The inline-six engine configuration has long been celebrated for its inherent balance, smooth power delivery, and refined performance characteristics. From luxury sedans to high-performance sports cars, the straight-six layout has powered some of the automotive world’s most iconic vehicles.

However, not all inline-six engines have earned stellar reputations for reliability and cost-effective maintenance. While these powerplants may deliver impressive performance and sophisticated engineering, some have become notorious among owners and mechanics for their tendency to develop expensive problems.

The reasons behind costly repairs vary significantly across different engine designs. Some inline-six engines suffer from fundamental design flaws that lead to catastrophic failures, while others require specialized tools, rare parts, or extensive labor hours for even routine maintenance.

Turbocharged variants often face additional complications from heat-related stress and complex forced-induction systems. Premium manufacturers sometimes employ exotic materials and cutting-edge technology that, while impressive on paper, translate to eye-watering repair bills when components fail.

Understanding which inline-six engines carry the highest ownership costs can help prospective buyers make informed decisions and prepare current owners for potential financial challenges ahead.

From German luxury marques to Japanese performance icons, this examination covers ten inline-six engines that have earned reputations for draining wallets. Whether due to fragile components, poor accessibility, discontinued parts availability, or simply over-engineered complexity, these engines represent cautionary tales in automotive maintenance. Let’s explore what makes these particular powerplants so expensive to keep running.

Also Read: Top 10 Inline-Six Engines Celebrated For Extreme Longevity

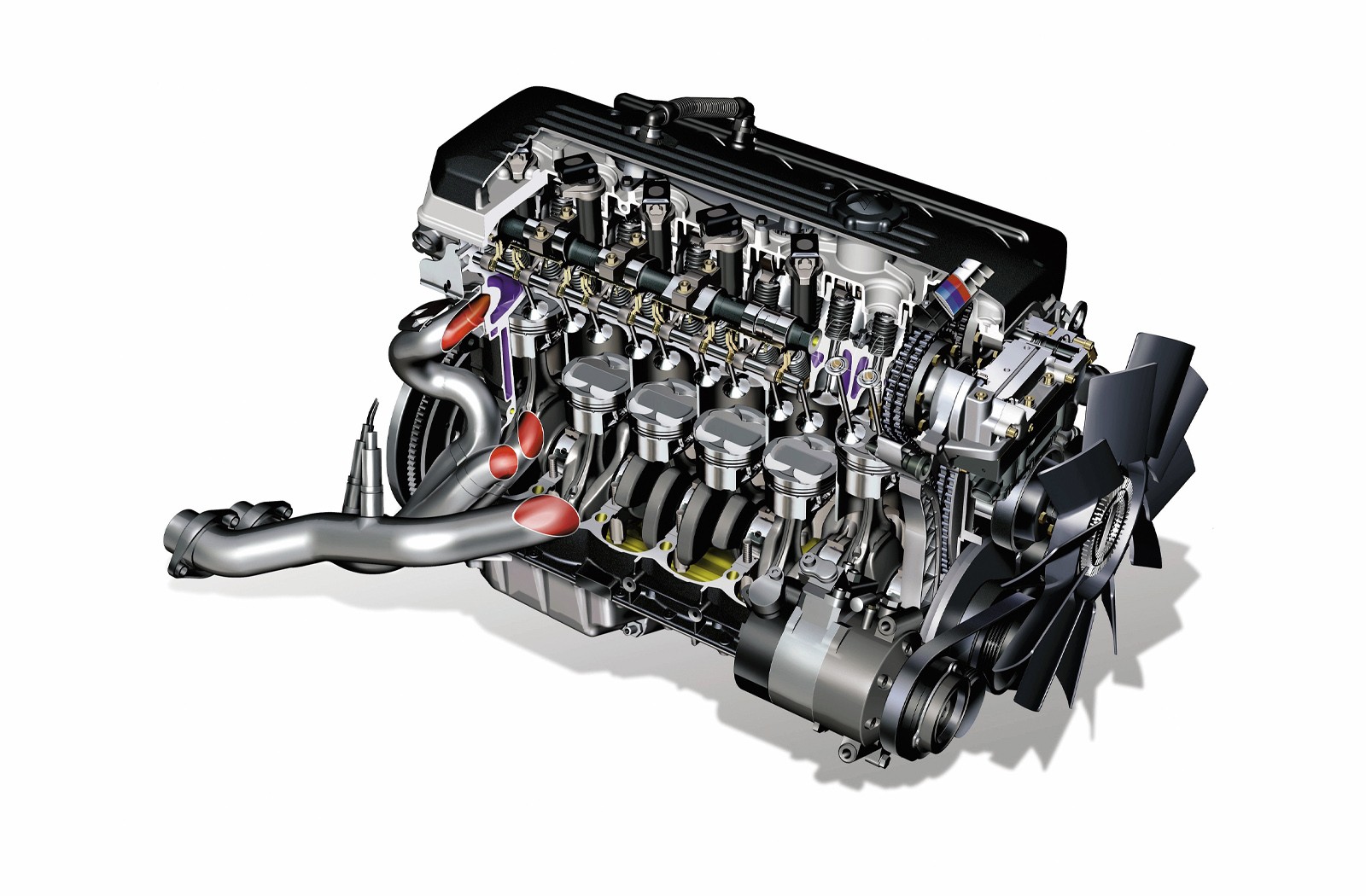

1. BMW N54 Twin-Turbo Inline-Six

The BMW N54 engine represents a watershed moment in the company’s history as its first production turbocharged inline-six since the 1940s. Introduced in 2006, this 3.0-liter twin-turbocharged powerplant replaced the naturally aspirated N52 and brought tremendous performance gains, producing between 300-335 horsepower depending on application.

Found in vehicles from the 335i to the 1M Coupe, the N54 earned enthusiast acclaim for its tuning potential and impressive power delivery. However, this engine has simultaneously become infamous for reliability issues that can devastate owners’ bank accounts.

The most notorious problem involves the high-pressure fuel pump, which tends to fail prematurely and without warning. When this component fails, it can send metal debris throughout the fuel system, contaminating injectors and requiring extensive cleanup that easily exceeds $2,000-$3,000.

The direct-injection system itself proves problematic, with fuel injectors failing regularly and costing $300-$400 each to replace. Given that six injectors exist, a complete replacement represents a significant investment.

Turbocharger wastegate rattle has plagued N54 engines extensively, caused by wastegate actuator arms that wear and create annoying rattling sounds. While initially just irritating, continued operation can lead to complete turbocharger failure, with replacement costs ranging from $2,500-$4,000 per turbo.

Many owners eventually replace both turbochgers simultaneously to avoid repeating the labor costs, pushing total expenses beyond $6,000.

The valve cover and oil filter housing gaskets consistently leak on higher-mileage examples, leading to oil consumption and potential engine damage if ignored.

Carbon buildup on intake valves represents another expensive maintenance item inherent to direct-injection designs, requiring walnut blasting services that cost $500-$800. The vanos solenoids, controlling variable valve timing, frequently fail and cause rough running, with replacement parts and labor totaling around $1,000.

Despite these issues, the N54 remains beloved by enthusiasts for its performance potential and character. BMW eventually addressed many concerns with the subsequent N55 engine, but N54 ownership requires substantial financial preparation for inevitable repairs that can easily total $10,000-$15,000 over the engine’s lifetime beyond normal maintenance.

2. Jaguar AJ6 4.0-Liter Inline-Six

The Jaguar AJ6 engine family powered the British luxury brand’s vehicles from 1984 through the early 2000s, with the 4.0-liter variant becoming particularly common in XJ sedans and XK sports cars during the 1990s.

This dual-overhead-cam engine represented significant engineering advancement for Jaguar, delivering smooth power and refined performance befitting the marque’s luxury positioning.

However, the AJ6 developed a notorious reputation for expensive failures that could bankrupt unsuspecting owners, particularly as these vehicles aged and depreciated.

The most catastrophic issue involves Nikasil cylinder liner failure, particularly in engines produced before 1996. Nikasil, a nickel-silicon carbide coating applied to aluminum cylinder bores, proved vulnerable to sulfur content in gasoline available in certain markets.

The chemical reaction gradually wore away the coating, leading to excessive oil consumption, poor compression, and ultimately complete engine failure. Repair requires either cylinder re-sleeving or complete engine replacement, with costs easily exceeding $8,000-$12,000. Jaguar eventually switched to steel liners, but numerous early engines remain affected.

The timing chain tensioners represent another expensive failure point that plagues these engines throughout their production run. When tensioners wear, the timing chains develop slack that can jump teeth or even break, causing catastrophic valve-to-piston contact.

The repair process requires substantial disassembly and typically costs $3,000-$5,000 including parts and labor. Many mechanics recommend replacing the entire timing chain system preventively on high-mileage examples, adding further expense.

Water pump failures occur regularly on AJ6 engines, and the replacement process proves labor-intensive due to cramped engine bay packaging. Combined with thermostat housing issues that cause coolant leaks, owners face regular cooling system repairs costing $800-$1,500.

The alternator placement at the bottom rear of the engine makes replacement an expensive undertaking, often requiring substantial disassembly and commanding $1,000+ in labor alone.

Electronic components including crankshaft position sensors and throttle position sensors fail frequently as these vehicles age, causing drivability issues and requiring diagnostic time to isolate.

Parts availability has become increasingly problematic as Jaguar discontinued many components, forcing owners toward expensive used parts or aftermarket alternatives of questionable quality. For those passionate about classic Jaguar ownership, the AJ6 demands a substantial maintenance budget and mechanical sympathy.

3. BMW S54 High-Performance Inline-Six

The BMW S54 engine represents the pinnacle of naturally aspirated inline-six development, powering the legendary E46 M3 and Z3/Z4 M Roadster from 2000-2008.

This 3.2-liter masterpiece produced 333 horsepower in North American specification, featuring individual throttle bodies, aggressive camshaft profiles, and an 8,000 RPM redline that delivered exhilarating performance.

Enthusiasts revere the S54 for its linear power delivery and intoxicating soundtrack. However, this highly-strung performance engine demands expensive maintenance and suffers from specific failure modes that shock owners accustomed to regular BMW ownership costs.

The rod bearings represent the most discussed and feared failure point on S54 engines. Unlike standard BMW engines, the S54 uses relatively thin bearing shells that wear more quickly under aggressive driving conditions.

When these bearings fail, catastrophic engine damage results as connecting rods contact the crankshaft and destroy internal components. Preventive bearing replacement requires dropping the oil pan and removing the crankshaft, typically costing $3,000-$5,000 at specialized shops. Many owners perform this service every 60,000-80,000 miles as insurance against complete engine failure.

The VANOS system, BMW’s variable valve timing mechanism, proves particularly troublesome on S54 engines. The VANOS units themselves develop issues with internal sealing, causing rough idle, poor performance, and eventual failure. Rebuilding or replacing both VANOS units costs $2,000-$3,000.

Additionally, the anti-rattle flaps inside the VANOS system can break loose and circulate through the oil system, potentially causing further damage to bearings and other components.

Throttle body linkage components wear and require replacement, with the individual throttle bodies themselves occasionally needing complete replacement at $800-$1,200 each.

Multiply by six cylinders, and costs escalate quickly. The engine’s aggressive camshaft profiles lead to accelerated valve train wear, making valve adjustment checks crucial but expensive maintenance items at $500-$800 per service.

Cooling system components fail regularly, with expansion tanks cracking, radiators developing leaks, and water pumps wearing out. The high-performance nature of the S54 means cooling system integrity is absolutely critical to prevent overheating and potential head gasket failure.

Even routine maintenance proves expensive, with specification oil requirements and large oil capacity pushing oil changes beyond $150-$200 at dealers. The S54 delivers incredible performance and driver engagement, but ownership requires financial commitment matching the engine’s enthusiast credentials.

4. Mercedes-Benz M104 3.2-Liter Inline-Six

The Mercedes-Benz M104 engine earned widespread praise during its production run from 1988-1999, powering various E-Class, S-Class, and SL models with refined performance and characteristic Mercedes solidity. The 3.2-liter variant particularly gained recognition for smooth power delivery and robust construction.

However, as these engines accumulated high mileage and aged beyond twenty years, specific design weaknesses emerged that translated into expensive repair bills surprising owners who expected Mercedes legendary durability.

The wiring harness represents the most widespread and expensive problem facing M104 owners. Mercedes used biodegradable wiring insulation during the early 1990s as an environmental initiative, but this material deteriorates over time, becoming brittle and crumbling away.

As insulation fails, wires short circuit, causing myriad electrical problems from misfires to complete failure to start. Complete engine harness replacement requires extensive disassembly and specialized knowledge, with costs ranging from $2,500-$4,000 at independent specialists or significantly more at dealers.

The head gasket has proven problematic on many M104 engines, particularly those that experienced overheating incidents. When head gaskets fail, they allow coolant into the combustion chambers and oil passages, causing white exhaust smoke and milky oil appearance.

The repair requires cylinder head removal, machining to ensure flatness, and complete gasket set replacement. Total costs typically exceed $3,000-$5,000, and many mechanics recommend replacing the timing chain components simultaneously since the engine is already disassembled.

The overvoltage protection relay, a small component designed to protect electrical systems, frequently fails and causes various electrical gremlins.

While the part itself costs under $100, diagnosis can consume hours of expensive troubleshooting time. The idle control valve regularly fails, causing rough idle and stalling issues that require replacement at $300-$500.

Mass airflow sensors, crankshaft position sensors, and oxygen sensors all fail with some regularity, each requiring diagnostic time and parts replacement.

The catalytic converters used on M104 engines were early designs that proved less durable than later generations, often requiring replacement that can cost $1,500-$2,500 depending on local emission requirements.

The automatic transmission commonly paired with M104 engines also developed reputations for expensive failures, compounding ownership costs.

While the M104 delivers wonderful driving characteristics and can achieve impressive longevity with proper care, the combination of aging components and German parts pricing makes maintenance budget-intensive for modern owners.

Also Read: Top 10 Luxury Bargains That Are Risky Without a Warranty

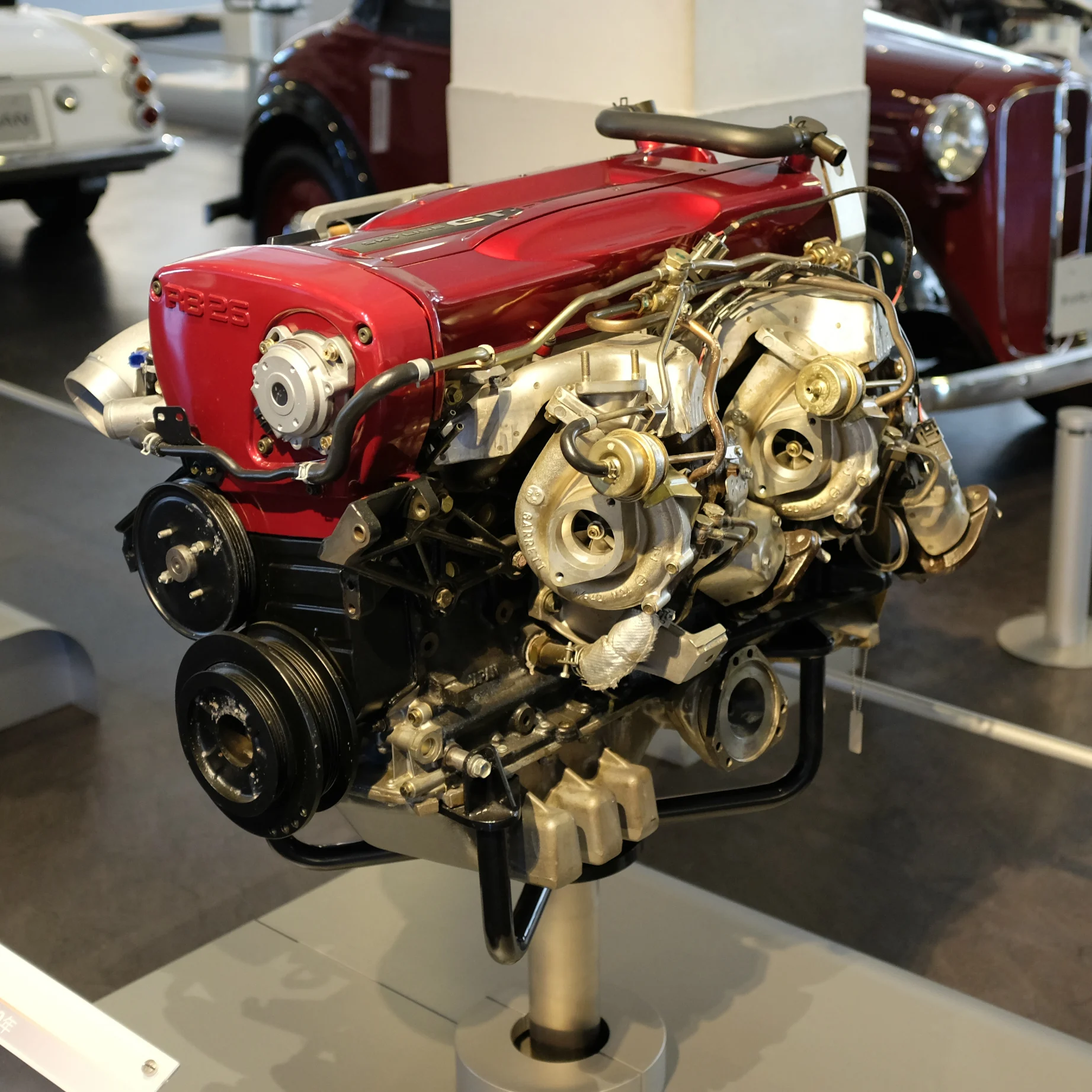

5. Nissan RB26DETT Twin-Turbo Inline-Six

The Nissan RB26DETT engine achieved legendary status powering the Skyline GT-R from 1989-2002, becoming an icon among performance enthusiasts worldwide.

This 2.6-liter twin-turbocharged inline-six produced 276 horsepower in stock form, though actual output often exceeded official figures due to Japanese gentleman’s agreement limitations.

The RB26 earned its reputation through domination of racing series and incredible tuning potential, with modified examples producing well over 1,000 horsepower. However, both stock and modified RB26 engines demand expensive maintenance and suffer from specific weaknesses that create substantial ownership costs.

The oil pump represents a critical weakness in RB26DETT engines, particularly under high-performance use or when revved beyond stock redline. The factory oil pump struggles to maintain adequate pressure at high RPM, leading to oil starvation that damages bearings and other internal components.

Upgraded oil pumps from aftermarket manufacturers cost $800-$1,500, but installation requires significant disassembly including front cover removal at $2,000-$3,000 in labor. Many owners discover this weakness only after catastrophic bearing failure necessitates complete engine rebuild at $15,000-$25,000.

The ceramic turbine wheels used in stock turbochargers prove fragile, particularly when subjected to rapid temperature changes or boost level increases. When these wheels shatter, ceramic fragments circulate through the engine, scoring cylinder walls and damaging bearings.

Complete engine teardown and rebuild becomes necessary, with costs easily exceeding $20,000. Most enthusiasts eventually upgrade to aftermarket turbochargers with metal wheels, but quality units cost $3,000-$6,000 for the pair plus installation.

The RB26’s sophisticated all-wheel-drive system includes attesa components that fail and require expensive replacement. The transfer case, front differential, and HICAS four-wheel-steering system all develop issues that demand specialized knowledge and expensive parts.

Transmission synchros wear quickly under aggressive driving, with gearbox rebuilds costing $3,000-$5,000. The twin-turbo setup requires extensive maintenance including wastegate actuator rebuilds, intercooler piping upgrades, and blow-off valve replacement.

Parts availability has become increasingly problematic as these engines age beyond twenty years. Nissan discontinued many critical components, forcing owners toward expensive used parts from Japan or aftermarket alternatives. Even routine maintenance proves costly, with specific oil requirements, expensive filters, and complex procedures for simple tasks.

For those who can afford the substantial maintenance requirements, the RB26DETT delivers unmatched character and performance potential that justified its legendary status.

6. BMW M54 3.0-Liter Inline-Six

The BMW M54 engine served as the mainstream inline-six powerplant across BMW’s lineup from 2000-2006, replacing the M52TU and powering everything from 3-Series sedans to X3 SUVs and Z4 roadsters.

This naturally aspirated 3.0-liter engine produced between 225-231 horsepower, delivering smooth power and refined performance characteristic of BMW inline-sixes.

While generally more reliable than some other BMW engines, the M54 developed several expensive failure modes that particularly affect higher-mileage examples and surprise owners with substantial repair bills.

The cooling system represents the most common expense for M54 owners, with multiple components failing regularly. The plastic expansion tank invariably cracks and leaks, typically around 80,000-100,000 miles, requiring replacement at $200-$300.

However, most mechanics recommend replacing the entire cooling system simultaneously including radiator, water pump, thermostat, and all hoses since labor for access represents the majority of costs. Complete cooling system overhaul typically runs $1,500-$2,500, and neglecting these repairs can lead to overheating and catastrophic head gasket failure costing $3,000-$4,000 to repair.

The VANOS system controlling variable valve timing develops issues causing rough idle, poor performance, and check engine lights. The VANOS solenoids fail regularly, but rebuilding or replacing the VANOS units themselves costs $1,000-$1,500.

The valve cover gasket consistently leaks oil, and replacement requires removing the intake manifold on some applications, pushing costs to $800-$1,200. Additionally, the oil filter housing gasket at the front of the engine leaks regularly, causing oil consumption and potential belt contamination.

The DISA valve, which adjusts intake manifold length for optimal power delivery across the RPM range, commonly fails with plastic components breaking. Replacement costs $400-$600.

The crankcase ventilation system clogs over time, causing excessive pressure that blows out gaskets and seals throughout the engine. Cleaning or replacing the entire system costs $500-$800. Window regulators, door lock actuators, and other BMW-specific electrical components fail regularly, each requiring expensive replacement.

Rear main seal leaks plague many M54 engines, and replacement requires removing the transmission, making it a $1,500-$2,000 repair. The manual transmission rear seal is particularly prone to failure. Oxygen sensors fail regularly at $200-$300 each, and mass airflow sensors require replacement at $300-$400.

While the M54 delivers pleasant performance and can achieve high mileage with maintenance, the accumulation of these expensive repairs makes total cost of ownership substantially higher than competing Japanese engines.

7. Toyota 2JZ-GTE Twin-Turbo Inline-Six

The Toyota 2JZ-GTE engine has achieved near-mythical status among enthusiasts, powering the fourth-generation Toyota Supra Turbo from 1993-2002. This 3.0-liter twin-turbocharged inline-six produced 320 horsepower in factory form and earned legendary status for extraordinary tuning potential and robust construction.

While the 2JZ-GTE deserves its reputation for strength, ownership costs have escalated dramatically as these engines aged and became collector items. Parts scarcity, specialized knowledge requirements, and the expensive nature of maintaining turbocharged performance engines create substantial financial obligations.

The sequential twin-turbo system, while innovative, proves complex and expensive to maintain. The smaller primary turbo spools quickly for low-end response, with the larger secondary turbo activating at higher RPM for maximum power. However, the vacuum-operated actuators controlling this system fail regularly, causing turbos to malfunction or activate improperly.

Diagnosis requires specialized knowledge, and replacement parts have become increasingly expensive and scarce. Many owners convert to single-turbo setups costing $5,000-$10,000 to avoid ongoing sequential system maintenance.

The automatic transmission commonly paired with 2JZ-GTE engines has proven less durable than the manual option, developing issues that require rebuilds costing $3,000-$5,000. Even the vaunted Getrag V160 six-speed manual transmission requires expensive maintenance, with clutch replacement jobs costing $1,500-$2,000 due to labor intensity.

The transmission tunnel insulation deteriorates over time, causing interior heat issues that require expensive restoration work. Parts availability represents a growing concern as these vehicles approach thirty years old.

Toyota discontinued many critical components, and remaining new-old-stock parts command premium prices. Used parts from Japan prove expensive due to the Supra’s collector status and export restrictions.

Aftermarket alternatives exist but vary wildly in quality. Even routine maintenance items like gaskets, sensors, and hoses cost significantly more than contemporary vehicles due to parts scarcity.

The fuel pump, located in the tank, regularly fails and costs $500-$800 to replace. Ignition coils fail frequently at $150-$200 each, and with six cylinders, costs accumulate. The power steering pump develops leaks requiring $600-$800 for replacement.

Suspension bushings throughout the vehicle deteriorate and require expensive renewal using upgraded aftermarket components. While the 2JZ-GTE remains an incredible engine with proper maintenance, escalating parts costs and specialized knowledge requirements make ownership increasingly expensive as these vehicles transition from used cars to collectibles.

8. BMW M88/S38 High-Performance Inline-Six

The BMW M88 and its evolution, the S38, represent legendary high-performance inline-six engines that powered some of BMW’s most celebrated models including the M1 supercar, first-generation M5, and M6.

Produced from 1978-1995, these engines featured individual throttle bodies, sophisticated valve train designs, and motorsport-derived technology delivering exhilarating performance.

The S38 particularly gained acclaim in the E34 M5, where its 3.6-3.8-liter displacement produced 310-340 horsepower. However, these hand-built performance engines demand extraordinarily expensive maintenance that shocks modern owners.

The Nikasil cylinder liner issue that plagued Jaguar engines also affected early S38 engines, though BMW addressed the problem more quickly. Engines requiring re-sleeving face costs exceeding $10,000-$15,000, essentially requiring complete rebuilds.

The valve train complexity proves both a blessing and curse, delivering incredible high-RPM performance but requiring precise maintenance.

Valve adjustments must be performed every 15,000 miles and require specialized knowledge, costing $800-$1,200 per service at knowledgeable shops. Neglecting this maintenance causes accelerated wear requiring cylinder head rebuild at $5,000-$8,000.

The Motronic engine management system uses components that have become obsolete, with replacement parts increasingly difficult to source.

The airflow meters fail regularly, and replacement units cost $800-$1,500 when available. Fuel injectors require periodic cleaning or replacement at $200-$300 each.

The distributor caps and rotors, while seemingly simple components, must be genuine BMW parts and cost $300-$400 for the set. Ignition components throughout the system prove expensive and critical to proper operation.

The oil pump pickup tube welds can crack over time, causing catastrophic oil starvation that destroys internal components within seconds. This failure mode occurs without warning and results in complete engine destruction requiring rebuild costs of $20,000-$30,000.

Preventive inspection and reinforcement requires oil pan removal and costs $1,000-$1,500, but provides essential insurance against catastrophic failure. The timing chain guides wear and must be replaced periodically at $2,000-$3,000 to prevent timing chain failure.

Parts availability has become critically problematic as BMW discontinued most S38 components. Remaining new parts command astronomical prices, with simple items like gaskets costing five to ten times typical prices. Specialist mechanics familiar with these engines charge premium rates, often $150-$200 per hour.

Complete engine rebuilds, increasingly necessary as these engines approach forty years old, easily exceed $25,000-$35,000. For those fortunate enough to own these legendary BMWs, the S38 demands financial resources matching its performance capabilities and historical significance.

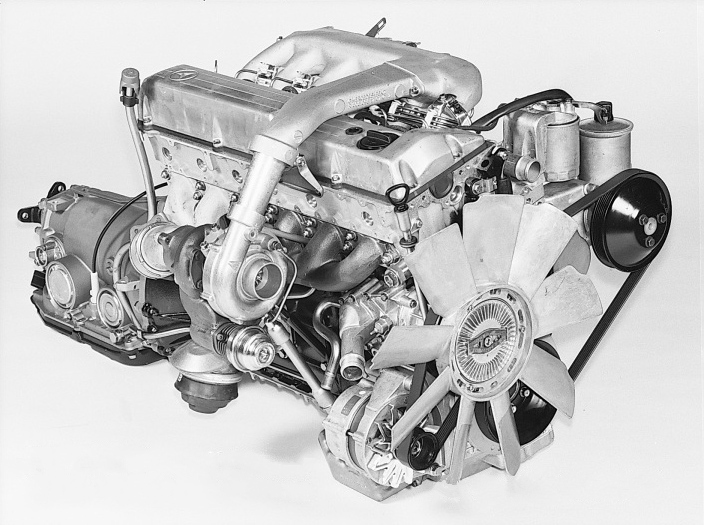

9. Mercedes-Benz OM603 Turbodiesel Inline-Six

The Mercedes-Benz OM603 turbodiesel inline-six powered various Mercedes models from 1984-1999, earning recognition for incredible durability and longevity when properly maintained.

These 3.0-3.5-liter diesel engines often achieved 300,000-500,000 miles with routine maintenance, cementing Mercedes’ reputation for building unstoppable diesel powerplants.

However, when these engines require major repairs or suffer catastrophic failures, costs escalate dramatically due to diesel-specific complexities and Mercedes parts pricing that creates substantial financial obligations for owners.

The cylinder head proves vulnerable to cracking when engines overheat or suffer cooling system failures. Diesel engines generate tremendous combustion pressures that stress cylinder head castings, particularly around the prechamber insertions used in indirect-injection designs.

When heads crack, complete replacement becomes necessary at $3,000-$5,000 including machining and parts. Many specialists recommend installing upgraded cylinder head studs during this repair, adding another $500-$800 to prevent future head gasket failures under diesel combustion pressures.

The injection pump represents the most expensive single component on OM603 engines, with Bosch mechanical injection pumps costing $2,000-$3,500 for remanufactured units.

When these pumps fail internally, fuel delivery becomes erratic causing poor performance, difficult starting, and eventual complete failure. Rebuilding injection pumps requires specialized equipment and knowledge unavailable at most repair facilities.

The injectors themselves require periodic replacement or rebuilding at $200-$300 each, with complete sets totaling $1,200-$1,800 plus labor for removal and installation.

Turbocharger failures prove expensive on OM603 engines, with replacement units costing $1,500-$2,500. The vacuum-operated wastegate systems develop issues requiring diagnosis and repair.

The exhaust gas recirculation systems used on later models clog with carbon deposits, causing performance issues and requiring cleaning or replacement at $800-$1,200.

Glow plugs fail regularly in diesel engines and must be replaced, but broken glow plugs can remain stuck in cylinder heads, requiring drilling and extraction costing $500-$1,000 in additional labor.

The automatic transmissions paired with OM603 engines, typically Mercedes’ 722.3 or 722.4 four-speed units, develop issues requiring rebuilds costing $2,500-$4,000.

Manual transmissions prove more durable but clutch replacement requires transmission removal at $1,200-$1,500 in labor. The diesel fuel system requires extreme cleanliness, with contaminated fuel causing cascading failures throughout injectors, injection pump, and fuel lines that can cost $5,000-$8,000 to completely rectify.

While OM603 engines can achieve incredible longevity, the diesel-specific components and German parts pricing make major repairs extraordinarily expensive when they inevitably become necessary.

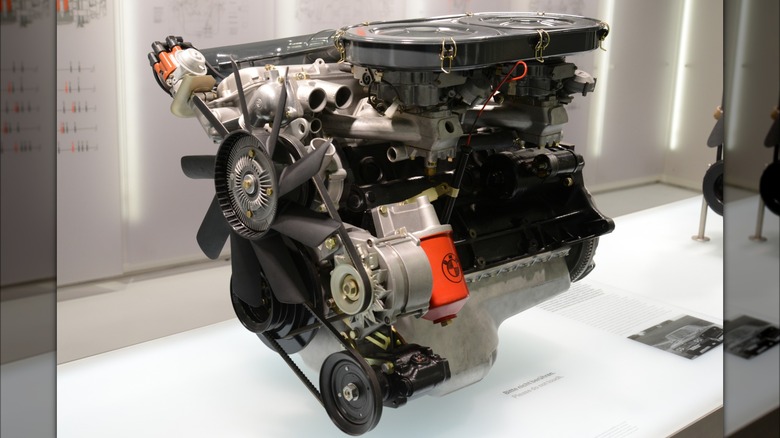

10. BMW M30 Big-Six Engine

The BMW M30 inline-six engine family powered BMW vehicles from 1968-1994, representing one of the longest-production engine designs in automotive history.

Displacement ranged from 2.5 to 3.4 liters across various applications, with the engine earning legendary status for smooth operation, robust construction, and potential for high mileage. Found in classic 5-Series, 6-Series, and 7-Series BMWs, the M30 delivers wonderful driving characteristics.

However, as these engines aged beyond thirty years, specific expensive failures emerged alongside challenges related to parts availability and specialist knowledge requirements.

The timing chain system represents the most critical maintenance item on M30 engines, with chains, guides, and tensioners requiring replacement around 100,000-150,000 miles.

Neglecting this service allows chains to stretch and jump timing, causing bent valves and extensive internal damage. Preventive timing chain replacement costs $2,000-$3,000 including guides and tensioners, but addressing damage from failed timing chains requires cylinder head removal and valve replacement pushing costs beyond $4,000-$6,000.

The timing chain cover gaskets invariably leak oil, and proper replacement requires extensive disassembly costing $1,000-$1,500. The cylinder head has proven prone to cracking in the area between the intake and exhaust valves, particularly on engines that experienced overheating.

When cracks develop, cylinder head replacement becomes necessary at $2,500-$4,000 including machining and reassembly. The valve guides wear over time causing excessive oil consumption and blue smoke, requiring complete cylinder head rebuild at $2,000-$3,000.

Valve adjustments must be performed regularly using mechanical adjusters, requiring specialized knowledge and costing $400-$600 per service.

The Motronic engine management system uses components that have become obsolete and increasingly difficult to source. The airflow meters fail regularly, with replacement units costing $600-$1,000 when available. Fuel injectors require periodic cleaning or replacement, and parts availability has diminished as these vehicles aged.

The oxygen sensors fail frequently requiring replacement at $150-$250 each. Distributor components wear out and require replacement, with genuine BMW parts commanding premium prices.

The cooling system requires complete overhaul periodically, with radiators, water pumps, thermostats, and hoses all requiring replacement. The radiator support structure on many E28 and E24 chassis rusts and weakens, requiring repair or replacement adding to costs.

Parts availability represents an increasing challenge as BMW discontinued most M30 components, forcing owners toward used parts of unknown condition or aftermarket alternatives of varying quality. Specialist mechanics familiar with these vintage engines charge $100-$150 per hour, and many modern shops refuse to work on thirty-plus-year-old BMWs

Despite these challenges, the M30 remains beloved by enthusiasts for its character and driving experience, but ownership requires financial commitment and realistic expectations about maintenance costs for aging German classics.

Also Read: 8 Electric Cars That Are Now Unbelievably Cheap Used