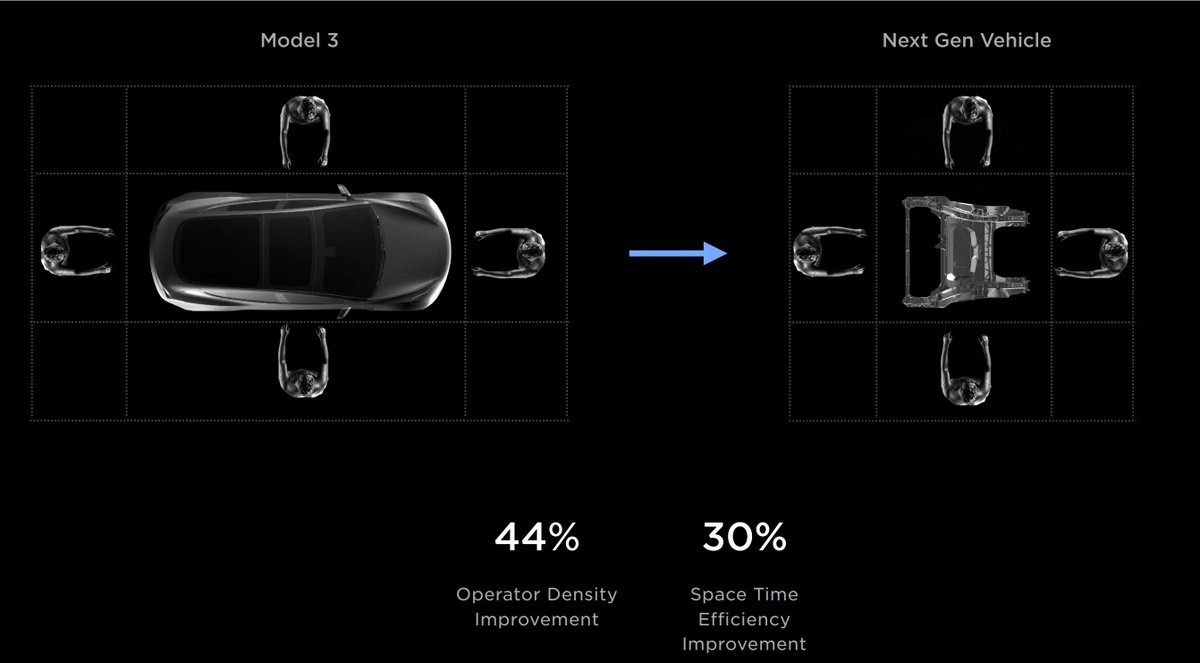

Tesla’s unboxed vehicle manufacturing process, once a revolutionary concept, has taken an unexpected turn. Initially envisioned as the cornerstone of the company’s next generation vehicle architecture, the unboxed process has now been relegated to a niche role, reserved solely for the development of Tesla’s robotaxi.

The unboxed process, which involves dividing vehicles into sections and assembling them separately, promised to streamline production and increase efficiency.

However, as Tesla shifted its focus towards artificial intelligence and robotics, the unboxed process lost its priority. Despite this, the company has not entirely abandoned the concept, as evidenced by a recently published international patent.

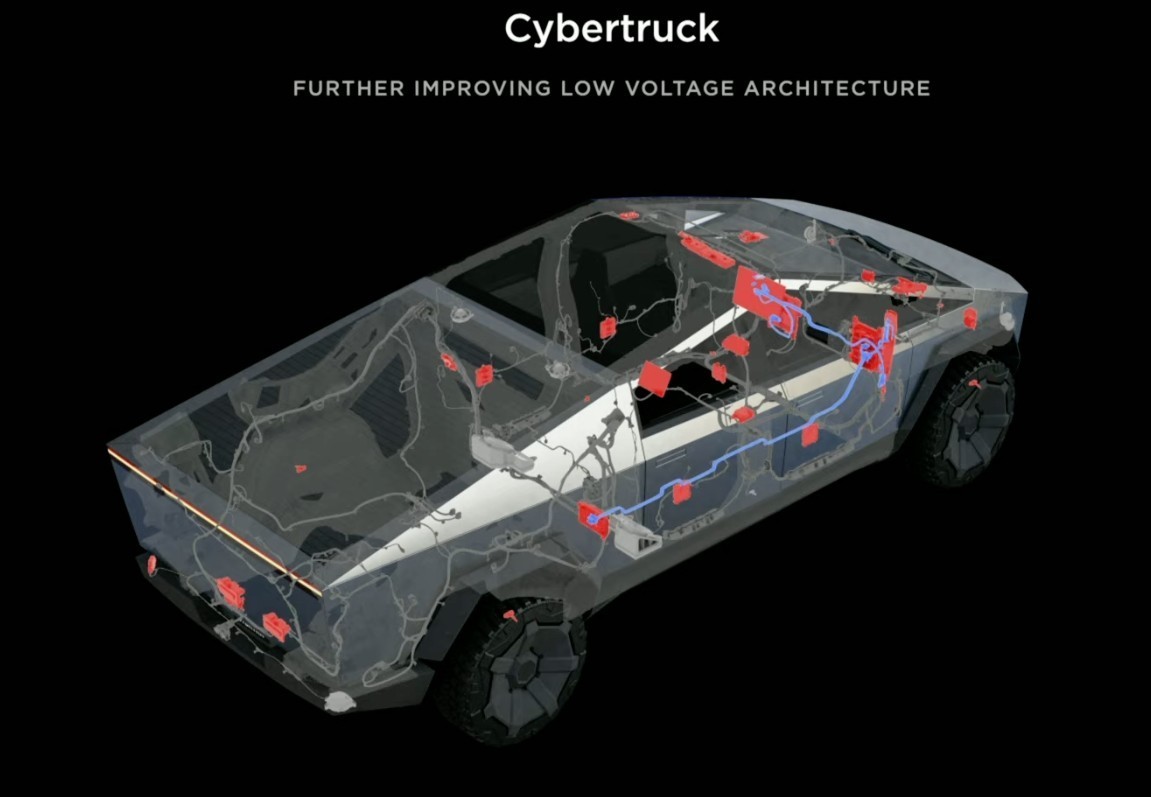

The patent filing for Tesla’s modular vehicle architecture offers a look into the Cybertruck’s original design, revealing the ambitious plans that were ultimately delayed.

This innovative concept, designed for efficient manufacturing and assembly, suggests that the Cybertruck was initially envisioned as a more modular and self contained vehicle.

However, the final product, while still impressive, falls short of fully realizing this vision due to factors such as time constraints and market expectations.