Tesla has decided not to continue its plan for a special way of making car parts called gigacasting. Two people who know about this decision said Tesla made this choice because its car sales are dropping, and other companies are making electric cars too.

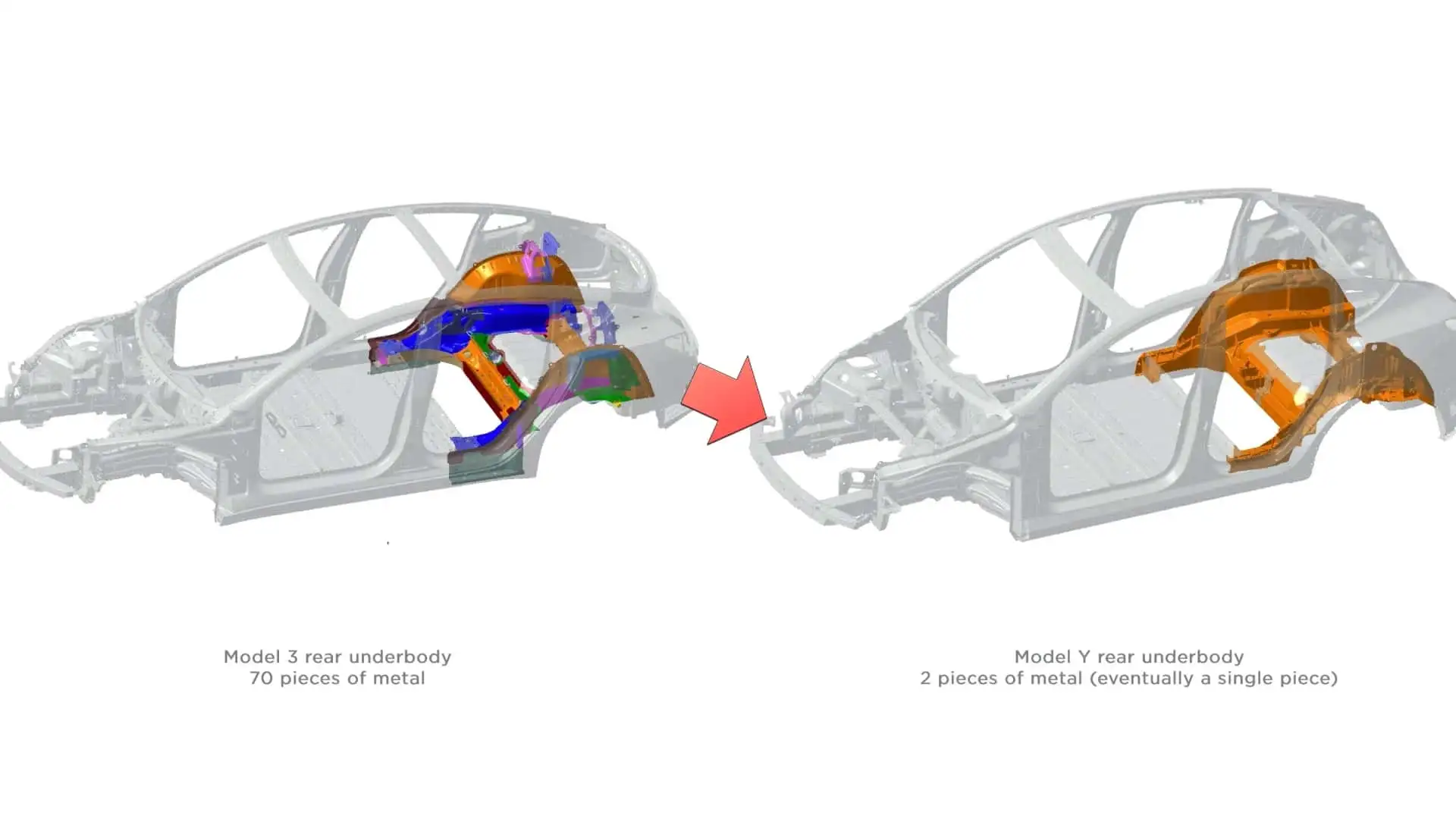

Gigacasting is a modern way to make big parts for cars. It uses strong machines to shape big pieces of the car’s bottom. Usually, this part has many small pieces.

Last year, Tesla wanted to make the car’s bottom in one big piece. This would make it easier to make and cheaper too. But now, Tesla has stopped this plan. They will keep making the car bottom in three pieces, like they did before.

This news about Tesla’s change in plans hasn’t been shared before. Tesla didn’t answer questions about it.

Tesla made this choice because they are trying to save money. They are not selling as many cars as before. Also, there are more companies making electric cars now, especially in China. Last month, Tesla laid off more than 10% of its workers from around the world. Some top bosses also left the company.

Now, Tesla is focusing more on making cars that can drive themselves than on selling lots of electric cars. This is a big change in their plan, and it’s not what many investors thought Tesla would do.

Tesla decided to stop the gigacasting plan last year, before they decided to stop making a new cheap car called the Model 2. They said they had a new plan to make more affordable cars, but they didn’t give many details.

Tesla hasn’t given up on the idea of making a small car like the Model 2. They will use the same plan to make a car that can drive itself, one of the people said. The companies that make parts for Tesla are now making changes to make this possible.

Both people said Tesla stopped the gigacasting plan to focus on making the new car and avoid any problems. Gigacasting needs a lot of money and time to work well. Tesla has had problems before with making new cars on time. Their Cybertruck, for example, was delayed and came out at a higher price than expected.