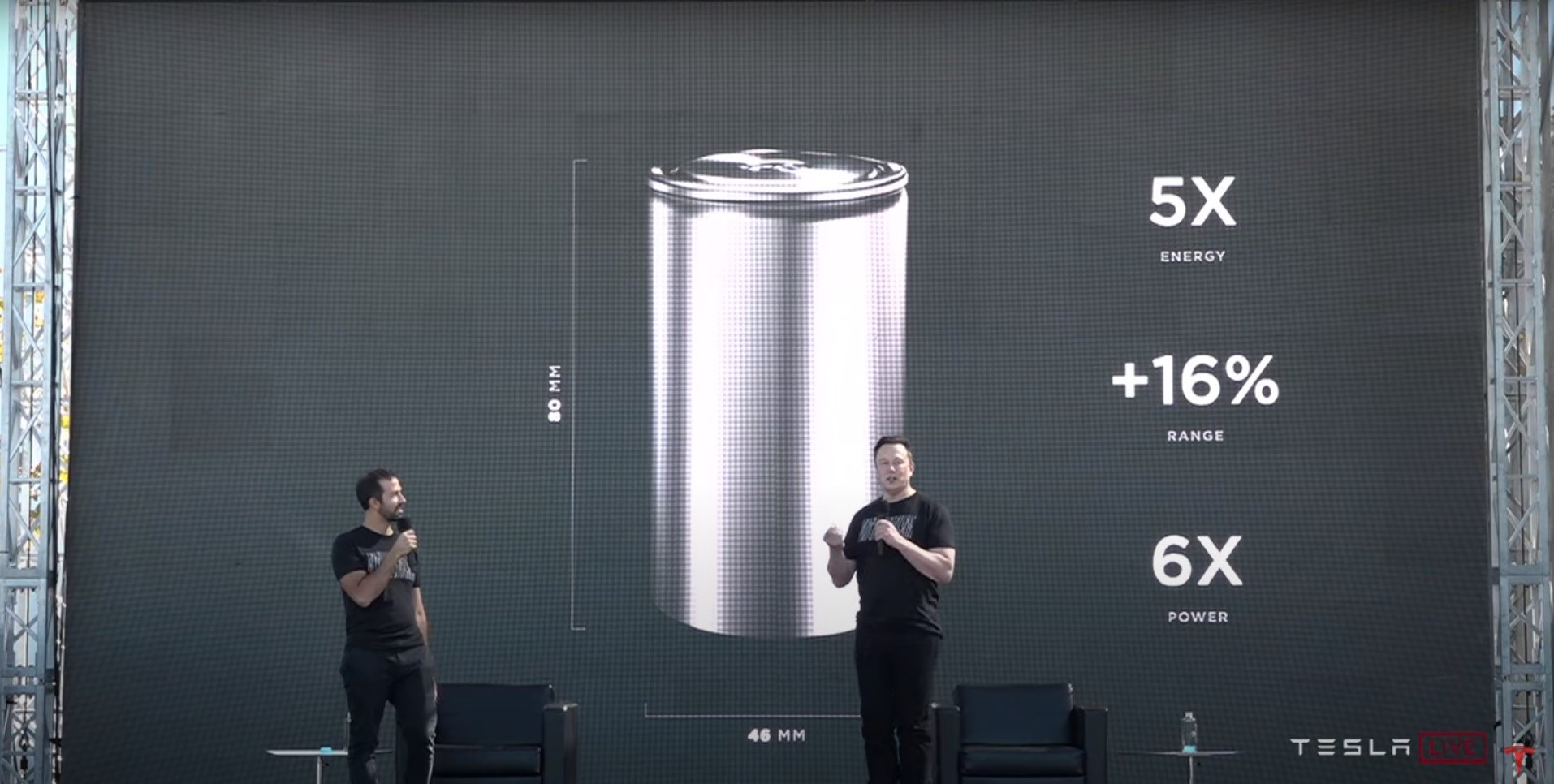

Tesla’s 4680 battery program, touted in 2021 for revolutionizing electric vehicles with lower costs and increased range, is facing hurdles.

The company might abandon in-house production and turn to external suppliers if they can’t achieve cost-competitive manufacturing.

While the 4680 design aimed for a significant leap in battery technology, Tesla has yet to deliver on its initial promises.

Early plans for a groundbreaking dry electrode method and a superior silicon anode haven’t come to fruition, resulting in the current 4680 cells largely resembling the older 2170 design in function.

This lack of innovation, along with the challenges of managing heat due to the larger size, has led to batteries that are both costlier to produce and offer no substantial performance benefits.

These drawbacks are believed to be contributing to Tesla’s recent financial struggles, and rumors suggest the company might be considering outsourcing production from Giga Texas to proven battery suppliers.

Tesla has reshuffled its leadership for the crucial 4680 battery program, placing Bonne Eggleston at the helm.

LGES has set its sights on Tesla, targeting August for their initial production run. Samsung, on the other hand, has a broader market in mind, with discussions underway to supply different-sized 46mm cylindrical batteries to car companies like BMW and Rivian.

Even SK On, a company specializing in pouch-type batteries, is expressing interest in the cylindrical battery market, potentially adding another competitor to the already crowded space.