failures